Senior Design 2 Documentation - University of Central Florida

UNIVERSITY OF CENTRAL FLORIDA - COLLEGE OF SCIENCES

COLLIDE-3: AVionics

Module

Group 2

Members

Mohammad Amori

Walter Castellon

Joshqua Steele

Tri Tran

Sponsor:

Dr. Josh Colwell

- 0 -

Contents

1.0 Executive Summary

Dr. Colwell, a planetary researcher at UCF, has been running the COLLIDE

(COLLisions Into Dust Experiment) experiments for over a decade. The most recent iteration of the experiment is COLLIDE-3, which was originally designed to fly aboard a rocket (called New Shepard) provided by Blue Origin, an emerging sub-orbital rocket flight company. At the time, the experiment consisted of two major elements:

1. The CPB, which housed the actual COLLIDE-3 vacuum chamber, camera recording equipment, and electrical components

2. The AVM, which was the “brain” of the experiment, transferring power to the various components within the CPB and storing the video coming out of the camera within the CPB.

Blue Origin supplied everything for the experiment that wasn’t COLLIDE-3 itself; they provided the CPB box itself, the camera, the feed through wires and connectors for the CPB, and of course the entirety of the AVM. All of the aforementioned were loaned to Dr. Colwell’s lab so that his engineers could design COLLIDE3 around working with Blue Origin’s hardware. Unfortunately, on the final test run, New Shepard experienced critical failure and was lost.

While COLLIDE-3, the CPB and the AVM were all not aboard New Shepard during the failure, everything on loan from Blue Origin was only allowed to be used if COLLIDE-3 flew on one of their rockets. Since their only rocket was New

Shepard, and that was now out of commission for quite some time, the only way to ever get actual data out of the COLLIDE-3 module was to re-create the elements of the experiment that belonged to Blue Origin, allowing Dr. Colwell to fly aboard any suborbital rocket that had room for his experiment.

Thus, the inspiration to create an AVM of our own came about. The CPB is almost literally just a housing unit with nothing electrical about it, so there was no reason to consider working on it for our project. The AVM, however, promised to be full of unique challenges that would prove to not only be an interesting senior design project, but would also have the added benefit of being used in the future to generate actual scientific data, something not many senior design projects can boast.

- 1 -

1.1 Background of COLLIDE-3

To understand what we are trying to achieve through the implementation of our

AVM, and to comprehend the vocabulary that will be used regularly throughout this paper, it is important to have a firm grasp of the experiment that our AVM is being designed around to control. However, before we get into that, it is equally important to know the scientific reason behind COLLIDE-3 existing in the first place.

1.2 The Science

Dr. Colwell is a planetary researcher in the Physics Department at UCF. One of his labs focuses on low-velocity particle collisions in microgravity environments.

The formation of a planet occurs in multiple stages. First, dust particles come together to form planetesimals. Once planetesimals grow enough in size, they are considered protoplanets. Finally, a protoplanet can become large enough to be considered a planet. Much is known about planet formation once it reaches the planetesimal stage, since from that stage on the body is large enough to attract particles through its own gravitational force.

However, before this stage, it’s unclear how enough particles come together to develop into something with its own gravitational force. This is where Dr. Cowell’s research comes in. Through observing collisions of tiny dust particles in a spacelike environment (vacuum chamber, microgravity) we can actually see the types of reactions that are likely to lead to planetesimal formation. Dr. Colwell specializes in low velocity impacts, specifically in ranges around 20cm/second.

Not only is a microgravity environment essential for reasons of watching the collision occur without gravity moving the particles, but the presence of gravity makes creating a collision at 20cm/second virtually impossible. What we hope to see in these collisions is particles starting to stick together.

1.3 The Experiment

COLLIDE-3 houses all of the necessary functions for a controlled collision experiment. Shown in Figure 1 are two of the main components of COLLIDE-3; the IBS module, which is where the actual collision occurs, and the vacuum chamber, in which the IBS module resides inside. The vacuum chamber is pumped down through the connection circled in yellow in Figure 1.3.1. A gauge

(orange circle) connects to the same place so that the level of vacuum on the inside can be read. Once a vacuum is achieved, COLLIDE-3 is loaded onto a suborbital rocket. A suborbital rocket is just that; it flies up into the area above

Earth’s atmosphere, outside the pull of Earth’s gravitational forces. Through not having to leave the actual orbit of the Earth, the rocket can be made much

- 2 -

simpler and cheaper than those designed to leave orbit, while being able to achieve the same environment for scientific experiments.

Figure 1.3.1-COLLIDE-3 IBS and Vacuum Chamber

The electrical connections circled on the left feed through the box, coming out on the red circle on the right.

Once the rocket reaches its peak altitude and has achieved a microgravity state,

COLLIDE-3 runs its experiment. First, the lights (blue, Figure 1.3.2) activate, allowing the now-recording camera looking in through the viewport (purple,

Figure 1) to witness the contents of the vacuum box. The microstep driver

(yellow, Figure 1.3.2) activates, running the stepper motor (purple, Figure 1.3.2) and moving the door down the track on the IBS (green, Figure 1.3.1). This door reveals a payload of dust particles to be collided into. Shortly after the door opens, a current is passed through the muscle wire (red, Figure 1.3.2), which activates the launcher located between the LEDs in Figure 1.3.2. The launcher propels a quartz marble into the dust payload basin, all of which is recorded.

After 30 seconds, the door is closed, the lights turn off, and the camera stops recording.

Figure 1.3.2-(Left) Electrical inside of IBS (Right) Microstep driver connected to stepper motor

- 3 -

Not shown is the CPB in which the vacuum box, camera, and circuit board is housed in. This is because the CPB is property of Blue Origin, and we are under a Non-Disclosure Agreeme nt which prevents us from picturing it anywhere. It’s a fairly straightforward box though, simply providing threaded holes to mount our boxes and room for electrical feedthroughs. The DC to DC converters shown in

Figure 1.3.3 are for regulating the voltage sent into the IBS module. Blue Origin’s

AVM, and the one we are replacing it with, only provided 28V DC. The lights and power of the microstep driver require 12V DC, while the PWM of the microstep driver and the muscle wire require 6V DC. The middle chip in Figure 1.3.3 is the

28-12 converter, with the two chips flanking it acting as 28-6 converters.

Figure 1.3.3-DC to DC converters for IBS components

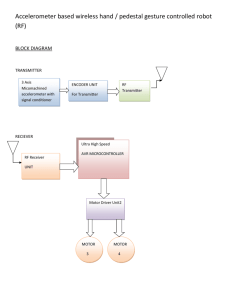

2.0 Accelerometer

2.1 Introduction and functions

One of the most important factors of our COLLission Into Dust Experiment-3

AVionics Module project is the accelerometer. In our project, the accelerometer is the component that essentially starts everything else that needs to start. Without the accelerometer, the Collide 3 AVM would not do anything at all because it would not detect any micro gravity. Hence, it is one of the most important components that we need to have working correctly and efficiently for the rest of the project to go accordingly to our experiment.

In order for us to start the mission, we need our accelerometer to sense that it is in mid air or in micro gravity which will simulates the same condition as out of space. The accelerometer will be used to start up many other components like the LED lights, muscle wires, the microcontroller or the FPGA board (we have not decided to use which one yet because we are still researching to see which one is the better fit for our project), solid state hard drives, and the camera. Thus, the accelerometer is very important to our project and should be researched and implemented correctly.

