Production and sensory analysis of yogurt with tangerine peel and

advertisement

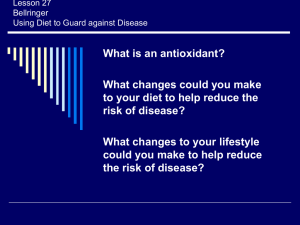

1 Production and sensory analysis of yogurt with tangerine peel and pulp 2 Produção e análise sensorial de iogurte com casca e polpa de tangerina 3 4 ABSTRACT: Brazil is rich in tropical fruits with specific flavors. Searching for alternatives that 5 provide a sustainable and integral use of these fruits, this study combined the yogurt to the 6 pulp end peel of Murcott tangerine. The yogurt was prepared respecting the specifications of 7 milk pasteurization and fermentation. The physicochemical analyses performed were: pH, 8 titratable acidity, and soluble solids (ºBRIX). The final product, with samples containing 9 2,84% peel and 97,16% pulp and 0% peel and 100% of pulp was subjected to sensory 10 analysis, with major acceptance for the second sample, although both had shown good 11 acceptance. 12 KEYWORDS: Yogurt, tangerine, peel. 13 14 RESUMO: O Brasil é rico em frutas tropicais de sabores característicos. Na busca por 15 alternativas sustentáveis e que proporcionassem o aproveitamento integral dessas frutas, o 16 presente trabalho combinou iogurte à polpa e casca de tangerina Murcote. O iogurte foi 17 preparado respeitando às especificações da pasteurização do leite e da fermentação. As 18 análises físico-químicas realizadas foram: pH, acidez total titulável, e sólidos solúveis 19 (ºBrix). O produto final, com amostras contendo 2,84% de casca e 97,16% de polpa e 0% de 20 casca e 100% de polpa, foi submetido a análises sensoriais, com aceitação majoritária para 21 a segunda amostra, embora ambos tenham apresentado boa aceitação. 22 PALAVRAS-CHAVE: Iogurte, tangerina, casca. 23 1 24 1 Introduction 25 Milk is one of completest food that exists. Besides calcium, it is rich in vitamins and minerals 26 too. In order to increase your consumption, techniques have emerged to prepare dairy as 27 cheeses, butters, condensed milks, milk drinks, yogurts, etc. There are many milk drinks 28 commercially available, but according to Santos (2003), the consumers look for innovator 29 products, with new textures and that bring health benefits. 30 Yogurt is a kind of fermented milk, which is obtained by coagulation and decreasing of milk’s 31 pH, or reconstituted through milk fermentation by the action of two specific microorganisms: 32 Streptococcus thermophilus and Lactobacillus bulgaricus that act in symbiosis at 33 temperatures between 42ºC to 45ºC. The fermentation consists on the transformation of 34 lactose, which is a carbohydrate, in lactic acid (BRASIL, 2007). 35 Mesurolle et al. (2013) point out that consumers are increasingly vigilant with regard to the 36 quality of food products due to the nutritional recommendations of public authorities and 37 current health issues. These authors mention that improving sensory quality of low-fat 38 yogurts, for example, is a real challenge for the food industry. 39 An alternative to increase the consume of yogurt, since it is usually consumed because of its 40 organoleptic characteristics and not because the nutritional aspects according to Rocha et al. 41 (2005), is the adding of fibers, which are found in vegetables, fruits, cereals and industrial 42 wastes (e.g. peels of fruits). 43 According to analysis of Gondim (2005), tangerine peel is very nutritive, rich in fibers, 44 calcium and potassium. It stood out among many peels and pulp fruits cultivated in Brazil. In 45 a sample of 100 g in natura of tangerine peel there are 10,38 g of fibers approximately, while 46 for the same weight of the edible part there is 0,9 g. Besides the fibers, for the same mass of 47 peel, there are contained about 478,98 mg of calcium, while in the pulp, this value decreases 2 48 to 13 mg. 49 Based on parameters of centesimal composition, the tangerine peel is also considered rich in 50 polysaccharides, group that stands in pectin (content higher than 15%) in citric albedos in 51 general. The pectin from fruits has important medicinal role, since it acts in the control of cell 52 walls porosity and in an important biological surface phenomenon: the adhesion of underlying 53 cells and control of the ionic ambient of the cell wall. Some types of pectin links also have 54 importance on strengthen of cell wall and intercellular adherence. 