the FITTED FURNITURE NOS

advertisement

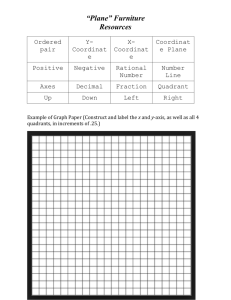

Fitted Furniture Installation Draft National Occupational Standards September 2015 Page 1 of 35 Contents Overview ................................................................................................................................................... 3 PROFFI02 - Provide advice and guidance on products and materials ...................................................... 5 PROFFI03 - Prepare location for assembly and placement of furniture ................................................... 6 PROFFI04 - Measure and mark out furniture components ...................................................................... 7 PROFFI05 - Prepare and assemble furniture using mechanical fixings .................................................... 8 PROFFI06 - Secure furniture components in location .............................................................................. 9 PROFFI07 - Fit and fix work surfaces ....................................................................................................... 11 PROFFI10 - Cramp components .............................................................................................................. 13 PROFFI11 - Sand wooden component .................................................................................................... 14 PROFFI12 - Apply edge treatment finishes ............................................................................................. 15 PROFFI13 - Cut and join components ..................................................................................................... 16 PROFFI14 - Attach fittings to furniture ................................................................................................... 17 PROFFI15 - First fit mechanical or electrical components to furniture .................................................. 19 PROFFI16 - Re-instate locations after furniture installation ................................................................... 21 PROFFI18 - Prepare specifications for furniture to be assembled.......................................................... 22 PROFFI20 - Secure furniture components in complex locations ............................................................ 24 PROFFI22 - Quality assure and co-ordinate furniture placements ......................................................... 26 PROGEN08 - Maintain tools and equipment .......................................................................................... 28 PROGEN18 - Solve problems in the workplace ....................................................................................... 29 PROGEN19 - Maintain quality standards ................................................................................................ 31 PROGEN20 - Comply with health and safety requirements in the workplace ....................................... 32 PROGEN21 - Apply techniques for continuous improvement in the workplace .................................... 33 PROGEN23 - Transport and handle installation equipment and materials ............................................ 35 Page 2 of 35 Overview A Fitted Furniture Installer is responsible for preparing and installing furniture as part of a team including kitchens, bedrooms, bathrooms and offices, shops, exhibitions and boat interiors. This is onsite at the customer's commercial or domestic premises. Installer Function Overview Maintain Tools & Equipment Perform regular autonomous maintenance tasks on machinery, tools and equipment used. Identify issues quickly, solve problems and apply appropriate solutions. Carry out work to required quality standards and output targets. Comply with health, safety and environmental requirements, relevant statutory regulations and industry standards/codes of practice at all times. Understand and apply continuous improvement techniques to work activities. Knowledge and understanding of industry materials. The safe transportation and handling of installation equipment and materials Prepare location for assembly and placement of furniture. Measure and mark out materials to specification. Set up and operate tools used to assemble furniture. Assemble components of fitted furniture and understand the sequence of assembly Problem Solving Achieve Quality & Output Targets Health & Safety Continuous Improvement Materials Transporting & Handling of Materials Prepare Location Measure & Mark Out Power Tools & Hand Tools Assembly Ref NOS Title PROGEN08 Maintain tools and equipment PROGEN18 Solve problems in the workplace PROGEN19 Maintain quality standards PROGEN20 Comply with health and safety requirements in the workplace PROGEN21 PROFFI02 PROGEN23 PROFFI03 PROFFI04 Measure and mark out products PROGEN08 Maintain tools and equipment PROFFI05 PROFFI06 Installation Finishing Cut Outs Cramping Sanding Veneers & Laminates Jigs & Templates Joints Fittings Electrical / Mechanical Fittings Re-Instate Location Install furniture on location to specification. Finish solid surface work tops to specification following manufacturers instructions. Complete standard cut-outs in work surfaces and carcases for general appliances Position components and apply cramps to ensure products are positioned securely to specification. Sanding wooden work tops, trims, cornices and laminate edgings. Apply edging tape to laminate worktops to specification. Use and maintain jigs and templates for furniture installation. Cut and join components on site. Prepare and assemble components to specification, finishing and checking the assembly conforms to specifications First fit mechanical or electrical components to furniture. Re-instate a location after assembly and placement of furniture. Apply techniques for continuous improvement in the workplace Provide advice and guidance on materials used Transport and handle installation equipment and materials Prepare location for assembly and placement of products Prepare and assemble furniture using mechanical fixings Secure furniture components in location PROFFI07 Fit and fix work surfaces PROSS06 Finish solid surfaces PROSS02 Cut standard solid surface (Import not included) PROFFI10 Cramp Components PROFFI11 Sand Wooden Components PROFFI12 Apply edge treatment finishes PROFM37 Produce and maintain jigs and templates (Import not included) PROFFI13 Cut and join components PROFFI14 Attach fittings to furniture PROFFI15 PROFFI16 First fit mechanical or electrical components to furniture Re-instate locations after furniture installation Page 3 of 35 Customer Service Develop customer relationships. CFA Develop customer relationships (Import not included) Senior Installer/Technician (Skills in addition to those listed above) Function Overview Ref NOS Title Specifications/Installation Plans Prepare specifications for installation PROFFI18 Prepare specifications for furniture to be assembled in location PROFFI20 Secure furniture components in complex locations PROFFI22 Quality assure and co-ordinate furniture placements Installation Quality Assurance Install complex furniture in complex location to specification. Automation (electronic drawers, digital lighting, sounds, vision, etc , free standing services (toilets, baths, etc), kitchen island, Quality assure and co-ordinate furniture installations, coordinate other services Page 4 of 35 PROFFI02 - Provide advice and guidance on products and materials Overview This standard covers the skills and knowledge required to be able to understand products and materials used in your organisations and provide information and guidance to customers. Customers can be internal or external to the organisation. Performance criteria You must be able to: 1. 