integrated safeguards datasheet - Documents & Reports

advertisement

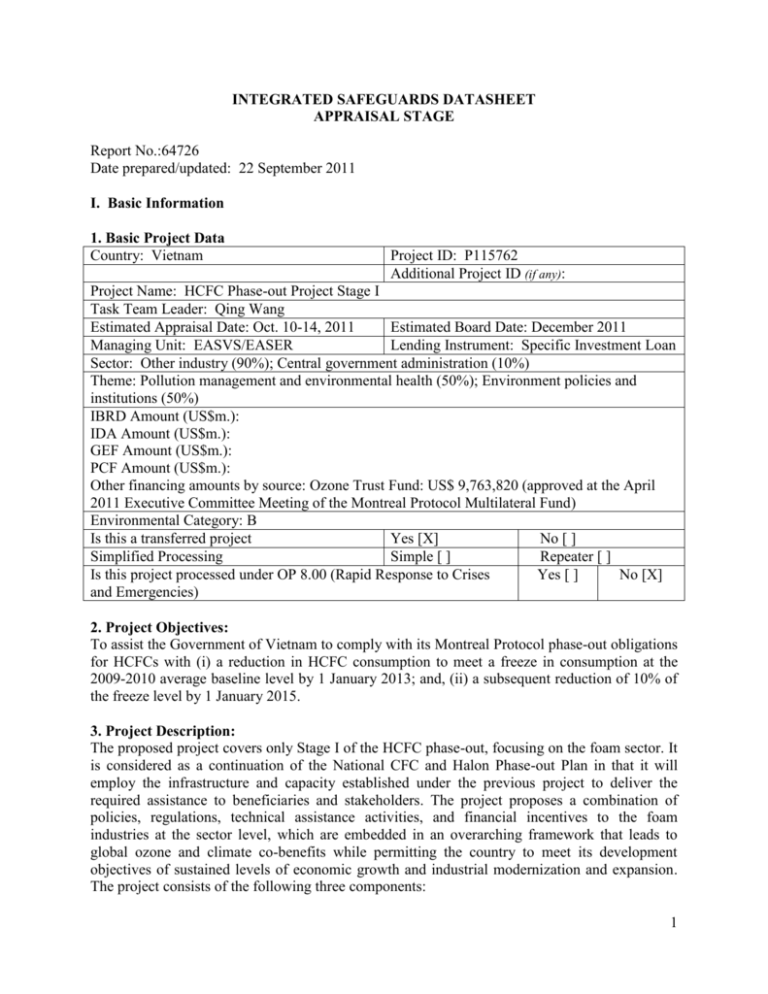

INTEGRATED SAFEGUARDS DATASHEET APPRAISAL STAGE Report No.:64726 Date prepared/updated: 22 September 2011 I. Basic Information 1. Basic Project Data Country: Vietnam Project ID: P115762 Additional Project ID (if any): Project Name: HCFC Phase-out Project Stage I Task Team Leader: Qing Wang Estimated Appraisal Date: Oct. 10-14, 2011 Estimated Board Date: December 2011 Managing Unit: EASVS/EASER Lending Instrument: Specific Investment Loan Sector: Other industry (90%); Central government administration (10%) Theme: Pollution management and environmental health (50%); Environment policies and institutions (50%) IBRD Amount (US$m.): IDA Amount (US$m.): GEF Amount (US$m.): PCF Amount (US$m.): Other financing amounts by source: Ozone Trust Fund: US$ 9,763,820 (approved at the April 2011 Executive Committee Meeting of the Montreal Protocol Multilateral Fund) Environmental Category: B Is this a transferred project Yes [X] No [ ] Simplified Processing Simple [ ] Repeater [ ] Is this project processed under OP 8.00 (Rapid Response to Crises Yes [ ] No [X] and Emergencies) 2. Project Objectives: To assist the Government of Vietnam to comply with its Montreal Protocol phase-out obligations for HCFCs with (i) a reduction in HCFC consumption to meet a freeze in consumption at the 2009-2010 average baseline level by 1 January 2013; and, (ii) a subsequent reduction of 10% of the freeze level by 1 January 2015. 3. Project Description: The proposed project covers only Stage I of the HCFC phase-out, focusing on the foam sector. It is considered as a continuation of the National CFC and Halon Phase-out Plan in that it will employ the infrastructure and capacity established under the previous project to deliver the required assistance to beneficiaries and stakeholders. The project proposes a combination of policies, regulations, technical assistance activities, and financial incentives to the foam industries at the sector level, which are embedded in an overarching framework that leads to global ozone and climate co-benefits while permitting the country to meet its development objectives of sustained levels of economic growth and industrial modernization and expansion. The project consists of the following three components: 1 Component 1: Investment in HCFC-141b Consumption Phaseout (MLF US$ 8,876,200) This component will consist of a series of investment activities (mainly procurement of equipment) at twelve foam producers. In response to Decision XIX/6 which requires that climate impacts be taken into account when phasing out HCFCs, the project will promote the adoption of hydrocarbon technology in the foam sector, except in the manufacturing of integral skin shoe sole, where water blown (CO2) system was found as the most cost-effective conversion method. In this regard, an analysis of eligible incremental capital and operating costs for each enterprise has been conducted on the basis of a conversion cost structure relevant to hydrocarbon/water blown (CO2) technology and subsequently approved by the Multilateral Fund Executive Committee. Component 2: Supporting Policies and Regulations and Technical Assistance Activities (MLF US$ 355,048) It is proposed that an import quota system to curb the supply of HCFCs be established and operational by 2012. This is critical for ensuring sustainable phase-out of HCFCs. A ban on the establishment of new or the expansion of existing HCFC-141b-based manufacturing facilities (including the use of HCFC in pre-blended polyol) starting in 2012 has been put into place during preparation. In addition, a total ban on the use of bulk HCFC-141b in the foam sector will be put in place by January 1, 2015. Technical assistance (TA) activities to support implementation of investment interventions, awareness campaigns on the need to phase out HCFCs and on future regulatory measures to eliminate HCFC use will be carried out with target groups. Capacity building of customs officers will be carried out in order to ensure effective control of import of HCFCs and products containing HCFCs. Training activities will be conducted to increase the technical capacity of local authorities to allow them to become more effective agents in identification and delivery of needed assistance to foam enterprises in their localities. TA activities in the residential air conditioning (RAC) manufacturing and servicing sectors will also be undertaken to control the demand of HCFC-22, although there will be no phase-out investment activities to be financed by the MLF under the project. Component 3: Project Management (MLF US$ 532,572) The project management unit (PMU), set up under the National CFC and Halon Phase-out Plan, will continue to be financed to implement and coordinate new project implementation and to assist MONRE to put into place both overarching regulations and sector specific policies. 