ME 581: Simulation of Mechanical

Systems

Inverse Kinematics of a 4-Degree of

Freedom Robotic Manipulator

Katie Briggs

Abstract

Increasing interest in robotic autonomous systems

has lead to a research emphasis of object

recognition, path planning and obstacle avoidance

for mobile robotic systems.

External sensing

methodologies can alert a robotic system of

obstacles, and suggest a global pose, or (X, Y, Z)

coordinate for a robotic end effector to move to in

order to complete a desired task. Consequently,

each robotic system must have derived inverse

kinematics and dynamics to allow the manipulator,

or mobile base to accurately follow a commanded

trajectory. This report focuses on deriving the

inverse kinematics of a 4-degree of freedom

robotic arm to arrive at a desired global pose, or

follow an end-tip trajectory.

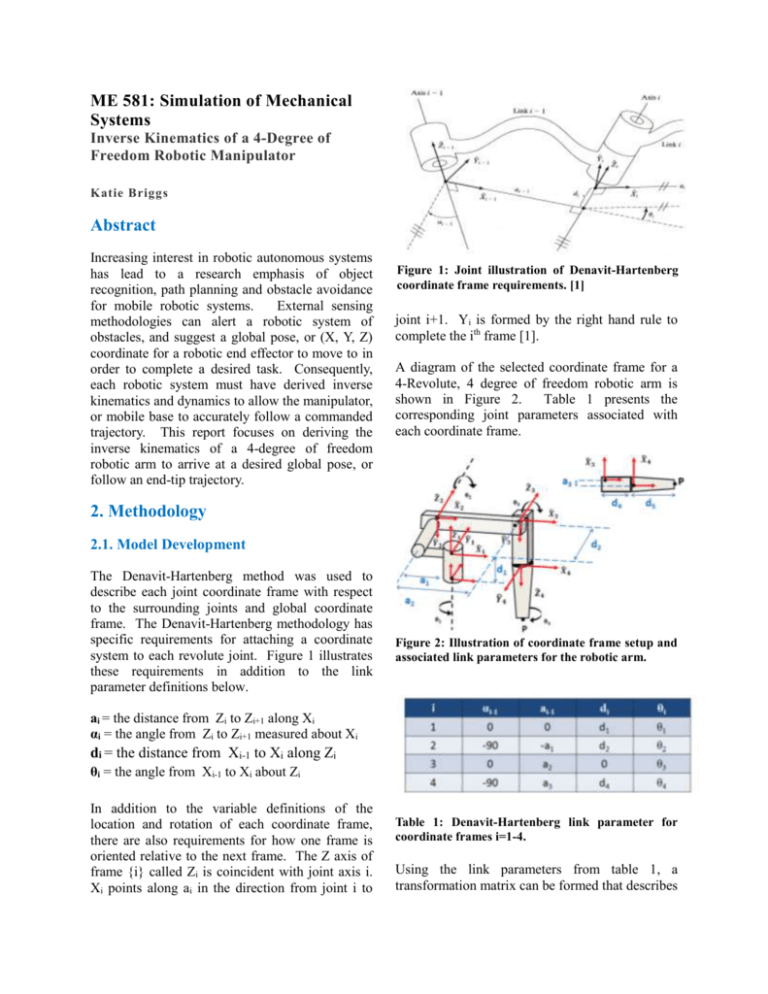

Figure 1: Joint illustration of Denavit-Hartenberg

coordinate frame requirements. [1]

joint i+1. Yi is formed by the right hand rule to

complete the ith frame [1].

