SOA flow tube - Sergey Nizkorodov

advertisement

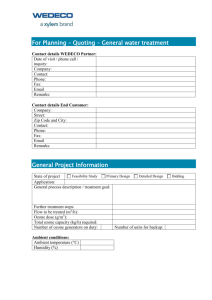

READ AND REVIEW ANY APPLICABLE MANUFACTURER/VENDOR SAFETY INFORMATION BEFORE DEVELOPING STANDARD OPERATING PROCEDURE AND PERFORMING WORK. PI Name: Sergey Nizkorodov Date Modified: February 8, 2016 Name of Work Unit: Aerosol Photochemistry Group #1 Standard Operating Procedure (SOP) for Operating Flow Tube Reactor Scope of Work/Activity: Describe the experiment purpose/scope. - Identify all apparatus that will be used, and associated requirements. List special equipment (X-ray generators, lasers, furnaces, etc.) that will be used for the project. - Identify measurement and test equipment, apparatus operating conditions, The system consists of: Pressurized oxygen gas cylinder Commercial ozone generator Purge gas generator Ozone meter Voltmeter Mass flow control box Flow tube (glass of Plexiglas depending on the version) Syringe pump Denuder Vacuum pump Test equipment needed: Flow meter to occasionally check calibration of mass flow control box. Valve 2 Notice valve locations Valve 1 This is what the system set up looks like. It does not display the mass flow control box. It is important to monitor the pressure in the system, which is displayed above the mass flow control box, to maintain 760 Torr (depending on the operation mode, it may deviate from this value but should not deviate by more than 200 Torr). Also be sure to check the moisture indicator attached to the purge gas generator to make sure only dry air is flowing. The VOC injection point should routinely be cleaned by sonication in an organic solvent. Do not vacuum pump VOCs or ozone. The denuder must be connected to the flow tube. #2 Specific Safety and Environmental Hazards: State the specific hazard and consequences if procedure not followed to person, environment, or property. Exposure to ozone can cause inflammation of the airways, leading to increased susceptibility to infections, difficulty breathing, and aggravated asthma, coughing or wheezing. Long term side effects of excessive ozone exposure can lead to diminished lung capacity, accelerated aging of the lungs, decreased lung function and other serious lung infections. #3 Describe in detail how the hazards will be controlled. a. Identify the Engineering Controls (e.g. interlocks, shielding), Standard Operating Procedures, or Personal Protective Equipment (e.g. respirators, gloves;) that will be employed to reduce hazards to acceptable levels. Active engineering controls include: Power switch on ozone generator to turn off the discharge and to stop producing ozone. Charcoal filter can be connected to airflow to prevent ozone from entering room air and preventing ozone exposure. Regulator valves located on the pressurized oxygen gas cylinder in “closed” position will not provide oxygen gas flow to the ozone generator and ozone will not be produced. Valves 1 and 2 labeled on the flow tube diagram will inhibit ozone containing air from flowing throughout the system. Switch on mass flow control box in the “off” position will stop all airflow throughout the system. Passive engineering controls include: The room has an air filtration system and if ozone is leaked it will be slowly removed. b. Address emergency shutdown procedures. Possible emergencies: exposure to high levels of ozone and increased system pressure. High levels of ozone exposure can occur IF Ozone generator is on and ozone is discharged in the room without protection by a charcoal filter. Strong “electrical” or “metallic” odor is present in the room that can cause lightheadedness or dizziness. Do the following: Turn off the ozone generator. Close all valves in the O2 supply line, and leave the room. Overpressure in the system can occur IF The tube exist is constrained with filter, plug, or other follow element with a high resistance. If this happens, one of the inlet tubes will “pop off” Do the following: #4 Close the bleeder valve on the regulator connected to the oxygen gas tank. Close all inlet valves on the flow tube diagram. Designated Area: Indicate the designated area for performing this process in the laboratory. Large table in Room 350 is the only area where the system can be operated. #5 Personal Protective Equipment (PPE): State the personal protective equipment selected and required. Examples: safety spectacles, work gloves, respiratory protection, steel toe shoes. Personal protective equipment includes: #6 Safety goggles must be worn by all people in the vicinity of the operating flow tube. Closed toe shoes must be worn by all people in the vicinity of the operating flow tube. Long sleeves must be worn by all people in the vicinity of the operating flow tube. Long hair should be tied back by the person operating the flow tube when using the vacuum pump or MOUDI. Important Steps to Follow: List the specific sequence staff should follow to avoid hazard. Refer to the instrument manual for the start up and power down procedures. A short version of these procedures is provided at the end of this document. #7 Emergency First Aid Procedures: a. Describe immediate medical treatment required in case of personnel exposure. -Complete online incident report form at www.ehs.uci.edu If someone is exposed to excessive levels of ozone: Make an appointment with a physician if the individual is experiencing symptoms of coughing, pain with breathing, and/or airway inflammation. Take the person to the emergency room if they are experiencing deep wheezing, difficulty breathing, and aggravated asthma or lung infections. If someone has been cut by glass shards then take the person to the emergency room for necessary treatment. #8 Training & Competency Requirements: Describe necessary