4. Project Location and salient physical characteristics relevant to the safeguard analysis: The project covers 12 foam enterprises. They are located in Hanoi, Da Nang, HCM City and Long An, Binh Phuoc and Ba Ria Provinces. Six enterprises (6M, Huu Nghi, Searee Danang, TST, Vietrust, Hoa Phat) are located in industrial areas and four (Saigon, Searefico, Glory Tabi) in residential areas. The four enterprises in the residential area have intentions to move to industrial areas before or during the project implementation stage expected to take place in late 2 2011 or 2012. These enterprises’ lands have been acquired from the IZ Management Bodies for at least three years already. A due diligence review on land acquisition was carried out during project preparation by reviewing red books, purchasing/renting contracts for plots of land and site visits to five enterprises and confirmed that there are not any legacies or outstanding issues regarding the land acquired or occupied. One other enterprise (Thanh Canh) is located in a rural area; on land the company purchased in 2007. Thanh Canh is to build a new and larger factory on the same site where the local government has decided to turn the rural area into an industrial zone. The remaining enterprise (Minh Dieu) is located in a residential area but relocation to an IZ is not needed because the HCFC alternative technology that will be applied in this case does not have safety issues as would be the case for HC technology. 5. Environmental and Social Safeguards Specialists on the Team: Douglas J. Graham Thuy Cam Duong Nguyen Van Trung 75790 390844 14108 Environmental Specialist Environmental Specialist Social Safeguard Specialist EASVS Consultant Consultant 3 6. Safeguard Policies Triggered (please explain why) Environmental Assessment (OP/BP 4.01) Yes X No The project will have a positive impact on the global environment by reducing the use of HCFCs, which are ozone-depleting substances and greenhouse gases with a global warming potential (GWP) ranging from several hundred to several thousand times that of CO2. While HCFCs have an impact on the global environment, they have no adverse local impact as these chemicals are stable and not considered toxic or otherwise dangerous for the environment. As described in more detail in Section II, minor environmental impacts could result from mishandling of some of the chemicals that are already used in foam production and which will be used to replace HCFCs. The manufacturing process also involves potential occupational and health safety issues. Therefore, OP 4.01 is triggered under the project. Natural Habitats (OP/BP 4.04) X The project will be implemented in industrial areas (except one enterprise in residential area), thus there is no impacts on natural habitat. Forests (OP/BP 4.36) X The policy is not triggered since there is no proposed investment involving forest harvesting or forest management. Pest Management (OP 4.09) X The policy is not triggered as the project does not involve the procurement or use of any pesticides or herbicides. Physical Cultural Resources (OP/BP 4.11) The policy is not triggered as the project area does not have any impact on any PCR. Indigenous Peoples (OP/BP 4.10) X X The policy is not triggered since no ethnic minority communities are present in or have collective attachment to the project area. Involuntary Resettlement (OP/BP 4.12) X All of the enterprises involved are either located on private land which they own or they are located on (or will move to) established industrial zones. A due diligence review of land issues for all 12 enterprises was carried out by the World Bank and confirmed that there are not any legacies or outstanding issues regarding the land acquired or occupied. Therefore, the policy is not triggered. Safety of Dams (OP/BP 4.37) The policy is not triggered since there is no construction or rehabilitation of dams or dykes. Projects on International Waterways (OP/BP 7.50) The policy is not triggered as the project does not have any impact on any international waterway. Projects in Disputed Areas (OP/BP 7.60) The policy is not triggered as the project is not located in any disputed areas. X X X 4 II. Key Safeguard Policy Issues and Their Management A. Summary of Key Safeguard Issues 1. Describe any