Environmentally-friendly and no refueling: The SENNEBOGEN 821

advertisement

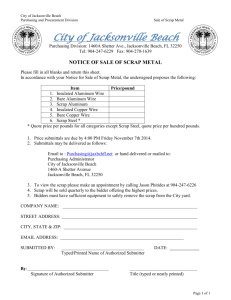

Environmentally-friendly and no refuelling: The SENNEBOGEN 821 Electro in scrap metal handling As one of the leading scrap metal and scrap handling companies in southern Germany, the specialist waste management company from Schweinfurt, Georg Lesch e. K., focuses on recovering valuable resources and sustainable material management. The SENNEBOGEN 821 Electro has been in use for material handling at the site since 2011. General manager Peter Heinlein and his colleagues have placed their trust in the tried-and-tested SENNEBOGEN quality for many years. The company has now added the stationary electric version of the 821 to its fleet, equipped with a 12 metre boom and magnetic grab - a true energy and performance miracle from the Green Line product line. The SENNEBOGEN 821 is used for sorting and loading, as well as supplying the packaging press. The benefits of the electrohydraulic drive, which was supplied by Baufahrzeuge Bordt GmbH in 2011, are clear for operators and drivers alike. Thanks to the electric motor, smooth and emission-free running with no refuelling stops is guaranteed. Further benefits include effective work processes and low maintenance and service costs, coupled with proven long service life. "We have been extremely satisfied with the SENNEBOGEN material handling machines for many years. They are environmentally-friendly, energy conscious and above all extremely reliable. By investing in the 821 Electro, we are placing our trust once again in the innovations from SENNEBOGEN - and I'm certain it won't be the last time", states Peter Heinlein, general manager at Georg Lesch e.K. 1 The stationary SENNEBOGEN 821 Electro reaches material with its 12 metre boom at the specialist waste management company Georg Lesch e.K. in Schweinfurt. 2