- 4 -

Our project is designed to simulate how the universe was created by putting the

Collide 3 AVM into space to conduct our experiment with a spherical object and dust particles. We obviously are not able to do this. We can not demonstrate it because we can not do it in spaces. For our senior design project, we will be simulating the micro gravity in space by using a drop tower. This drop tower is provided for us by Dr. Josh Colwell which is our sponsor. We will be using his lab to conduct our experiment which will sense micro gravity instead of the conventional space beyond our earth. The drop tower is basically a structure that is about ten to twelve feet tall and made out of PCP pipes and other metal materials. The drop tower also has soft cushions at the bottom to hold the object so it would not break our project when it hits the bottom. We will be lifting our project up to the top of the tower and then we will drop it. Once our project is being dropped in mid air, the accelerometer will detect the micro gravity in that very instance.

Once our accelerometer sense micro gravity from the free fall with the help of the drop tower, it will basically flag a switch which states that it is in space or free fall.

Most likely we will have to test it out in the drop tower first to make sure the accelerometer actually senses the micro gravity and activates the switch to flag it on. We will probably keep the micro gravity flag on for the rest of our project because we might not be able to present it in the lab. Thus, our presentation will probably start with a switch that turns the accelerometer on. Of course, we will have some kind of documentations that shows that the accelerometer actually working either on paper or video.

When the accelerometer sense micro gravity, it will initially turn on the LED lights which will provide the Collide 3 AVM with visibility in space. After that, it will initiate the muscle wire by letting current go through it. The muscle wires will squeeze the hinge which will open the door to release the bigger spherical object. It will also open the doors to release some dust particles. The dust particles will most likely orbit around the bigger object. Here is when the camera shines. The camera will start to take pictures and it will store these images onto the solid state hard drive or drives, we have not decided how many solid state hard drives will be implemented into our project. Essentially, everything will proceed after the accelerometer detects micro gravity.

The reason we are using an accelerometer for our project is because we need a device that measures active acceleration which is the force due to the gravity of the Earth. We can experience this force during freefall. An accelerometer in a gravitational freefall will measure its force to be zero because its reference to the earth is weightless during this timeframe. Even though the speed is increasing with every second during the fall, there is no normal force to push back which is used to determine the weight. With no weight on the accelerometer, it is essentially weightless. This is the reason why we will be using the accelerometer to simulate micro gravity in out of space.

There are lots of different types of accelerometers out there. The Collide 3 AVM is suppose to go into space as well, thus it might be better to explore our options

- 5 -

of accelerometers by getting a more advance one. Some of them even sense the direction and the magnitude of the accelerations in vector and quantity respectively. The advance accelerometer models with these features can be used to detect vibration and shock during the flight. The Collide 3 AVM does not care of the orientation of itself nor does it care about the angles it is in compared to the Earth. Even though those features are not important, most accelerometer are able to sense them anyways, but we did not use it.

We only need it to sense micro gravity and handle the shock and vibration while it is on its way into space. Most accelerometers are small and is able to handle vibration. This is essential to our project because if it is big and bulky, then the vibration from the flight might shake it and make it not function correctly. The smaller the accelerometer is, the more secure and safe it can be integrated into our Collide 3 AVM. Thus, we tried to find a small size and dimension accelerometer in figure 2.1.1.

Figure 2.1.1. This picture shows what an accelerometer should look like and its real life scale compared to a quarter. This accelerometer provides digital PWM or Analog output. This picture is provided by Zagrosrobotics.com

As mentioned above, our project only demonstrats the process after the accelerometer activates the on switch from the existence of micro gravity. It should also be able to handle vibration and shock. Our sponsor wants this because the Collide 3 AVM will have to endure to flight. Our accelerometer should have some kind of sensor or mechanism that should output a zero flag once it detects micro gravity. Also, it should be low powered consumption because it will be running on battery. We researched what accelerometers are and what the different types are. Then we determined what type we need.

Thereafter, we narrowed our selection down to three to choose from. After we have our three main accelerometers, we compared and saw which one was the best choice.

- 6 -

2.2 Research

Accelerometers are known to be electromechanical devices and are used for many different applications. An accelerometer acts as a mass on a spring.

Whenever it experience acceleration of any kind, that mass will moves so that the spring will accommodate it’s acceleration to the same rate as the housing of the component. This movement is measured as displacement, calculated, and is formed into integer as a quantity for the acceleration of the whole ordeal. You can say it is an inertial sensor used to measure the acceleration. This can be obtained by deducting the gravitational acceleration (g) from the movement acceleration (a) along the direction of the axis its going in. we use the following formula to explain this process: A= a-g. Therefore, a three axis accelerometer will indicate zero for all three of its axis. It senses this simultaneously during the free fall. This will only happen during a free fall. This process can be simply demonstrated by the picture below in figure 2.2.1.

Figure 2.2.1 This is not an accelerometer, it is just a demonstration of how the accelerometer is structured to calculate and determine its value. This picture is provided by Education.com in the

Acceleration Help section.

For this theoretical situation, the indicated output values of the three axes will all show zero simultaneously. With this characteristic, we can say that the accelerometer is in the condition of free fall. In the state of free fall, it means that there is no external force except for gravity. During this free fall, there is only air resistance. Thus, no external force acts upon it to create any kind of stir inside the accelerometer.

In most common devices, there are several different technology types which consist of capacitive, piezo-electric, and piezo-resistive accelerometers. These different types are used to convert mechanical motion into measurable electrical signals. The designs of these accelerometers are also abundant. Some examples of their design are flexural, inverted compression, single ended

- 7 -

compression, isolated compression, and shear type design. Also, there are many grades of accelerometers.

The types of accelerometer are important to know what is needed and what we do not need. Obviously, the more it cost the better it is, but we do not need it to do everything. The high vibration accelerometer design is made to stand high vibration levels which are used in heavy machining tools, vibrations labs, and many other high vibration applications. This is good in our designed project because it will be able to withstand the initial launch and flight into space. There are many other types such as premium grade, triaxial, and industrial grade.

The premium grades are made from top rated crystals and are secure from the environment with stainless steel housing. They produce top quality and low noise using low noise circuits for their accelerometers. The industrial grade accelerometers are most common and are used in regular shops that do not need high attention for their job. These accelerometers are also protected against all sorts of weather and rough environments. The next one is the triaxial accelerometer. These use the x, y, and z coordination plane with three separate crystals to give three signals respectively to each of the three coordinates. After researching these different types of accelerometer to decide which one is needed, we definitely do not need to spend more than we have to for some of these accelerometers because we do have a budget we have to go with. But we did keep a good eye on them and kept them up for consideration. It is always good to have our options open.

Accelerometers have different important specifications that can be compared.

The accelerometer’s sensitivity, its bandwidth, if it’s analog or digital, it’s and buffering ability are things to consider for picking the right accelerometer for your project. The accelerometer’s sensitivity is the measurement of ‘g’ force which produces an output voltage. The accelerometer’s bandwidth is the total number of times a reading is being recorded per second. Obviously we want the most sensitive accelerometer and high rate bandwidth so it can detect micro gravity at the instant it happens and activates quickly. Our drop tower is only about ten to twelve feet tall, thus the drop will be really quick and short. So it needs to detect micro gravity as quickly as possible.

In order to pick between analog accelerometer and/or digital accelerometer depends on which microcontroller or FPGA board we will be using to make a better choice. We ended up using a microcontroller. Digital accelerometer uses square waves of frequency like we have seen before in our digital system class and lab. The acceleration was measured by the number of times the voltage is in its high state. All of these accelerometers we researched was used to interface with our microcontrollers.

For analog accelerometers, the output is dependent on the continuous voltage.

Some accelerometer delivers both output in digital or analog. Everything being researched should be incorporated into which accelerometer we used and its structure as shown in figure 2.2.2. Whether the output be analog or digital, we

- 8 -

have a converter for our microcontroller when it is needed. Thus, we researched on converters to help with the accelerometer.