safeguard issues and impacts associated with the proposed project. Identify and describe any potential large scale, significant and/or irreversible impacts: There are no large-scale, significant and/or irreversible impacts caused by the project or caused by foam production. The following texts describe small-scale (and easily mitigable) impacts. Hydrocarbon and CO2 have been selected as blowing agents to replace HCFC-141b that is being used in the foam sector. Hydrocarbon has a Global Warming Potential of less than 25. Hydrocarbon (cyclopentane) is classified as a Volatile Organic Compound (VOC), but its use results in very low levels of emissions of about 2-3% of the blowing agent, which results in minuscule emissions, compared for example, to emissions from two-stroke motorcycle traffic in urban areas. Therefore, there is no significant environmental impact from the cyclo-pentane itself. The other chemicals involved in foam production are MDI, polyol, amine catalysts and fire retardants. The 12 foam enterprises purchase pre-formulated polyol (blended with or without HCFC-141b) and polymeric MDI (isocyanates) for their rigid foam production. The probability that a spill of polymeric MDI - a liquid at room temperature - contaminates the soil and water is very low, because the floor of the foam production areas consists of cement coated with an antileakage, low permeability/chemical layer such as epoxy. In the case that MDI leaks into the soil, it will react with moisture, and the reaction would result in CO2 and insoluble polyurea compounds, which are not biodegradable but chemically inert. MDI may cause health impacts such as eye, respiratory system and skin irritation. Exposure via skin contact and inhalation can result in respiratory sensitisation. Fire retardant and amine catalysts (very limited amount) are mixed/pre-formulated in the polyol at the system houses (pre-blended polyol suppliers), from which the foam enterprises purchase pre-blended polyol and MDI, so the foam enterprises will not handle these toxic chemicals directly. Fire retardant and amine catalysts will remain in the final foam products and are not likely to be emitted to the environment during the foam production or later. Therefore, there are no anticipated legacy environmental contamination issues that are associated with foam production. Methylene chloride is the cleaning agent now used in the foam production process. It can affect the body if it is inhaled or if the liquid comes in contact with eyes or skin or is swallowed. Methylene chloride can be a hazardous waste but only when present in large quantities and high concentrations, as defined in Vietnamese regulations. However, only small quantities are used in foam production and the mixing heads for the new cyclopentane based foaming units to be purchased under the project will facilitate the phase-out of the use of methylene chloride as a cleaning agent. There are minor environmental and OHS risks associated with inappropriate handling of the various foam production chemicals or which could be caused by spills. The project itself will not result in any additional impacts or risks as all these chemicals are already in use at the plants. Nevertheless, good operational procedures and mitigation measures must be in effect at all facilities supported by the project. 5 As a result of new processes and chemicals introduced by the project, there are however additional safety requirements regarding fire and explosion risks associated with the adoption of the hydrocarbon (cyclopentane) technology during the foam production process. Finally, there is non-hazardous solid waste generated during foam production process which needs to be adequately disposed of. 2. Describe any potential indirect and/or long-term impacts due to anticipated future activities in the project area: There are no indirect, cumulative, or long-term impacts caused by the project. 3. Describe any project alternatives (if relevant) considered to help avoid or minimize adverse impacts: The technology choices for Phase 1 are well proven and robust, which would be feasible from a technical or economic point of view. And they are all “low” GWP options. Continuing with the use of HCFCs is not an option for Vietnam due to its obligations under the Montreal Protocol. 