Section 2.3

advertisement

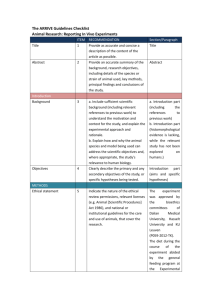

NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 1 2 3 Section 2.3 Animal Research Facility (ARF) Programming 2.3.1 General 4 5 6 7 8 9 10 11 12 13 This section describes planning and programming requirements for animal facilities constructed for biomedical research at animal biosafety level 2 (ABSL-2) or lower. There are a wide range of animal facility types including small animal facilities used primarily for rodents, rabbits and other small mammalian species; large animal facilities used primarily for cats, dogs, sheep, swine, non-human primates and other mid-sized mammalian species; farm animal facilities, breeding facilities, and others. This document focuses on small and large animal facilities which comprise most projects constructed for the NIH. For laboratory planning and programming, reference Section 2.1 (link). For ARF specific requirements, abide by this section. Additional requirements for facilities supporting ABSL-3 research are included in Sections 2.5 and 2.6. 14 15 16 17 18 19 20 NIH animal facilities shall be planned to ensure the welfare of both research animals and facility staff. Research facilities requiring animal use shall conform to The Guide for the Care and Use of Laboratory Animal, 8th edition (the guide). Conformance with this standard is required for accreditation by the Association for Assessment and Accreditation of Laboratory Animal Care International (AAALAC). Another primary standard used by AAALAC to evaluate animal care and use programs is the Guide for the Care and Use of Agricultural Animals in Research and Teaching (Ag Guide). 21 22 23 Animals shall not be housed in laboratories or spaces other than approved animal housing facilities for periods exceeding 24 hours unless the area is established as a satellite animal housing facility. 24 25 26 27 28 29 30 31 The NIH requires an integrated planning and design process which seeks the active and continuing participation of all stakeholders who are affected by the project from planning through activation and operation. A list of stakeholders to be involved is included in Section 2.1.1. Additional stakeholders that must be included for animal facility projects are veterinary, animal care and animal facility management staff. These individuals are the primary users and may reside within the facility. Investigators utilizing research animals housed within the facility may also need to be included to gain an understanding of research-specific procedures, equipment, and protocols that may affect facility design. 32 2.3.2 33 34 35 36 37 38 39 40 41 Research animal facilities are process-driven workplaces. Material flow and standard operating procedures inform planning and design. Programming requires a thorough understanding of the specialized processes and activities to be conducted. Designers must verify the specific animal species to be housed, special procedures in place to ensure animal health and research integrity, animal husbandry processes and other factors that impact requirements. ARFs may be designed for small animals, large animals or a mix of species. Other specialized functions may include aquatics holding, insectaries and other less common animal models. Facilities shall be generically planned with the flexibility to accommodate multi-species housing to the greatest extent possible. ARF Programming Page 1 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 42 2.3.2.1 Project Parameters 43 44 45 46 47 Program development shall include identification of limitations and constraints that frame the project scope. The design team shall identify limitations during the programming phase so the challenges may be addressed appropriately in the design phase. Specific areas to be investigated are identified in section 2.1.2.1. Additional areas of concern for animal facilities are as follows: 48 49 50 51 a) Infrastructure: Utility services serving animal facilities require enhanced performance for dependability, control, airflow and redundancy. Infrastructure that is suitable for laboratories may not meet the requirements for animal facilities. Refer to engineering sections for further information. 52 53 54 55 56 b) Schedule and Phasing: Expanding or renovating existing, functioning animal facilities requires special consideration to ensure that ongoing operations are not disrupted or compromised since a variety of animal species are intolerant of noise and vibration. Utility outages are also problematic since research animals should not be exposed to environmental fluctuation and cannot be easily moved. 57 2.3.2.2 Data Collection 58 59 60 61 62 63 64 A needs assessment shall be conducted, starting with completion of the ARF Program Questionnaire. (link). The program questionnaire collects data on the general mission of the animal facility, species and quantities to be housed, animal health status, biosafety level(s), existing and projected staffing, procedure space requirements, equipment requirements, standard operating procedures, storage needs, and use/storage of hazardous chemicals, biologics, and radiologicals. Specific data to be collected is identified in section 2.1.2.2 (as applicable), supplemented as follows: 65 a) User Questionnaire: An ARF-specific questionnaire shall be completed by users. <LINK> 66 67 68 69 70 b) Animal Census: Quantity and species of resident animal colonies and their attendant caging requirements are primary factors affecting facility design. Caging may be fixed or mobile, static or ventilated. Cage size is governed by the guide as well as specific research protocols. Caging may be cleaned in place or require special laminar flow containment equipment for change-out and animal transfer. 71 72 73 74 75 c) Animal Health Status: Research animals are often purpose-bred and certified to be free of specific pathogens that can be transmitted to other animals or affect research outcomes. Specific Pathogen Free (SPF) animals require special handling procedures to ensure that their health status is not compromised. SPF animals may also need to be housed in barrier facilities separated from conventional, non-SPF animals. 