55 The present study aimed to use different concentrations of peel and pulp of Murcott tangerine 56 for the yogurt production so as to obtain an innovator product with high nutritional value and 57 toothsome. 58 59 2 Material and Methods 60 To carry out this work, murcott tangerines were commercially obtained close to Centro 61 Universitário de Belo Horizonte – UniBH (Minas Gerais, Brazil), in which laboratory of 62 Bromatology this research happened. 63 At the beginning of the experiment, the operators led the procedures of personal hygiene, 64 cleaning and sanitization of equipment, countertops and utensils, as provided in the Ordinance 65 6/99 of the Health Surveillance Center, which points out the parameters and criteria for the 66 hygienic-sanitary control in food establishments (BRASIL, 1999). 67 68 2.1 Peel treatment 69 Sodium hypochlorite solution 2,5% w/v, filtered water, analytical balance model QUIMIS 70 Q520-4100, hot air oven with air forced circulation and renovation model DeLeo DL-AFD 3 71 and an industrial liquefier model Skymsen LI-1,5-N were used to treat the fruits. 72 The fruits were weighed, washed in running water, dipped in sodium hypochlorite solution, 73 over again washed in running water, dried with a clean cloth and their peels were removed to 74 separate them from the pulp. The peels were heated with filtered water in a metallic recipient. 75 After three minutes of water boiling, the heat supply was interrupted and the peels were 76 cooled at room temperature for four hours. The peels were after transferred to a plastic 77 recipient and changes of filtered water were done every three hours during the day, and at 78 night they rested at 4ºC. This procedure was repeated for four days. 79 At the end of the bitterness removal procedure, the peels were again weighed and subjected to 80 drying for 12 hours in a hot air oven at 60ºC and air circulation with velocity equal to 0,7 m/s. 81 When dried, the peels were milled in a liquefier and sieved, so it was possible to obtain a fine 82 flour of them. 83 A sample of 143,86 g of peel was weighed and from the data, the water mass and the moisture 84 content were calculated through the equations 1 and 2 below. 85 𝑚𝑤 = 𝑚𝑝𝑤 − 𝑚𝑑 86 Where mw is the mass of water, mpw is the mass of peel and water and md is the dried mass. 87 𝑀% = 88 Where M% represents the moisture content. 𝑚𝑤 𝑚𝑝𝑤 × 100 Eq.1 Eq. 2 89 90 2.2 Yogurt production 91 Fresh milk, which was collected in a day before the pasteurization and preparation of yogurt, 92 was provided by Várzea Alegre farm, which is located in Santa Luzia/MG (Brazil). 4 93 The milk was heated at 85ºC during 15 minutes and after cooled at 45ºC. Then, the 94 microorganisms were added using the lactic culture BioRich® (to lactic fermentation occurs) 95 and placed in a hot air oven to the temperature control at 43ºC for 8 h. After the fermentation, 96 the yogurt was cooled at room temperature for 1 h and, next, it rested for 12 h at 5ºC. 97 Two kinds of jelly were prepared: one containing peel and pulp of tangerine and the other one 98 with only pulp. To prepare the jellies, it was used: filtered water, sugar, crushed pulp seed- 99 free tangerine and utensils and industrial kitchen equipment. 100 Under constant stirring in an industrial stove, the components were mixed to acquire jelly 101 consistency. It was divided into two portions, and to one of them were added 2,84% m/m of 102 peel flour. 103 The product finalization was carried out mixing 20% in mass of jelly and 80% of yogurt. 104 105 2.3 Analysis of milk and yogurt 106 It was performed with milk and natural yogurt tests to determine the specific mass, using a 107 picnometer and dinamic viscosity by the falling ball method described by Soares (2011). It 108 was also obtained the soluble solids content using a refractometer and the lactic acid content 109 by titration (BRASIL, 2006). 