4. Describe measures taken by the borrower to address safeguard policy issues. Provide an assessment of borrower capacity to plan and implement the measures described: An Environmental Management Plan (EMP) has been prepared by the Borrower to guide foam enterprises to address all of the issues noted above relating to environmental or OHS risks. The EMP was prepared following relevant national legal documents, the Bank’s OP 4.01 and The World Bank Group OHS guidelines. The World Bank has reviewed and found acceptable the EMP. Some of the most typical mitigation measures are the following: - Proper design and construction of foam workshop and proper chemical storage - Good practice of chemical handling; specifically, careful cyclopentane handling to avoid uncontrolled reactions and conditions resulting in fire and explosion and careful MDI handling to avoid inhalation and skin contact resulting in eye, respiratory system and skin irritation and respiratory sensitisation - Communication and training workers about the potential risks - Preparation of appropriate emergency preparedness and response measures - Use of proper labor safety devices - Using of efficient and adequate extraction ventilation - Conduction of safety audit at each foam production workshop before foam production start-up - Putting in place appropriate measures for solid waste collection as per legal requirements of the Government of Vietnam Each participating enterprise in the project will be legally required to follow the environmental and safety provisions of the EMP. The EMP describes the measures that will be taken by the project implementing agency, the Ministry of Environment and Natural Resources, to monitor compliance and to ensure enforcement. 6 The World Bank has evaluated the capacity of both MONRE, the implementing agency and that of the foam production companies, each of which has been visited by technical specialists. The project management unit falls under the National Ozone Unit set up in MONRE. This Unit has been implementing for almost 5 years a similar project, the CFCs and Halon Phase-out Project, so they are very familiar with relevant World Bank and GoV requirements. Their capacity has been evaluated and appropriate training on safeguards has been carried out under the CFCs Project. The foam production companies have good operational procedures in place and are in compliance with good-practice occupational, health and safety measures as well as with environmental requirements. However, before most project financing is released to these companies, an audit of the production facility will be carried out and they will also be legally required to follow the OHS and environmental requirements of the EMP. The project will support training and capacity building for the foam enterprises in these areas. 5. Identify the key stakeholders and describe the mechanisms for consultation and disclosure on safeguard policies, with an emphasis on potentially affected people: Because there are no likely impacts of the foam production enterprises that extend beyond the plant itself, the stakeholders from an environmental perspective are the enterprises themselves and their labor force. The EMP has been disclosed in Vietnamese and in English in the Vietnam Development Information Centre (VDIC) and in English in the Bank InfoShop before appraisal. B. Disclosure Requirements Date Environmental Assessment/Audit/Management Plan/Other: EMP Was the document disclosed prior to appraisal? Date of receipt by the Bank Date of "in-country" disclosure Date of submission to InfoShop For category A projects, date of distributing the Executive Summary of the EA to the Executive Directors Resettlement Action Plan/Framework/Policy Process: N/A Was the document disclosed prior to appraisal? Date of receipt by the Bank Date of "in-country" disclosure Date of submission to InfoShop Indigenous Peoples Plan/Planning Framework: N/A Was the document disclosed prior to appraisal? Date of receipt by the Bank Date of "in-country" disclosure Date of submission to InfoShop Pest Management Plan: N/A Was the document disclosed prior to appraisal? Date of receipt by the Bank Yes 9/19/2011 9/23/2011 in English; 9/27/2011 in Vietnamese 9/23/2011 7 Date of "in-country" disclosure Date of submission to InfoShop * If the project triggers the Pest Management and/or Physical Cultural Resources policies, the respective issues are to be addressed and disclosed as part of the Environmental Assessment/Audit/or EMP. If in-country disclosure of any of the above documents is not expected, please explain why: C. Compliance Monitoring Indicators at the Corporate Level (to be filled in when the ISDS is finalized by the project decision meeting) OP/BP 4.01 - Environment Assessment Does the project require a stand-alone EA (including EMP) report? If yes, then did the Regional Environment Unit or Sector Manager (SM) review and approve the EA report? Are the