Figure 2.2.2 This picture is a basic structure of an accelerometer labeled with its important components provided by Dliengineering.com

2.3 Narrow down to 3 Accelerometers

We researched a couple of accelerometer that we could use for our project. At first we did not think that we need to get the higher grade accelerometer because of price, but with this being in space with technically no axis. We basically decide on getting the 3-Axis accelerometer modules as appose to 2-Axis. The 3-Axis accelerometer gives us more sense of direction, thus it will be more sensitive to detect any kind of acceleration for micro gravity or none at all when it is in space.

The most important factor of the accelerometer is to accurately sense micro gravity or in other words ‘zero gravity’. We research lots of accelerometer but we have narrowed it down to three to chose from.

MMA7361 3-Axis Accelerometer Module

MMA7260QT 3-Axis Accelerometer Module

Hitachi H48C Tri(3)-Axis Accelerometer Module

The first accelerometer that has all of the features we need for our Collide 3 AVM project is the MMA7361 3 Axis Accelerometer Module from Freescale

Semiconductor. This one can be bought for the amount of ten dollars and ninety five cent on ‘modern device’ website. We search many accelerometers with the features that we wanted. The most important feature is the ability to detect micro gravity and sends and output so that the rest of our project may continue its process. All in all, the accelerometer has to be small, vibration resistance, and low power consumption.

This accelerometer meets our requirements. Thus, we picked it as one of the accelerometers to do more research and compare. This MMA7361 3 Axis

Accelerometer Module operates in two simple selectable sensitivity modes. It has

- 9 -

a +/- 1.5g mode for more sensitivity activities and it also have a +/- 6g mode for applications that you do not want anything to change with a slight tap. The default will be +/- 1.5g mode which is 800 mV/g @ 1.5g but you could change it to the other mode which is 206 mV/g @ 6g by simply selecting 0 or 1. 0 is defaulted to the +/- 1.5g mode while 1 is changed to the +/- 6g mode. This feature will be very useful if one mode does not work. We would just have to change it to the more sensitive mode.

Another awesome feature of this accelerometer is its sleep mode. The normal current operates at 400 micro amperes. Once it is in its sleep mode, the output turns off and this significantly reduce the operation of current being used. The current is reduced down to 3 micro amperes. This can and is useful due to it being powered by a battery to conserve as much as possible. This will save power till the battery is being needed.

The most important feature of this accelerometer is the 0g detection feature. This feature is important because it is exactly what we need for our Collide 3 AVM senior design project. That is the main functionality that we need for our project.

This feature will provide a logic high signal when all three of the axes are all measured at 0g. This feature signal is connected to an interrupt pin or a poled I/O pins on the microcontroller. This accelerometer module has the technical data sheet which includes the functional block diagram, the pin connections layouts, dimensions of it, and spec information. This is just the first accelerometer we found that is suitable and has all the necessary features for our senior design project. Table 2.3.1 below shows the description for the MMA7361 3-Axis

Accelerometer.

Rating

Maximum Acceleration (all axis)

Supply Voltage

Symbol g

V max

DD

Value

±5000

–0.3 to +3.6

Unit g

V

Drop Test

Storage Temperature Range

D

T drop stg

1.8

–40 to +125 m

°C

Table 2.3.1 above shows the maximum acceleration for all 3 axis, the supply voltage, meters for drop test (important for our drop tower), and temperature of the accelerometer for space simulation.

Secondly, an accelerometer that has all the features we need for our Collide 3

AVM project is the 3-Axis Accelerometer with the MMA7260QT module. This accelerometer is from Freescale Semiconductor and it is manufactured by

Liquidware with Modern Device. This accelerometer can be purchase for

- 10 -

nineteen dollars and ninety five cents from Jameco Electronics website. It is a low cost capacitive micromachined accelerometer.

The main reason why we scaled down our research and picked this accelerometer is because of its Zero-g offset full scale span feature. Our project requires a micro gravity detection option, thus we pick this one to do more research and consideration on. This accelerometer also has more than one sensitivity modes. The first accelerometer has two options of sensitivity mode, while this one operates in four different selectable sensitivity modes. The four selectable modes are +/- 1.5g, +/- 2g, +/- 4g, and +/- 6g. With these four sensitivity modes, we can adjust it to what we need our accelerometer to be. If one mode is not sensitive enough for our freefall drop test, we can try the other three modes. The more options we have, the better we can test our Collide 3

AVM in micro gravity and freefall test.

This accelerometer also has a sleep mode which helps our battery powered senior project. It consumes the same amount of current in sleep mode as the first accelerometer we chose, which is 3 micro amperes. On the other hand, in regular operated power mode, its current consumption is much higher than the first accelerometer we chose. It consumes about 500 micro amperes for regular mode. This accelerometer is still low power consumption, but it consumes more current than the first one.

Additionally, this accelerometer also has a temperature compensation feature which can be useful for the purpose of our project during flight then in space.

Some typical applications for this accelerometer are that it works for laptop pc’s and HDD mp3 player. Its purpose for these applications is for freefall detection and has many uses for many other applications which does not relate to our project. Thus, they were not discussed.

To complete the total package, it has a pdf data sheet which has pin connections, pin descriptions, PCB Layout for interfacing accelerometer to microcontroller, block diagrams, dimensions, and spec table. One thing this one has that the first one does not have are sample codes which can help us have a better understanding how to code it. Of course we have to write our own code which will fit our ports and pins for our microcontroller, but any example is a big help for a better understanding.

There is also a sample helicopter projects which we looked at to help us get a better feel of what we need to do. This accelerometer has lots of information and examples. It also has a maximum rating table which scores the same as the first one as well so we did not include the table. All in all, this accelerometer has more feature than the first accelerometer does but it does have its downside, such as more power consumption.

- 11 -

Characteristic

Operating Range

Supply Voltage

Supply Current

Supply Current at

Sleep Mode

Operating

Temperature Range

Acceleration Range,

X-Axis,Y-Axis,Z-Axis

Symbol Min Typical Max Unit Sensitivity

V

DD

I

I

DD

DD

2.2

-

-

3.3

500

3.0

3.6 V

800 µA

10 µA

-

-

-

T

A

-40 - +105

°C

-

g-Select1 & 2: 0 0 g

FS

g-Select1 & 2: 1 0 g

FS

-

-

+/-1.5

+/-2.0

-

- g 800 mV/g g 600 mV/g

g-Select1 & 2: 0 1

g-Select1 & 2: 1 1 g

FS g

FS

-

-

+/-4.0

+/-6.0

-

- g 300 mV/g g 200 mV/g

Table 2.3.2 shows the specs we needed to know for the 3-Axis Accelerometer MMA7260QT. It shows the voltage range, current range, current at sleep mode range, temperature range, and the four selective sensitivity ranges with its sensitivity magnitude.

Last but not the least, the accelerometer that has all the features we need for our

Collide 3 AVM project is the Hitachi H48C Tri (3)-Axis Accelerometer Module shown in figure 2.3.1. This accelerometer module is produced by Hitachi Metal. It can be purchased at ‘Parallax’ for twenty four dollars and ninety nine cents. We were happy to find this accelerometer because it had a lot of information and contents with it and that should help us with our project greatly.

Unfortunately, they do not sell this single component one at a time anymore. This accelerometer module can only be bought in a package deal which will include other components that could also be helpful to our Collide 3 AVM project. This package deal does cost a little more than it is to buy the accelerometer by itself.

It probably cost more because of all the other components included in the package. But in order to get this accelerometer to work with, we would need to buy the whole package. Good thing we are sponsored by Dr. Colwell, thus we can spend a little more.

- 12 -

Figure 2.3.1 This is the actual picture of the Hitachi H48C Tri-Axis Accelerometer Module next to a quarter. It is 17.8mm x 20.3mm in size.

Even though it was only sold in a package deal and not by itself, we still consider this accelerometer because it has a lot of contents that we can go from to help us learn more about it. Also, it is breadboard friendly for us to test. Another reason why we still consider this highly reliable accelerometer is because of its ceramic package and the air-tight seal. Our project should be able to handle flight and space, so this feature is a plus for us. And of course, we included this accelerometer to our narr ow selection is because of its “free-fall” output which indicates simultaneous 0g on all axis.