76 77 78 79 d) Equipment: Animal facilities equipment typically includes caging, cage sanitation and decontamination equipment, procedure room equipment including biosafety cabinets, treatment tables and lights, surgical equipment, etc. An equipment schedule shall be used to collect the data, supplemented with manufacturer data sheets that identify Page 2 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 variability in size, service clearances, utility demands, heat output, etc <LINK TO SCHEDULE>. e) Standard Operating Procedures: Facility design and operating procedures are interdependent, and incomplete understanding of SOPs often results in functional design deficiencies. Every effort shall be made during the programming phase to document SOPs that have a direct affect on design. These include, at a minimum: Use of personal protective equipment (PPE) Entry and exiting procedures for different zones within the facility Cage handling and sanitation procedures Decontamination procedures (waste, space, caging, animal carcasses and material) Security protocols Feed, bedding and animal drinking water use, storage and disposal Animal intake and quarantine procedures Emergency management procedures Maintenance and repair procedures 96 2.3.2.3 Data Recordation 97 Comply with section 2.1.2.3. Additionally, record SOPs in either narrative or flow chart format. 98 2.3.3 ARF Planning 99 2.3.3.1 Location Considerations 100 101 102 103 104 105 106 107 108 109 Several factors should be considered in locating the ARF within a research building. Since these facilities typically require access to loading docks and heavy use of water prone to leakage to lower levels, a lower level location may be optimal. Other factors that may affect facility location include: investigator access animal transport security and intrusion protection environmental issues (odors, vibration, noise) utility maintenance access material handling 110 111 There may also be risk factors such as natural hazard mitigation and biosafety that should be considered to establish acceptable locations for the ARF within a building. 112 2.3.3.2 Space Requirements 113 114 115 116 Calculating optimal size for a vivarium begins with determining the animal holding capacity and procedure space requirements. These functions typically occupy approximately 50% of the overall net usable area for facilities operating at ABSL-2 or lower. Other functions will include sanitation (cage wash, decontamination), animal health (treatment, surgery, quarantine), Page 3 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 117 118 personnel support (office, break) and logistics (loading dock, receiving, storage). The following chart illustrates proportional net space allocation for typical facilities. 119 120 121 122 123 This rule of thumb does not take into account special functions that may be incorporated such as advanced animal imaging, research-specific procedure rooms, isolation suites for barrier colonies, biocontainment suites, etc. Factors that affect animal holding and procedure space requirements are listed in section 2.4.5 124 2.3.3.3 Contamination Control 125 126 127 128 129 130 131 132 133 Layout, engineering controls and SOPs play a coordinated role in controlling the spread of infection within research animals housed in a facility. Animals, materials and personnel can be characterized as “clean” or “dirty”, referring to their potential for transmitting diseases to resident animals. For example, animals from an unapproved source are considered “dirty” until they have been evaluated for health status during a quarantine period. Feed, bedding and other incoming materials may also be considered “dirty” until decontaminated. Animal bedding and caging that is soiled from use may be considered “dirty” until it has been sanitized. Staff must also follow designated SOPs for gowning, hand wash, and circulating through the facility to minimize opportunities for cross contamination. 134 135 136 137 138 139 140 141 142 143 144 Areas of the animal facility that are prone to contamination and need to be protected by contamination control SOPs are located within a contamination control “Barrier”. Typically, these areas comprise animal holding and procedure rooms as well as animal support areas where caging is cleaned and decontaminated and “clean” expendable materials used within the facility are stored. The barrier is defined as the assembly of partitions, floors and ceilings that encapsulate this area. Personnel entering into the barrier must gown per established SOPs. Material entering into the barrier must be decontaminated. Anterooms typically afford access in and out of the barrier so that directional airflow can be maintained and gowning SOPs facilitated. Circulation of animals, materials, personnel and waste within the barrier should be configured to move from cleaner towards dirtier areas of the facility whenever possible to minimize opportunity for contamination. 145 146 147 In some facilities, additional suites are located within the overall vivarium barrier that require enhanced protection or containment. The perimeters of these suites are also protected by barrier-type enclosures and subject to additional SOPs and directional airflow. 148 Page 4 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 149 2.3.3.4 Functional Relationships 150 151 152 153 154 155 156 The zones within an animal research facility include animal holding and procedure, vivarium support, personnel support, and logistics. Grouping compatible functions within their respective zones enhances contamination control and facilitates workflow. Circulation pathways between zones should be designed to facilitate directional movement of “clean” and “dirty” materials, animals, caging, waste, and personnel. The HVAC design must also be coordinated with the zoned planning approach to facilitate directional airflow from cleaner to dirtier areas. The following diagram illustrates the relationship among typical animal facility zones: 157 ARF Typical Relational Diagram Barrier Lockers/ Gowning Holding / Procedure Zone e Lockers/ Gowning e Visitors & Staff Animal Holding & Procedure Personnel Zone Admin Offices Personnel Support (Lockers & Gowning) Ante Room Ante Room Clean Cage Wash Soiled Cage Wash Loading Dock & Storage Animals & Supplies Waste Logistics Zone Access Control Circulation Vivarium Support Zone Zone 158 159 160 161 162 163 164 165 166 The Project Officer and the Programmer shall work with the facility representatives to prepare functional and adjacencies flow charts that will facilitate the design process. Adjacencies shall be planned to facilitate operational procedures, enhance contamination control and maintain zonal relationships. Proper arrangement of critical adjacencies enhances the process of animal based science, improves the quality of life of the animals, and facilitates animal caretaking SOPs. Appropriate adjacency planning also helps isolate noise and vibrations, economize circulation routes, and simplify facility operations. 