VEGETABLE OILS: A SOURCE OF WELL

advertisement

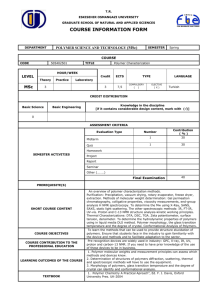

VEGETABLE OILS: A SOURCE OF WELL-DEFINED BUILDING BLOCKS FOR THE SYNTHESIS OF RENEWABLE POLYMERS Pr. Henri Cramail Laboratoire de Chimie des Polymères Organiques (UMR5629) Université de Bordeaux/IPB/CNRS, Pessac, France Most of the polymer materials consumed each year (nearly 300 Mtons) are obtained from fossil resources (mainly petroleum). These resources will arguably be depleted within one or three generations. Due to this depletion and to escalating prices, polymer chemists have turned their attention to obtain monomers and polymers from renewable resources [1]. Vegetable oils have a large potential to provide renewable chemicals, thanks to their availability, sustainability and biodegradability. The latter bring different functional groups (esters, unsaturations) that can be derivatized to design novel well-defined functional building blocks for the synthesis of speciality polymers [2]. In this talk, recent investigations, performed at the LCPO, in the fields of polyurethanes and polyesters will be presented. Polyurethanes: With a worldwide production of around 20 million tons in 2011, polyurethanes (PU) represent an important class of polymeric materials. [3] Following the classical route, we have designed new diols containing ester or amide linkages from castor and sunflower oils to prepare TPU with amorphous to semi-crystalline morphology and tuned thermo-mechanical properties. [4-6] Due to the hazard concerns of isocyanate and phosgene, the development of isocyanate and phosgene free strategies to bio-based PU is requested. Isocyanate free TPU with respectable molar masses were synthesized from diamines and bio-based bis cyclic carbonates from castor oil. [7] Using a different phosgene free method, we successfully transformed fatty acid derivatives into diisocyanate precursors such as diacyl azide or diacyl hydrazide. The latter were reacted with bio-based diols to obtain fully or partially bio-based TPU with adjusted properties. [8-10] Polyesters : Poly(lactic acid) (PLA) is an aliphatic polyester that fits remarkably well with the high demands for greener materials. [11] However, the brittleness of PLA prevents its use for a wide range of applications. Thus environmental friendly solutions such as copolymerization or blending with soft bio-based polymers are needed. We have first synthesized triblock copolymers PLA-b-poly(ricinoleic acid)-b-PLA by a sequential self-condensation of ricinoleic acid methyl ester and ring-opening polymerization of L-lactide, and tested these copolymers as additives in blends of PLA with poly(ricinoleic acid). [12] Second, poly(ester-amide)s (PEAs) were synthesized from novel diols from methyl 10-undecenoate and melt-blended with PLA. During this presentation, a critical discussion about the potential of such fatty-acid based polyesters as toughening agents of PLA will be made. [4] References 1. Gandini, A. (2011). Green Chemistry,. 13(5): p. 1061-1083 2. Cramail H. and coll (2013). Polymer Chemistry DOI: 10.1039/C3PY00791J 3. PlasticsEurope, Plastics - the Facts 2012 an Analysis of European Plastics Production, Demand and Recovery for 2011, 2012. 4. EP patent 11306491 (2011), H. Cramail, and coll. 5. Maisonneuve, L., et al. (2012). Polymer Chemistry 3(9): 2583-2595 6. Lebarbé, T., et al. (2012). Polymer Chemistry 3(10): 2842-2851 7. WO patent 061452 (2011), H. Cramail, and coll. 8. More, A. S., et al. (2012). Polymer Chemistry 3(6): 1594-1605 9. More, A. S., et al. (2013). European Journal of Lipid Science and Technology 115(1): 61-75 10. More, A. S., T. Lebarbé, et al. (2013). European Polymer Journal, 49: 823-833 11. Garlotta, D. (2001). Journal of Polymers and the Environment, 9 (2) : 63-84 12. Lebarbé, T., et al. (2013). Polymer Chemistry 4(11): 3357-3369