Electrical System Inspection Criteria

advertisement

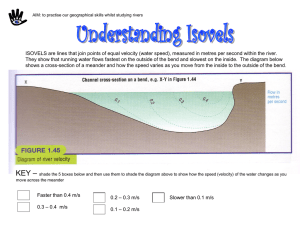

APPENDIX – A Section 1. Maintenance and Repair Work. It is agreed that the jurisdiction of ILA mechanics or whichever craft historically has this jurisdiction shall cover the maintenance and repair of equipment (which term includes containers and chassis) and such equipment as its members have historically maintained and which is owned, controlled, operated, or interchanged by USMX members and/or owned, financed or organizations with which USMX members are associated with (eg. OCEMA) including, but not limited to (a) container cranes, (b) container handling equipment and (c) container cranes (d) Rubber Tire Gantry Cranes, (e) Straddle Carriers, (f) Yard Hustlers, (g) Top Loaders, (h) empty handlers, (i) stick cranes, (j) fork lifts, (k) terminal vehicles, (l) pay loaders, (m) snow removal equipment, (n) sweepers, (o) bomb carts/trailer trains equipment which are acquired for all deep-sea terminal and or off pier facilities; tire work shall be maintained and repaired by ILA mechanics. The ILA’s jurisdiction remains in effect at waterfront container facilities and/or off-pier premises used for servicing and repair of equipment covered by this Master Contract in accordance with the Containerization Agreement. Further, all said equipment, be it owned, leased or controlled by USMX members and/or signatories to the Master Contact, etc., once it is presented at waterfront facilities, shall be covered by this Master Contract. Furthermore, it is recognized that the marine terminal work of all ILA crafts has been traditionally performed on piers and waterfront facilities. When such marine terminal work is moved off the marine terminal by the terminal operator or by a signatory carrier to an offsite facility the ILA shall retain its work jurisdiction, where the work is the work that would have been performed in the marine terminal or port area in accordance with the terms and conditions of Article VII, Section 8, “Marine Terminal Work”. All general maintenance and repair work performed under initial equipment warranties and guarantees’ shall require a minimum of 2 ILA mechanics being trained, or whatever manning is required to maintain the full complement of equipment involved. A copy of all warranty / guarantee documentation will be furnished to the local ILA union with that jurisdiction and repair equipment and manuals shall be provided by the management. Any and all equipment used to diagnose, monitor, track, and or repair, any equipment used in operational support of Marine terminal work, shall be operated and repaired by the ILA. All necessary training to preform these duties shall be provided by management. Section 2. Major Damaged Equipment. Damaged equipment must be repaired in the port where the damage is discovered. Thereafter, it shall also report the time, place and nature of the repairs performed by ILA labor in that respective ILA port. Such notification shall be subject to the audit procedures. In fulfilling the above objectives, it is agreed that: 1 (a) (b) (c) (d) (e) (f) (g) (h) (i) (j) (k) (l) No damaged equipment shall be loaded aboard ship for export No employer or carrier shall permit damaged equipment to leave the compound except under the procedures provided herein. The employers and carriers shall not enter into any leasing agreement that circumvents the work jurisdiction of the ILA covered under this Master Contract. There will be a minimum of one (1) TIR employee per lane. Any changes to the manner in which the TIR inspections are performed, either by written form, computer, scanner, or other methodology, will be discussed with the Union prior to implementation. No such changes will be implemented without the mutual consent of the parties. T.I.R. inspections must be performed in every instance where an intermodal container and/or chassis are entering or leaving a Port, and or, off pier facility. All owner operated equipment, with the exception of Tractor Trailer/Truck, must be inspected to insure roadworthiness before a USMX signatory box/Container is mounted. If driver refuses the required inspection, for purposes of public safety, then the ILA shall refuse to mount a container(s). A mandatory roadability T.I.R. inspection must be performed on every inport move leaving a terminal or related facility. Any unit presented at a Marine terminal, and or, an ILA off pier facility, requires an ILA TIR inspection. Any damage identified must be repaired by an ILA facility All FHWA inspections will be performed by I.L.A. mechanics in complete conformance with Federal law and regulations. In order to perform a proper inspection, the container and/or box