167 a) Personnel Support Zone 168 169 170 171 172 The personnel support zone includes an administrative office area serving the facility manager, administrative staff, and technician cubicles where staff wear street clothes. It may also include a veterinarian office and conference/training room. This area should be located to serve as a “gateway” into the ARF, so that incoming staff, visitors and investigators can be received or observed prior to entering secure areas of the facility. The Page 5 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 173 174 175 176 177 178 179 180 181 182 183 personnel support zone is categorized as “dirty” because there is limited control of potential contaminants in this area. Toilet / locker / gowning areas serve as a transition into the barrier, and should be located between the administrative area and the facility barrier. Gowning vestibules for donning PPE may be separate from the toilet / locker / shower room, and must be provided with sufficient floor area for PPE storage racks and disposal bins so as not to obstruct required circulation and egress paths. A break room is required for facility staff to use for consumption of food outside the barrier. In some cases, it may be appropriate to locate a staff write-up area and break facility within the barrier for caretaker convenience, but this requires special SOPs and must be approved by the veterinarian and facility manager. Separate toilet / shower / locker facilities are required for men and women, except in very small facilities. 184 b) Animal Holding and Procedure Zone 185 186 187 188 189 190 191 192 The animal holding and procedure zone is considered to be a “clean” area located within the barrier. Personnel entering this area must be gowned using PPE established by SOP. Material entering this area must be decontaminated per SOPs. Clean caging enters this area after sanitation in the cage wash area. Soiled caging is returned to the cage wash area via a separate pathway, or along the same path utilizing a movement/timing pattern that minimizes cross contamination between clean and soiled items. Animal holding and procedure spaces are often comingled so that animals do not need require excessive transport. 193 194 195 196 197 198 199 200 Procedure space may be general, shared rooms designed for generic procedures or highly specialized space customized for specific uses. In some cases, the program may require dedicated procedure rooms interconnected with the holding rooms they serve. Specialty procedure functions may include surgical rooms or suites, behavioral suites, animal imaging rooms, irradiation rooms, and other purpose-built areas. The number of required procedure rooms varies in accordance with species, equipment needs, and animal transport restrictions, however, sufficient generic procedure space should be provided to ensure flexibility for both current and future research initiatives. 201 c) Vivarium Support Zone 202 203 204 205 206 207 208 209 210 211 212 213 214 The primary activity within the vivarium support zone is cage processing including cleaning and decontamination of caging and caging accessories, soiled bedding removal, and preparing caging for return to animal holding rooms. Many of these activities occur in the cage wash area, which shall be divided with a dirty side for incoming soiled caging and a clean side for caging that has passed through sanitation equipment. Facilities housing SPF animals may also require a sterile caging area adjacent to clean cage wash for caging setups that have been autoclaved. Other areas include feed and bedding storage, clean cage storage, and diet kitchen for large animal facilities that prepare fresh feed. Soiled caging and waste shall be routed along separate pathways than clean material and caging to the greatest extent possible. If separate clean and dirty circulation cannot be fully achieved, a single corridor may be utilized with one-way circulation or time separated clean and dirty use. Cage processing SOPs must be confirmed by veterinary and caretaker staff, and proposed SOPs must be described. 215 216 217 Other vivarium support zone functions may include quarantine, rederivation and other functions related to bringing animals from unknown sources into the barrier or reintroducing animals after they have been removed from the barrier. Location of quarantine functions Page 6 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 218 219 outside of the barrier should be considered. Cage decontamination and transport from quarantine areas should be managed to maintain contamination control. 220 d) Logistics Zone 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 The logistics zone includes the loading dock, receiving area vertical transport from the loading dock to the animal facility, medical pathological waste (MPW) storage freezers or cold room, and storage space for cage wash detergents, disinfectants and other material. In larger facilities, automated bedding dispensing and waste soiled bedding removal equipment may also require space. Areas associated with the loading dock are considered to be an extension of the vivarium and shall be separated from general building logistical areas to the greatest extent possible. Ideally, they should connect directly to the vivarium. When direct connection is not possible, a dedicated pathway for transport of animals, materials and waste shall be defined. They shall be designed to promote proper sanitation and resist pest infestation. The loading dock area accessing the dumpster and waste disposal operations should be separated from the animal and material receiving area. Large animal facility truck bays should be configured to allow vehicles to enter a screened, sheltered off-loading area, or otherwise dock to the receiving area. The pathway between receiving and the barrier shall include a vestibule or anteroom for decontamination of incoming materials. Finishes and detailing shall facilitate sanitation and pest management 236 2.3.3.5 Circulation 237 238 239 240 241 242 243 244 245 246 247 Circulation pathways are critical for facilitating operations and enhancing contamination control within the animal research facility. Planning of circulation focuses on the movement of personnel, cages, racks, materials, and waste through the facility. During the planning phase the design team must work with the facility manager and veterinarian to determine the extent to which the corridor system and SOPs governing time and direction of movement can accommodate clean and dirty circulation. Personnel, equipment and supplies shall move from areas of least contamination to areas of greater contamination. Movement of personnel, equipment and supplies shall be planned to minimize the potential for contamination of cleaner areas. Consideration shall be given to provision of space for staging clean and soiled caging and materials as well as space for personnel gowning and gown removal. Movement of sterilized materials into barrier suites must also be considered. 