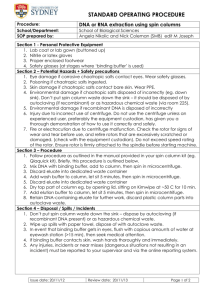

SOP BAL-001 - Biotech Virtual Mentors

advertisement