2015 ChemStatRepGr.3

advertisement

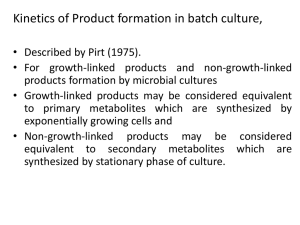

The continued process of a chemostat for optimized growth of Sporasarcina pasteurii, comparison to a batch culture, and promotion of biocementation function through increased urease function Authors Jack Weatherhead 32210638 Susan McPhee 31865152 Rachel Brewer 31853317 Tan Nguyen 32226147 Abstract Construction Microbial Biotechnology, the production of ureolytic bacteria for the use in biocementation is a relatively new technology being studied today. The method of production using a selective growth medium to allow ureolytic bacteria Sporasarcina pasteurii. To grow and proliferate in a bioreactor via an open system chemostat. Whilst controlling and maintaining via a software computer program, the chemostat was observed and changes in enzyme activity under various conditions, such as airflow rate, stirrer rate, dilution rate and retention time at a constant temperature of 28oC and pH of 10 together with batch like culture implementation during the chemostat running of 15 days were tested for levels of enzyme activity. High enzyme activity was achieved and maintained with its harvest proving successful in producing a rock like sample through the implementation of a biocementation method. 1 Introduction Bioreactors are incredible living reactors that combine aspects of engineering, biology and chemistry, used in many industries globally. Industries use bioreactors for treatment for disposal of wastewater, in medicine for production of antibiotics such as penicillin (Pirt et al., 1967), for production of biofuels (Temudo et al., 2007), as well as in beer-making (Tata et al., 1999). These reactors can be sterile or non sterile environments dependent on the product required, in some industries such as beer brewing (Tata et al., 1999) a non-sterile environment is suitable; whereas in medical bioprocesses (Pirt and Righelato, 1967) a sterile environment is required (Cheng et al., 2013). There are many types of bioreactors, in this report there will be a focus on chemostat and a fed-batch reactor. The conditions of a batch culture change over time (Meyer et al., 1985). in conditions that require different parameters, it is therefore difficult to automate. As conditions change in a batch culture, the concentrations of solutes in the solution changes and product build up inevitably occurs which can lead to product inhibition (Novick et al., 1950). As no solution is either added or removed, the batch culture relies on time and therefore does not run continually, leading to a definitive end where a condition prevents further change. Thus, the batch culture experiences the phases of growth that lead to its variable growth rates and an overall decreased productivity when compared to the chemostat which is fixed in the exponential phase of growth giving a constant high productivity (Stanbury, 2013). However, as the batch culture goes through multiple phases of growth, it is possible to synthesise secondary metabolites in the stationary phase within a batch culture, which is not possible in a chemostat, as the microbes are fixed in the exponential phase (Meyer et al., 1985). 2 A chemostat is an apparatus used to cultivate bacteria in continuous and constant conditions in order to produce a specific primary product; such as in the production of some pharmaceuticals (Whiteley, 1997). Alternatively, the chemostat can be used to study microbes where specific enviromental conditions can be maintained, allowing such appropriate studies (Whiteley, 1997). A chemostat is a continuous bioprocessor with static conditions which include dissolved oxygen (ppm), pH, temperature, cell density, and nutrient substrate; this steady state is achieved by maintaining inflow and outflow at constant volume (Novick et al., 1950). Specific conditions can be set and adjusted to suit the micro-organism of interest at optimum growth, but result in harsher conditions (>9.5pH) to keep undesired contaminants at (Novick and Szilard, 1950). In order to maintain the media concentrations lost from the catabolism by the microbes, a constant volumetric flow of fresh medium enters the culture vessel, driven by a pump at a constant rate; termed the inflow (Makri et al., 2010). With simultaneous removal of the homogenous culture removed from the vessel at the same volume and rate in order to collect the product and remove the equivalent volume added by the inflow pump; termed the outflow (Makri et al., 2010). The chemostat facilitates automation and is therefore regulated by a computer program which maintains the inflow pumps and regulatory pumps at a constant rate. The chemostat will eventually reach steady state where biomass concentrations remain constant at a given