110 So as to analyze taste, aroma, visual aspect and texture of both yogurts (with and without the 111 peel), sensory analysis was performed with 57 untrained volunteers at the sensory analysis 112 laboratory of Centro Universitário de Belo Horizonte – UniBH, in individual booths under 113 white light and at room temperature. The samples were served in plastic cups of 50 mL. 114 115 5 116 3 Results e Discussion 117 The results of the tests, which were simultaneously done with the milk and yogurt with pulp 118 and peel, are related on the TAB.1 and the standard deviation was calculated using the 119 Student’s t-testst for degrees of freedom n = 3 and significance α = 0,05. Tests Milk Yogurt Specific mass (kg/m³) 1028,68 ± 0,93 994,39 ± 0,79 Viscosity (cP) 8,84 ± 0,23 556,70 ± 1,21 Soluble solids (°Brix) 12,6 ± 0,1 16,6 ± 0,3 Titratable Acidity (°Dornic) 15,5 ± 0,6 97,5 ± 0,7 120 Table 1 121 Results of tests with milk and yogurt 122 123 About the ratio between mass and volume at 15ºC, the milk that was used had a result in the 124 range of 1028 and 1034 g/L, which is the established by the Normative Instruction nº 51, of 125 September 18th of 2002, of Ministério de Estado da Agricultura, Pecuária e Abastecimento 126 (BRASIL, 2002). 127 Lee and Lucey (2010) showed that the texture of yogurt and its propensity to syneresis (serum 128 separation) are among the main characteristics that define yogurt’s quality. The addition of 129 thickeners can be used in order to increase the product’s viscosity, making firmer the texture, 130 decreasing the syneresis and increasing its acceptability. 131 The viscosity value found in the product was higher than that found by Mathias et al. (2013) 132 for three brands of commercial yogurts containing thickening, whose first brand had viscosity 133 of 286,3 cP; the second 236,3 cP and the last one 144,7 cP. 6 134 Thus, the yogurt produced in this research has waived the addition of thickeners, fact that 135 made it more economical and has indicated its good quality. 136 According to Robert (2008), the milk acidity is a fundamental parameter to the evaluation of 137 its quality, because it reflects on the resistance against thermal treatment and its 138 transformation in products of good quality. The milk acidity ranges from 12 to 20ºD (Dornic 139 degrees), with acceptable values in the range of 15 - 18ºD. For situations out of these limits, 140 this parameter indicates milk from cows milked in colostrum phase, cows with any sanitary or 141 nutritional problems, with inflammatory and/or infectious processes in mammary gland. 142 Compared to the results obtained for the parameter “acidity” of milk, there was compliance as 143 to the established limit, which indicates the quality of milk and its derivate yogurt. 144 Concerning to the parameter “soluble solids”, there was a considerable increasing if compared 145 to the milk probably because of adding of pulp and peel, that have own sweet and the sugar 146 adding too. The produced yogurt had value close to those found by Cavalcanti et al. (2006), 147 who evaluate the characteristics of ten commercial yogurts and found average of 16,79 148 ºBRIX, and lower than the seven formulations of yogurts added of fruits from Amazon 149 obtained by Santa Rosa (2011), who found average of 19,41 ºBRIX. 150 The sensory analysis revealed that the produced yogurt with jelly of tangerine with peel was 151 well rated, considering that in all the criteria there was prevalence of answers “good” or “very 152 good”, as can be seen in the Graphic 1. 7 60.0% 50.0% 40.0% Very good Good 30.0% Regular Bad 20.0% Not answered 10.0% 0.0% Taste 153 Aroma Visual aspect Texture 154 Graphic 1 155 Sensory analysis of yogurt with peel and pulp of tangerine 156 157 The analysis of Graphic 1 in complement of Graphic 2 below allow the inference that there 158 was preference for the yogurt with no addition of peel, although both had showed good 159 acceptance. 60.0% 50.0% 40.0% Very good Good 30.0% Regular Bad 20.0% Not answered 10.0% 0.0% 160 Taste Aroma Visual aspect Texture 161 Graphic 2 162 Sensory analysis of yogurt with only pulp of tangerine 8 163 4 Conclusion 164 The produced yogurt had physicochemical characteristics in accordance to the established by 165 the current Brazilian Law and close to that found by other authors, which indicates its good 166 quality, besides it was showed as economic mainly because of the no need of adding 167 thickeners and the using of peel, that is usually discarded and whose cost is already associated 168 to the value of the integral fruit. 