Chemical Hygiene Plan - Utah Valley University

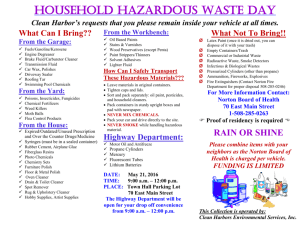

advertisement