concentration; the concentration at which the biomass reaches steady state depends on the microbial species and the parameters of the chemostat (Makri et al., 2010). When one or more of 3 the operational variables are changed, the chemostat reaches a new steady state (Makri et al., 2010). In contrast to a batch culture, the chemostat is a highly productive, time-redundant, constant culture of a microbe (Burton et al., 2001). Variables such as concentrations of solutes in the solution, pH changes and biomass concentration changes are negated (Meyer et al., 1985), allowing the ability to problem monitor. The chemostat also selects for the fastest growing strain (Meyer et al., 1985), which is based on the parameters set; thereby allowing the experimenter to artificially select a desired strain by favouring conditions for the microbes growth. However, genetically modified microbes might cause contamination from the inside due to back mutation to the wild type(Meyer et al., 1985), which favours a faster growing microbe that does not synthesise the desired product; as a compromise, a shorter run time is usually implemented. An understanding of the principles behind operating these bioreactors is required to exploit the micro-organisms full potential in these systems. Parameters such as airflow, feed input, reactor outflow, media type, stirrer rate, dissolved oxygen concentration, temperature, and pH must be considered and their relationship understood. Knowledge of these factors allows the exploitation of the specific functions of the bacteria, such as optimising activity of an enzyme for conversion of a desired product that can be used to produce urease enzyme. 4 In this report we used knowledge of these parameters to increase productivity and specific activity of the enzyme urease, by cultivating the gram positive bacteria Sporasarcina pasteuriis. This microbe is able to survive in high pH conditions and within liquids containing high concentrations of ammonia (Cheng and Cord-Ruwisch, 2013). This enabled targeted growth of these bacteria within the reactor through these selective pressures. The use of an open system (non sterile) chemostat was employed to produce urea enzyme (amidohydrolase) within an environment with a constant temperature of 28 degrees C and with a pH10 that is optimal for increased activity of urease. The urease produced by these bacteria catalyses the hydrolysis of urea to carbon dioxide and ammonia as follows: UREASE H2N-CO-NH2+2H20 -------------------> 2NH4+ + CO32- The ammonia increases the pH of the surroundings, which in turn induces calcite precipitation. S. pasteurii can precipitate calcite and solidify sand in the presence of calcium and urea through a process known as biocementation (Siddique et al., 2011). The binding strength of the precipitated calcium carbonate can be increased by regulating the rate of carbonate formation by S. pasteurii. A CaCO3 product can be used in many industrial applications such as reinforcing cement and solidifying soil in earthquake prone areas (Sarayu et al., 2014). A new type of building material known as biobricks have been developed by a North Carolina company in the USA bioMASON, which were produced through the biocementation process. This method enables huge reductions in CO2 emissions normally produced in traditional brick making methods, which in term contribute to the reduction of the carbon footprint. 5 The aim of this experiment was to operate, test and, document the daily running of a chemostat using the microbe S.pasturii to cultivate and maintain a high specific productivity by varying certain parameters for optimum growth and quality, harvesting a sample to be used to create a rock like sample using biocementation technology. Method Bacterial strain S. pasturii was provided by Murdoch Teaching with a recorded activity of 1.55 mS/10min; in conditions of temperature of 28-30 degC, pH 10, stirred at 400 rpm. at an airflow rate of approximately 100L/h. The culture was grown in yeast extract feed media. During the chemostat process this strain was grown in yeast extract media at 28degC at different airflow rates and differing stirrer rates (as indicated in results), at pH10. Feed media Yeast extract (provided by Murdoch Teaching) 1L volume (20g/L yeast extract, 10.21g/L Urea (0.17M) 20g/L sodium acetate and 2ml of 50mMstock/L NicL2(0.1mM) Chemostat set-up, biocementation set-up, and computer program An open chemostat system, and all equipment required was provided by Murdoch University teaching (as shown inFiguress 1 to 3 below) and the computer program provided for this experiment was LabView software. 