169 Both yogurts, with and without peel, had interesting sensory aspects (taste, aroma, texture, 170 visual aspect) and were well rated. Although the yogurt with peel adding has greater 171 nutritional value due to its higher contents of many nutrients when compared to the edible 172 part, as fibers, calcium, iron, magnesium, potassium and proteins, the sample without peel in 173 composition was the more preferred by tasters in the sensory analysis. 174 175 4 Acknowledgements 176 The authors of this search thank the volunteers that have collaborated in the sensory analysis 177 and the workers of Pilot Plant of UniBH, who had helped with the methods and yogurt 178 production. 179 180 5 References 181 BRASIL – CENTRO DE VIGILÂNCIA SANITÁRIA DA SECRETARIA DE ESTADO DA 182 SAÚDE. Regulamento Técnico, que estabelece os Parâmetros e Critérios para Controle 183 Higiênico-Sanitário em Estabelecimento de Alimentos. Portaria CVS-6/99, of March 10, 184 1999. 185 9 186 BRASIL. Normative Instruction No. 51, of September 18, 2002. Regulamentos técnicos de 187 identidade e qualidade de produtos lácteos. Diário Oficial da União, Brasília, 20 sep. 2002. 188 189 BRASIL, Ministério da Agricultura, Pecuária e Abastecimento. Normative Instruction nº 190 68, of December 12, 2002. Dispõe sobre a oficialização dos Métodos Analíticos Oficiais 191 Físico-Químicos, para Controle de Leite e Produtos Lácteos que devem ser atendidos pelos 192 Laboratórios Nacionais Agropecuários. Diário Oficial da União, Brasília, jan. 21th, 2005. 193 194 BRASIL – Ministério da Agricultura, Pecuária e Abastecimento. Regulamento Técnico de 195 Identidade e qualidade dos leites fermentados. Normative Instruction nº 46, of October 23, 196 2007. 197 198 CANTERI, M.H.G; WOSIACKI, L.M; SCHEER, A.P. - Pectina: da Matéria-Prima ao 199 Produto Final – Polímeros: Ciência e Tecnologia, vol. 22, n. 2, p. 149-157, 2012. 200 201 CAVALCANTI, A. L.; OLIVEIRA, K. F.; PAIVA, P. S.; RABELO, M.V.D.; COSTA, S. K. 202 P.; VIEIRA, F. F. Determinação dos Sólidos Solúveis Totais (ºBRIX) e pH em Bebidas 203 Lácteas e Sucos de Frutas Industrializados. Pesq. Bras. Odontoped Clin Integr, João 204 Pessoa, v. 6, n. 1, p. 57-64, jan/apr. 2006. 205 206 FERREIRA, C. L. de L. F. Estratégia na produção de leites fermentados probióticos: 207 utilização de microrganismos bioajustadores de pH. Revista Leite & Derivados, n°71, Jul. 208 2003. 209 10 210 GONÇALVES, A. A.; EBERLE, I. R.. Frozen Yogurt com bactérias probióticas. Revista 211 Alimentos e Nutrição, Araraquara, v.19, n.3, p. 291-297, jul./sep. 2008. 212 213 GONDIM et al.. Composição centesimal e de minerais em cascas de frutas. Revista Ciência 214 Tecnologia e Alimentação, Campinas, 25(4): 825-827, oct.-dec. 2005. 215 216 GUIMARÃES, T. G. Cultura da Tangerina. Revista Toda Fruta, Aug. 2007. 217 218 LEE, W. J.; LUCEY, J. A. Formation and physical properties of yogurt. Asian-Australasian 219 Journal of Animal Sciences, Seoul, v. 23, n. 9, p. 1127-1136, 2010. 220 <http://dx.doi.org/10.5713/ajas.2010.r.05>. 221 222 MATHIAS, T. R. S.; ANDRADE, K. C. S.; ROSA, C. L. S.; SILVA, B. A. Avaliação do 223 comportamento reológico de diferentes iogurtes comerciais. Braz. J. Food Technol. [online]. 224 2013, vol.16, n.1, p. 12-20. Epub Mar 05, 2013. ISSN 1981-6723. 225 226 MESUROLLE, J.; SAINT-EVE, A.; DÉLÉRIS, I.; SOUCHON, I. Impact of fruit piece 227 structure in yogurts on the dynamics of aroma release and sensory perception. Molecules, 18, 228 6035-6056; ISSN 1420-3049, 2013. 229 230 ROBERT, N. F. Dossiê Técnico – Fabricação de iogurtes. Rede de Tecnologia do Rio de 231 Janeiro, Serviço Brasileiro de Respostas Técnicas – SBRT. Rio de Janeiro, 2008. 232 233 ROCHA, E. M.; AGUIAR, S. F.; ARAÚJO, V. S.; DUARTE, W. K. C.; MAGALHÃES, M. 234 M. A. Elaboração e caracterização de sobremesa láctea à base de frutas tropicais. Higiene 235 Alimentar, São Paulo, v.129, n.19, p. 12-14, 2005. 11 236 SANTA ROSA, R. M. S. Iogurte de leite de búfala adicionado de polpa de frutas da 237 Amazônia: parâmetros de qualidade. Tese de Doutorado. Universidade Federal 238 Fluminense, 2011. 239 240 SANTOS, J. A. O toque final nos subprodutos lácteos: Os preparados de polpas de frutas e 241 aromas abrem ao segmento lácteo possibilidades de inovação nas linhas de refrigerados. 242 Revista Leite & Derivados, n°69, Mar/Apr., 2003. 243 244 SOARES, M. C. F. Fluidos aquosos baseados em poliacrilamida e nanotubos de carbono. 245 Masters Dissertation, Chemistry Department of the Institute of Exact Sciences of 246 Universidade Federal de Minas Gerais. Belo Horizonte, 2011. 12