2. 3. 4. 5. advise customers on the products and materials your company sells and uses use appropriate questioning techniques to get information from customers advise customers on the suitable uses for the different products and in your organisation explain the limitations of products and materials to customers following standard operating procedures provide technical information on products and materials to customers following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. standard operating procedures and how to apply these importance of products and materials knowledge different uses of materials used within your organisation properties and characteristics of products and materials used within your organisation processes used to produce raw materials methods of improving performance of products and materials where raw materials are sourced statutory and legal requirements for materials and combinations of materials used within your organisation performance requirements of products and materials storage requirements for raw materials disposal and recycling routes for products and materials Page 5 of 35 PROFFI03 - Prepare location for assembly and placement of furniture Overview This standard covers the skills and knowledge required to prepare for the assembly of fitted furniture in location. This involves: 1. interpreting information 2. making the assembly and placement area ready for work 3. ensuring all resources are ready for use 4. working in ways that ensure your own and other’s safety Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. standard operating procedures and how to apply these confirm locations and schedules of assembly work with relevant people obtain agreement to proceed before starting work with relevant people isolate work areas to protect areas exposed to debris ensure customers remove vulnerable items to clear work areas and access routes prepare work areas following standard operating procedures establish safe and secure storage areas for resources and components follow safe and effective working practices at all times identify problems relating to the installation and deal with them in line with standard operating procedures maintain effective communication with the customer in line with customer care procedures check specified quality and quantity of components and resources are taken to the location confirm specified resources, tools and equipment are present and are in safe working order carry out preparatory work on components and materials following standard operating procedures lay out resources and components in a logical order for effective working Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. how to interpret work specifications including drawings who to confirm work requirements with and why it is important to have all the required agreements before you begin areas to be isolated and suitable protective coverings to be used types of vulnerable objects to be moved by customers and why personal responsibilities with regard to Health and Safety issues whilst in location when to set up storage areas and safety and security issues to consider problems that can occur on location and how you should deal with them how to provide information clearly to customers, what information they require and why how to dispose of waste in accordance with current legislation resources needed for furniture assembly in a location and preparation processes components assembled in location and preparation needed on location tools and equipment needed good practice methods for laying out resources and components Page 6 of 35 PROFFI04 - Measure and mark out furniture components Overview The standard covers the skills and knowledge required to measure and mark out furniture components. This includes: 1. using marking and testing tools 2. producing setting out details 3. producing cutting lists The standard is aimed at operators working in a furniture installation environment. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up correctly and in good working order following standard operating procedures and any manufacturer’s instructions check all materials required are to specification and free from faults following standard operating procedures obtain cutting lists for work to be carried out following standard operating procedures check and calibrate marking, measuring tools and ancillary equipment following standard operating procedures use marking and measuring tools and ancillary equipment following standard operating procedures and manufacturers’ instructions mark out from setting out details and cutting lists following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. standard operating procedures and how to apply these your relevant health and safety responsibilities, obligations procedures that need to be followed how to interpret drawings, specifications, schedules, cutting lists, risk assessments and manufacturers' information how to check equipment is set up and is in good working order how to use and describe how to check materials and the common faults that can occur how to check materials and the common faults that can occur cutting lists and apply these how to mark out components from cutting lists calibration of measuring equipment and why this is important marking, measuring tools and ancillary equipment Page 7 of 35 PROFFI05 - Prepare and assemble furniture using mechanical fixings Overview This standard covers the skills and knowledge required to prepare and make furniture using mechanical fixings. This involves: 1 checking and preparing components 2 prepare and assemble components to specification 3 working in ways which maintains your own and others’ safety 4 finishing and checking assemblies conform to specifications Performance criteria You must be able to: 1 2 comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up and in good working order following standard operating procedures and manufacturer’s instructions check materials required are to specification and free from faults ensure surfaces are in suitable condition following standard operating procedures position fittings for correctness of fit within the required tolerances following standard operating procedures attach fittings using required methods following standard operating procedures pass on completed work to the next stage following standard operating procedures 3 4 5 6 7 8 9 Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur different types of fittings used and their purpose quality checks to be made before fittings are used and the consequences of not doing these consequences of incorrect positioning of fittings consequences of not securing fittings correctly when and why different methods for attaching fittings are used functions and uses of different types of equipment used in assembly Page 8 of 35 PROFFI06 - Secure furniture components in location Overview This standard covers the skills and knowledge required to secure furniture components in location. This involves: 1. interpreting information 2. site safety and awareness 3. selecting materials, components and equipment 4. preparing and installing proprietary and/or purpose made furniture components for domestic, commercial, industrial and public environments 5. working on new, alteration or refurbishment contracts 6. working in ways that ensure your own and others’ safety There is also a scope statement which defines the coverage of this standard. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. comply with relevant legislation and official guidance to carry out work maintain safe areas of work for yourself and customers/members of the public or workers follow safe and effective working practices at all times in line with current health and safety legislation confirm locations are ready and preparations have been completed following standard operating procedures assess any unforeseen features of locations and identify how these affect placements following standard operating procedures mark out locations following standard operating procedures adjust components to provide best possible fit to locations following standard operating procedures select components as specified and confirm quality meets company standards deal with problems and faults during the placement following standard operating procedures minimise risk of damage to components/workpieces and surrounding areas following standard operating procedures maintain effective communication with supporting personnel and customers cut, shape, trim and scribe components to specification following standard operating procedures fit components in sequence following standard operating procedures adjust components to ensure joins and alignments between components, furniture and surrounds are to required tolerances level and secure components in location following standard operating procedures check decorative features are aligned to specification following standard operating procedures finish components to specification following standard operating procedures make good faults within limits of responsibility following standard operating procedures complete work within required time following standard operating procedures reinstate locations with supporting personnel/customer following standard operating procedures complete required documentation following standard operating procedures Page 9 of 35 Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. standard operating procedures and how to apply these how to interpret work plans or specifications including drawings relevant health and safety / risks associated with installation of components why it is important to prepare and protect work areas procedures to follow to confirm preparations are complete features of assembles affected by locations how to mark out and scribe uneven surfaces whilst maintaining level, plumb or alignment of components how to determine required angle cuts at locations how to mark out for joints between components fixings used to secure placement of components handling characteristics of components and how these affect the assembly and fitting of components in location problems that occur and how to deal with them how to check completed work against specifications or drawings or plans working components and how these affect the assembly and fitting of components in location fixing sequencing of components in location fixings for securing components in location how to adjust alignment and movement of components how to measure alignment in three dimensions personal responsibilities towards health and safety when at location with regard to Health and Safety legislation how to provide information clearly to customers, type of information customers require, and why it could be important to them timescales specified for work documentation required how to dispose of waste in accordance with current legislation Page 10 of 35 PROFFI07 - Fit and fix work surfaces Overview This standard covers the skills and knowledge required to fit and fix work surfaces in location. This involves: 1. interpreting information 2. fitting and fixing work surfaces according to specification 3. finishing 4. working in ways that ensure your own and others’ safety There is also a scope statement which defines the coverage of this standard. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up and in good working order following standard operating procedures and manufacturer’s instructions check materials required are to specification and free from faults make accurate templates following standard operating procedures following standard operating procedures cut, shape and trim work surfaces to specification following standard operating procedures check dimensions and alignments are to required specification following standard operating procedures assemble work surfaces to specification following standard operating procedures adjust work surfaces to ensure joins and alignments meet required tolerances following standard operating procedures check decorative features are aligned in position to specification following standard operating procedures fit the work surface in location to specification following standard operating procedures check seals are achieved to specification following standard operating procedures finish work surfaces to specification following standard operating procedures repair faults within limits of own responsibility following standard operating procedures complete work within required time following standard operating procedures maintain effective communication with the customer following standard operating procedures complete documentation following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications Page 11 of 35 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. how to check equipment is set up and is in good working order how to check materials and the common faults that can occur measurements required for production of templates and cut outs why it is important to prepare and protect the work area procedures to follow to confirm preparations are complete features of work surfaces affected by location fixings used to attach work surfaces in location handling characteristics of natural and manmade materials used for work surfaces problems that can occur and how they should be dealt with how to provide information clearly to customers type of information customers require and why it could be important to them timescales specified for work factors that affect sequencing when placing multiple work surfaces measuring alignment in three dimensions documentation required and how it should be completed how to check completed work against specifications or drawings Page 12 of 35 PROFFI10 - Cramp components Overview This standard covers the skills and knowledge required to position components and apply cramps to ensure products are positioned securely to specification. It covers: 1. 2. 3. positioning and assembling materials and components applying adhesives cramping Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up correctly and in good working order following standard operating procedures and any manufacturer’s instructions check all materials required are to specification and free from faults position materials to specification following standard operating procedures apply adhesives to specification following standard operating procedures assemble components to specification following standard operating procedures apply cramps to specification following standard operating procedures check piece is square and true to specification following standard operating procedures rectify any faults to specification following standard operating procedures remove excess adhesives following standard operating procedures allow piece to dry to specification following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur how to position materials adhesive drying times assembly processes different cramps available and their uses Page 13 of 35 PROFFI11 - Sand wooden component Overview This standard covers the skills and knowledge required to sand wood components. It covers: 1. 