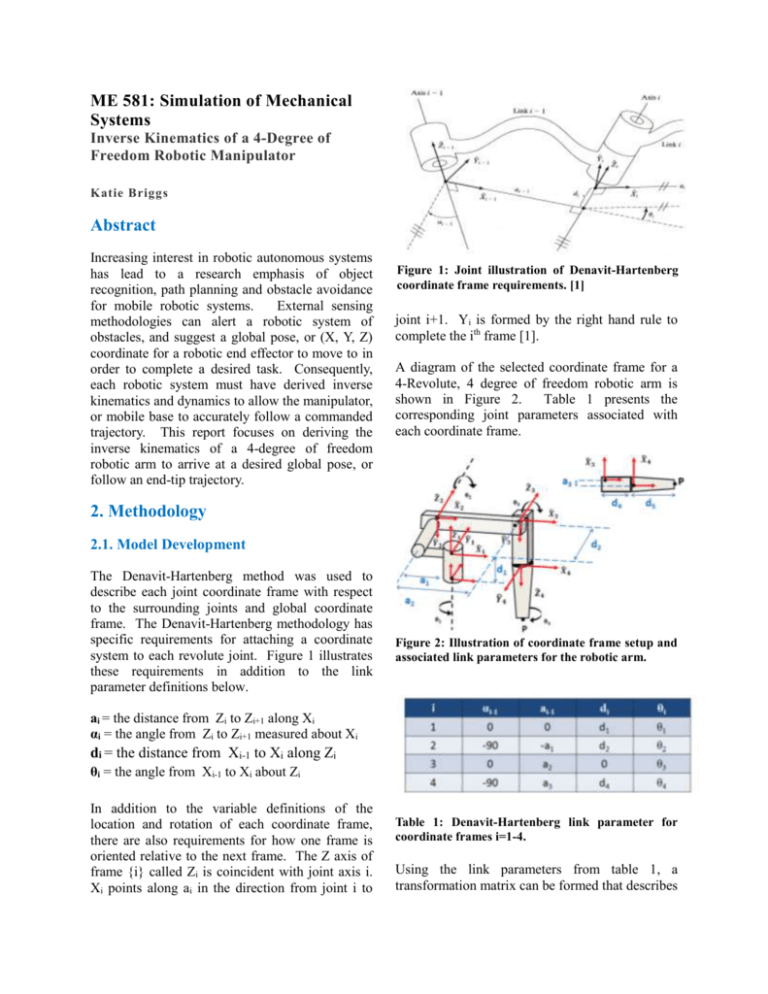

A diagram of the selected coordinate frame for a

4-Revolute, 4 degree of freedom robotic arm is

shown in Figure 2.

Table 1 presents the

corresponding joint parameters associated with

each coordinate frame.

2. Methodology

2.1. Model Development

The Denavit-Hartenberg method was used to

describe each joint coordinate frame with respect

to the surrounding joints and global coordinate

frame. The Denavit-Hartenberg methodology has

specific requirements for attaching a coordinate

system to each revolute joint. Figure 1 illustrates

these requirements in addition to the link

parameter definitions below.

Figure 2: Illustration of coordinate frame setup and

associated link parameters for the robotic arm.

ai = the distance from Zi to Zi+1 along Xi

αi = the angle from Zi to Zi+1 measured about Xi

di = the distance from Xi-1 to Xi along Zi

θi = the angle from Xi-1 to Xi about Zi

In addition to the variable definitions of the

location and rotation of each coordinate frame,

there are also requirements for how one frame is

oriented relative to the next frame. The Z axis of

frame {i} called Zi is coincident with joint axis i.

Xi points along ai in the direction from joint i to

Table 1: Denavit-Hartenberg link parameter for

coordinate frames i=1-4.

Using the link parameters from table 1, a

transformation matrix can be formed that describes

the rotation and translation of coordinate frame i in

relation to coordinate frame i-1. Equation 1

derived the transformation T, from i to i-1 [1, 2].

(1.1)

sin i

0

ai 1

cos i

sin cos

cos

cos

sin

sin

i 1di

i

i 1

i

i 1

i 1

i 1

T

i

sin i sin i 1 cos i sin i 1 cos i 1 cos i 1di

0

0

0

1

(1.6)

1

0

4

5T

0

0

0 0 0

1 0 0

0 1 d5

0 0 1

A final description of the end point P with relation

to the global coordinate frame can be reached by

multiplying all transformation matrices together.