should be off the chassis. “Sale boxes or Sale Containers/Chassis” must be repaired, and prefixes and numbers must be removed before being terminated and/or sold. ILA shall retain work jurisdiction on all equipment associated with the movement of signatories’ equipment by rail or other transportation methods. All work deemed dangerous by the ILA Safety Department shall have a minimum of 2 ILA mechanics working together at all time, or whatever manning is negotiated at the local level, with the concurrence of the Safety Department, or whichever is greater. All steam cleaning on said equipment shall be performed by ILA mechanics. COMPONENT 2 CONDITION/DESCRIPTION RAIL INSPECTION: All rails, including side rails, headers and sills Holed, cut, torn or cracked; broken component and/or weld Top and bottom rails Bent or dent within 10 in of a corner fitting Front headers and flat-bar side rails Any deformation such as bend, bow, dent, holes,etc. if more than 1 in. deep Box-section top side rails Any deformation such as bend, bow, dent, holes,etc. if more that 1-3/6 in. deep Rear headers Any deformation such as bend, bow, dent, etc. if more than 1-3/8 in. deep Rain gutters Any deformation such as bend, bow, dent, etc. if door operation, or securement, is impaired Bottom side rails, front & door sills Any deformation such as bend, bow, dent, etc. if more than 2 in. deep Door headers and sills POST INSPECTION: All corner posts, including J-bars Interference with door closure, securement and/or weather tightness Holed, cut or torn; broken component and/or weld Missing or loose parts or fasteners All corner posts, front and rear Any single deformation such as bend, bow, bent,etc. two (2) or more dents on a single post if more than 1in or inside crack Rear corner posts Any deformation causing interference with door Operation, securement or water tightness J-bars 3 Any deformation such as bend, bow, dent, etc. that impairs doors from opening fully or locking SIDE/FRONT PANEL INSPECTION: Interior panel liners Holes, cut, torn, cracked or broken; missing or loose Fasteners Ventilator covers Broken, missing, if damage exceeds 3/8 in. DOOR INSPECTION: Door assembly, including hardware Holed, cut,torn or cracked; broken component and/or Weld. Missing or loose parts. Seized, frozen , rusted or Stiff. Lack of water tightness Door panels Any deformation such as bend, bow, dent,holes, etc if more 1 3/8 in. deep. Any bow involving the length or height of a panel if internal dimensions are reduced more than 2 in. Door gaskets Loose or missing. Cut, torn, cracked or burned if not light tight and water tight ROOF INSPECTION: Roof panels, header extension plates, corner protection plates and roof bows Holed, cut, torn or cracked; broken componet and/or weld. Missing or loose parts or fastners Roof bows Any deformation such as bend, bow, dent, etc. if more than 2 in. Corner protection plates and header extension plates Any deformation such as bend, bow, dent, etc. if internal dimensions are reduced by more than 2 in. All roof panels Open Tops/tarps Any deformation such as bend, dent, etc. if more than 1 3/8 in. on any corrugation, inboard or outboard 4 Any deformation such as a hole, cut, and/or missing bars. FLOOR INSPECTION: Floor, including threshold Plate and center spacer Holed if light leaks. Light leakage gaps between boards Plank flooring Cracked or split Threshold plate Bent upwards if more than 3/16 in. UNDERSTRUCTURE: Crossmembers, forklift Pocket components (including straps), outriggers and Gooseneck tunnel components Holed, torn, cut or cracked; broken component and/or weld. Missing or loose parts or fastners. Any deformation such as bend, bow, dent, etc. if more than 2 in. Any deformation such as bend, bow, dent, etc. on bottom flange. Any on top flange if more than 2 in. Gooseneck tunnel assembly and Any deformation such as bend, bow, dent, etc. if more forklift pocket top plate than 2 in. MISCELLANEOUS: Lashing fittings Markings required by regulations, international standard Broken parts and/or welds; missing or loose parts or fastners. Bent if more than 2 in. Missing, loose or defaced Marking plates Loose, broken, missing plate or fasteners; illegible data Corner fittings and their weld attachments Cracked, loose, broken; apertures outside ISO dimensional tolerances Clean outs Hangar beams, and any type of debris 5 CHASSIS DAMAGE CRITERIA Brake System Inspection Criteria Component Service brakes Parking brakes Condition Absence of braking action on any axle required to have brakes upon application of service brakes; missing brake Absence of braking action on vehicle or combination upon actuation of parking brake control, (including driveline hand-controlled parking