2. 3. completing preparation processes sanding components raising the grain Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up correctly and in good working order following standard operating procedures and any manufacturer’s instructions check all materials required are to specification and free from faults following standard operating procedures sand wooden components using appropriate grit sizes and blocks following standard operating procedures clean wooden components between sanding following standard operating procedures scrape tight corners following standard operating procedures raise fibres of the grain following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur relevant health and safety requirements that apply when machine and hand sanding is required grade sizes and their uses order different grit sizes need to be used faults and defects how to recognise and how these can be rectified during the production process why it is important to sand with the grain how to prevent the appearance of a raised grain different sanding blocks available and when to use these de-nibbing and how to carry out how to sand different components fillers used during preparation different machinery and equipment to use and why Page 14 of 35 PROFFI12 - Apply edge treatment finishes Overview The standard covers the skills and knowledge required to apply edge treatment finishes in furniture installation. It covers: 1. 2. 3. preparing adhesives and components applying edge treatments quality assuring completed work Edge banding is the process of applying a trim or edge to the piece of furniture to make it neat and aesthetically pleasing. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up correctly and in good working order following standard operating procedures and any manufacturer’s instructions check all materials required are to specification and free from faults prepare adhesives and components for application following standard operating procedures position edge finishes to specification following standard operating procedures apply edge finishes to products to specification following standard operating procedures trim edge finishes to specification following standard operating procedures check and finish components to specification following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur edge finishes available, their uses and how to apply these adhesives and how to prepare these curing times trimming process quality checks that need to be carried out and why Page 15 of 35 PROFFI13 - Cut and join components Overview This standard covers the skills and knowledge required to joint wood components. It covers: 1. 2. 3. marking out components cutting joints jointing components Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up and in good working order following standard operating procedures and manufacturer’s instructions check materials required are to specification and free from faults identify joints required and type of joint to be made following standard operating procedures mark out components following standard operating procedures set machinery, jigs and equipment following standard operating procedures and manufacturers’ instructions cut joints to within required tolerances following standard operating procedures check joints fit accurately and are square following standard operating procedures strengthen joints following standard operating procedures deal promptly and effectively with any joint faults that arise following standard operating procedures check finished joint components meet specified quality for alignment shape and grain orientation check joints and assembly are square following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur consequences of inaccurate measuring and cutting mechanics of joint construction limitations of different jointing components and alternative jointing techniques that can be used types of joints and their uses ways of strengthening joints how to use manual and powered tools and equipment safely in ways that protect yourself and others from risk Page 16 of 35 PROFFI14 - Attach fittings to furniture Overview This standard covers the skills and knowledge required to attach fittings to furniture. This involves: 1. checking and preparing fittings against specifications 2. attaching fittings to match specifications 3. working in ways which maintain your own and others’ safety Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up correctly and in good working order following standard operating procedures and any manufacturer’s instructions check all materials required are to specification and free from faults following standard operating procedures ensure surfaces are in a suitable condition following standard operating procedures position fittings for correctness of fit within the required tolerances following standard operating procedures attach fittings using required methods following standard operating procedures check fittings are plumb, level and free from binding to specification following standard operating procedures complete quality checks and confirm they have been met before passing on work following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur different types of fittings used in furniture production and their purpose quality checks to be made before fittings are used and consequences of not doing these consequences of incorrect positioning of furniture fittings consequences of not securing furniture fittings correctly different methods for attaching furniture fittings how to handle powered tools safely in ways that protect yourself and others from risk handling characteristics of natural timber and wood composites and how these affect fitting of doors, falls and drawers and making good of fitting faults 13. quality checks that need to be carried out and why Page 17 of 35 14. why it is important to check that fit tolerances are met 15. levels of fitting fault that can be made good and when to reject and report a fault 16. functions and uses of the different types of equipment used in assembly Page 18 of 35 PROFFI15 - First fit mechanical or electrical components to furniture Overview This standard covers the skills and knowledge required to first fit mechanical or electrical components to furniture. This includes: 1 assembling components 2 fitting components 3 quality assuring components You will be required to fit a range of mechanical, electrical and electronic components. Electrical installations can be divided into first, second and third fixes: 1. First Fix: Positioning and securing of accessory boxes 2. Second Fix: Preparation and positioning of cables 3. Third Fix: Termination of conductors to accessories and protective devices This standard is aimed at operatives in the furniture and furnishings industry. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up correctly and in good working order following standard operating procedures and any manufacturer’s instructions check all materials required are to specification and free from faults following standard operating procedures follow instructions, assembly drawings and any other specifications following standard operating procedures ensure specified components are available and they are in a usable condition following standard operating procedures assemble components in position following manufacturers’ instructions and standard operating procedures secure components following manufacturers instructions and standard operating procedures check completed assembly to ensure all operations have been completed and finished assembly meets specification following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order Page 19 of 35 5. 6. 7. 8. 9. 10. 11. 12. how to check materials and the common faults that can occur purpose and function of components including identification systems, colour codes and manufacturer's specification preparations that need to be undertaken on components prior to fitting assembly and securing methods and procedures used, and the importance of adhering to them quality control procedures to be followed during the fitting and assembly operation how to conduct necessary checks to ensure the accuracy, position, security, function, completeness and electrical continuity of the assembly types of problems that can occur and the standard operating procedures for dealing with them information systems that should be used and why it is important to record information Page 20 of 35 PROFFI16 - Re-instate locations after furniture installation Overview This standard covers the skills and knowledge required to re-instate a location after furniture installation. This involves: 1. interpreting information 2. confirming the end of placement 3. ensuring all resources are cleared 4. maintaining customer liaison Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. comply with health and safety requirements and procedures at all times confirm specifications have been completed following standard operating procedures check installations are to required quality in the specification check decorative effects are to the required quality and fixed following standard operating procedures deal with problems that occur following standard operating procedures maintain effective communication with customers complete work in the required time following standard operating procedures complete documentation following standard operating procedures confirm tools and items of equipment leave locations clear all debris and other waste materials from locations ensure mains services are re-instated following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. standard operating procedures and how to apply these relevant health and safety responsibilities why it is important to check specifications have been completed and how to do this why it is important to check and confirm quality of installations and how to do this why it is important to check all decorative effects and their fixings and how to do this problems that can occur and how to dealt with them how to provide information clearly to customers information customers require and why it is important importance of time schedules in assembly how to store tools and equipment safely how to organise for tools and equipment to leave locations methods to clear debris and other waste items safely from locations how to co-ordinate re-instatement of mains services documentation required Page 21 of 35 PROFFI18 - Prepare specifications for furniture to be assembled Overview This standard covers the skills and knowledge required to prepare specifications for assembly of fitted furniture in its final location. This involves: 1. interpreting information 2. evaluating what is involved 3. preparing specifications 4. specifying methods, techniques, tools, materials to be used 5. working in ways that ensure your own and other’s safety Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the work following standard operating procedures assess types, qualities and quantities of material resources needed to meet requirements assess skill and knowledge base needed to carry out assemblies identify tools and equipment needed to meet requirements following standard operating procedures estimate time needed to achieve requirements check availability of required personnel, time, resources, tools and equipment identify suitable alternatives where requirements cannot be met in full identify any problems which arise from requirements and report to appropriate person agree options to be followed where choices are possible in meeting requirements specify outcome qualities which must be met following standard operating procedures specify measurements and tolerances following standard operating procedures use appropriate technical terms in the specification specify processes, methods and techniques to achieve required results following standard operating procedures specify appropriate tools and equipment for work following standard operating procedures detail type and quality of resources to be used following standard operating procedures detail allowed time for each stage of process and overall deadlines within which it must be completed following standard operating procedures include examples to provide accurate specification of finished requirements following standard operating procedures record specifications following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. steps, techniques, timings, skills, materials, tools and equipment needed to conduct furniture assembly/placement different types of skills and knowledge needed to carry out different processes within furniture assembly/placement Page 22 of 35 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. handling characteristics of different species of wood and of wood composites used how these affect their use for different types of assembly identification and growth characteristics of different species of timber and its importance to tensile and compression strength, seasoning, durability, degradation, infestation and density typical time requirements for furniture assembly in location why it is important to check availability of different sorts of resources before committing to a piece of work constraints that can arise and why these might interfere with meeting requirements who to report problems to if you cannot solve them personal responsibilities with regard to health and safety conventions used in preparing work specifications and specifying measurements and tolerances for furniture assembly terminology used within furniture assembly uses of different methods, techniques and processes involved different materials used within furniture assembly, what they are used for, and why uses and descriptions of fixings, fittings and other attachments used in furniture assembly and in placement of furniture in location why it is of value to include examples when describing finishes and outcomes to be achieved personal protective equipment worn when handling different sorts of materials and using different types of tools and equipment, and why Page 23 of 35 PROFFI20 - Secure furniture components in complex locations Overview This standard covers the skills and knowledge required to secure furniture components in complex locations. This involves: 1. interpreting complex information 2. selecting materials, components and equipment for complex installations 3. preparing and installing proprietary and/or purpose made furniture components for domestic, commercial, industrial and public environments 4. working