1.2 Yeast Products

advertisement

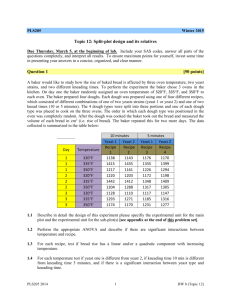

1.2 Yeast Products Yeast breads are divided into two categories, lean doughs and rich doughs. Lean dough are made with flour, yeast, and water. Breads made from lean dough tend to have a chewy texture and a crisp crust. French bread and hard rolls are examples of lean doughs. Rich doughs are made with the addition of shortening or tenderizing ingredients such as sugars, syrups, butter, eggs, · and cream. When these ingredients are introduced, they change the bread's overall texture, as well as the way the dough is handled. Rich doughs should have a cake-like texture after baking. Parker House rolls, cloverleaf rolls, soft rolls, and Danish are examples of rich doughs. Mixing methods: The straight mix method and the sponge method are the most common methods used to mix yeast breads. The straight mix method and the sponge method are the most common methods used to mix yeast breads. The straight mix method can be used for all types of doughs lean, rich, and sponge. When using the straight-mix method to mix dough, all ingredients can be combined at the same time. A starter, which is a mixture of flour, yeast, sugar, and a warm liquid, is used to make sure the yeast is alive and to give the yeast a “kick start.” After mixing the dough, it must be kneaded until it is elastic and smooth. To knead (NEED) dough is important because it develops the gluten in the dough, and gives the dough the ''stretch" and "give" it needs to develop the proper texture. Like the straight mix method, the sponge method is also used to mix yeast batters. The first stage of this method involves mixing the yeast, liquid, and half of the flour to make a thick batter called a sponge. After the sponge rises and doubles its size, the remaining fat, salt, sugar, and flour are added. The dough is kneaded and left to rise. Breads made with the sponge method have a lighter texture and more unique flavor than breads made using the straight dough method. Once the dough is in the pan, it must be proofed, or allowed to rise a second time. Proofing, the final rise of the yeast product before baking, should be between 95°F and 115°F (warm room). The product should continue proofing until it is about twice its original size and bounces back when lightly touched. Scoring and proofing provides not only a decorative crust, but it also affects the texture too. Desired Effect Type of wash Water Egg white and water Whole egg and water Whole egg and milk milk Once the product is placed in the oven, it will rise quickly. Oven spring is the sudden and quick rise of the product as the heat from the oven causes gases in the product to grow and expand. The doneness of a baked good is determined by its color, size, and the sound it makes when thumped with a finger (it should make a deep, hollow sound). After cooling, breads can either be sliced immediately or stored. Most breads can be held for a short time on parchment lined trays or in baskets. For longer storage, wrap cooled bread in plastic wrap. Most yeast breads can be frozen for longer storage. After they have hawed, reheat breads before service. Some items, such as hard rolls and Italian bread that are made from lean doughs, can stale quickly. These items can be reheated in convection ovens before service to maintain their quality. 12 Basic steps in making Yeast breads. 1. Scaling All ingredients must be measured accurately. 2. Starter …is a mixture of flour, yeast, sugar, and a warm liquid, is used to make sure the yeast is alive and to give the yeast a “kick start.” 3. kneading . During mixing, the ingredients are combined, the yeast is distributed, and the gluten is developed. The dough is kneaded to develop the gluten, until the dough is smooth and elastic. This will influence the texture and “chew” of the bread. 4. Fermentation. 5. Punching down. During fermentation, the yeast acts on sugars and starches in the dough to produce carbon dioxide and alcohol. Carbon dioxide gas gets trapped in the gluten. The dough is gently folded down to expel and redistribute gas pockets in the dough. Punching also relaxes the gluten and evens the temperature. 6. Portioning. Weigh portions on a portion scale to ensure uniform size and weight. This will affect appearance and consistency in cooking. 7. Rounding. After portioning, shape the dough into smooth, round balls. The outside layer of gluten becomes smooth. This holds in the gases and makes it easier to shape the dough. 8. Shaping. Dough can then be shaped into a variety of forms, depending on the desired type of bread. 9. Proofing. Proofing is the final rise of the shaped yeast dough just before baking. The dough is kept in a warm, draft-free area, or in a proofing box, and allowed to double in size. 10. Scoring and washing Provides a decorative and a textured crust 11. Baking. Load the ovens carefully because proofed doughs are fragile Common baking temperatures are between 400°F and 425°F A golden brown crust color normally indicates the loaves are done. 12. Cooling and storing. Loaves should be removed from their pans and placed on racks to allow air circulation. INGREDIENT FUNCTION FLOUR SALT Binds ingredients x x Absorbs liquids x x x Adds to shelf life x x x x Add structure x x x x Affects eating qualities x x x x x Add nutritional value x x x x x Affects flavor x x x x x x Affects rising x x x Affects gluten x x x x Adds texture x x x x x Colors crust x x x x x Affects shape x Affects volume x Adds tenderness SUGAR FAT MILK SOLIDS WATER YEAST x x x x x x x x x x x x x x x x x x x x