6 Figure 1:The chemostat set up adapted from Murdoch teaching hand out and presented past report. Figure 2:A photograph of the inflow and outflow pumps, and the pH regulating pump. 7 Figure 3: A photograph of the waterbath containing the reactor. Dissolved oxygen readings A dissolved oxygen HANNA instruments conductor was calibrated prior to each use. Use of conductor as per HANNA instruments instruction sheet. pH A pH metre was used as per provided instructions. The calibration was checked prior to use, and checked throughout the experiment. The computer program performed constant control of the pH and 3M NaOH was added into the reactor when required by this program. Biomass assay Biomass assays were performed using a spectrophotometre at 600nm, using the feed media as reference. Absorbance readings were converted into biomass concentrations using C (biomass concentration, g/L) = 0.44 x O.D (600nm) equation. Dilutions using feed media were performed when the initial absorbance readings were above 2. 8 Urease assay Urease assay was performed as per instructions provided by Murdoch University teaching in which biomass, 3M urea and deionised water were added at a 2ml:10ml:8ml ratio; at room temperature. Conductivity readings over 10mins were recorded in mS/10mins to determine activity of urease in the reactor Producing cement sample through biocementation The biocementation process was performed as per instructions provided by Murdoch Teaching in which 30ml of reactor outflow and with an activity rate of 2.3 mS/10min, was passed through a 60ml PVC cylinder containing SiSo2. This was followed by slowly adding 10mL of cementation solution calcium chloride/urea (CaCl2 H2O/Urea 1M ) allowing time (8 hours) for adhesion of bacteria to SiSO2, and for excess bacteria to wash out. Three 20mL additions of cementation solution was added with a time lapse of seven hours between each addition until the desired strength and solid appearance was achieved. Figure 4:A photograph of the biocementation setup. 9 Results Dissolved Oxygen mg/L The effect of the change of stirrer speed on dissolved oxygen levels 8 7 6 5 4 3 2 1 0 0 10 20 30 40 50 Time (hours) 60 70 80 Figure 5: An aeration curve of the dissolved oxygen concentration (mg/L) over time during the changes in the stirrer speed test, at constant airflow of 250L/h. From 0-35 hours the stirrer speed was set at 350rpm, from 53 hours the stirrer speed was set at 650rpm. An increase of the stirrer rate from 350rpm to 650rpm was performed to increase the dissolved oxygen level in the reactor. As per figure 5. this did not occur, the level remained constant after the change took place. As seen on the figure 5 between time 0 to 35 hours the stirrer speed was at 350rpm noting the dissolved oxygen was decreasing during this period to a stable level, which then remained after 35 hours once the stirrer speed had been increased. The effects of doubling dilution rate on biomass concentration, productivity, and enzyme activity in the chemostat. A decrease in enzyme activity rate by 23.21% was observed however an overall increase in productivity was seen as productivity had increased to 0.06955, a overall increase of production rate by 65.67%. Table 1 contains the relevant data for determination of the enzyme activity rate change. 10 Table 1: Effects of Doubling Dilution Rate on enzyme activity, biomass, and productivity in the chemostat trial. Dilution (D) was calculated by D(h-1) = F(L/h)/V(L) and Productivity (R) was calculated (R)(g/L/h) = X(g/L)*D(h-1). Parameters Dilution Rate (D) (h-1) 0.03985 0.0797 Air flow (L/h) 150 150 Stirrer (rpm) 404 405 pH 10.2 10.7 D.O (mg/L) 5.69 0.77 O.D Biomass (600nm) 0.675 Average Enzyme Activity (1:10 0.754 Dilution) Dilution) 2.8 2.15 0.02367 0.06955 (1:10 (ms/10mins) Productivity (R)(g/L/h) The effect of using a batch culture to revive biomass concentration and productivity, and enzyme activity Biomass concentration and productivity were observed to be low, so forcing a batchtype culture by preventing inflow of feed and outflow of the reactor was performed to increase the biomass to allow for increase in productivity and therefore increase in enzyme activity. Variations in pH of the bioreactor during a batch culture Data for the pH of the batch culture solution was recorded between hours 0, 8 and 25 which included the starting and finishing times of the batch culture. Over the 25 hour period of the batch culture, the pH of the solution seemed to increase; however, with limited data, it is unsure what the pH reading was during the intervals between the 11 measurements. At time 0, the pH was measured at 10.2; after 8 hours in batch, the pH increased to 10.9. Finally, at the completion of the batch culture, the pH of the solution reached its highest value of 11. Figure 6: Relationship between biomass concentration and the activity of the enzyme urease