on complex, new, alteration or refurbishment contracts 5. working in ways that ensure your own and others’ safety Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. comply with health and safety requirements and procedures at all times obtain specifications and requirements of the items to be produced following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up and in good working order following standard operating procedures and manufacturer’s instructions check materials required are to specification and free from faults carry out treatment and repairs to background surfaces following standard operating procedures confirm locations are ready and preparations have been completed assess any unforeseen features and identify how these might affect placements following standard operating procedures mark out locations taking into account any problems identified following standard operating procedures adjust components and their placement to provide best possible fit following standard operating procedures select components as specified for each location and confirm quality meets company standards deal safely and effectively with any problems and faults during placements following standard operating procedures minimise risk of damage to components/workpieces and surrounding areas following standard operating procedures maintain effective communication with supporting personnel and customers following produce templates following standard operating procedures produce joints between components following standard operating procedures cut, shape, trim and scribe components to fit and align to specification following standard operating procedures fit components in logical and safe sequence to specification adjust components to ensure joints and alignments between components, furniture and surrounds are to required tolerances level and secure components in location to specification check decorative features are aligned in position to specification finish components including cleaning, wiping glue joints, staining to specification complete work within required time following standard operating procedures Page 24 of 35 24. complete documentation following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur how to interpret work plans or specifications including drawings why it is important to protect work areas procedures to follow to confirm preparations are complete how to mark out and scribe uneven surfaces whilst maintaining level, plumb or alignment of components how to mark out joints between components how to determine angles at locations features of assemblies affected by location of components fixings used to secure placement of components handling characteristics of components and how these affect assembly and fitting of components in location how to check completed work against specifications or drawings or plans measurements required for production of templates and cut outs handling characteristics of natural timber, wood composites and sheet material and how these affect the assembly and fitting of components in location working characteristics of natural timber, wood composites, glass, stainless steel and how these affect assembly and fitting of components in location how to cut materials to scribed outlines and internal /external curves fixing sequencing of components in location fixings required for securing components in location how to adjust alignment and movement of components how to measure alignment in three dimensions how to provide information clearly to customers, type of information customers require, and why it could be important to them timescales specified for work documentation required how to dispose of waste in accordance with current legislation Page 25 of 35 PROFFI22 - Quality assure and co-ordinate furniture placements Overview This standard covers the skills and knowledge required to co-ordinate and assure the quality of furniture placements and installations. This involves: 1 interpreting information 2 co-ordinating furniture placements and installations 3 confirming quality 4 maintaining customer liaison 5 working in ways that ensure your own and others’ safety Performance criteria You must be able to: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 comply with health and safety requirements and procedures at all times obtain specifications and requirements for placements following standard operating procedures obtain equipment and materials required to carry out the job following standard operating procedures check equipment is set up and in good working order following standard operating procedures and manufacturer’s instructions check materials required are to specification and free from faults confirm work areas are ready for placements and preparations have been completed inform and co-ordinate mains service providers following standard operating procedures check required components and materials are at specified locations pre-assess any unforeseen features of assemblies which may affect how placements can be achieved safely check placements are proceeding as required in specifications deal safely and effectively with any problems that may occur during placement maintain effective communication with customers following standard operating procedures specify outcome qualities which need to be met monitor furniture placements following standard operating procedures confirm quality standards have been met on completion of installation complete work within required time following standard operating procedures complete required documentation following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. standard operating procedures and how to apply these relevant health and safety responsibilities meaning of terms used in specifications how to check equipment is set up and is in good working order how to check materials and the common faults that can occur how to interpret work specifications including drawings why it is important to complete preparations how and when it is necessary to inform mains service providers Page 26 of 35 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. features of assemblies affected by location of placement why it is important to check all material and components are at location problems that can occur and how would they be dealt with ways to co-ordinate furniture placements why it is important to prepare work areas how to provide information clearly to customers, type of information customers require and why it could be important to them methods of monitoring installations and how to apply them how to check completed work against specifications or drawings and the importance of this faults that occur and how to deal with them methods used to confirm quality of furniture placements Page 27 of 35 PROGEN08 - Maintain tools and equipment Overview This standard covers the skills and knowledge required to maintain tools and equipment. It covers: 1. 2. 