2.2. Forward Kinematics

(1.7)

Using the general transformation definition from

equation(1.1), transformation matrices for each

coordinate frame are created below, using

parameters from table 1.

(1.2)

cos 1

sin

1

0

1T

0

0

sin 1 0 0

cos 1 0 0

0

1 d1

0

0 1

(1.3)

cos 2

0

1

2T

sin 2

0

sin 2

0

cos 2

0

T T T T T T

0

5

1

2

2

3

3

4

4

5

Each index of the final matrix is represented by a

rotation, rii, or coordinate point Pi. This is used to

substitute for lengthy equations that belong to each

index of the final transformation matrix [1].

Equation (1.9) represents the global coordinates of

the arm end point P shown in Figure 2. Variables

PX, PY, and Pz correspond to the global X, Y, and

Z coordinates.

(1.8)

r11

r

0

21

T

5

r31

0

0 a1

1 d 2

0 0

0 1

0

1

r12

r22

r32

r13

r23

r33

0

0

PX

PY

PZ

1

(1.9)

(1.4)

cos 3

sin

3

2

3T

0

0

sin 3

cos 3

0

0

0 a2

0 0

1 0

0 1

PX c1[a1 a2c 2 a3 cos 23 s 23d5 d 4 s 23 ] d 2 s1

PY s1[a1 a2c 2 a3 cos 23 d 4 s 23 s 23d5 ] c1d 2

PZ d1 c 23d5 d 4c 23 a3 s 23 a2 s 2

(1.5)

cos 4

0

3

4T

sin 4

0

sin 4

0

cos 4

0

0 a3

1 d 4

0 0

0 1

Now that a forward kinematic description of the

robotic manipulator has been checked, it is useful

to verify the correctness of the math by isolating

each joint angle, and varying it from 0 to π to

validate the end point of the arm is at the correct

global coordinates. Figures 3, 4, and 5 below

confirm this validation process.

2.3. Inverse Kinematics and Matlab

Execution

Once the forward kinematics of the transformation

matrices has been validated, the inverse kinematic

equations can be derived. The inverse kinematics

of the robotic arm allows you to input a desired

trajectory and solve for the required joint angles,

velocities or joint accelerations to achieve

specified trajectory requirements for end point P.

Closed form solutions can be solved for joint

angles algebraically, however with increasing

complexity it is better to solve the equations

numerically, or with an iterative solving algorithm.

Figure 3: Yaw joint motion from 0 to π, shoulder

kept at 90 degrees, and elbow kept at zero degrees to

illustrate movement of arm.

Figure 4: Shoulder motion from 0 to π, elbow and

yaw joints kept at zero degrees.

When solving the inverse kinematics for a high

degree of freedom manipulator, there are often

many solutions to reach a specific coordinate.

Often times it is desired that the robotic arm keep

an “elbow up” configuration to prevent the arm

from hitting the ground or itself, like it would in

an elbow down configuration. Due to geometry

constraints, as well as joint limits, it is often

helpful to find a solution that is close to a specified

pose. For this reason, it is useful to use the

Newton-Raphson iterative technique to solve for

joint angles.

The Newton-Raphson equation works by

providing an initial guesstimate of all the model’s

states, such as estimated joint angles, and plugging

these states into the Newton-Raphson equation

below(1.10). The equation will get closer and

closer to a correct solution by minimizing the

system’s residuals, or error, to a given value

specified by the user.

qi 1 qi J 1 (qi ) T (qi )

(1.10)

The Jacobian and residuals used in (1.10) are

described in equations (1.11) , (1.12) and(1.13).

(1.11)

Figure 5: Elbow motion from 0 to π, shoulder joint

kept at 90 degrees, and yaw joint kept at zero

degrees.

PX X

T (qi ) PY Y

PZ Z

(1.12)

1

X

q 2 , T Y

3

Z

to follow. Figure 6 illustrates the general structure

of the Matlab code.