This accelerometer also has a very low powered consumption feature. It’s STBY

(standby) mode operates are only 1 micro ampere. This accelerometer

STBY/SLEEP mode beats out the other two by one third. It is high shock durable which is also relevant to our project because of the flight into space. One thing that this accelerometer does not have that the other two have is different sensitivity mode. The Hitachi H48C Tri-Axis Accelerometer Module only have one mode which measures +/- 3g on any axis.

Like the other two accelerometers, this one also has the data sheet which contains most of the component’s information needed to help us make a decision. It includes data such as the connection pins and descriptions, functional block diagrams, dimensions, and general spec sheet. This is the third accelerometer that we chose to research more in dept on because it has great features that fulfill our requirements.

2.4 Comparison and Chosen Accelerometer

We pick these three accelerometers above because they met the functionality that is needed for our Collide 3 AVM project. One first two have sensitivity modes which can be helpful for our project to determine micro gravity. The third one did not have the different sensitivity modes but +/- 3g might be sufficient. Thus, the first two wins in that category. The first one did not have much information and examples we can go with compare to the second and third. The third

- 13 -

accelerometer actually had the most information and example we can look at so the Hitachi H48C won that. As far as power consumption goes, the obvious winner here is also the Hitachi H48C with standby consuming only 1 micro ampere while the other two consumes 3 micro amperes. This gives us more power to use when needed.

All three accelerometers have a 0g detection feature so that is a no contest. They also all have block diagrams, dimensions, pin connections and description. After comparing all three of the accelerometers that we narrow down, we had a discussion to choose the accelerometer we are going to be using. Our discussion was short and the obvious winner that we should choose is the Hitachi H48C.

Even though it did not have different modes for sensitivities, we figured +/- 3g is good enough to determine micro gravity during the free fall experiment we are going to do in the lab. The Hitachi H48C is our choice.

The Hitachi H48C 3-Axis Accelerometer that we choose is an integrated module that can sense gravitational force for all three X, Y, and Z axis. It can sense up to

+/- 3g on those three axes. This module has an onboard regulator which provides

3.3 volt power to the H48C. It also contains an MCP3204 analog to digital converter to read the H48C output voltages and it also has analog signal conditioning. This accelerometer uses MEMS (Micro Electro Mechanical System) technology. These are the pin layouts that was being considerated as shown in figure 2.4.1.

Pin layouts

Figure 2.4.1 Shows the pin layout of the Hitachi H48C

The Zero Gravity detection system built into our chosen Hitachi H48C 3-Axis

Accelerometer is the most important feature. Aside from the other features on this accelerometer, without this feature, we would not have picked it at all.

Hence, it’s the most important feature that we are looking for. The Zero Gravity detector compares the absolute value of the acceleration outputted from the three axes with threshold Gt. During a free fall event is occurring, the absolute

- 14 -

value of the acceleration should become smaller than the threshold Gt for all three of the axis.

Description Table

Pin Label Definition

1 CLK Synchronous clock input

2

3

DIO

Vss

Bi-directional data to and from the host

Power supply ground which is 0v

“Free-fall” detection output; active-high

4

5

Zero-G

CS\ Chip select input; active-low

6 Vdd +5 vdc

Table 2.4.1 Is the essential connections layout, pin, labels, and a little description that we need to know for the H48C module. As you can see, the Zero-G output pin is pin 4. That is the pin we will be using to detect micro gravity or free fall.

After the acceleration becomes smaller than the threshold on all three axes happens, the detector judges the state is Zero Gravity and the ZeroG flag is outputted. That is exactly what we want to happen. The ZeroG flag is on pin 4 of the accelerometer. It is always comparing the two forces. The comparison happens repeatedly around every 0.4milli seconds. Once the comparison does not satisfy the rule (a<G), then the ZeroG flag will disappear and not be outputted anymore. The standard specification of the Gt is about 0.4g. This is what we were talking about earlier in the introduction about the Zero flag shown in figure

2.4.2. Since we have to demonstrate this without a drop tower, we might have to set the Zero flag on. The picture below explains this phenomenal process in a block diagram of the H48C ZeroG detector of the H48C.

Figure 2.4.2 The block diagram for the H48C for the zero gravity detector

- 15 -

2.5 Software side

The hardware and spec/data sheets are fun and all but it does not help us with the coding part. Nothing will work without some kind of software application. With this accelerometer, we had some basic samples of projects and codes that was relevant for us to use as a guide. What we noticed is that it depends on which microcontroller we choose. A simple code to determine the Gf can be as follows.

IF (axCount >= rvCount) THEN This gives positive g-force

gForce = ( axCount – rvCount ) ** GfCnv

ELSE This gives negative g-force

gForce = - ( ( rvCount – axCount ) ** GfCnv )

ENDIF

The code above shows a sample of a code segment that measures the G-force by the accelerometer. The accelerometer gets the integer for axCount and rvCount then calculates the answer for the G-force.

There are many different types of software applications wer can code in for our senior design project. It all depends on which type of microcontroller. The sample on their website uses BASIC Stamp 2 module as a host controller. While with some research, we found other programs like Arduino and we can also use java and C to actually program our accelerometer. Most microcontrollers have their own drivers and applications that they use. In those cases, we use those coding application to also control our accelerometer. As far as errors that happens during our coding process. We are familiar with debugging with the classes we have taken. Taking coding classes like C, Java, CS1, and CS2 gave us experience with errors and problems.

3.0 Power Source

The power source is another important aspect of our Collide 3 AVM project.

Almost every senior design projects’ most important component is the power supply or some kind of battery. We had to find out a way to efficiently use our power supply and deliver it to each of our components accurately and successfully. There are many different components in the circuit that needs to be powered. Each component had a different voltage or current being carried to it.

Thus, it was very important for us to know each of the components inside out to know how much power each needs. This power supply has to last long enough to power the accelerometer, the microcontroller, LED lights, take pictures with the camera, store data and run the solid state hard drives, and give enough current to the muscle wires to open the hinges. We have to find a good battery source and a converter that can distribute the power to each component as needed to

- 16 -

make sure everything will be fully functional. It should be able to last the time length of the simulation as well.

Researching the power source took longer than expected. Thinking that any power supply would do, we were wrong. There are so many different types of power source and what they are good at. This power supply we pick should be able to last for at least a good minute to make sure that we got enough pictures to see the movement of any dust particles. It should also operate correctly no matter what environment and weather it is in because it will be going through a flight into space. There are lots of choice of battery and power source out there such as Alkaline Batteries, Lithium-ion, Nickel-metal hydride, and Nickelcadmium. There are probably other types of batteries out there we can research on but these are the ones that would work most efficiently for our project. After our research, we were able to pick the right type of battery to power our Collide 3

AVM senior design project.

3.1 Lithium-Ion Battery

In the world today, the most common batteries out there for electronic devices are lithium-ion batteries. These batteries are everywhere in every portable device you know and love. You can find these in iPods, iPads, cell phones, laptops and many other devices that need to be supported on the go. Researching this battery for our Collide 3 AVM is a must, because these batteries can give a higher voltage than others can to split and support all of our components needs.

These can range between 3.2 volts to 3.7 volts. Lithium-ion batteries in smaller portable electronic devices uses prismatic lithium-ion cells while bigger electronic device like laptops uses cylindrical 18650 cells. Lithium-ion batteries are energetic and they are also rechargeable. There are three primary functional components in the lithium-ion battery. They are anode, cathode, and electrolyte.

Depending on what material is being used, voltage, life, capacity, and safety can all be changed. Lithium batteries are more expensive than Nickel batteries. Thus, they are so common and widely used. Also they have many important advantages over other competing technologies. This is a very important option for us.