3. carrying out routine maintenance checking the condition of tools and equipment arranging for repair or replacement when required Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. comply with health and safety requirements and procedures at all times check tools and equipment are in working order on a regular basis oil and grease tools and equipment to prevent them being damaged and to maintain their effectiveness keep tools and equipment clean and free from dust and debris test the condition of tools and equipment so they are appropriate for use identify components, tools and equipment that are damaged and remove them for repair identify any components, tools or equipment which are beyond repair arrange for repair or replacement of faulty tools or equipment following standard operating procedures check tools and equipment are stored safely when not in use wear the appropriate personal protective equipment for the work you are carrying out Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. standard operating procedures and how to apply these relevant health and safety responsibilities tools and equipment used what to look for when checking the condition of tools or equipment and the implications of not keeping tools or equipment maintained and free of dust and debris hazards that can arise from defective and faulty tools or equipment how often to oil and grease tools and equipment and what sorts of oils or greases to use how to calculate the consumption of materials and components why it is important to store tools and equipment properly how to test tools or equipment for performance accuracy damage that can occur and including damage that can be repaired as well as damage that cannot be repaired what to look for when assessing the condition of tools or equipment and what needs to be done to bring them into a working state how to arrange for repair or replacement how to recognise tools or equipment that are damaged and need more than routine maintenance to bring them into working condition Page 28 of 35 PROGEN18 - Solve problems in the workplace Overview The standard covers the skills and knowledge required to solve problems. You will need to Identify issues quickly, solve problems and apply appropriate solutions. It covers: 1. identifying problems 2. carrying out problem solving activity 3. rectifying problems Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. comply with health and safety requirements and procedures at all times diagnose problems and keep relevant people informed of progress following standard operating procedures obtain relevant information relating to the problems following standard operating procedures evaluate problems and possible solutions following standard operating procedures identify nature and extent of problems following company procedures consult with relevant people about the extent of problems and impact on activity select appropriate solutions to rectify problems monitor outcomes and make revisions to plans of action communicate proposed solutions to relevant people and obtain feedback ensure problems are rectified to the agreed level of acceptability ensure information is documented to provide an audit trail following standard operating procedures implement preventive measures to ensure that there is no recurrence of problems following standard operating procedures ensure that the rectification complies with all relevant regulations and guidelines implement preventive measures to ensure that there is no recurrence of problems following standard operating procedures recognise any difficulties and correct them, report difficulties outside your control to the appropriate person following standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. standard operating procedures and how to apply these relevant health and safety responsibilities implications of not taking account of legislation, regulations, standards and guidelines when determining solutions how to access and use appropriate information and documentation systems how to obtain and interpret drawings, charts, specifications, manufacturers’ manuals, history/maintenance reports and other documents needed in the problem solving process business needs for problem identification and removal effects of problems on associated activities communication techniques used to obtain information how to involve users/customers in the problem solving process Page 29 of 35 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. importance of collecting as much relevant information as possible and collating in a way which facilitates decision making importance of analysing problems from a variety of perspectives how to define and verify root causes of problems importance of involving a range of relevant people in generating possible solutions importance of developing a range of possible options in solving problems factors to be taken into account when resolving problems and determining suitable solutions methods and techniques for evaluating information and how to apply these how to present possible solutions in a way which helps relevant people to reach an informed and realistic judgement process used in the organisation to validate the solution to the problem how to prevent recurrence of problems importance of maintaining records of the problem solving activities and what needs to be recorded Page 30 of 35 PROGEN19 - Maintain quality standards Overview This standard covers the skills and knowledge required to maintain quality standards. It covers the quality standards which apply to products and how to check that these have been met. Reading and interpreting specifications, drawings, cutting lists and other relevant technical information used within your organisation. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. comply with health and safety requirements and procedures at all times check quality criteria has been met for products produced following organisational procedures complete production records following standard operating procedures comply with work instructions and legal requirements complete work to the required quality and output levels in accordance with production schedules and targets, work instructions and legal requirements pass on completed work to the next stage in line with work instructions and organisation procedures, quality standards and throughput rate identify problems with materials and/or equipment and correct or report to appropriate person identify any damaged or faulty products and record or report them in line with your work instructions Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. standard operating procedures and how to apply these relevant health and safety responsibilities quality criteria used for different types of products and processes quality assurance methods available quality assurance processes, who is involved and who is accountable for these why quality assurance is important to the organisation and impact of not meeting quality standards recommendations that could emerge from quality assurance processes your responsibilities for quality assurance where to find and how to follow technical specifications for the work you are carrying out meaning of terms used in technical specifications organisation standards and industry standards for products you are producing and how to apply these tolerances for products you are producing how to determine the resources that are necessary to meet specifications relevant regulations and guidelines for your work and how to apply these Page 31 of 35 PROGEN20 - Comply with health and safety requirements in the workplace Overview This standard covers the skills and knowledge needed to conduct your day to day work in a healthy and safe way and that you are competent in following emergency procedures for your workplace. This involves: 1. workplace health and safety policies 2. legal and workplace environmental procedures 3. maintaining your own and other’s safety while working Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. comply