Supporting information_revised

Supporting information for

Top-gate zinc tin oxide thin-film transistors with high bias and environmental stress stability

M. Fakhri, M. Theisen, A. Behrendt,

P. Görrn, T. Riedl

Institute of Electronic Devices, University of Wuppertal, Wuppertal, 42119, Germany

The environmental stability of top-gate thin-film transistors (TFTs) with Al

2

O

3

/ZrO

2 dielectric is crucially affected by the choice of the oxidizing agent during deposition of ZrO

2

.

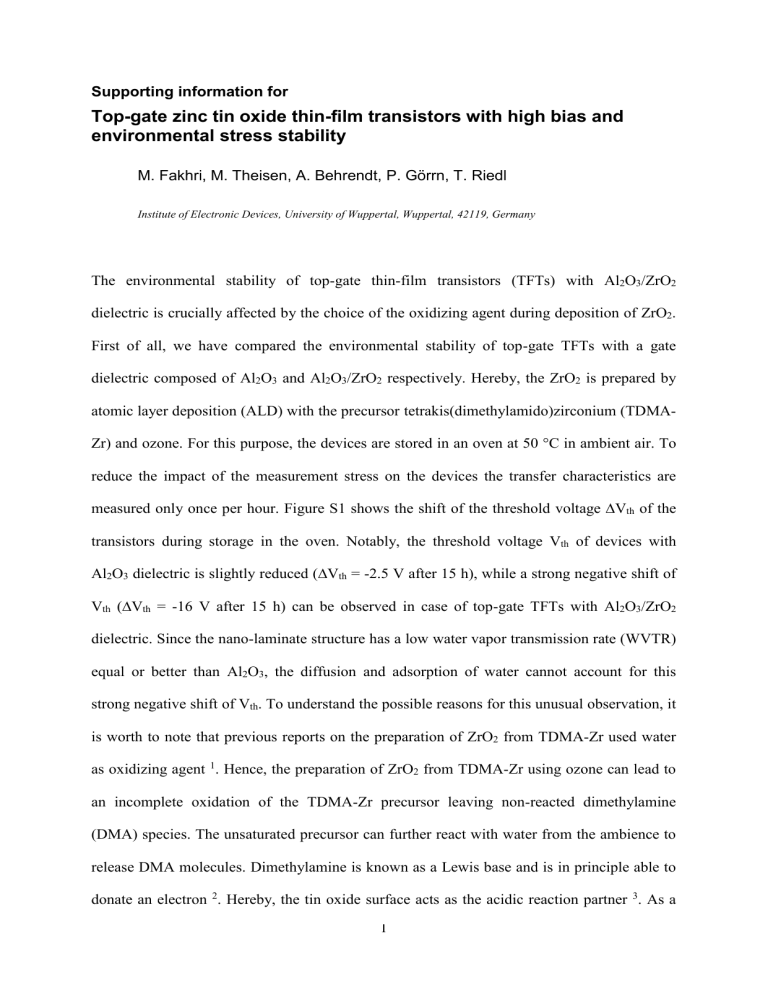

First of all, we have compared the environmental stability of top-gate TFTs with a gate dielectric composed of Al

2

O

3

and Al

2

O

3

/ZrO

2

respectively. Hereby, the ZrO

2

is prepared by atomic layer deposition (ALD) with the precursor tetrakis(dimethylamido)zirconium (TDMA-

Zr) and ozone. For this purpose, the devices are stored in an oven at 50 °C in ambient air. To reduce the impact of the measurement stress on the devices the transfer characteristics are measured only once per hour. Figure S1 shows the shift of the threshold voltage ∆V th

of the transistors during storage in the oven. Notably, the threshold voltage V th

of devices with

Al

2

O

3

dielectric is slightly reduced (∆V th

= -2.5 V after 15 h), while a strong negative shift of

V th

(∆V th

= -16 V after 15 h) can be observed in case of top-gate TFTs with Al

2

O

3

/ZrO

2 dielectric. Since the nano-laminate structure has a low water vapor transmission rate (WVTR) equal or better than Al

2

O

3

, the diffusion and adsorption of water cannot account for this strong negative shift of V th

. To understand the possible reasons for this unusual observation, it is worth to note that previous reports on the preparation of ZrO

2

from TDMA-Zr used water as oxidizing agent

1

. Hence, the preparation of ZrO

2

from TDMA-Zr using ozone can lead to an incomplete oxidation of the TDMA-Zr precursor leaving non-reacted dimethylamine

(DMA) species. The unsaturated precursor can further react with water from the ambience to release DMA molecules. Dimethylamine is known as a Lewis base and is in principle able to donate an electron

2

. Hereby, the tin oxide surface acts as the acidic reaction partner

3

. As a

1

consequence upon DMA adsorption on the zinc-tin-oxide (ZTO) semiconductor surface the channel becomes more electron rich and V th

of the TFT concomitantly is reduced. The incomplete reaction of the TDMA-Zr in ZrO

2

from TDMA-Zr/ozone can be confirmed by investigating the relative permittivity

r

of the resulting dielectric. Table SI gives an overview of

r

for Al

2

O

3

and ZrO

2

prepared with ALD based on both water and ozone as oxidizing agent. As a reference, typical values of these dielectrics are extracted from literature

4

.