248 249 250 251 252 253 254 255 256 a) Corridor Width: Corridor width shall be dependent on the flow of traffic and cage staging requirements within the animal facility. The Guide recommends a corridor width of 1 825 mm (6’-0”) – 2 450 mm (8’-0”). Two animal cage racks or pieces of the largest mobile equipment must be able to pass each other without restriction in the corridor. Minimum corridor width of 7’-0” is recommended for NIH facilities provided that this allows for twoway cage passage clear of wall protection rails (typically protruding 3” from each wall). Sufficient storage shall be provided within the facility so that caging and equipment does not have to be stored in the corridors. Marshalling alcoves for racks and carts shall be provided in congested areas so that corridors are not obstructed by equipment. 257 258 259 260 261 b) Vertical Transportation: In multilevel facilities, dedicated clean and dirty animal elevators are required. The elevator for transporting clean material shall be located near the clean side of the cage wash area, while the elevator used for soiled material shall be in close proximity to the soiled side of the cage wash area. Refer to Section 4.10, Vertical Transportation for additional ARF elevator requirements. <LINK> Page 7 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 262 2.3.3.6 Workplace Enhancement 263 264 265 Animal facilities are staffed with highly trained and educated personnel who often spend large portions of their time within an industrial workplace. Maintenance of a safe, ergonomic and aesthetic work environment is essential. 266 267 268 a) Functional Zoning: Personnel office areas must be separated from animal and vivarium support areas. Vivarium equipment that creates excessive noise, heat, or vibration should also be buffered from normally occupied areas. 269 270 271 272 273 274 b) Personnel Support: A break room equipped with kitchenette and tables shall be provided where staff can eat, drink and interact outside of the vivarium environment. Lockers shall be provided for animal caretakers and technicians to store street clothing and personal items. Cubicle lockers may also be considered for investigators using the facility. Showers are also required in any facility that includes cage wash, and as stipulated by SOPs. 275 276 277 278 279 280 c) Natural Lighting: Natural lighting and exterior views should be provided in office areas, break rooms, and other areas normally occupied areas outside of the barrier to the greatest extent possible. Natural lighting shall not be provided within holding and procedure areas unless specifically approved by the facility manager, veterinarian and security officer. Corridors and support vivarium support functions within the barrier can also benefit from natural lighting if there are not specific reasons preventing it. 281 2.3.3.7 Flexibility 282 283 284 285 Animal facilities require flexibility to meet fluctuating research needs. Flexibility is also needed to incorporate changing technologies in scientific procedures and instrumentation, and accommodate functional use changes without disrupting mission-critical functions. The following planning concepts can maximize flexibility: 286 287 288 289 290 a) Generic Design: The animal facility shall be flexible and adaptable to accommodate changes in function and protocols without having to make major changes to the facility. Spaces should be designed to hold multiple species over time as protocols change. Individually planned or customized spaces are to be avoided. Animal holding and procedure rooms shall be designed to allow for interchangeability. 291 292 293 294 295 b) Modularity: Significant portions of animal facilities comprising holding and procedure areas can be organized in a modular pattern that supports a variety of caging types and layouts. Modularity shall extend to utility delivery systems. Modular distribution arrangements shall allow individual areas to be shut down for alteration or repair without impacting utility delivery to adjacent areas. 296 297 298 299 c) Furnishing Systems: Vivarium furnishing systems shall be flexible and, where practical, movable to allow for reconfiguration of benches and instrumentation without major renovation. Modular systems shall be utilized that permit interchangeability of components or substitution of equipment for bench elements. Page 8 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 300 301 302 303 d) Utility Systems Flexibility: Components of the utility infrastructure and distribution system that require routine maintenance should be accessible without requiring entry into the barrier or disruption of day-to-day operations. Distribution modes shall allow individual areas to be shut down for alteration or repair without major disruption to adjacent areas. 304 305 e) Expansion: Planning analysis shall include consideration for future expansion of the animal facility without disruption to the operational facility. 306 2.3.3.8 Utility Systems: 307 308 309 Utility systems serving animal research facilities shall be designed to maintain stable environments, flexibility to accommodate changing demands, redundancy to insure dependability, and accessible for maintenance without disrupting operations. 310 311 312 313 314 a) Maintenance Accessibility: Utility system mains and components requiring service or periodic adjustment should be located in areas that allow for alteration and adjustment without entry into the animal areas to the maximum extent practicable. Branch services shall be extended to individual spaces on a modular basis so that individual rooms can be isolated with minimal disruption to adjacent spaces. 