with health and safety requirements and procedures at all times comply with approved workplace practices for your job role ensure personal conduct in the workplace does not endanger health and safety of yourself and others follow workplace practices and suppliers/manufacturer’s instructions for safe use of equipment, materials and products report any differences between workplace practices and suppliers/ manufacturer’s instructions to responsible/ appropriate person work safely at all times, complying with all rules and regulations take action to minimise risk of personal injury if an emergency should occur Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. legal duties for health and safety in the workplace health and safety legislation covering your job role workplace practices for job role and why it is important to follow them why it is important to comply with health and safety requirements and work safely why it is important to follow workplace practices and suppliers/manufacturer’s instructions in the workplace who to report differences between workplace practices and suppliers/ manufacturers written instructions why it is important to ensure your personal conduct does not endanger yourself and or others emergency procedures in your workplace why it is important to work safely at all times methods of raising alarms if an emergency should occur in the workplace when it may be necessary for you to find and inform a responsible and/or appropriate person of emergencies ways of minimising risk of personal injury why it is important to follow the emergency procedure promptly, calmly and correctly Page 32 of 35 PROGEN21 - Apply techniques for continuous improvement in the workplace Overview This standard covers the skills and knowledge required to apply techniques to give continuous improvement (Kaizen) to work activities. It involves analysing work methods before and after actions in order to set quantifiable goals and targets for planned improvement procedures. Any activity carried out will consist of identification of all forms of waste, problems or issues within work area where improvements can be made. It is necessary to concentrate on improvements which could give benefits to the organisation such as safety, reduced costs of product, quality, working practices and procedures and reduction of waste. Improving standard working procedures is an important part of this standard and you will be required to create and be a factor in such improvements. These could include things such as cleaning and maintenance of equipment, health and safety procedures, manufacturing operations and improvements to quality processes. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. comply with health and safety requirements and procedures at all times utilise values and procedures of Kaizen activity contribute to identification and planning of measurable objectives and goals when planning Kaizen activity identify areas where improvements can be made initiate Kaizen activity within identified and agreed work area or procedure initiate a controlled waste eradication activity based on identified problems or conditions assist with creation and updating of standard operating procedures (SOPS) resulting from Kaizen activity, identify and calculate measures of performance for cost, quality and delivery document and explain business improvement using key performance indicators confirm improvements by contrasting process before and after Kaizen activity work out and visually symbolise resources based on customer demand Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. relevant health and safety responsibilities and obligations and procedures that need to be followed how a work area or activity is chosen to undergo the Kaizen activity background, values and principles for use of Kaizen the eight wastes and how they can be eliminated problem solving and root cause analysis how to carry out problem solving activity how a Kaizen activity should be carried out how to differentiate between fact and opinion in order to identify improvement actions how to utilise knowledge and experience of stakeholders involved in processes how improvements can be made to procedures within the workplace how to assess ideas to improve processes and select those that could be of use Page 33 of 35 12. 13. 14. 15. 16. 17. 18. 19. 20. how to set and recommend measurable aims and objectives how to generate or bring up to date Standard Operating Procedures (SOPs) how to communicate recognised changes due to implementation of Kaizen activities to stakeholders within processes business key measures of competitiveness and how to apply them how cycle time of processes can be defined how to calculate required production rates for processes by using calculations including Takt Time how to calculate optimum resources such as equipment, facilities, people and materials required for a process based on customer demand techniques used to distribute work content to balance cycle times to rate of customer demand and how to visually represent them relevant people to advise and update to ensure problems and issues can be settled Page 34 of 35 PROGEN23 - Transport and handle installation equipment and materials Overview This standard covers the safe transportation and handling of installation equipment and materials. The correct type and quantity of installation equipment and materials have to be located and then transported so that they arrive at the location of the installation in good order. They have to be stored at the installation site, handled and then positioned for use. Performance criteria You must be able to: 1. 2. 3. 4. 5. 6. 7. 8. comply with health and safety requirements, relevant statutory regulations and industry standards/codes of practice at all times select equipment and materials according to requirements of installations load equipment and materials in a way that safely balances their weight, doesn’t exceed safe working load of vehicles and ensures their protection during transit transport equipment and materials by using suitable transportation methods to deliver them to locations according to agreed schedules handle equipment and materials by using suitable handling methods to prevent damage to them, individuals, product and surrounding environment position equipment and materials according to standard operating procedures store equipment and materials = following standard operating procedures identify any problems and deal with them according to standard operating procedures Knowledge and understanding You need to know and understand: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. relevant health and safety requirements, relevant statutory regulations and industry standards/codes of practice that have to be complied with types of equipment and materials that need to be transported and handled identification markings for materials how to load different types of equipment and materials transportation methods used for different types of equipment and materials safe working loads of vehicles handling methods used for different types of equipment and materials damage that can occur as a result of handling equipment and materials incorrectly how different types of equipment and materials should be positioned for handling and installation problems that can occur during transportation and handling of equipment and materials and standard operating procedures for dealing with them Page 35 of 35