In general, these batteries are picked to be in portable electronic devices are because they are very light weight and are rechargeable. These batteries are great to put into consideration. They are made of light weight lithium and carbon which make them so light. Also, another reason for their popularity is their ability to store a lot of energy. Lithium is the result of this ability. It is a highly reactive element. Thus, lithium-ion batteries have a very high energy density. Most lithium-ion batteries can hold up to one hundred and fifty watts hours of electricity in one kilogram. Compared to other types of batteries, this one has the highest capacity per kilogram.

- 17 -

Another important feature that these batteries have over their competitor is that they do not have any memory leak effects. This means you do not have to discharge them fully before you can recharge them again. You might have remember in the pass that you have to discharge a battery co mpletely so it’s capacity can stay the same. Now with these batteries, there is no need for such a draining process. Lithium-ion batteries also can hold their energy for a long amount of time. They only lose 5 percent of their energy in a span of a month. It can also provide very high current to applications that needs powerful force such as power tools. These are just some of the advantages of using the lithium-ion batteries. Now let us check out what the disadvantages are that might make us abandon this type.

Everything has a downside to it, including this battery. For starters, these lithiumion batteries need some kind of on board computer to keep their level in check. It requires some kind of power managing which could be more work for us and might be even more expensive than it is worth. These types of batteries also start to degrade very fast. They usually last for about three years whether you use them or not. A very important disadvantage is that it is very sensitive to high temperatures. This battery need to be able to withstand the heat from the launch and flight into space. Not so much in space but the heat dissipated from the launch might ruin the battery. These batteries also have a chance of bursting into flames if they fail. The chances are small but it could still happen. Being in space and enduring space, the battery might be put under lots of stress and usage. This is not good for these types of batteries because once they are completely dead, they are ruined. Unlike other batteries that needs to kill completely before you can charge them again, these can not be totally dead or they will be ruined.

Cathode Materials Advantages Disadvantages

Lithium-cobalt-oxide

(most common)

Lithium-phosphate

(newest)

Lithium-manganeseoxide

High Capacity

Very low ESR

Very high charge and discharge rates

High temperature operation

Inherently safer

Lower ESR

Higher charge and discharge rate

Higher temperature

Lower Charge and discharge rates

Higher cost

Lower discharge voltage

Lower float voltage

Lower capacity

Lower capacity

Lower cycle life

Shorter lifetime operation

Inherently safer

Table 3.1.1 Shows the advantage and disadvantages of Lithium-ion batteries with different materials

- 18 -

3.2 Alkaline Batteries

Most regular electronic device around your house that uses batteries are mostly alkaline batteries. When you open up the back cover of your television remote control, you will probably see an alkaline battery. They can also be found in CD players, digital cameras, simple kids’ toys, radios, and other electronic devices.

One reason why we could use these batteries in our Collide 3 AVM is because they are cheap and disposable. They are cheaper than the other batteries are to make, thus they are usually disposable. These batteries make up most batteries out in there today. They are dependent on the reaction with zinc and manganese dioxide. You might have seen AA, AAA, D, and etcetera. These batteries are most common around the house.

The normal voltage of a new alkaline battery cell is 1.5 V. You can get more voltage by putting multiple batteries together in series. The amount of current these batteries can give depends on the size of the batteries. For example, AA batteries can deliver about 700 mA, while D cell batteries can deliver a lot more.

Devices that use more current can be a flash light, which need the juice to handle this extra load it needs. A normal battery in used can vary between 1.1 voltage to

1.3 voltage. If the battery is old and almost dead, its remaining voltage can vary between 0.8 voltage to 1.0 voltage. You can noticed this when they flashlight start to dim as the battery is almost depleted.

A disadvantage of the alkaline batteries is that it leaks. They can leak potassium hydroxide as shown in figure 3.2.1. This usually happen to disposable alkaline batteries that are being recharged. Thus, they are called disposable batteries, because you should not recharge them. This can also happen when you mix battery types and new with old batteries. These batteries were not always disposable. Alkaline batteries produced before 1996 contained mercury which is not environmental friendly. Today they are safer and still there are special areas to dispose of these batteries. So even though these batteries are easy to use and are very cheap to buy, they are not that reliable if we need a high voltage source.

Figure 3.2.1 This picture shows the corrosion and leakage of potassium hydroxide out of the outer steel shell of an Alkaline battery.

- 19 -

3.3 Nickel-metal hydride Battery

These types of batteries are rechargeable and use a hydrogen-absorbing alloy for the negative electrode. The typical specific energy for a nickel-metal hydride double A battery cell is about 100 W-h/kg. Most applications for nickel-metal hydride batteries are expected in all electric plug-in vehicles. Same examples are

Honda EV Plus and Vectrix scooter. These types of batteries are widely used in rechargeable electronic devices. It is dangerous to over charge these batteries.

That is why you should not use any kind of battery charger to charge these. You should use a charger is made for nickel-metal hydride batteries. Thus, you have to be careful to not over charge.

There are advantages of nickel-metal hydride which includes high energy density but still lower then Lithium ion. These batteries discharge linearly but falls rapidly at the end of the cycle as shown in figure 3.3.1. A good thing about these batteries is that they can operate at a wide range of temperature which is good for our project. These batteries can also charge really quickly, as fast as an hour’s time frame. A great environmental friendly factor is that these do not contain cadmium, lead, or mercury. These are a lot safer then Lithium based batteries.

They do have their negatives as a whole. This type of batteries suffers from memory leaks. You have to discharge them completely before recharging them.

One important factor is that you can not overcharge these batteries or they will get destroyed, hence you have to get a charger made for it or have some kind of timer set for charging. Nickel-metal hydride batteries usually lose approximately thirty percent of their life force every month even if you do not use them at all.

Also, these batteries can only give off about 1.2 volts to our components. We would have to put these in series to get the power we need to support our components. Despite their negative contribution as batteries, they still hold strong advantages for us to consider.

Figure 3.3.1 This graph shows the rate of discharge of nickel-metal hydride battery compared to alkaline batteries. Alkaline gives more juice but the discharge curve is steeper than that of the

Nickel-metal hydride.

- 20 -

3.4 Power Source: Nickel-cadmium

Last but certainly not the least, is the nickel-cadmium battery. Also a great important source we could use in our Collide 3 AVM project. Like the nickel-metal hydride, it also only produce 1.2 volts, but nothing a series of these can’t add up in series to handle. It is also a type of rechargeable battery which uses nickel oxide hydroxide and metallic cadmium as electrodes. These batteries are simular to the NiMH batteries but do not have the same energy density but it gives off more current than the alkaline batteries do. Its main reason to be included in the research is of its ability to provide large amounts of current. That is something we should consider for our Collide 3 AVM.

In comparison to the other batteries, these have better long term storage and last longer. These batteries also have a slower curve of discharge rate. Their voltages decline much slower than other batteries. Another advantage for this type of batteries is that they are difficult to damage. Some disadvantages are that they are hazard to the environment, they cost more, and their temperature is relevant to their internal resistance and usually falls when temperature rises.

They use to be a primary use until lithium-ion and nickel-metal hydride became less expensive. Their main advantages are their high source of current. That is why we included them into research.