315 316 317 318 319 320 321 There are numerous design strategies that facilitate maintenance accessibility including provision of an interstitial floor above the animal facility, utility corridors, saddlebag mechanical rooms, etc. Some allow for near complete access to utility system components without entry into the animal facility. Others may limit maintenance access to less sensitive areas of the animal facility such as corridors. The selected approach shall consider tolerance of the specific program to maintenance activities, operational effectiveness of utility access, and life cycle costs. 322 Utility Distribution Strategies 323 324 325 326 327 b) Redundancy: HVAC systems serving animal facilities shall be designed with redundant components or standby equipment with the capability to ensure continuous operation during equipment failure, power outages, and maintenance outages. The degree to which the facility must remain partially or fully operational shall be established by the Page 9 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 328 329 planning team during the programming phase. At a minimum, all areas of the facility that house animals or support animal procedures shall be capable of ongoing operation. 330 331 332 333 c) Spare Capacity: Reserve capacity shall be designed into the primary building utility systems including vertical shafts to accommodate future growth and change. Spare capacity shall be designed into the building systems to allow flexibility to add equipment and instrumentation as required. 334 335 d) Segregated Systems: Systems serving the vivarium shall be largely isolated from nonvivarium building systems to minimize operational fluctuations. 336 337 338 e) Directional Airflow: The HVAC system shall be capable of providing directional airflow from more contaminated towards less contaminated areas of the facility to effectively meet the contamination control strategy. 339 <LINK TO ENGINEERING SECTIONS> 340 2.3.4 341 342 343 344 345 346 347 348 349 350 351 352 The objective of security in an animal research facility is to ensure the safety and security of the staff, animals, equipment, biological agents, and data. At NIH owned or leased facilities; the site is the first level of security. The site may be open to the public or it may have controlled access depending on the location. The second level of security is the building. Access to the building must be managed. Air intakes and any central utilities must be safeguarded from intruders. The third level of security is the access to the animal research facility. Administrative staff, research and veterinary staff, maintenance staff and vendors will require access to the animal research facility. A controlled point of entry is required prior to entering the vivarium. Security features must also be provided for the loading docks and service entries for the animal facility. The fourth level of security is the specific animal rooms, containment suites, surgical suites, pharmacy, or other areas within the facility that require a higher level of controlled access and surveillance. Security requirements shall be coordinate with DPSM. 353 Security <LINK TO SECURITY / BIOSECURITY> 354 2.3.5 Biological Risk Assessment and Biosafety Level Criteria 355 Refer to section 2.1.3.7 and the following: 356 357 358 359 Animal biosafety levels are designated in ascending order from ABSL-1 to ABSL-4. All animal facilities designed for the NIH shall be designed to Animal Biosafety Level 2 (ABSL-2) standards (minimum) in accordance with the latest edition of the BMBL (Biosafety in Microbiological and Biomedical Laboratories). (LINK). 360 2.3.6 Design Considerations 361 Refer to section 2.1.3.6. 362 2.3.6.1 Animal Holding Rooms 363 There are several factors affecting animal holding room design: Page 10 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 364 365 366 367 368 369 370 371 372 373 a) Holding Room Population: The size of holding rooms is determined by the species, number of cages or cage racks and accessory equipment per room. Larger rooms are more efficient in terms of SF/cage; however, they increase the risk of infection of larger numbers of animals in the event of infection outbreak, and may also require multiple studies to be conducted within one space. There are ergonomic considerations as well, including the number of cages that can be reasonably managed by a single caretaker that may need to regown when entering different holding rooms, and space clearances required to safely perform caretaking activities and procedures. Holding room sizes must be determined by the full planning team. 374 375 376 377 378 379 380 381 382 383 b) Caging Types: The guide provides species-specific data on minimum floor area and volumetric requirements for caging. Caging may be fixed for larger species, or freestanding racks housing multiple cages. Sufficient clearance must be provided to care for and observe the animals, move carts and equipment around the room, and egress from the room. Space for feed storage bins, waste container, cage change equipment, and hand wash sinks must be accounted for. If crash rails are used within holding rooms to protect walls or anchor cages, they must be accounted for in space calculations. Utility systems must coordinated with caging requirements in terms of effective cooling, air distribution, lighting and connections for specialized caging systems that may require power and exhaust connections. 384 385 386 387 c) Species Separation: Different species often cannot be housed within the same holding room due to different environmental requirements or other incompatibilities such as predator-prey considerations. In facilities that serve both small and large animals populations, the two should be segregated. 388 389 390 391 392 d) Barrier Suites: When animal facilities house both SPF and conventional (non-SPF) animals, SPF animal holding rooms should be located within suites that are isolated from conventional animal populations. When required by SOP, these suites should be separated from other areas of the facility by anterooms. Dedicated autoclaves may be required for SPF suites. 393 394 395 396 397 398 399 e) Noise and Vibration: Rodents are particularly sensitive to noise and vibration. Background noise shall be minimized, and sudden variable noise producing elements, such as fire alarms must be mitigated through use of strobes or voice systems. Species that generate noise should be segregated from other animal populations. Adverse noise may be generated by electronic devices and equipment such as occupancy sensors that generate infrasound at frequencies undetectable to humans. Sensitivity to noise at different frequencies also varies among species. 