Process mineralogy of copper and lead concentrates and MLA data

advertisement

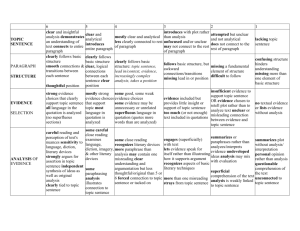

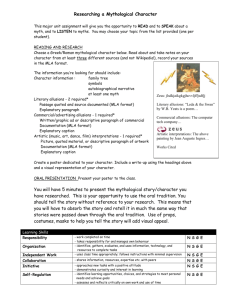

ABSTRACT Process mineralogy of copper and lead concentrates and MLA data calibration Emilie Ré, Agnico Eagle Mines, QC, Canada Raphaël Mermillod-Blondin, Agnico Eagle Mines, QC, Canada Hassan Bouzahzah, Unité de Recherche et de Service en Technologie Minérale, Université du Québec en AbitibiTémiscamingue, QC, Canada Jean-François Wilhelmy, COREM, QC, Canada Mostafa Benzaazoua, Université du Québec en Abitibi-Témiscamingue, QC, Canada Two copper and lead concentrates from the LaRonde mill were analyzed using MLA technology (Mineral Liberation Analyzer) to identify the contaminants and to quantify their size distribution and liberation. The MLA mineral quantification was compared with traditional mineralogical techniques (Scanning Electron Microscopy, Optical Microscopy, X-Ray Diffraction and Chemistry). The reliability of the MLA data was then assessed (minerals identification, minerals quantification, particles sizing and liberation quantification). Different well-known materials were prepared from pure minerals and analyzed with the MLA. MLA concentrates analyses have shown that lead concentrate is mainly contaminated by pyrite and sphalerite. These minerals are liberated above 70 % and at a floatable size around 15 to 35 µm (Figure 1). Surface activation by dissolved lead from galena is therefore assumed for these contaminants. Figure 1 – 3D diagram presenting pyrite iron content versus liberation and size of the particles The use of standard samples showed that mineral quantification and size distribution given by the MLA are consistent with chemical and laser particle sizer analyses. Investigation led to conclude that the MLA liberation measurement is biased by the stereological effect. The resulting overestimation was confirmed by modeling (Figure 2). Figure 2 – Liberation frequency of standard material (black) by MLA (blue) and modeling (red) The MLA characterization emphasizes the source of contamination in the LaRonde copper and lead concentrates which is linked to liberated and size-floatable sulfides. Understanding of the liberation overestimation by the MLA, based on the analyses of standard samples, enabled to shift our processing issues cause identification from a surface chemistry problem to a potential liberation problem. Calibrating and including ore texture and stereological bias in the MLA data interpretation should lead to improved results. KEYWORDS Quantitative mineralogy, MLA, liberation, standards, stereology, chalcopyrite, galena