3.5 Compare and result

All these batteries have their strengths and weaknesses. Now let’s compare and seek out which one is the best for our Collide 3 AVM project. The first one that comes to mind for the best fit is the Lithium ion battery. It has the highest capacity per kg compare to all the other batteries. It produces the most amount of voltage as well. Thus it is very efficient to our project, but it is expensive, its discharge rate is really high and most importantly it is very sensitive to high temperature. Alkaline batteries have less voltage than the lithium ion but it is very cheap and disposable. It does have higher voltages than the other two nickel batteries though. The two nickel batteries are very similar but nickel-cadmium is hazardous to the environment. Nickel-metal hydride has an over charge problem and also degrade fast having age-related degeneration effect. On the other hand, nickel-metal hydride has a two to three times higher capacity than the same size nickel-cadmium can hold. The nickel-metal hydride has a self discharge rate of

30% per month as to the nickelcadmium only 20% per month. Lithium’s self discharge rate is the best at only 5% per month. Due to the higher voltage that a lithium battery can operate at, you would probably need two to three or more nickel batteries in series to operate at the same voltage that one lithium battery.

- 21 -

At first, the lithium-ion batteries seem like the best choice because it fits everything we need for it to be. After doing a little more research, one of its downfalls is the ability to withstand heat so there might be some heat involved during the flight. The alkaline batteries are cheap but they just do not cut it for what we are trying to do. The two nickel batteries are very close but we are going to go with the nickel-metal hydride battery. It is currently more widely used, thus cheaper and for our project, it won’t be up there for months so the self discharging rate is not a big deal. It is more environmental friendly so if anything happens to the project during the flight or in space, we didn’t have to worry about ruining the environment.

Battery Type Alkaline (non rechargable)

Ni-Cd Ni-MH Lithium-ion

Energy density 40-60 40-60 60 120

Cycle life

Power density

(W/kg)

Cost ($/kWh)

1

1800

150

2000

250-1000

2000

1800

3500

200 280 500-1000 Consumer electronics:

300-800

Vehicles:

1000-2000

Small size, light weight

Battery characteristics

High reliability, low cost

Memory effect

Currently, best value and most popular

Applications Small electronic device

Flashlight battery and electronic device

Flashlight battery and electronic device

Consumer electronics , cell phones, mp3 players

Table 3.5.1 Shows the description of all the different types of batteries and their applications.

All of our research and comparisons of battery types were liberated as we decided to use the power from the housing of the rocket. It wasn’t in vain though, because we understood batteries better from our researches. For our experiment and demonstrations, we temporarily used a 5v power supply to power it. While the flight will be hooked up to the rocket for power.

- 22 -

4.0 Research of FPGA

4.1 Introduction

A field programmable gate array (from here on referred to as an FPGA) is essentially a large array of combinational and sequential logic gates in a programmable environment. Each gate can be programmed to complete some digital logic circuit. Consideration of an FPGA versus a micro-controller for use in collide-3 AVM is necessary to determine the most accurate and fastest system to meet the high requirements of this project.

Summarizing the basic tasks that must be accomplished, in order to weigh in the use of an FPGA is necessary. In the initial stage of flight the system will be in a low power mode, during this time a monitoring system will be in place to poll the accelerometer for microgravity detection. After microgravity is achieved the system will activate an array of LED’s, send a pulse width modulated signal to open the experiments chamber doors, and finally start taking high shutter speed photos of the experiment. The camera in use will output a digital signal over

Ethernet which must be processed by the FPGA and stored to the solid state hard drive. The target frame rate of this system will be around 100 photos per second, which means the experiment will process a photo every 10ms on average. At that rate with an average file size of 1MB per photo, times 100 of those per second means we will be writing about 100MB per second without a buffer stage.

Because the system must be a hard real-time system in order for the experiment to be deemed successful, an FPGA can be beneficial since all operations going on are happening with minimum processing overhead, since an FPGA can be designed for each specific task unlike a microprocessor. Another advantage of an FPGA is its ability to do multiple tasks in parallel unlike a processor which must execute each instruction sequentially. FPGA’s can be programmed by using a few different methods, one simple way is schematic capture, which is simple pick and place design using block diagrams to describe your system.

Schematic Capture isn’t used for large projects due to the complexity required; hardware descriptive languages such as Verilog, VHDL, SystemC, etc. are used mainly because they allow a higher level abstraction essential to complex design.

For all implementations considered, Verilog will be the standard language due to the engineer’s on this team having most development time with it compared to the other languages.

One aspect of the environment that we had to consider for our system is the presence of ionizing radiation and high-energy electromagnetic energy in low orbit space. Ionizing radiation has the potential to flip the state of a memory cell; this is known as a “soft error” and is the common cause of single event upset

(SEU). SEU’s can affect user memory, registers, and memory cells. Because of

- 23 -

the extreme conditions of space, the components that will be considered will need to have gone through a process known as Radiation hardening to ensure mission critical data will not be affected.

4.2 Analysis of current FPGA boards

Having explained all the necessary requirements for an FPGA system, we can now look at different FPGA’s that are available to us. The main competitors in the market to choose from are Xilinx and Altera. Due to the need of Rad-Hard components, only Xilinx offers products geared towards the harsh conditions of low orbit space.

The virtex-5QV is the first high-performance space rated FPGA offered by Xilinx.

Xilinx chooses to use logic cells to determine logical capability, of which the

Virtex-5QV has 130,000 cells available. These cells allow the programming of various digital logic functions by using a ROM look up table. The virtext-5QV has a max temperature range of -65 to 150 degrees Celsius putting us within range of low orbit space temperature. In terms of turn on voltage required to power the device, 0.95 -

1.05 Volts is all that’s required. Of all FPGAs considered this one provided the most radiation hardened and tested components, making it a prime candidate for COLLide-3 AVM project.

The next device is the next step down, the Virtext-4QV. This Device actually contains more logic cells then the Virtex-5QV (over 200k). It contains a 350 MHz

PowerPC® core that can be easily dropped in, and a 400 MHz XtremeDSP TM.

This FPGA required 0.95

– 1.2 Volts to operate. Also featured are built in

Ethernet Media Access Control (MACs) to abstract the low level Ethernet protocol. The temperature range of the Virtex-4QV is -55 º C to 125º C making it less capable than the Virtex 5QV in terms of extreme temperature range.

However this board contains over 200,000 logic cells available, surpassing that of the Virtex-5QV.

Kintex-7 is actually the newer line up of Xilinx offerings, while not available in

Radiation hardened form, its use will be considered due to potential issues with procurement of the Radiation hardened FPGA mentioned above. The Kintex-7

FPGA is a high speed, low power, moderate cost solution if permissible use is allowed. Advantages to using this for the design would be its high transceiver speed, which reaches speeds of 12.5 GB/s, which greatly exceed the amount of data being received from the camera. It can also reach a LVDS (Low voltage differential signaling) speed of about 1.6 GB/s, which can potentially help with writing data to the hard drive. The Kintex also supports Full Duplex (Data can transfer both ways simultaneously) Serial communication with speeds of up to

800 GB/s. Also on board are 478K Logic cells, easily out pacing the other 2

FPGA’s considered thus far. Kintex temperature operation range can go from -

- 24 -

40C to 100C on its industrial grade series, however further testing would be required to determine how it would fair under such harsh conditions as a launch.

4.3 FPGA design

Now that the FPGA requirement’s and potential package solutions have been considered, it is time to discuss how the FPGA itself will perform the required tasks. The following tasks were divided under their own sub section to further expand on the challenges each one presents: µGravity detection, PWM line for motor control, LED Array power on, Ethernet Signal processing, Serial ATA processing, Display module, and finally File Storage Format.

The first element to consider for this design is micro-gravity detection sensor input. Any implemented design must take into consideration any false signals sent from the accelerometer, so that our experiment doesn’t start pre-maturely.

For this problem, a digital counter can be implemented, one of n-bit length, that increments itself every time the sensor sends a no gravity flag, and resets itself whenever a gravity signal comes in from the accelerometer. Once the counter reaches say all 1’s then this specific pattern can be matched by a sequence detector. An example of a 2-bit system is shown below in figure 4.3.1.

Figure 4.3.1 Once the final state is reached, a global flag can be set, initializing all other systems, or a cascade system could be used, where certain sub-systems can be powered on in a time delayed sequence.

