Undergroud Construction Paper

advertisement

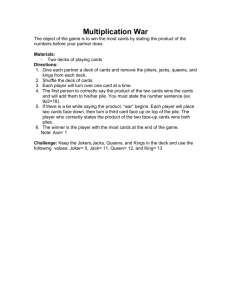

A NEW APPROACH TO CONSTRUCTION OF UNDERGROUND STATIONS AND LAUNCH BOXES James C. Thomson C.Eng Jacked Structures SA Background The use of jacking methods to install underground pipes was first recorded more than a 100 years ago. It was some 50 years ago that a new wave of development in mainland Europe and UK that rapidly established pipe jacking as an effective method of direct installation of sewers and other utilities. Initially excavation was by hand from within open face shields. In Japan the development of remote control slurry pressure balance machines in combination with jacked installation of pipes allowed non-man entry, smaller diameters and use in difficult ground conditions . Applications developed including larger diameters tubes of 3 and 4m diameter jacked into place beneath existing highways and railway infrastructure for pedestrian subways. Smaller rectangular sections were also jacked in below rail tracks and roads to form culverts and pedestrian subways. There was an increasing need to install larger structures, such as road underpasses under rail tracks and highways with minimal disruption which encouraged the author to make a number of developments when working for Cementation/Trafalgar House contractors in the nineteen sixties and seventies. A patented development was modular jacking where precast box sections are jacked into position one above the other to form composite abutments and piers with the deck installed during a short possession of the railway or highway. An example of this method is the Wandsworth Bridge underpass which was installed in 1969 below 7 busy rail tracks coming into central London. The concept is illustrated in Figure 1. Figure 1 Modular System The Brent Cross Tunnels installed in 1974 under the busy A41 arterial route in north London was one of the earliest full size jacked box installations for road underpasses with box widths of 9.5m and height of 7m the tunnel units were cast on site adjacent to the existing highway embankments The patented friction reducing drag sheets were used and proved to be a key to jacking large box sections with shallow cover. The concept of box jacking is illustrated in Figure 2 Fig 2. The Box Jacking Concept Both box jacking and modular jacking has been employed on numerous jobs in UK and internationally. These techniques are still widely used today. Jacked Arch and Jacked Deck Development The modular and the jacked box have some shortcomings in certain circumstances. Jacked boxes: Require a large site footprint for the construction of the box which can involve large expensive launch pits when the underpass is deep below ground level. In unstable soils face stability can be a concern in large boxes with exposed faces 8m or more high Jacking forces and reaction arrangements are required to accommodate high loads as boxes get larger in cross section and drive length. It can be sometimes difficult to control line and level; in harder conditions at the invert there is a tendency to climb as it is difficult to trim accurately. In soft invert conditions it is difficult to stop a tendency to settle. With large boxes steerable shields are not effective Modular Jacking although overcoming several of the shortcomings of large boxes has the major disadvantage that an abnormal possession of the highway or railway is required to install the deck. Considering these drawbacks the author has developed patent protected innovations of the Jacked Arch and the Jacked Deck. These provides safer, faster and less disruptive ways of installing large underground structures of greater clear spans over longer lengths. Both methods have in common the use of a slide path which is installed within a jacked box or tunnel. This ensures that the slide track is fully prepared ahead of installation and the structure is installed with lower jacking forces and to close accuracy. The Jacked Arch Figure 3 Jacked Arch Concept The process consists of the following stages : Stage 1. The installation of man-entry foundation boxes designed for the foundation loads and the soil conditions. These are jacked in to position. Stage 2. After driving the boxes a guide path for the arch is pre-set manually inside the boxes Stage 3. The main structure is formed from pre-cast arch sections (2 or 3 pin) which are jacked in behind a shield to form the canopy structure. The leading arch unit is fitted with a compartmentalized raking shield. The base of the arch sections, as they are driven forward, are located and slide in the guide path (installed at Stage 2). The foundation boxes have roof sections which can be removed progressively from inside the arch shield to expose the guide path. Stage 4. Joint sealing, internal finishes and a floor are installed appropriate to use. A number of variations are possible including elements of the modular system to create vertical walls combined with flat arches. It is also possible to use circular foundation tubes rather than boxes. Such a configuration could allow the use of pressure balance tbm’s where ground conditions and water tables are a concern. The Jacked Deck Figure 4 The Jacked Deck Concept The jacked deck is appropriate for spans of 10m or greater and figure 4 shows alternative options for creating the slide path and foundation. The outer abutments are installed using modular jacking and the slide path is installed in the top unit The central pier support is formed by jacking a high level box and piling from inside the box. The deck can be constructed from precast concrete beam sections or multiple cast on site units and is designed with a downstand providing an overall minimum depth of 2.5 m or more. It is possible to install on the leading edge of the deck a suitable compartmentalized shield in which general labour and machines can excavate the face. The preinstalled piers and abutments support and confine the earth allowing excavation to a greater depth below the deck units providing access for machines and men and spoil disposal This concept is being employed in the construction of a key road underpass below rail tracks by the Volker Fitzpatrick Hochtief JV as part of the £62 million East Kent Access project. With a 19.950 m clear internal span and a drive length of 125m it is one of the largest and longest underpasses ever constructed beneath an operational railway In this case the contractor opted for installing 3.4m segment access tunnels from which piles are driven to provide the abutments and for the installation of the slide path. This is illustrated at Fig 5 The detailed design was developed by Atkins with Jacked Structures SA. providing specialist technical support on the installation. Figure 5 Cliffsend Jacked Deck Underpass (VolkerFitzpatrick Hochtief JV) Application of Jacked Arch and Jacked Deck to Underground Stations Having established some background and an example of the jacked