throughout the process of an unsterilized batch culture containing S. pasteurii. The results from the provisional batch culture showing the relationship between the relative biomass concentrations within the bioreactor culture vessel and the enzymatic activity, and therefore the relative amount of urease produced by S. pasteurii, indicates there is a relationship between the two. As shown in figure 6 when biomass concentrations decreased by 0.38 g/L during the first 8 hours of the batch culture, there was a significant decrease in the enzymatic activity by a difference of 0.01 g/L/h. After 25 hours as a batch culture, both the biomass and enzymatic activity reached a culmination, with biomass reaching a concentration of 0.774 g/L and enzyme activity increasing 63 fold to 0.04 g/L/h, this is shown in figure 7. 12 Figure 7: Variations in urease activity within an unsterilized chemostat culture containing S. pasteurii. Both trials 1 and 2 are shown, with enzyme activity relating to the activity of urease in the presence of urea. Variations in doubling time of the biomass during a batch culture The doubling time was calculated in relation to the specific growth rate of the culture during the batch process. Data for the doubling time of the batch culture was recorded at 52.35 hours at time 0 hours. At 8 hours, a decrease in the doubling time 2 fold was seen with a result of 26.33 hours generation time. At the 25th hour, an increase in the doubling time by 6 fold was seen, with a result of 156 hours per generation. 13 Biocementation process Figure 8 shows the process of biocementation overtime after multiple additions of cementation solution, made up of 1M Calcium Chloride and 1M Urea. The initial product was a grainy sand, which after addition of the chemostat harvest and cementation solution, became solidified. Figure 8: The biocementation process overtime. A) prior to addition, b) after the first addition, c) after second addition, d) after final addition. 14 Discussion Doubling Dilution Rate Doubling the dilution rate refers to the amount of feed entering the chemostat is increased two fold, therefore more food available for the culture to use for growth and production, also simultaneously increasing the outflow by two fold. Since productivity is dependant on the dilution rate, it is possible to increase the productivity by increasing the dilution (Nakashimada et al., 1998). Increasing dilution rate increases productivity because the amount of feed that is being provided to the reactor has increased, this means more feed to use by the bacteria for growth and product production. More feed in the reactor allows the bacteria to take up more of the feed that can be used for the growth of biomass. More biomass means the enzyme production is increased meaning enzyme activity also increases (because there is enzymes working) and this increases productivity of the overall bacteria in the chemostat (Van Hoek et al., 1998). This is evident in Groups 2 data as when their chemostats culture had increased in biomass there was also an increase in enzyme activity, with the highest activity recorded at 1.6ms/10mins when the biomass concentration was at 2.8864g/L (the highest biomass concentration recorded for group 2). Group 1’s data does support the theory of increase in biomass concentration increases enzyme activity, as their highest activity was recorded at 2.1ms/10mins at a biomass concentration of 4.2768g/L (not the highest but biomass concentration but it is one of the highest recordings they had). So it can be concluded that a change in biomass concentration does change enzyme activity. Increasing dilution rate should be able to increase productivity infinitely but this is only in theory, as test has shown that there is a limit to how much the dilution rate can 15 be increased by, for once a certain dilution rate is reached the bacteria in the reactor will simply not be able to grow as fast as they are being pumped out (Van Hoek et al., 1998). This value is known as the Critical Dilution value or ‘Dcrit’. When the Dcrit is reached there will be ‘washout’ of the bacteria in the reactor. ‘Washout’ occurs because the bacteria is unable to grow as fast as they are being pumped out of the system, to avoid ‘washout’ of the bacteria the dilution value must not be higher than the growth rate of the bacteria (Meers, 1971). The Dcrit value is different for each chemostat, depending on the bacteria that are being used in the chemostat. The Dcrit of our chemostat was not achieved nor known, as simply doubling the dilution rate did not cause ‘washout’ of the bacteria. The chemostat achieved a very high enzyme activity from the bacteria S.pasturii however are unable to ascertain how the high activity was achieved it