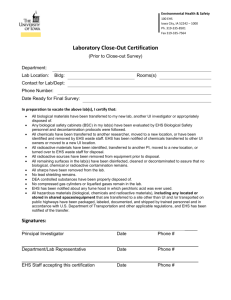

DownloadEnvironment Health & Safety Manual

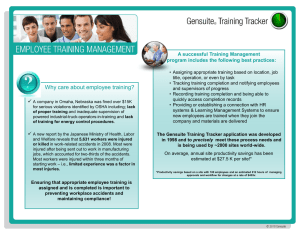

advertisement