- 25 -

Unfortunately the FPGA’s we are considering do not have any onboard PWM output lines, which means this had to be implemented in Verilog code. In order to reproduce a PWM line we simply need to toggle between on and off at a certain frequency within one clock cycle. Since this PWM will not operate at high frequency, the clock can be generated from the FPGA itself. Two things we had to consider are the Duty Cycle and the frequency. Duty cycle is simply how much time a pulse is active for over its clock duration, while frequency is simply how often it switches on and off in one clock cycle. Also this PWM line will not be variable frequency, making it even simpler.

An LED power on can be achieved simply by a controlled switch between the

LED arrays and a power source, a FET could achieve this goal, by connecting the base of the transistor to the I/O line for the power on flag. When the I/O line is set high it will close the gate allowing current through, but while no voltage is applied the mosfets gate will remain in depletion mode and will cut off any current from passing through as shown in figure 4.3.2.

Figure 4.3.2 Show cut off current pass.

In this Project the camera is sending a digital signal over a Ethernet wire, this wire is received onto the FPGA, processed and prepared for SATA transmission to the solid state drive. Ethernet speeds of about 100 Gbps can be achieved, again outperforming our design requirements. Xilinx FPGA’s contain an onboard

GTB transceiver useful for taking the signal from the Ethernet line and getting the signal into the system.

Serial Advance Technology Attachment is the protocol that was needed to interface with any Solid State Drive at a reasonable speed. Serial ATA can provide a transfer speed of up to 6 Gb/s, which is more than enough for the speed we are looking to transmit. Implementing this however may prove to be the most challenging aspect of this project, the Protocol involves many layers of bit packing and processing overhead in order to send and receive data, and implementing that into an FPGA would require grounds up approach.

- 26 -

Serial ATA Architecture consists of 5 layers of functions that must be carefully considered in order to implement correctly, as shown in the diagram below, those layers are: OS/Application, Command, Transport, Link, and Physical. Each layer adds its own overhead to the data bits, by packaging them with their own information, this is done to prevent errors and ensure data can be recreated after transmission as shown in figure 4.3.3.

Figure 4.3.3 Shows the cables connector to the Device and the Application

Physical Layer is the lowest level of the interface, it is responsible for generating the signal that will actually be transmitted over data bus, and to decipher signals received over the data bus.

Link Layer defines the encoding for the data being transmitted, and defines the control signals and protocol that reliably transmits packets of data between a transmitter and receiver. Link layer is also responsible for recovering the Clock signal, since the clock signal is implicitly determined from the actual data sent.

Transport Layer defines the format and functions of data structures that are exchanged between the transmitter and receiver. SATA refers to these data structures as FIS (Frame Information Structures). Transport layer is the bridge from hardware and software.

Command Layer defines the sequences of FIS frames exchanged to support all the command protocols that are defined in the SATA specification.

- 27 -

Application/Device Control are specific programming registers that must be written to actually give the ability of software to interface with this Data.

Essentially a SATA controller must be created; fortunately Xilinx provides documentation for implementing the physical layer, however the rest was implemented in the design. Another factor that was considered is Power management since the goal is a mobile application.

4.4 Display Module

The Display Module is essentially a method for a user to read current system settings, and change certain variables as they see fit, it will consist of a simple

LCD screen and a few push buttons to change Data. The variables that need to be changeable are, Experiment start time, LED turn on time, Camera turn on/off time, motor activation time. Users interaction with the application shown in 4.4.1.

Figure 4.4.1 Use Case for Display module

- 28 -

5.0 Microcontroller Research

5.1 Overview

COLLIDE-3 has many components that will need to be activated in a set order throughout the flights experiment. Specifically, we need to be able to read an input from an accelerometer, and send outputs to relays which will be controlling

LEDs, muscle wire, microstep drivers (both with a flat DC level and a PWM line), and a camera. Important features of the microcontroller for us will include: Flash memory available, number of I/O lines, clock speed, package type, operating voltages, output voltage levels, power consumption, robustness, temperature ranges, and ease of programming. Perhaps the most important feature of all, however, was how does it integrate with the camera when we decide on utilizing the microcontroller to process the data received from the camera’s Ethernet output line.

5.2 Requirements

Some features of our microcontroller are fairly set in stone, while others should be considered to eventually adapt to future iterations of the COLLIDE-3 experiment. Thus, we aimed at finding a microchip to interact correctly. For instance, while our current experiment needs a minimum of 7-8 controllable I/O pins, future versions of the experiment may add additional control variables, so upwards of 14 I/O pins would be ideal. Clock speed for most of the components is not essential; even the lights turning on a full second after they should have would not have a massive impact on the experiment. Outside of the camera, the only set frequency requirement is the 800hz that we wish to operate the microstep driver’s multiple PWM lines off of. If our project decides to implement an FPGA or other device to control the camera rather than using the microcontroller, we will need to try to match the clock frequency of the microcontroller to that of the FPGA/device.

Package type will be considered mostly for convenience/expansion. A DIP style pin layout is more intuitive and something we have more experience creating than a QFP/QFN package style. Also, while it obviously wouldn’t be ideal, it is possible to modify a DIP style pin on a PCB board with last minute wirings, while nearly impossible to do the same with a QFP/QFN.

Since one of our considerations is whether to have an on-board power source or to rely on the availability of one aboard the rocket, power consumption is of heavy consideration throughout the entirety of our project. Likewise, since we

- 29 -

had to provide the voltages to control the microcontroller, the operating voltage were considered. Finally, depending on the relays we use to be controlled by the microcontroller, output voltages were kept in mind, though we adapted the relay to match the microcontroller, rather than the other way around. It is unlikely that a microcontroller will operate in such a range that the industry doesn’t make relays to support it.

The chip we selected is robusted enough to pass a suborbital vibe-test. While the chip doesn’t necessarily have to be military grade, it also cannot be fragile. The purpose of suborbital flights, and also this AVM, is eventually to be manned flights, thus the chips does not experience vibrations, temperatures, or forces that humans are incapable of.

Another consideration for our microcontroller is the ease of which they can be programmed. One of the main advantages we see in microcontrollers over

FPGAs is that they can be written in languages such as C/Assembly, rather than

HDL/Verilog. If the programming of the microcontroller proved to be unjustifiably complex/unable to integrate with the LED display we plan to implement, any advantage of the microcontroller would essentially be lost.

Our final limiting factor for our microcontroller choice was either completely inconsequential or our most important consideration, depending on how we decide to handle the data coming out of the camera. The microcontroller must have a good way of handling data coming from an Ethernet port and transferring it onto whatever data storage device we choose, most likely a Solid State Drive.

Since data from the camera might be coming in at speeds as high as 100MBps, the microcontroller must also be able to handle high volumes of memory transfer at any given time. However, if we end up using a different method for storing data off of the camera (FPGA, Gumstix, etc), then we won’t need to consider this at all.

6.0 Microcontroller Choices

6.1 ATmega328/328P with Arduino Optiboot

The ATmega328 is a fairly popular microcontroller on the market, being only improved on by the 328P which offers the option of a picopower mode, and matches the requirements of our project quite well. It contains 32kb of flash memory, with .5kb of that being used for the bootloader. Flash memory works well with our project, since it is robust enough to survive the vibrations COLLIDE-

3 is likely to experience during flight. Also, while flash memory only survives

10,000 read/write cycles, it is extremely unlikely that we utilized the flash on the chip to anywhere near that capacity during COLLIDE3’s experiments. Since the

- 30 -

temperature range of the chip is listed as

–40 to 85 degrees C, the chip should be robust enough for our needs.

The Atmega contains between 28 and 32 total pins (depending on package type, discussed below), with 23 of those having I/O capabilities, and a staggering 6 of them capable of acting as PWM lines, far exceeding any amount future iterations of the AVM may need. The chip operates in a voltage range of Vcc = 1.8V-5.5V, which is fairly standard and was easy to supply. The maximum operating frequency of the clock is 20Mhz.