was proposed that a test be carried out to see the high level of activity could be maintained whilst increasing the production rate over time. The dilution rate was increased and the chemostat run for a further three and a half days to allow changes to establish. After 24 hours the control variables were still the same with only slight to minor changes that did not affect the overall system. The first test done on enzyme activity after 48 hours showed that the enzyme activity had decreased from 3.1ms/10mins to 2.5ms/10mins, another test that was done was biomass concentration. There was an increase in biomass concentration. This decrease is correlated to the decrease in biomass concentration that was also discovered. Though the enzyme activity had decreased slightly the overall chemostat was still running twice as fast as it was before the change meaning that the overall productivity had increased. Therefore we were able to increase productivity as we had hypothesised by increasing the dilution rate but 16 we were not able to maintain the high levels of enzyme activity as we had before the dilution rate change was made. The revival through a batch-culture setting Over the incubation period the pH of the solution seemed to steadily increase to a maximum of 11 at 25 hours. The pKa of ammonia is 9.24 (Korner et al., 2001), indicating that half of the ammonia is unionised and half is in the ionised form, ammonium. The increase in pH could be explained by the increase in urease activity; as urease breaks down the compound urea into NH3 and CO2, the increasing concentration of NH3 in the system would have led to an increase in the pH of the solution. Due to the lowest pH of the batch culture being 10.2, it can be said that most species would be in the form of NH3 and not in the ionised form NH4+. NH3 is toxic to most cells (Korner et al., 2001) and its small size and non-polar nature allow it to cross the cell membrane by simple diffusion (Korner et al., 2001). Thus, the conditions in the culture vessel would have increasingly harshened as pH increased, leading to increased NH3 and a decrease in NH4+ concentrations causing further cytotoxicity. However, Bacillus pasteurii is an alkalophile , suited to basic pH levels, most suitably at 9.5 (Burton and Prosser, 2001). The high pH allowed for the selection of S. pasteurii and the inhibition of microbes sensitive to the higher pH levels of 10.2 to 11. This was seen in the results; between 8 to 25 hours, biomass increased with increasing pH, however, despite being a small change the activity increased additionally, indicating a higher ratio of S. pasteurii in the bioreactor with respect to the other microbes after the increase in pH. It has been shown that pure enzyme hydrolyses urea approximately 20 times faster than ureahydrolysed by S. pasteurii. The ureolytic rate of bacteria is dependent on a 17 number of factors, including the concentration of urea, cellular levels of urease and the transport rate of urea in the cell. In this experiment, urea was in excess; thus, the urease activity was dependent on the rate of urea diffusion across the plasma membrane, which is determined by the concentration of urea in the solution. At time 0 hours, high potential energy for urea to enter the cells would have occurred, leading to the influx of urea. However, the rate of synthesis and relative abundance of urease might have been low, due to the microbes lacking sufficient urea media, in contrast with the modification of the solutes in the solution by the addition of 450ml feed media, the bacteria would therefore be adjusting to the conditions causing the lag phase and the lower activity. In comparison to a chemostat with limiting urea concentrations due to feed limitation, the batch culture has the capacity to process urea faster, increasing urease activity; that is if sufficient concentrations of intracellular urease have been synthesised. Interestingly, urease constitutes about 1% of the dry weight of S. pasteurii, with urease being expressed constitutively. This explains the rapid increase in enzyme activity during time 8 and 25 hours, which was caused by the high concentrations of urease intracellularly due to the absence of urease synthesis regulation. However, the increase in activity and therefore the increase in urease synthesis would only occur in the exponential phase of the batch culture, as lack of growth would occur in both the lag and stationary phase (Burton and Prosser, 2001). At time 8 hours, the doubling time was most efficient at 26.33 hours as compared to time 0 and 25 hours at 52.35 and 156 hours respectively. As the batch culture was inoculated previously as a chemostat, the culture was in a starved state as the urea media was the limiting