brakes) Missing, loose, bent, broken or frozen All mechanical brake system components, including shoes, lining, pads, springs, anchor pins, spiders, cam shaft rollers, push rods, air chambers and all mounting or support brackets and fasteners Gladhands Cracked, broken or leaking; Twisted, turned or loose; Clogged leaking or non-functional; Any audible leak; cracked or damaged by heat Gladhand gaskets Cut, torn, cracked or burned; missing Antilock brake system ABS malfunction indictor lamp remaining illumination over 5 seconds, or illuminated at any time while chassis is moving at road speed; ABS malfunction indicator lamp does not operate during a bulb check, bulb or lens broken Crimped, collapsed or broken; cut or torn; clogged, leaking or non-functional; Any audible leak; Cracked or damaged by heat Excessive abrasion or kinking; Cut or torn; Clogged, leaking or non-functional; cracked, broken or crimped; Damage extending through outer reinforcement ply; Bulge or swelling when air pressure is applied; Any audible leak; two hoses improperly joined Cracked or broken; clogged, leaking or non-functional Air line tubing Air hoses Relay valve Air reservoir tank Air brake chamber/spring brake Cut, torn or punctured; Leaking or broken mounting; loose mounting fasteners Non-functional; audible air leak; severe corrosion Slack adjusters Cracked, broken or non-functional; Seized, broken or stiff Brake linings or pads Excessive or uneven wear(If lining thickness is less than ¼ inch at the shoe center; cracked or chipped in the vertical direction at the lining edges; Cracked or chipped in the horizontal direction, if crack is EITHER more than 1/16 in wide OR more than 1 ½ in long; lining or pad not firmly attached to shoe; saturated with oil, grease or fluid; Lining separated from shoe by more than 1/16 in. Brake drum or rotors Brakes (readjustment) External cracks that open upon brake application and deep scoring; Any portion missing or in danger of falling away Any brake ¼ inch or more past readjustment limit, or any two brakes on the same vehicle that exceed the readjustment limit by any amount Electrical System Inspection Criteria Component Receptacle (7-way plug) Clearance, marker, tail, stop and license plate lamp bulbs, lenses and assemblies Reflectors Condition Missing or loose parts or fasteners; Any bend or distortion of pins; broken pins or insulation; faulty ground; corroded; exposed wiring connections Inoperable or missing; broken or cracked; inadequate illumination; moisture accumulation Missing, broken, chipped or cracked through Wiring Short circuit; Bare, cut or frayed insulation; dangling loose All lighting devices and reflectors required by 49 CFR 393 Inoperable or missing Landing Gear Inspection Criteria Component All landing gear components Landing leg brace (diagonal or cross brace) Landing legs Gear box Condition Missing or loose parts or fasteners; Holed, cut or torn; Cracked or broken weld. *Landing leg upper tube cannot be re-welded to the landing leg mounting plate. It must be replaced. Any deformation such as bend, bow, dent, ect. Cracked or kinked Uneven height; Out of alignment; Any deformation such as bend, bow, dent, ect. Inoperable in high, low or both gears Cross shaft Any deformation such as bend, bow, dent, ect. Crank handle Any deformation such as bend, bow, dent, ect. Crank handle retainer Any deformation such as bend, bow, dent, ect. Sand shoes (or wheels) Any deformation such as bend, bow, dent, ect. Sand shoe axle Seized; ability of sand shoe to swivel is impaired Securing devices (safety devices), including twistlocks, locking pins, twistlock collars, springs, twistlock handles and handle retainers (ALL locking devices must be operable) retainers or springs Missing component, handles, retainers or unattached, inoperable or incapable of securing attachment; Cracked or broken components or welds; Seized or frozen; Any deformation such as bend, bow, dent ect. Bent handles which are not operational and/or which protrude beyond envelope of chassis when in locked position Miscellaneous System Inspection Criteria Component Coupling devices; pintle hook assembly (integrity) Coupling devices; pintle hook assembly (mounting to frame) Coupling devices; frame crossmember providing pintle hook attachment All conspicuity markings required by 49 cfr 393 Coated surfaces Condition Cracks; any welds repairs to pintle hook; any part of pintle hook horn section reduced by more than 20%; latch insecure Missing or ineffective fasteners; Mounting surfaces cracks extending from point of attachment; loose mounting Cracked, broken weld Missing Burns due to heat or other contamination due to contact with foreign substances; Uncoated and/or corroded