Remarkably, Al

2

O

3

reveals an

r

= 6 - 7 close to the literature value independent of the choice of the oxidizing agent. However, the slightly lower value for

r

of Al

2

O

3

can be attributed to the low processing temperature of 80 °C resulting in layers with reduced density

5

. In case of

ZrO

2

a significant impact of the oxidizing agent on

r

is observed. While we find

r

= 22 when water is used as oxidizing agent,

r

= 10 is obtained for ZrO

2

layer produced with ozone. In fact, this hints to a significantly lowered layer density and the presence of a significant amount of not fully reacted precursor species. To take these findings into account, we have prepared top gate TFTs with a hybrid nano-laminate Al

2

O

3

/ZrO

2

where we have used water as oxidizing agent to produce the ZrO

2 sub-layers. As the nano-laminate starts with a 10 nm thick Al

2

O

3

layer produced with trimethylaluminium (TMA)/ozone this layer already functions as barrier that suppresses any unwanted interaction of the metal-organic precursor

TDMA-Zr with the zinc-tin-oxide semiconductor

6

. The resulting stability of these TFTs is discussed in the main part of the paper.

Furthermore, we have demonstrated the environmental stability of top-gate TFTs with a hybrid nano-laminate Al

2

O

3

/ZrO

2

gate dielectric. Thereby, the V th

of the devices is monitored during storage at 50 °C. Figure S2 shows the shift of V th

during storage in air (open symbols) as well as in vacuum (p = 10

-3

mbar) (solid symbols) at 50 °C. In view of the similar value of

∆V th

obtained in both experiments in air and vacuum, an intrinsic mechanism (independent from the surrounding atmosphere) must account for the shift of the threshold voltage.

2

Commonly, this effect is attributed to thermally generated charge carrier during storage at elevated temperatures

7

.

Notably, the break-down electric field of the nano-laminate with water as oxidizing agent is higher (4.5 MV/cm) than the nano-laminate with ZrO

2

produced with ozone as oxidizing agent (2.6 MV/cm). The difference in the break-down field may be explained by the inferior layer quality (e.g. lower density as reflected in the substantially lower

r

) of the ZrO

2

sublayers when prepared with ozone as oxidizing agent compared to that based on water. In either case, the corresponding break-down voltages (52 V and 90 V) are significantly higher than the typical operation voltage of our devices (V

GS

= 10V).

3

FIGURES

0

-5

-10

-15

Al

2

O

3

Al

2

O

3

/ZrO

2

-20

0 5 10 15 20 t [h]

FIG. S1. Shift of threshold voltage ∆V th

of TFTs during storage in an oven at 50 °C. Devices with an Al

2

O

3

top-gate dielectric are represented by triangular symbols and devices with a nano-laminate Al

2

O

3

/ZrO

2

by squared symbols. Both dielectrics are prepared by ALD with ozone as oxidizing agent.

0.0

-0.1

-0.2

-0.3

TG-TFT (in air)

TG-TFT (in vacuum)

0 2 4 6 8 10 12 14 time [h]

FIG. S2. Shift of the threshold voltage ∆V th

of top-gate (TG) TFTs with a hybrid nanolaminate gate dielectric Al

2

O

3

/ZrO

2 composed of Al

2

O

3

from TMA/ozone and ZrO

2

from TDMA-Zr/water gate dielectric during storage in an oven in ambient air at 50 °C (solid symbols). In addition, ∆V th

of these devices in vacuum (p = 10 -3 mbar) at 50 °C is depicted by open symbols.

4

10

0

10

-3

10

-6

E break-down

E break-down

10

-9

Al

2

O

3

/ZrO

2

(ZrO

2

w. H

2

O)

Al

2

O

3

/ZrO

2

(ZrO

2

w. O

3

)

10

-12

0 20 40 60 80 100

V [V]

FIG. S3. Leakage current density of the nano-laminate gate dielectric with ZrO

2

produced with water or ozone as oxidizing agent. The breakdown electric field for the nano-laminate with ZrO

2

produced with water as oxidizing agent is E break-down

=

4.5 MV/cm and ozone as oxidizing agent is E break-down

= 2.6 MV/cm.

3

bottom-gate (non-encapsulated)

bottom-gate (encapsulated)

top-gate

2

1

0

0 5 10 15 20 25 time [h]

FIG. S4. Change of mobility ∆µ sat

of investigated devices during storage in an oven at 50 °C (air). The top-gate TFT with a hybrid nano-laminate Al

2

O

3

/ZrO

2

composed of Al

2

O

3

from TMA/ozone and ZrO

2

from TDMA-Zr/water is represented by star symbols. A reference bottom-gate TFT with a typical encapsulation with Al

2

O

3

is denoted by solid rectangular symbols.

The effect of the encapsulation can be judged by comparing with a bottom-gate TFT without encapsulation (open rectangular symbols).

5

3

2

1

0

-1

-2

BG-TFT (non-encapsulated, air)

BG-TFT (encapsulated)

TG-TFT

-3

0 1000 2000 3000 4000 5000 time [s]

FIG. S5. Change of mobility ∆µ sat

of top-gate TFTs during positive bias stress (star symbols). The stress conditions are V

GS

= 10 V and V

DS

= 15 V. The gate dielectric consists of a nano-laminate Al

2

O

3

/ZrO

2

composed of Al

2

O

3

from TMA/ozone and ZrO

2

from TDMA-Zr/water. As a reference, ∆µ sat

of Al

2

O

3

encapsulated bottom-gate TFTs is illustrated by solid rectangular symbols and of non-encapsulated bottom-gate TFT by open rectangular symbols, respectively.

TABLES

4

5

2

3

7

6