factor, the generation time would therefore correlate with the speed of the media inflow, which explains the higher doubling time at time 0 hours 18 compared to time 8 hours. As the culture was diluted in feed media, the feed was in excess, allowing for rapid growth after the lag phase, which explains the higher doubling time of 26.33 hours at 8 hours. At 25 hours, the doubling time seemed to have increased dramatically; this could possibly be due to lack of feed in the solution causing a proportion of the microbes to enter dormancy. This shows that there was 6.95 mg per litre of dissolved oxygen in the solution at time 25 hours, indicating minimal oxygen uptake compared to time 0 with a dissolved oxygen reading of 0.46 mg per litre. The resultant growth might have been due to endogenous respiration. However, if feed was still available in the culture vessel, growth might have been reduced by the build-up of end products and secondary metabolites, which could have resulted in product inhibition. Investigating the relative concentrations of urea in the solution would need to be tested in order to identify the exact reason for the increase in doubling time during time 8 and 25 hours. The process of biocementation Biocementation is a technology whereby biological agents are used as catalysts for increasing stiffness and strength, where the carbonate from microbial hydrolysis of urea where excess calcium ions together with calcite (CaCO3) precipitate. Calcium carbonate in the form of solid crystalline known as biocement is produced by microbial urease activity in a calcium rich environment. Cementation is a calcium carbonate precipitation forming natural rocks in marine, freshwater and soil environments. The technology has potential to be used to strengthen or improve materials such as cement products, soil and possibly timber through the precipitation reaction of calcite 19 and sand in the presence of calcium and a urea (Siddique and Chahal, 2011). Possible applications could include stabilizing embankments, repairs to concrete that have developed cracks, countering soil liquefaction, potential use as an alternative for bitumen for walkways/cycle paths (more environmentally and aesthetically pleasing) more suitable for structures built on sandy environments such as on Rottnest Island. Tests performed on timber have shown that it becomes petrified and fire resistant when a solution of biocement was applied and absorbed this may be a potential treatment for termite resistance, though further studies are required (Bang et al., 2001; Ramachandran et al., 2001; Cheng and Cord-Ruwisch, 2013). Running and operating chemostat and problems encountered Prior to running chemostat on day one tests using plain water were carried out to determine the flow rate and calculate the on/off times for retention of 600mL over 24 hours. The pH probe, which was linked to the computer program for automatic adjustment with NaOH pump for correction, was calibrated and antifoaming solution was applied to reactor cover. Several issues were encountered including the shut down of the automotive monitoring computer program as well as non-functioning regulators for the air supply and detachment of tubes from pumps. After these issues were resolved the bioreactor was inoculated by adding the batch culture supplied. All parameters were checked and adjusted and left overnight with a air flow rate of 175 L/h and stirrer rate of 263 rpm and feed (dilution rate 0.039850 p/h) and outflow bottles surrounded with ice (to keep feed fresh). 20 On day two it was discovered that the pH probe had not been placed in the reactor, which had caused the automated addition of NaOH to such a high concentration, the culture had died. Culture (250mL) was obtained from group 2 outflow (replacement to enable a restart of the reactor) and brought up to a volume of 600mL with feed media (350mL). Again a computer shutdown occurred over night and by day 5 the DO was recorded at zero and it was decided to reduce the reactor volume to 150mL then bring volume up to 600mL with feed media (450mL) to create a batch like culture to be left 48 hours with just stirrer running with the view to increasing the activity rate. Unfortunately after the 48 hour period the reactor was found to have only 150mL volume, no explanation for this was ascertained as evaporation could not be attributed to this about of lost volume. The chemostat was left to run for another 24 hours to bring the volume back to 600mL. It was proposed that we reproduce these past events to test whether the batch like conditions were indeed the reason for the following increased activity readings but conditions could not be reproduced as there were too many variables and sample culture to be tested