290715163414SusChemEAbstract

advertisement

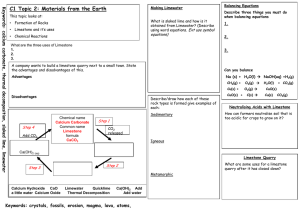

SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai ------------------------------------------------------------------------------------------------------------------------------- High Temperature Carbon Capture using of Limestone doped with Flyash B.Sreenivasulua, I.Sreedhar a,*, K.V.Raghavanb, B.Mahipal Reddyc a Department of Chemical Engineering, BITS Pilani Hyderabad Campus, Shameerpet, Hyderabad-78, India Reaction Engineering Laboratory, Indian Institute of Chemical Technology, Tarnaka, Hyderabad, India c Inorganic and Physical Chemistry Division, Indian Institute of Chemical Technology, Tarnaka, Hyderabad, India Email: vasulu.b@gmail.com,isreedhar@hyderabad.bits-pilani.ac.in,ondapuramiict@gmail.com,bmreddy@iict.res.in b -----------------------------------------------------------------------------------------------------------------------------1. Introduction High temperature CO2 capture (CC) has gained societal and industrial significance due to global warming. It is mainly due to the CO2 emissions from thermal power generation stations which are the prime source of energy for the world. But, industrial flue gas emissions are at ambient conditions. Liquid absorbents, organic adsorbents and hybrid forms of metal organic frameworks provide high CO2 capture capacity. But, The liquid absorbents suffer from higher energy penalty and disposal hazards [1]. These also suffer from drawbacks viz., flue gas contaminations, moisture, fewer life cycles and scale-up issues. Alkaline earth metals are good to capture CO2 but are expensive with environmental hazards. The only option is to use abundantly available low cost ecofriendly mineral like limestone [2]. It captures CO2 at temperatures >400oC and its spent material could be used in cement industry. Lower number of calcination-carbonation cycles is a major drawback due to its pore blocking nature. It is due to minimal surface area for adsorption in its native form. This could be resolved by the addition of inert materials like industrial flyash to increase pore size and surface area [3]. For our study, we synthesized limestone with flyash based monolith. Surface area, pore sizes, crushing strength, CO2 adsorption capacities, SEM analysis and X-RD analysis were measured during carbon capture and analyzed. 2. Materials and Experimental Methods The solid adsorbents are synthesized with organic binding agent for pelletizing monoliths. These are again sintered in a muffle furnace to a temperature of 1050 oC. These are used in the following interpreted experimental setup. The CO2 capture capacities on doped limestone with CFA based adsorbents at 5%, 10%, 15% were measured using gas analyzer connected to the set-up. Fig.1. Schematic of the experimental set-up 3. Results and Discussions The following Table.1, shows the parameters that were measured. BET surface areas were measured for different compositions to find porosity with corresponding CO 2 adsorption capacities (1st cycle) with sample weight of 100g monoliths. Adsorption isotherms were compared with Langmuir and Freundlich isotherms. For different CO2/N2 gas compositions with SEM analysis were shown in Fig 1, Fig 2 and Fig 3. 1 SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai ------------------------------------------------------------------------------------------------------------------------------Table 1 Adsorbent pore size with capture capacity Composition Crushing value Surface (MPa) & area (m2/g) morphology 50%CFA+50%limestone - &Powder 3.42 60%CFA+40%limestone 0.06& monolith 2.83 70%CFA+30%limestone 0.2& monolith 2.18 80%CFA+20%limestone 0.4 & monolith 1.64 Surface volume(cm3/g) Pore size (Ǻ) CO2 capture (g CO2/gads) 0.00652 0.00459 0.003 0.0019 76.257 64.87 55.046 46.341 0.192 0.103 0.082 0.04 Fig.1: flue gas CO2 concentration (%CO2) vs time of adsorption. Fig 2. Fresh sample Fig 3. Sample after 1st Cycle 4. Conclusions ` Different combinations of cost effective adsorbents are compared with reference to their performance in CC, their pore size and volume, physicochemical changes during CC. By comparing CC with time, the intrinsic adsorption kinetics was done by comparing our results with Langmuir and Freundlich isotherms to identify the suitable mechanisms. 2 SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai ------------------------------------------------------------------------------------------------------------------------------References: [1] D.Y.C. Leung, G. Caramanna, M.M. Maroto-Valer, Renew. Sustain. Energy Rev. 39 (2014), 426–443. [2] S. Kumar, S.K. Saxena, Mater. Renew. Sustain. Energy. 3 (2014)1-15. [3] B. Sreenivasulu, D. V Gayatri, I. Sreedhar, K. V Raghavan, Renew. Sustain. Energy Rev. 41 (2015) 1324– 1350. 3