STD/1460

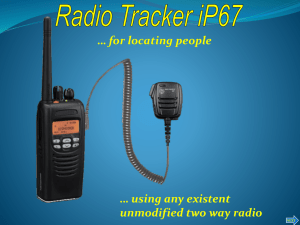

advertisement