had died. After a further 24 hours it was discovered that due to the low volume in the reactor, the pH probe had not been sitting in the liquid and needed to be re calibrated as the computer was recording a pH > 11 a recalibration showed that the pH probe was reading at least 2 levels higher than actual pH of the reactor. From this time forward tests continued to show a consistent high activity reading with varied DO readings (may have been due to faulty meter). Two hypotheses were tested and results recorded and shown here in this report. On the fifteenth day the chemostat 21 was stopped due to a power failure during the night which stopped the program which resulted in the death of the culture. Group comparisons The urease activity of group three chemostat had increased to approximately 32.00 umol/min/ml over a period of 5 days (Monday to Friday), after the dilution of the original reactor volume from 600ml to 150ml together with 450ml of feed media (to bring the total volume back to the original to 600ml). The newly diluted reactor was run as a batch-like culture over a 48 hours period, with only the stirrer at 240rpm (no inflow, outflow or airflow), However the volume of the reactor had decreased to approximately 150mL cause unknown, therefore the reactor volume was gradually increased to the original 600ml volume over a 24 hour period. It is proposed that the afore mentioned actions over the 72 hour period may have contributed to the increased enzyme activity values. Group Two operated their chemostat without achieving a high activity rate compared to group three, even with a change in feed concentration and pH change. Group one’s chemostat did however start to achieve an increase in activity rate by increasing the rate of food supplied over time whether this would have continued if the chemostat had run for a longer time is unknown. 22 Conclusion The non-sterile chemostat working process was found to be successful in growing, producing and maintaining a high enzyme activity from a culture of S.pastuerii in conditions chosen to provide selective pressures for targeted growth. The use of a batch culture to revive enzyme activity and biomass growth was successful, and caused an increase in the urease activity. Though problems with reliability of this data and inability to reproduce this batch-like system must be acknowledged. The doubling of dilution rate showed the high enzyme activity rates were maintained, but not at the same rates as with the batch culture, concluding that it may be possible to have a quicker productivity over time whilst maintaining a high activity rate. The change in the stirrer rate had no effect on the system, and did not increase in dissolved oxygen as expected. Other groups did not achieve a higher enzyme activity through their changes the chemostat; increasing feed media concentration by group two did not achieve a higher activity production, nor did an increased stirrer rate change as seen in group one. Acknowledgements We would like to acknowledge Murdoch Teaching staff for proving the set up for this project, and for the supply of material, and assistance. We would also like to acknowledge the other class members of BIO301 for use of their data for comparison of chemostat functions. Overall the report shows excellent understanding and good literature research in 23 addition to good lab work. The few parts where the report could be improved, and I am saying this from the position of mini-research honours project, or mini publication: Shorter by avoiding some info that is not essential to bring your points across. More emphasis on explaining what your thinking is (hypothesis) how you tested it and what it means. Less emphasis on generic literature background of chemostats. More format of publications (like the one we gave you): short clear paragrphs that have a clear point at the end. 8/10 References Bang, S.S., J.K. Galinat and V. Ramakrishnan, 2001. Calcite precipitation induced by polyurethane-immobilized bacillus pasteurii. Enzyme and microbial technology, 28(4-5): 404-409. Available from http://www.ncbi.nlm.nih.gov/pubmed/11240198. Burton, S.A. and J.I. Prosser, 2001. Autotrophic ammonia oxidation at low ph through urea hydrolysis. Applied and environmental microbiology, 67(7): 2952-2957. Available from http://www.ncbi.nlm.nih.gov/pubmed/11425707. DOI 10.1128/AEM.67.7.2952-2957.2001. Cheng, L. and R. Cord-Ruwisch, 2013. Selective enrichment and production of highly urease active bacteria by non-sterile (open) chemostat culture. Journal of industrial microbiology & biotechnology, 40(10): 1095-1104. Available from http://www.ncbi.nlm.nih.gov/pubmed/23892419. DOI 10.1007/s10295-013-1310-6. Korner, S., S.K. Das, S. Veenstra and J.E. Vermaat, 2001. The effect of