training and demonstration of competency for performing the hazardous operation. Everyone operating the flow tube must: Pass basic laboratory safety training Pass the compressed gas cylinders safety course Read this SOP #9 Identify waste stream and disposition of unused stock of chemicals List concentrations and amounts of hazardous wastes or emissions and control measures. Additional guidelines regarding hazardous waste at : http://www.ehs.uci.edu/programs/enviro/ Ozone emissions >100 ppb are considered hazardous in working environments and EH&S should be contacted. Human symptoms begin to show when ozone levels reach ≥300 ppb. #10 Decontamination and spill clean-up procedures VOCs injected into the flow tube reactor are on the scale of µL. Chemical spills of VOC should be cleaned using Kim wipes and methanol. As the Principal Investigator, it is your responsibility to ensure that all individuals listed in this protocol is taught correct procedures for the safe handling of hazardous materials involved in this study. It is also your responsibility to assure that your personnel attend Lab Core Safety Training and other applicable safety training courses. Both PI and all persons associated with the protocol must sign the following acknowledgement: I have read, asked questions, and understand the hazards of and safe working procedures for the activity/materials described herein. PI Signature: DATE Other Personnel: Name/ Signature DATE Name/Signature DATE Name/Signature DATE Summary of Operating Procedures for Flow Tube Reactor Last updated on February 8, 2016 Turning on the flow tube 1) Make sure the outlet from the flow cell is connected to a charcoal filter. This step is important to make sure ozone from the system doesn’t get into the air of the room. 2) Turn on UV lamp connected to voltmeter. Allow the lamp to warm up for 1 hour. The box works properly even though the display flashes that the wheel inside is broken. 3) Make sure the mass flow control and pressure meter boxes are on. They are usually left on all the time. a. Changing the air flow. Switch the box to channel 4 and use knob to change the air flow. It is usually set to about 48.4. b. Changing the oxygen flow. Switch to channel 3 and use knob on the box. It is usual set to 95. 4) Make sure the syringe pump is on. Allow to warm up for 10 minutes if not already on. a. The Table menu can be used to set the volume and flow rate that you are using. b. A typical flow rate is 25 L/hr. 5) Open valves to the oxygen supply. a. Open the main valve at the top of the gas cylinder b. Open the left-most valve on the regulator (after opening the valve, the regulator should read ~170 Pa) c. Following the tubing, open the next valve. It opens in a 90° motion. When the valve is up the valve is closed. 6) Air flow is never changed. It should already be flowing correctly. 7) Turn on the voltmeter. Record the reading in millivolts. 8) Turn on the ozone generator. The knob on the box controls the amount of ozone that is made. Typical setting is “2”. Let it run for about 10 minutes before beginning to collect sample. Record the new reading on the voltmeter. Calculate V/V0 and use the chart by the voltmeter to determine the amount of ozone generated. Making samples 1) Use 50 μL syringe for sample injection. Usually about 20 μL is sufficient for sample preparation. 2) Secure syringe on syringe pump. Insert syringe through the septum in front of the syringe pump and secure. Select desired settings on syringe pump for sample collection. a. Set up syringe pump. Press the “Select/Menu” button and use arrows to navigate to Table option. Press “Select/Menu” again to choose settings for volume and rate. Check to make sure the syringe pump is set up for the type and size syringe you are using. Press select until you get to “Volume”. Use the arrow buttons to select your volume. Press select again. Now you can adjust the rate of injection. Use the arrow buttons to select the rate that you want. Press select again. b. Inject sample. Once all the desired settings have been selected, press the “Run/Stop” button to begin injection. The syringe pump will display the volume that has been injected so far. The syringe pump will stop once it has injected the volume you selected. 3) Connect your sample collector (MOUDI/Impactor/Filter holder) to the pump. a. MOUDI instructions: Place MOUDI on the Deposit Impactor and flip rotating switch up. Once secure, connect the vacuum tubing and pump to the MOUDI. b. Impactor instructions: If using foil, prepare impactor beforehand. Then connect the top of the impactor to the top of the T connected to the HEPA filter with conductive tubing. Connect the bottom of the impactor to the flow meter with conductive tubing. 4) Connect the side of the T connected to the HEPA filter to the denuder. 5) Turn on the pump by flipping the switch on the power strip. 6) Test the flow rate through your sample collector using an electronic flow meter. Turning off the flow tube: 1) Turn off the ozone generator. 2) Turn off the pump. Unplug the pump and disconnect the sample. 3) MOUDI: Disconnect from sample from air supply. Disconnect MOUDI from the air filter. a. MOUDI Instructions: To disconnect MOUDI from the Deposit Impactor when sample collection is complete, flip the rotating switch down until MOUDI is released. 4) Connect denuder to the dump. 5) Close the 90° valve for the oxygen flow 6) Close the left-most valve on the oxygen regulator 7) Close the valve at the top of the oxygen tank 8) Air flow is kept open 9) Turn off the UV lamp. 10) Turn off the syringe pump. 11) Turn off the voltmeter. 12) Check pressure of the system. Make sure the pressure reading is around atmospheric pressure in the system.