A good feature about this choice is its power consumption. Even the 328, which lacks the picopower mode of the 328P, offers many power saving tools. When operating at 1MHz and utilizing a 1.8V Vcc at standard temperatures (25 degrees

C), the chip will consume .2mA in active mode. However, the chip has a power save mode available which lowers consumption to .75uA, and a power down mode which further lowers power consumption to just .1uA. These features make the ATmega328/328P described as a “low-power microcontroller”, which was something heavily considered when we didn’t have an active power source available on our flights. All of the power saving modes (5 in total, though the ADC

Noise Reduction mode was irrelevant for our project) are selectable through software.

Mode Power Consumption Chip Status

Active

Power Save

.2mA

.75uA

Standby*

Power Down

.50uA

.1uA

Everything running

Asynchronous timer running. User can maintain timer base while rest of device sleeps.

Crystal/resonator running, rest of device is sleeping.

Registers saved, but oscillator frozen. All other chip functions disabled until next interrupt or hardware reset.

*

Standby mode allows very fast chip startup, producing stable clocks in just eight clock cycles.

Table 6.1.1 Shows the power consumption of each mode of the microcontroller and their chip status.

Package types encompass just about anything we would want depending on our

PCB design. Atmel offers the following choices for package type with the

328/328P:

- 31 -

TQFP, Thin Plastic Quad Flat Package

QFN, Quad Flat No Lead

PDIP, Plastic Dual Inline Package

Of these three, the first and the third are the ones most likely to be used in our design, depending on whether we want a through-hole chip (as offered by the third), or a surface mount chip (as offered by the first). It should be mentioned that the TQFP and QFN both are a 32-pin design, while the PDIP has 28 pins.

Programming for ATmega chips is fairly simple, and the same holds true for the

ATmega328/328P. The chip itself comes preburned with a bootloader, meaning it’s ready to have code uploaded to it without the use of any external hardware programmer. As for the creation of the code it used, the ATmega328/328P utilizes the Arduino 0023 software, which is simply an open-source language of

C/C++ functions that can be called in the code.

Finally, we have the data transfer side of the microcontroller. This is where the

ATmega328/328P, and evidently most (if not all) microcontrollers fall apart. We estimate that with our camera resolution and frame rate, upwards of 100MBps will be transmitted through the Ethernet cable out of the camera, through the microcontroller, and then written onto the hard drive. Unfortunately, the

ATMega328/328P protocol acts as follows; It sets pins to allow the reading of a packet, fills the buffer, then sets a different set of pins to allow the writing of the packet. Running at a clock speed of 14.76 MHz, the ATmega328/328P can only transfer 57.6kbps. This is obviously not even a noticeable fraction of the data we intend to transfer, meaning when we utilize this chip, we had to find a new method of data transfer.

6.2 ATmega644

The ATmega644 is very similar to the ATmega328/328P, with only a few minor differences, explained in the table below:

ATmega328/328P ATmega644

Flash Memory

Pin Count

Max I/O pins

32k

28 PDIP/32 TQFP/32 QFN

23

64k

44 VQFN, TQFP, 40 PDIP

32

Table 6.2.1 Shows the minor differences of the two Atmega models.

The ATmega644 obviously has the advantages of more flash memory and more pins capable of being assigned to I/O operations, but the increased pin count will

- 32 -

also increase the amount of our PCB board required to allocate to the microcontroller chip. We didn’t need to use the extra memory/pins from the 644, the 328/328P proved to be the more intelligent choice.

6.3 Parallax Propeller

The Propeller is one of many microcontroller chips offered by Parallax. Its main draws are its ease to integrate to external hardware components, and 8processors which can operate at the developers discretion, either independently or cooperatively. Its ease of integration to external components could be very useful for our LED control panel, while the multi-processors could ensure the ability to be running various protocols at any given time during an experiment.

The packages available for the Propeller are very similar to that of the ATmega

328/328P:

40-pin DIP layout

44-pin QFN layout

44-pin QFP layout

Again, the best candidates for our project would be the DIP or QFP layouts, with

DIP the front-runner. In both the 40-pin and 44-pin layouts, there are 32 I/O ports available (28 general purpose, the rest are utilized by the boot up protocols, then become available after), more than double the theoretical max needed for

COLLIDE-3. While none of the pins are explicitly stated as having PWM capabilities, the presence of eight processors means the timing hardware contained in the chip could be utilized to implement PWM signals.

Effective clock ranges are very high for the Propeller compared to the

ATmega328/328P, running at effective clock rates of 32kHz to 80kHz. Power input for the Propeller is 2.7-3.3V DC, which is very easy to supply. Power usage by the Propeller is not nearly as optimized as that of other chips on the market, but the user can have a lot of impact on the power consumption through intelligent programming. Obviously, lowering the clock rate can have significant impacts on power usage of the part, but also utilizing less of the eight processors can reduce power consumed by the microcontroller.

Programming for the Propeller ranged from very simple to intermediate programming skill required. This is due to the variety of languages that are compatible with the Propeller. Users have the option of using any of the following programming choices:

Spin

Assembly Language

C

- 33 -

Of the three option, Spin is by far the easiest and most common, with assembly requiring some sort of programming background to be able to implement properly. The Propeller can be programmed and compiled in a C environment due to a compiler provided by ImageCraft, but the compiler is considered in its

“End of Life” state, so it will not be considered for this project. Naturally, while spin has its upsides, it also has drawbacks compared to assembly language. The two choices are compared in the table below:

Language Advantages Disadvantages

Spin

Runs slower than pure Propeller assembly

Assembly

Very minimal programming difficulty

More space efficient

Avoids memory segmentation issues

Faster run time

Better for exact timing

I/O routines

Opcodes 4x larger than Spin

Memory segmentation issues must be considered by programmer

Table 6.3.1 Shows the advantage and disadvantages of spin and assembly language.

Since our group has experience with assembly language, and run time is most likely more important than space efficiency, the extra work required to create the routines through assembly might prove worth it if we decide on the Parallax

Propeller microcontroller.

The same glaring problem occurs with the Propeller that we ran into with the

ATmega328/328P/644, in which the amount of data reading/writing would not approach anywhere near 100MBps, which renders this microcontroller also useless if we were dead set on utilizing a microcontroller to transfer data from the

Ethernet line onto a hard drive. This was upsetting with the Propeller especially, since one of the advertised features is its ability to provide direct video output.

However, the resolution and speed of the video referred to by these statements from Parallax nowhere near approach the specifications COLLIDE-3 will deal with.

- 34 -

6.4 PIC16C57

The PIC16C57 is mostly known due to being used in the Parallax Basic Stamp 2 microcontroller module, which is the veritable flagship of Parallax, and for good reasons. It’s extremely easy to use, a lot of documentation is readily available for it, and if your project doesn’t need the complex features of more advanced microcontrollers (eight processors, video generation capability), it can do everything you would need. We decided to utilize the microcontroller for only the more basic features of our project, the PIC16C57 might pull ahead of the other choices just due to simplicity.

In terms of raw requirements, the PIC16C57 doesn’t pull away like the rest of the microprocessors, but it meets all of the standards set by us. A 20MHz processor speed is fairly standard, and is likely to mesh well with an FPGA if we were to implement one but we did not. 16 I/O pins is slightly more than our maximum projected pins required for future project expansion, so while other chips might have 30+ available, any over the max theoretical needed are just redundant.

Current draw is rated at 3mA in run mode, and 50uA in sleep mode (assuming a

5VDC).

Parallax offers the Basic Stamp (PIC16C57) in two different package types:

28-pin DIP

28-pin SSOP (Shrink Small outline package)