cost and the accountabilities for the EMP incorporated in the credit/loan? OP/BP 4.04 - Natural Habitats Would the project result in any significant conversion or degradation of critical natural habitats? If the project would result in significant conversion or degradation of other (non-critical) natural habitats, does the project include mitigation measures acceptable to the Bank? OP 4.09 - Pest Management Does the EA adequately address the pest management issues? Is a separate PMP required? If yes, has the PMP been reviewed and approved by a safeguards specialist or Sector Manager? Are PMP requirements included in project design? If yes, does the project team include a Pest Management Specialist? OP/BP 4.11 – Physical Cultural Resources Does the EA include adequate measures related to cultural property? Does the credit/loan incorporate mechanisms to mitigate the potential adverse impacts on physical cultural resources? OP/BP 4.10 - Indigenous Peoples Has a separate Indigenous Peoples Plan/Planning Framework (as appropriate) been prepared in consultation with affected Indigenous Peoples? Yes [X] No [ ] N/A [ ] As a transferred project, the SM reviewed and approved the EMP. Yes, financing for EMP accountabilities are included in the financing agreement to be signed with each participating enterprise. Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] 8 If yes, then did the Regional unit responsible for safeguards or Sector Manager review the plan? If the whole project is designed to benefit IP, has the design been reviewed and approved by the Regional Social Development Unit? OP/BP 4.12 - Involuntary Resettlement Has a resettlement plan/abbreviated plan/policy framework/process framework (as appropriate) been prepared? If yes, then did the Regional unit responsible for safeguards or Sector Manager review and approve the plan/policy framework/process framework? OP/BP 4.36 – Forests Has the sector-wide analysis of policy and institutional issues and constraints been carried out? Does the project design include satisfactory measures to overcome these constraints? Does the project finance commercial harvesting, and if so, does it include provisions for certification system? OP/BP 4.37 - Safety of Dams Have dam safety plans been prepared? Have the TORs as well as composition for the independent Panel of Experts (POE) been reviewed and approved by the Bank? Has an Emergency Preparedness Plan (EPP) been prepared and arrangements been made for public awareness and training? OP/BP 7.50 - Projects on International Waterways Have the other riparians been notified of the project? If the project falls under one of the exceptions to the notification requirement, has this been cleared with the Legal Department, and the memo to the RVP prepared and sent? What are the reasons for the exception? Please explain: Has the RVP approved such an exception? OP/BP 7.60 - Projects in Disputed Areas Has the memo conveying all pertinent information on the international aspects of the project, including the procedures to be followed, and the recommendations for dealing with the issue, been prepared Does the PAD/MOP include the standard disclaimer referred to in the OP? The World Bank Policy on Disclosure of Information Have relevant safeguard policies documents been sent to the World Bank's Infoshop? Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [ ] No [ ] N/A [X] Yes [X] No [ ] N/A [ ] N/A 9 Have relevant documents been disclosed in-country in a public place in a form and language that are understandable and accessible to project-affected groups and local NGOs? All Safeguard Policies Have satisfactory calendar, budget and clear institutional responsibilities been prepared for the implementation of measures related to safeguard policies? Have costs related to safeguard policy measures been included in the project cost? Does the Monitoring and Evaluation system of the project include the monitoring of safeguard impacts and measures related to safeguard policies? Have satisfactory implementation arrangements been agreed with the borrower and the same been adequately reflected in the project legal documents? Yes [X] No [ ] N/A [ ] D. Approvals Signed and submitted by: Task Team Leader: Environmental Specialist: Social Development Specialist Additional Environmental and/or Social Development Specialist(s): Name Qing Wang Douglas J. Graham Nguyen Van Trung Thuy Cam Duong Date 9/22/2011 9/22/2011 9/22/2011 9/22/2011 Approved by: Regional Safeguards Coordinator: Comments: Does not need to be approved by RSC as this is a transferred project. Sector Manager: Jennifer Sara Comments: 9/27/2011 10