400 401 402 403 404 405 406 f) 407 Vibration stability is also important to maintaining a controlled environment for sensitive animals such as rodents. Rodent holding and test rooms shall be located away from areas such as a cage wash, mechanical rooms and elevator shafts. Vibration may not as much of an issue for large animals except in behavior testing areas. Vibration stability is required in areas housing specialized equipment such as imaging suites. Vibration studies shall be performed to determine how best to achieve the maximum allowable vibration levels as determined by instruments and animals to be used in the area. <LINK TO STRUCTURAL VIBRATION CHART> Page 11 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 408 <SUGGESTED LINK TO NIST STANDARDS> 409 410 411 2.3.6.2 Cage Wash Areas 412 413 414 415 416 417 418 419 420 421 422 423 Cage wash areas shall be buffered from animal holding and administrative support areas to mitigate the high levels of heat, humidity, noise and vibration produced by cage wash equipment. Design of cage wash area HVAC systems must consider the extensive heat gain and humidity generated by cage wash equipment and procedures so that an acceptable working environment is achieved for cage wash technicians. Clean and dirty sides of the cage wash area are separated by a contamination control barrier to enhance environmental separation, and facilitate airflow from the clean to the dirty side. Cage wash sanitation equipment that may include rack washers, tunnel washer, soiled bedding disposal unit, sterilizers, etc. should be configured for dirty-to-clean pass-through operation. When caging and materials are autoclaved for use in SPF areas, a second pass-through sterilizer may be required between the clean cage wash and sterile cage storage areas. The clean cage wash area equipment may include a bedding dispenser and bottle filler. 424 425 a) Cage Wash Sizing: Factors that must be typically considered for sizing the cage wash areas are as follows: 426 427 428 429 430 431 432 433 434 435 436 Dirty Cage Wash Equipment placement space including service and working clearances Marshaling space for racks and cages to be washed Prewash/soaking area for hosing or spray down of racks and caging prior to cleaning Area for flushing animal drinking water manifolds, when required Area for queuing waste Area for loading carriages and component racks used in washers and autoclaves. Hand wash area and commercial pot sink Hose station 437 438 439 440 441 442 443 444 445 446 447 448 Clean Cage Wash Area for wet caging to “drip-dry”, typically in front of rack washers Working space for preparing cages Area for unloading carriages and component racks used in washers and autoclaves Queuing area for stacking clean caging and caging components Bottle filling area Space for clean cage marshaling or storage Hose station Compressed air system for clearing animal drinking water lines, when required Clean cage marshaling Page 12 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 449 450 Typical Cage Wash Area Relational Diagram 451 452 Soiled Caging 453 Waste 454 455 Waste Clean Caging Tunnel Washer Soiled Cage Wash Wash Down Area Service Area Rack Washer Waste Feed & Bedding Storage 457 Sterile Caging Sterilizer Autoclave 456 Clean Cage Waste Storage Clean Cage Wash Waste 458 459 460 461 462 463 464 465 466 b) Cage Wash Equipment: Through-put calculations shall be provided based on userprovided data and SOPs on the animal species, census, caging types, cage change frequency, animal drinking water modes, operational schedule, staffing, redundancy requirements, etc. to determine the type, size and quantity of equipment required for cage sanitation and decontamination. Calculations shall be included with planning deliverables. Equipment analysis for larger facilities shall include evaluation of the cost effectiveness of automated systems for waste removal, cage handling and bedding dispensing. 467 2.3.6.3 Storage 468 The following storage areas are required: 469 470 471 472 473 474 475 476 477 a) Feed Storage: Feed type is species dependant, and may include both commercial bagged feed and prepared fresh food. Bagged feed often requires a cold room to maintain product quality. The volume of feed that must be stored is based on the projected consumption rate and frequency of delivery. Typically, a minimum of 2 week supply is stored on site in a dedicated room located near the clean cage wash area; however, more may be required for emergency contingency. Fresh feed may be required for large animal facilities, and typically requires both refrigerated storage and work area for preparation. The requirements for receiving, preparation and storage of animal feed shall be determined by program personnel. 478 479 480 481 482 483 b) Bedding Storage: Bedding type is species dependant, but must also be compatible with caging type and waste disposal methodology. The volume of bedding storage is based on the projected consumption rate and frequency of delivery. Typically, a minimum of 2 week supply is stored on-site. Bulk, bagged bedding is stored near the clean cage wash area. Large facilities may use automated systems that include hoppers located near the loading dock. Page 13 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 484 485 486 487 488 489 c) Cage Storage: Surplus caging and caging components are required to allow for cleaning and change-out. Quantity is based on SOPs for frequency of cage cleaning that determine the percentage of cages that must be cleaned on a daily basis. Typically, this is 10%-20% of each caging type. Clean cage storage is typically located within or adjacent to the clean cage wash area. A separate area may be required for storage of sterilized caging and material in SPF facilities. 490 491 d) Soiled Cage Marshalling: Space shall be provided in or adjacent to the dirty cage wash area for temporary queuing of soiled caging awaiting sanitation. 492 493 494 e) Supply Storage: Additional storage space is required for supplies, PPE, clean laundry and other items. The location and size of this area shall be calculated with the facility manager. 495 496 497 498 499 f) Bulk Detergent Storage: Space is typically required for storage of bulk detergents and disinfectants used for sanitation. Where possible, bulk detergent should be stored near the loading dock or other area outside of the barrier to facilitate resupply, and pumped to the point of use. The size and number of tanks required for detergent storage is a function of delivery interval and types used, which must be determined by the program. 