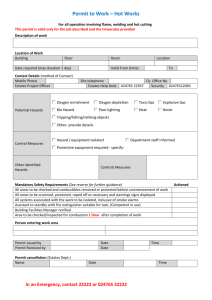

Policy and Procedure for Hot Work Permitting OBJECTIVE: To

Policy and Procedure for Hot Work Permitting

OBJECTIVE: To provide effective management to control the potential ignition hazard associated with “hot work” situations.

AUTHORITY:

INTRODUCTION:

Vice President for Administration

Hot work is defined as any temporary activity that produces sparks, heat, or flame. Examples of hot work include, but are not limited to, welding; torch cutting; grinding (with hand held grinders); soldering; brazing; torch applied roofing; etc.

Whenever possible avoid hot work in favor of other, safer methods of work. If hot work cannot be avoided, try to do it outdoors away from any combustible materials.

If hot work must be performed indoors, a permit program must be in place to properly manage the procedure and to control the possibility of fire.

Hot Work Permits are required for any hot work activities performed by anyone in any campus facility or university owned or leased property

(employees or contractors).

EXPLANATION: An active Hot Work Permit program at Concordia University Chicago is required by LCMS Risk Management and AXIS Property Insurance as part of our property loss prevention measures and risk management program.

RESPONCIBILITIES: There are three trained positions of responsibilities associated with the

Hot Work Permit program:

1.

Safety Supervisor (Campus Safety Officer or Director of Physical

Plant, Secondary Safety Supervisor)

Be a university employee.

PROCEDURE:

Has overall responsibility for proper implementation of the Hot

Work Permit program.

Issues and follows up on all Hot Work Permits.

2.

Fire Watch

Must ensure that safe conditions are maintained during hot work activities.

Has the authority to stop hot work if unsafe conditions develop.

Has a fire extinguisher readily available and shall be trained in its use.

Be familiar with the facility and procedures for sounding an alarm in the event of a fire.

3.

Hot Work Operator

Trained in the safe use of hot work equipment.

Verify that the hot work equipment is in proper and safe working condition.

Has a signed Hot Work Permit prior to starting any hot work activities.

Hot Work Permitting

1.

The Hot Work Operator requests a Hot Work Permit from the Safety

Supervisor.

2.

Prior to beginning any hot work activity, the work area will be inspected by the Safety Supervisor using the permit check list to ensure that all recommended precautions are being followed as applicable. The Safety Supervisor checks off each applicable precaution and records the date and time that the permit will expire.

Note: All Hot Work Permits shall expire within a single shift or 8 hours. If work continues beyond this time frame, a new permit shall be issued.

3.

Upon satisfactory inspection of the hot work area, the Safety

Supervisor will assign a Fire Watch and they will sign the permit indicating that precautions on the check list have been taken and permission has been authorized to start the work. The Safety

Supervisor will issue the Hot Work Permit to the Hot Work Operator.

Upon receiving the Hot Work Permit the Hot Work Operator will notify Security, at extension “O”, that hot work will take place at

location of work and the number of the Hot Work Permit.

4.

The Operator must display the permit in the hot work area until completion of the work.

5.

The Fire Watch will be provided for the duration of the hot work and for at least 30 minutes after work ceases. The Safety Supervisor may extend the fire watch past the 30 minutes if he feels that conditions warrant it.

Note: A relief fire watch will be provided for breaks and lunch.

Contractors are responsible for supplying their own fire watch.

6.

When the fire watch has been completed, the permit must be returned to the Safety Supervisor, who will complete a final inspection of the hot work area to ensure that it is safe and fire free.

He will then complete the final sign off and notify Security, at extension “O”, that the hot work is complete and the number of the

Hot Work Permit.

7.

All completed Hot Work Permits shall be maintained by the Safety

Supervisor in a file for at least one year.

Off-shift Emergencies:

ADOPTED: 10/20/2010

If a hot work situation comes up on off-shift hours or week-ends, it must be determined if it can wait to be done on regular work hours or if it is an emergency that needs to be done as soon as possible. If it is determined to be an emergency the Director of Physical Plant will contact the appropriate employee(s) or vendor(s) needed to come to the campus to do the emergency repairs. Hot Work Permit(s) will be issued at that time and a Fire Watch will be assigned.

Latest Review: 10/10/2013

Note: The Fire Watch will have a fire extinguisher at the work site and know how to use it in the event of a fire. The Fire Watch is authorized to halt work if precautions are not being met or not being followed or if circumstances change.