(1.13)

X

1

T Y

J (q) i

q j 1

Z

1

X X

2 3

Y Y

2 3

Z Z

2 3

The Jacobian matrix is derived by taking the

partial derivatives of PX, PY, and PZ from equation

(1.9) with respect to θ1, θ2, and θ3. The residual δT

is computed by plugging the guesstimate angles

into the forward kinematic equations (1.9) to solve

for PX, PY, and PZ. The residual is the difference

between the resulting P coordinate values, and the

desired X, Y, Z coordinate from the trajectory.

How big or small the residual is determines the

error between the robotic arm end point P, and the

desired trajectory coordinate. Once the NewtonRaphson equations have converged to a minimal

residual, the Jacobian matrix can be used to solve

for the joint velocities required achieve specified

end tip velocity. The equation to solve for joint

velocities is shown below [1, 2].

(1.14)

1

X

1

2 J Y

Z

3

The inverse kinematic equations (1.10)-(1.14)

above were put into a Matlab script to compute the

joint angles and velocities of the robotic arm as its

end point P moved along a specified trajectory.

Two loops were created within the Matlab script

containing an inner while loop and outer for loop.

The inner while loop used the Newton-Raphson

equations to solve for joint angles and joint

velocities until the residual reached a specified

tolerance. The outer for loop iterated along a

desired trajectory, specifying a new X, Y, Z end tip

coordinate and corresponding velocity for the arm

Figure 6: Outline of Matlab script

3. Simulation and Results

A simple straight line trajectory was simulated

with the following values from i=1:101:

(1.15)

i

0.5

PX

100 [m]

P d d [m]

5

Y 4

[m]

PZ

a2

X 0.1 [m/s]

Y 0 [m/s]

Z 0 [m/s]

1

Global Z [m]

0.8

0.6

0.4

0.2

0

0.6

0.4

0.4

0.2

0.2

0

0

Global Y [m]

-0.2

-0.2

-0.4

Theta 1 [rad]

Theta 2 [rad]

Theta 3 [rad]

-1.8

-1.9

-2

20

0

20

0

20

-0.15

-0.2

0

20

40

60

80

100

Point along trajectory path

Plot of Shoulder Joint Along Trajectory

0

20

0

20

0.1

0

-0.1

40

60

80

100

Point along trajectory path

Plot of Elbow Joint Along Trajectory

120

0.1

0

-0.1

40

60

80

Point along trajectory path

100

120

4. Conclusion

40

60

80

100

Point along trajectory path

Plot of Shoulder Joint Along Trajectory

40

60

80

100

Point along trajectory path

Plot of Elbow Joint Along Trajectory

120

120

0.8

0.7

40

60

80

Point along trajectory path

120

Figure 9: Plots of joint velocities along the trajectory

Plot of Yaw Joint Along Trajectory

0

Plot of Yaw Joint Along Trajectory

-0.1

Global X [m]

Figure 7: Arm link outline as it follows the

trajectory

2

1.5

1

Theta1 dot [rad/sec]

Arm motion along trajectory

Theta3 dot [rad/sec] Theta2 dot [rad/sec]

Using these trajectory values, corresponding joint

angles and joint velocities were solved for within

Matlab. Plots of the resulting joint angles and

velocities are shown below.

100

120

Figure 8: Plot of joint angles along trajectory path

Computation of joint angles and joint

velocities using the Newton-Raphson iterative

method has many useful applications within

the field of robotics. Robotic manipulators are

often used to assist and perform dexterous

tasks that require the arm end effector to

follow a trajectory at a given speed. These

tasks are possible through inverse kinematics

and dynamics. This paper has provided an

initial overview of the steps taken to analyze

the inverse kinematics of a 3-dimensional

mechanism to assess joint speeds while

conducting a commanded task.

References

[1] Craig, J., Introduction to Robotics

Mechanics and Control, Third edition,

Chapter 3, Manipulator Kinematics,

Pearson Prentice Hall, New Jersey, USA,

2005.

[2] R. Jazar.: Theory of Applied Robotics,

Second edition, Springer, New York,

USA, 2010.