500 2.3.6.4 Animal Intake and Quarantine 501 502 503 504 505 506 507 508 509 Intake SOPs typically require animals to be transferred into facility standard caging and quarantined prior to assimilation into holding rooms. This activity should be located at the barrier perimeter, remote from clean animal populations so that potentially contaminated animals are not transported through clean areas of the facility. Animal transfer typically requires a biosafety cabinet or laminar flow change cabinet for handling micro-isolator caging and SPF animals. A pass-through configuration or transfer box facilitates this procedure. Quarantine holding rooms shall comply with the same criteria as other holding rooms. SOPs for decontaminating quarantine caging prior to transport through interior barrier corridors must be accommodated by the design. 510 2.3.6.5 Necropsy 511 512 513 514 515 516 517 A necropsy area may be required, particularly for large animal holding facilities. This room is considered to be “dirty”, and should be located at the barrier perimeter, or outside of the barrier along the waste removal pathway. Space requirements must be determined by equipment and furnishing needs as well as working space for personnel performing autopsies and tissue harvesting. Animal carcasses are considered to be MPW, and require a designated cold storage area, often adjacent to the loading dock waste area. Both refrigerator and freezer storage are required. 518 2.3.6.6 Surgical Suites 519 520 521 522 523 524 Large animal holding facilities and some small animal holding facilities require surgical facilities. Large animal surgical suites consist of one or more surgery rooms, a surgeon scrub area, animal prep room, surgical supply and work room, and recovery area. Depending on SOPs, recovery may occur within holding rooms. Small animal surgery may be performed within a typical procedure room or designated rooms equipped with exhausted surgical stations designed to contain biological contaminants and scavenge anesthetic gasses. Directional Page 14 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 525 526 airflow is particularly critical in surgical suites to maintain aseptic conditions within the operating room. The following diagram illustrates typical large animal surgery suite organization: 527 Surgical Suite Relational Diagram Animals 528 529 Pass through Cabinet 530 Animal Waste Recovery Prep 531 Clean Materials 532 533 Surgical Supply Waste Sterilizer Operatory Waste Waste Staff Waste 534 Surgeon Scrub 535 Wast e 536 2.3.6.7 Insectaries 537 538 539 540 541 542 543 544 545 546 Insectaries are containment suites designed to house insect research models. Guidelines for Insectary design are provided in the Arthropod Containment Guideline, Version 3.1 published by the American Committee of Medical Entomology and the American Society of Tropical Medicine. Co-locating an Insectary with a mammalian holding facility must consider the risk of disease transmission via insect vector. Functional components of insectaries typically include environmental chambers (walk-in or cabinet type) for insect holding and breeding, procedure room and anteroom to facilitate containment. Insectary suites shall be separated from other vivarium areas by a vestibule with two self-closing doors. Sufficient space shall be provided for procedures involving live insects to be performed within the suite, thereby minimizing the need for transport of live insects. 547 2.3.6.8 Aquatics 548 549 550 551 552 553 554 555 556 557 558 559 560 Aquatic holding rooms require special planning to support their unique environmental requirements and engineering systems. They are wet areas that require drainage systems, generate humidity and can adversely affect surrounding areas. Environmental criteria differ depending on species housed and aquatic water system specification, and must be established with user consultation. Aquatic holding racks require water filtration and treatment systems that may be self-contained or require dedicated equipment space. It is important to note that the aquatic water system forms the animal microenvironment and must be specified to meet research and animal husbandry parameters for biological filtration, temperature, flow rate, purity, pH, particulates, salinity, and oxygenation. Aquatic support areas may include procedure rooms for microinjection and mutagenesis, brine shrimp hatcheries, and wash areas that are separated from other cage wash areas to prevent detergents and disinfectants from contaminating the aquaria. Some aquatic water systems utilize gravity drainage that requires lower level water filtration systems. 561 2.3.6.9 Animal Imaging Page 15 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 562 563 564 565 566 567 568 569 570 571 572 Advanced imaging suites utilizing various modalities including MRI, PET, CT, ultrasound, and bioluminescence are becoming increasingly critical for animal based research. Facilities for animal imaging must typically meet criteria equivalent to similar facility for humans, except that equipment size is often smaller, especially for small animals. Imaging suites may be core facilities serving both resident animals as well as animals from other facilities. Imaging suites typically include imaging rooms, imaging support equipment rooms, animal prep, holding and procedure space, and space for equipment control consoles. Space size and configuration must comply with imaging equipment manufacturer field installation criteria and accepted by manufacturer representatives. Spatial relationships must facilitate user defined work flow and SOPs for animal handling. Location of animal imaging facilities should take the following issues into consideration: 573 574 Vibration stability and isolation from vibration sources required meet equipment operating criteria. 575 Structural capability to accommodate equipment weight 576 577 578 Isolation from sources of interference. For MRIs this may include separation and/or shielded from large moving ferrous metal objects (vehicles, elevators) that distort data output. 579 580 Isolation for personnel safety. For MRIs, areas within the 5 gauss magnetic field must be secured to exclude people. 581 Pathway for delivery and installation of large, heavy equipment components 582 583 584 Equipment components that are not required to be within the same room as the animal should be located outside of the barrier to the greatest extent possible to facilitate maintenance access. 