Owner’s and identification markings Missing, defaced or illegible Foreign markings Present Registration holder Holed, cut, torn, non-watertight or missing; distorted Registration Expired, invalid, illegible or missing License plate mounting Any cut, tear, bend or broken weld License plate Expired, invalid, ineligible or missing Safe loading; any part of If loading permits tire, load or vehicle, such as tire carrier mounting, or any part of load Slider Assemblies Inspection Criteria Component Adjustable axle assemblies (sliding subframes or sliding tandems) – all components Slider frame Locking (indexing) pins Indexing holes Stops Safety devices, including locking pins, indexing holes and stops Condition Missing, unengaged or loose parts or fasteners, including locking pins Cut, torn, cracked or broken; Any deformation such as bend, Bow, dent, ect. Cracked, chipped or broken; Any deformation such as bend, Bow, dent, ect. Elongation; Cracked or deformed around perimeter of hole Cracked or broken, distorted or worn out; cracked or broken weld Missing or cannot be engaged; Unattached or incapable of attachment Structure Inspection Criteria Component All mainframe components, including crossmembers Kingpin Upper coupler Main rails, main rail gussets Bolsters, bolster gussets Crossmembers Crossmember gusset Underride protection (ICC bumper) Light box Mud flaps Mud flap bracket Condition Missing or loose parts or fasteners; Cracked, broken, loose or sagging; Any condition, including loading, that causes frame or body to be in contact with a tire or any part of wheel assembly Cracked, chipped or distorted movement in any direction; distortion or unusual wear that affects operation; Worn beyond wear limits Cut or broken welds; Cut, torn or cracked component; uneven wear, dished, bulged or distorted upwards; Blockage of drain holes; severe corrosion Cracked or broken welds; Cut or torn component; Any deformation such as bend, bow, dent, ect.; Elongation of hole in web for passage of landing leg shaft Cracked or broken welds; Cut or torn component; Any deformation such as bend, bow, dent, ect.; Severe corrosion Cut or torn; Cracked or broken weld; Any deformation such as bend, bow, dent, ect.; Severe corrosion Cut Component; Cracked or broken weld Cut Component; Cracked or broken weld; Missing (if provided originally) or partially removed; Any deformation such as bend, bow, dent, ect. Torn, bent or severe corrosion; loose, cracked Holed, cut or torn; Marking other than owner’s; loose or missing fasteners; improper length Cut or torn; Cracked or broken welds; Any deformation such as bend, bow, dent, ect. Dock bumpers Missing Suspension Inspection Criteria Component Condition Springs Distorted; Broken Spring hangers and equalizer Inoperable; Worn bushings; any deformation such as bend, bow, dent, ect. Cracked, broken, loose or missing; severe corrosion Any spring hanger or other axelpositioning parts Seats and U-bolts Leaf spring assembly Torque, radius or tracking components or any part used for attaching same to vehicle frame or axle Cracked, broken, loose or missing Any broken main leaf; any leaves broken or missing; One or more leaves displaced in a manner that could result in contact with a tire, rim, brake drum or frame Cracked, broken, loose or missing Tire Inspection Criteria Component Tires Condition Tire is flat or has noticeable leak ; Body ply or belt material is exposed through tread or sidewall; Tread depth is 2/32 inch or less measured at any point on a major tread groove; Any tread or sidewall separation; Any cut on sidewall or tread where ply or belt material is exposed; regrooving damage; visible blisters or knots; severe weather checking; blown out or missing tire; any tread variation in excess of 3/32 inch between the average tread depth and a flat spot; Any mismatched tire with a height variance more than 7/16 inch between adjacent tires; any abnormal or uneven wear resulting in a tread variance more than 5/32 inch; mixing of bias ply and radial tires on the same axel; contact of side walls of adjacent tires; Over or under-inflated per manufacturer’s specification; Mounted or inflated so that it comes into contact with any part of vehicle; Any tire marked “not for highway use” or words of similar meaning; Weight carried exceeds tire load limit due to under-inflation Missing or broken Valve caps Valve stems Rim Spacer Pinched, crushed or unable to be sealed by valve cap; clogged Improper parts; cracked or broken; warped or distorted; elongated bolt holes; any welded repair, or any significant deformation, such as bend, bow, dent, etc. on a rim flange which impairs integrity of tire Distorted or crushed; Improper tire clearance Rim stops / valve