deck concept the second part of this presentation is concerned with the application of these concepts to the construction of underground stations , TBM launch boxes and similar large underground structures. The jacked arch and jacked deck technologies have a capability for installing underground stations. All the options described provide for a slide track within a foundation, access or wall box along which the arch or deck units are jacked as excavation proceeds. One method is based on the modular construction of piers and abutments with the top wall box providing the location of the slide track. An alternative is the jacked access box from which piled foundations can provide abutment walls or columns as well as the slide track. A variant is to use a circular tunneled access instead of the jacked box which could be used where ground conditions warrant. Where ground conditions require treatment these same access boxes or tunnels can be used for pre-stabilization of the ground prior to installing the jacked arches or deck beams. The following sketches are illustrative of the method and both the dimensions and the configurations can be varied to meet the specific needs In most cases, because of restricted space at the working site, it is anticipated that precast box units, arch sections and deck beams will be factory cast and transported to site. Regulations vary from one country to another on the maximum size of unit that can be transported on public roads. For larger diameter arches it would be necessary to precast these in two sections, for example a 3 pin arch or for the two elements to be joined at site to form a 2 pin arch It is envisaged that the techniques set out below would have application wherever surface disruption is to be avoided. Where structures have to be constructed with a few meters of cover these techniques, particularly the jacked deck, would be beneficial as they are engineered to minimize any surface settlement. Equally large deep structures would benefit as the area of exposed soil face within the shield is minimized and a full structural lining is provided at each stage of excavation. The sketches show a range of alternative abutment and pier configurations and can be modified depending on the needs and the site conditions. The illustrative graphics are based on a 12m width between platforms which would accommodate twin tracks with wider trains than London underground requirements. London Underground stations are typically 6.2-6.7m diameter to accommodate a single track with platform. A central platform requires a minimum 6m plus two tracks therefore a 14m arch would be sufficient. Figure 6 A station configuration for twin tracks and side platforms based on driving foundation boxes and full arch sections jacked in on slide tracks Figure 7 An alternative station configuration for twin tracks and side platforms based on driving foundation boxes. wall boxes and top arch sections jacked in on slide tracks Figure 8 An alternative station configuration for twin tracks and side platforms based on piling from jacked high level access boxes deck sections jacked in on slide tracks Figure 9 An alternative station configuration for four tracks and side platforms based on piling from jacked high level access boxes deck sections jacked in on slide tracks Figure 10 shows a design for a complete station and is based on driving in both directions from a central excavation which would form the access concourse. In this example a high level box with piling and relative flat arch with down-stands is shown. But the Jacked Arch and Jacked Deck options shown in previous graphics could equally been used. The length of station is determined by platform length required to accommodate the number of carriages. A platform length of 140m is shown which will accommodate up to 8 carriages. Longer lengths would be possible. Figure 10 An underground station based on abutments formed from piles installed from a high level box and a jacked arch The jacked arch and jacked deck approaches offer alternatives to existing methods of installation. As full structural lining is installed at every stage as excavation proceeds this can be an advantage in risk minimization. Application of Jacked Deck to Launch Boxes Launch boxes are constructed to provide an underground box from which TBMS are launched to construct the running tunnels. Thereafter they provide the basic structure within which the permanent station is constructed. Typically these will be 22-24m span and around 200m long. The height will be determined by the diameter of tunnel to be driven. For a twin track tunnel this could be 6/ 7m diameter with internal depth of box up to 8-10m. Launch boxes could be driven from a central access shaft in both directions using the jacked deck method to give the clear spans required. The various geometric alternative configurations for jacked arch and deck concepts described and illustrated above would be modified to provide the required span, length and height. Application to Other Large Underground Structures Underground Parking Both the jacked arch and jacked deck could used to create underground parking below streets, buildings, parks etc. We envisage that a series of interconnecting bays would be created either using an arch or a jacked deck concept. A clear span of 10-12m for each bay would typically be required to provide parking bays either side of a central access road Underground Storage Caverns There are a number of developers and industries that have a need to create storage space in locations where open cut would be too disruptive or not cost effective. These could be constructed by the jacked arch and deck techniques. Advantages of the Jacked Approach The application of jacked arch and deck methods provides safer, faster and less disruptive installation of large underground structures including underground stations and launch boxes. Specifically: By breaking down the process into elements reduces the exposed soil face at any point and reduces jacking forces and reaction arrangements. Continuous support of the excavation with a full structural lining as installation proceeds minimises the possibility of soil collapse The risk of injury or death to workers is virtually eliminated Any surface settlement is minimal and adjacent buildings, property and the public are protected Use of precast units allows higher quality construction A wide range of geometry and configuration can be tailored to each project Installation to very close line and level tolerances The methods are applicable to constructing both shallow and deep structures Jacked arch and jacked deck structures can provide greater clear spans over much longer drive lengths than existing jacking techniques. Jacking precast elements to form the underground structure can be undertaken from relatively small launch platform excavations. James C. Thomson C.Eng. Jacked Structures SA james.thomson@jackedstructures.com