ph variation at the ammonium/ammonia equilibrium in wastewater and its toxicity to 24 lemna gibba. Aquat Bot, 71(1): 71-78. Available from <Go to ISI>://WOS:000171326600006. DOI Doi 10.1016/S03043770(01)00158-9. Makri, A., S. Fakas and G. Aggelis, 2010. Metabolic activities of biotechnological interest in yarrowia lipolytica grown on glycerol in repeated batch cultures. Bioresource technology, 101(7): 2351-2358. Available from http://www.ncbi.nlm.nih.gov/pubmed/19962884. DOI 10.1016/j.biortech.2009.11.024. Meers, J.L., 1971. Effect of dilution rate on outcome of chemostat mixed culture experiments. J Gen Microbiol, 67(Aug): 359-&. Available from <Go to ISI>://WOS:A1971K658600012. Meyer, H.P., O. Kappeli and A. Fiechter, 1985. Growth-control in microbial cultures. Annu Rev Microbiol, 39: 299-319. Available from <Go to ISI>://WOS:A1985ARS4100014. Nakashimada, Y., K. Kanai and N. Nishio, 1998. Optimization of dilution rate, ph and oxygen supply on optical purity of 2,3-butanediol produced by paenibacillus polymyxa in chemostat culture. Biotechnol Lett, 20(12): 1133-1138. Available from <Go to ISI>://WOS:000078348200009. DOI Doi 10.1023/A:1005324403186. Novick, A. and L. Szilard, 1950. Description of the chemostat. Science, 112(2920): 715-716. Available from http://www.ncbi.nlm.nih.gov/pubmed/14787503. Novick, A. and L. Szilard, 1950. Experiments with the chemostat on spontaneous mutations of bacteria. Proceedings of the National Academy of Sciences of the United States of America, 36(12): 708-719. Available from http://www.ncbi.nlm.nih.gov/pubmed/14808160. Pirt, S.J. and R.C. Righelato, 1967. Effect of growth rate on the synthesis of penicillin by penicillium chrysogenum in batch and chemostat cultures. Applied microbiology, 15(6): 1284-1290. Available from http://www.ncbi.nlm.nih.gov/pubmed/16349736. Ramachandran, S.K., V. Ramakrishnan and S.S. Bang, 2001. Remediation of concrete using micro-organisms. Aci Mater J, 98(1): 3-9. Available from <Go to ISI>://WOS:000166886200001. 25 Sarayu, K., N.R. Iyer and A.R. Murthy, 2014. Exploration on the biotechnological aspect of the ureolytic bacteria for the production of the cementitious materials--a review. Applied biochemistry and biotechnology, 172(5): 2308-2323. Available from http://www.ncbi.nlm.nih.gov/pubmed/24395694. DOI 10.1007/s12010013-0686-0. Siddique, R. and N.K. Chahal, 2011. Effect of ureolytic bacteria on concrete properties. Constr Build Mater, 25(10): 3791-3801. Available from <Go to ISI>://WOS:000292664700001. DOI 10.1016/j.conbuildmat.2011.04.010. Stanbury, P.F., Whitaker, A. Hall, S.J., 2013. Principles of fermentation technology. 2 Edn., Amsterdam: Elsevier. Tata, M., P. Bower, S. Bromberg, D. Duncombe, J. Fehring, V.V. Lau, D. Ryder and P. Stassi, 1999. Immobilized yeast bioreactor systems for continuous beer fermentation. Biotechnology progress, 15(1): 105-113. Available from http://www.ncbi.nlm.nih.gov/pubmed/9933520. DOI 10.1021/bp980109z. Temudo, M.F., R. Kleerebezem and M. van Loosdrecht, 2007. Influence of the ph on (open) mixed culture fermentation of glucose: A chemostat study. Biotechnology and bioengineering, 98(1): 69-79. Available from http://www.ncbi.nlm.nih.gov/pubmed/17657773. DOI 10.1002/bit.21412. Van Hoek, P., J.P. Van Dijken and J.T. Pronk, 1998. Effect of specific growth rate on fermentative capacity of baker's yeast. Applied and environmental microbiology, 64(11): 4226-4233. Available from http://www.ncbi.nlm.nih.gov/pubmed/9797269. Whiteley, M.B., E. McLean, R.J.C., 1997. An inexpensive chemostat apparatus for the study of microbial biofilms. Journal of Microbiology Methods, 30: 125132. Available from http://www.dzumenvis.nic.in/Physiology/pdf/An inexpensive chemostat apparatus.pdf. 26 Appendix Bioreactor volume was 600mL retention time was 24 hours RT =600ml/24hr = 25mL/hr = 0.416mL/min The excel spreadsheet containing the calculations for results is supplemented as an attachment upon submission. Additional data such as kLa and OUR values are found within this attachment. Additional figures Table 2: Comparison of test readings at different temperatures, showing how temperatures affects the results obtained. Time (mins) Activity at room temperature (mS) Activity in ice (mS) 1 5.6 5 2 5.8 5.3 3 6.1 5.4 4 6.4 5.5 5 6.6 5.6 6 6.9 5.6 7 7.1 5.7 8 7.4 5.7 27 9 7.6 5.7 10 7.8 5.8 Activity (ms/10 min) 2.2 0.8 Temperature Time (mins) Dissolved oxygen (mg/L) O2 change/2 min 22 (addition of ice) 0 5.64 0.2 15 2 5.84 0.25 13 4 6.09 0.2 12.5 6 6.29 0.26 11.5 8 6.55 0.2 10.5 10 6.75 28 Figure 9: The overall process of the chemostat, including batch culture, for group three. Figure 10: The overall comparison of biomass productivity vs. specific activity of the chemostat, including batch culture, overtime, for group 3. 29