locators Missing or rewelded Rims or rim base Wheel Group Inspection Criteria Component Condition All Wheel Group Components Loose or missing parts or fasteners Lock or side rings Bent, broken, cracked or sprung; Improperly seated; Mismatched rings Cracked or broken; Elongated bolt holes Wheels Fasteners Welds attaching disc to rim Broken, missing, cracked, stripped, loose or otherwise ineffective; bent or mismatched Cracked Welds attaching tubeless demountable rim to adapter Hub caps (oil) Cracked Inner hub (oil seals) Low fluid level; evidence of leakage; contaminated oil Hub caps (grease) Cut, torn, cracked or broken; leaking grease; contaminated grease Cracked, pitted or worn Bearings or cones Cut, torn, cracked or broken, leaking oil, low oil level All deadline chassis must have deadlining reason clearly stated on the TIR and the unit tagged before the carrier will accept it as a deadline. Refrigerated Units When a refrigerated container cannot operate to carry refrigerated cargo due to a mechanical failure, the ILA shall retain its jurisdiction to repair such failures. The ILA shall have jurisdiction of the installation, maintaining, operating, monitoring and commissioning of all GPS, remote monitoring and all other similar devices. REEFER COMPONENTS AND DAMAGES ELECTRICAL Component Effect of Damage 440v power plug loss of power unit will not run 440v power cable loss of power unit will not run 25 amp circuit breaker 440v/25v low voltage transformer loss of power unit will not run loss of control power unit will not operate phase contactors compressor contactor loss of power unit will not run compressor will not run, unit will not cool evap fan contactor loss of power to fans, no cooling condenser fan contactor loss of power to fan, no cooling micro controller loss of power to heaters, evap coil will freeze, no cooling none of the components will operate relay boards loss of power, unit will not run compressor motor compressor will not run, no cooling evaporator fans motor unit will not cool condenser fan motor unit will not cool evaporator pan heaters hpco safety switch evap coil will freeze, no cooling unit reads high pressure, shuts down lpco safety switch unit reads low pressure, shuts heater contactor down LED display wire harnesses datalogger in-line modem unit runs but set point and actual temperature cannot be seen no power to components unit runs but unable to download data or upgrade software unit runs but unit unable to communicate with remote monitoring system MECHANICAL Component Effect of Damage compressor compressor seizes, unit will not cool condenser coil leak, loss of refrigerant, unit will not cool evaporator coil leak, loss of refrigerant, unit will not cool modulation valve broken valve will restrict refrigerant flow resulting in no cooling thermo expansion valve broken valve will not meter refrigerant or, restrict refrigerant, flow resulting in no cooling liquid line solenoid broken valve will restrict refrigerant flow resulting in no cooling drier clogged drier will restrict refrigerant flow resulting in no cooling receiver tank leaking tank will result in loss of cooling capacity all copper piping leak will cause loss of refrigerant resulting in no cooling, damage to other components line solenoids broken valve will restrict refrigerant flow, resulting in no cooling pressure safety valves ruptured valve will result in loss of refrigerant, resulting in no cooling STRUCTURAL Structural Effect of Damage evap fan foundation motor will be unsecured causing damage to motor, fan blade and evap coil condenser fan foundation motor will be unsecured causing damage to motor, fan blade and condenser coil compressor foundation compressor will be unsecured causing damage to compressor and copper piping evaporator access panel unit will not cool due to air leakage, unit is unsafe due to exposed fan blades condenser fan grille unit is unsafe, due to exposed fan blades control box door unit is at risk to water damage of all electrical components and micro boards control box if box is damaged all electrical components are at risk of electrical short or fire damage fresh air vent door unit will not cool due to air leakage unit is at risk to water damage of all door and panel hinges and all electrical components and latches micro boards ILA Mechanics shall perform all mechanical work to reefers, Gen-sets, etc., including but not limited to pre-trips, mounting and dismounting Gen-sets, all PM’s, quick checks, temp checks and TCIR inspection; prior to leaving terminal, all units must be pretriped. Any type of refrigerated equipment including, but not limited to, reefer container, gen-sets that is not properly functioning shall be deemed major damage.