585 586 587 Transport of animals to and from the facility. If the facility serves as a core that images animals from outside sources, transport and handling of potentially “dirty” animals must also be considered. 588 2.3.6.10 Behavioral Suites 589 590 Behavioral suites and procedure rooms shall be located remotely from sources of noise and vibration such as cage wash areas and large animal holding rooms. 591 2.3.7 Planning and Programming Deliverables 592 593 Refer to Section 2.1.3 for predesign deliverable requirements. Additions to this list are as follows: 594 595 596 597 598 599 Flow diagrams indicating proposed circulation of animals, staff, caging sanitation, waste, and materials based on SOPs listed in Section 2.3.2.2. Projects including sanitation or decontamination equipment shall include through-put calculations validating that the equipment is properly sized ARF Questionnaire (link) Page 16 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 600 Animal Research Facility - Program Questionnaire 601 602 603 The purpose of this questionnaire is to obtain information from the customer that is necessary to produce the Program of Requirements (POR) for BSL2 research animal facilities. Other questionnaires are provided for Laboratories and ABSL-3 facilities. 604 1 General Requirements 605 1.1 List all of the Institutes / Centers to be accommodated in this space. 606 1.2 Identify project stakeholders and responsibilities 607 1.3 Identify Facility Manager 608 1.4 Identify Safety Officer 609 1.5 Identify the point of contacts and their roles. 610 1.6 Identify all staff and occupants anticipated to be within this space. 611 1.7 Identify roles of all staff. 612 2 Program Requirements 613 2.1 Describe project objectives including schedule and budget 614 2.2 Identify the assigned sq. ft. for the project. 615 616 2.3 Identify office, administrative, conference/training and personnel functions to be provided. 617 618 2.4 Are lockers, showers, toilet rooms required? Separate Men’s and Women’s facilities? Pass-through design? 619 2.5 List attributes and deficiencies of your current facility. 620 2.6 Identify material storage requirements. 621 2.7 Identify need for personnel lockers. 622 2.8 Identify need for Janitor Closets. 623 3 Functional Relationships 624 3.1 Describe functional relationships among program components (use matrix provided) 625 3.2 Identify preferred location of offices and tech areas. 626 4 Animal Holding & Caging 627 4.1 Identify each population of animals to be housed (species, number, health status) 628 4.2 Identify types of caging to be used for each group (existing and new) 629 4.3 Identify required separation among groups, and need for barrier suites 630 631 4.4 Identify animal holding room requirements for each group (features, drains, sinks, cages/room, equipment, environmental requirements, etc.) 632 4.5 Identify sanitation procedure and schedule for each animal group 633 4.6 Identify animal intake and quarantine holding requirements Page 17 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 634 5 Procedure Space 635 636 5.1 Describe types and sizes of desired procedure rooms, and required proximity to animal holding areas. 637 5.2 Is a necropsy room needed? 638 5.3 Are there any advanced imaging areas required? 639 640 5.4 Other specialized areas (gamma cell, aquatics, surgical facilities, isolation rooms, rederivation, etc.) 641 6 Standard Operating Procedures 642 4.1 Describe desired personnel, material and waste flow through the facility. 643 4.2 Identify desired security hierarchy and special security requirements. 644 645 4.3 Identify PPE and gowning requirements and entry / exiting procedures for different areas of the facility 646 647 4.4 Identify delivery schedule and storage requirements for feed, bedding and other materials 648 649 4.5 Describe decontamination procedures and sterilization requirements (waste, space, caging, animal carcasses and material). 650 651 652 4.6 4.7 4.8 Identify security protocols Identify emergency management procedures Will laundry be used and/or cleaned on site? 653 5 Cage Processing SOPs 654 5.1 Identify cage change schedule for each caging type 655 5.2 Identify decontamination and sanitation procedure for each caging type 656 5.3 Identify bedding waste disposal SOP 657 658 5.4 Identify desired sanitation and sterilization equipment, including minimum chamber or belt sizes, if known. 659 6 Design Parameters 660 6.1 Identify proposed biosafety level(s). 661 662 6.2 Identify environmental parameters for each animal housing group (temperature, humidity, air change rate, lighting) 663 6.3 List sustainability objectives and features desired for this project. 664 665 6.4 List Hazardous materials (chemical and radiological) to be used and stored within the project area (use Chemical Inventory template for collecting this information <LINK>) 666 6.5 Identify any special noise or vibration restrictions. 667 668 669 7 Technical Requirements 7.1 Complete Room Data Sheet for each type of desired space. (use Room Data Sheet template <LINK>) Page 18 NIH Design Requirements Manual Section 2.3 November 27, 2012 Draft 670 671 7.2 List required services (i.e. CO2, O2, Vacuum, Compressed Air, etc.) and location required (use room data sheets) 672 7.3 Identify animal drinking water requirements and distribution approach 673 7.4 Identify sink, eyewash fountain and deluge shower requirements (room data sheets) 674 7.5 Casework: identify type and location (use room data sheets) 675 7.6 Identify any special signage or program identification requirements. 676 7.7 Identify drain and floor sloping requirements (room data sheets) 677 7.8 Identify desired noise limitations for alarm systems 678 7.9 Identify minimum door sizes 679 7.10 Identify minimum ceiling heights 680 7.11 Identify requirements for environmental monitoring 681 7.12 Special communication requirements (intercom, WiFi, etc.) 682 8 Equipment Requirements 683 684 8.1 Identify all existing and new vivarium equipment to be housed within this space (use equipment schedule template for collecting this info <link >) 685 8.2 Provide equipment data sheets for existing and proposed equipment. 686 687 8.3 Identify equipment items that require unusual or excessive clearances, structural support, headroom, vibration control, sound isolation, or other physical features. 688 9 Proposed Project Site 689 9.1 Identify the proposed project location. 690 691 9.2 For renovations, identify physical condition and known spatial and infrastructure deficiencies. 692 693 9.3 Identify and/or provide any available documentation for current and proposed space. Page 19