A stable non-dissipative numerical scheme and its application to

advertisement

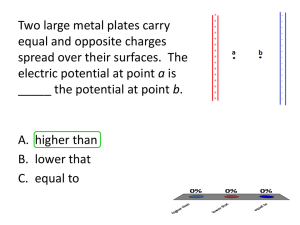

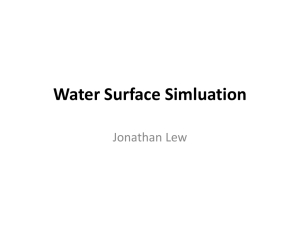

A stable non-dissipative numerical scheme and its application to noise predictions of subsonic hot jets using LES Zhong-Nan Wang, Iftekhar Z. Naqavi, Paul G. Tucker Engineering Department, University of Cambridge, Cambridgeshire CB3 0DY, UK The numerical scheme used in large eddy simulation should be non-dissipative in regions where the flow is smooth. Especially for hot jets, the additional numerical dissipation can contaminate the turbulence development and even, in extreme cases, laminarize jets. To increase the simulation fidelity, a non-dissipative numerical scheme for unstructured meshes is used in this research. The numerical dissipation is removed using central averaging with the stability enhanced by ensuring the kinetic energy preserved (KEP) in the discrete form. This numerical scheme was tested on some canonical cases, such as isentropic vortex convection, Tollmien–Schlichting waves and homogenous isotropic decaying turbulence. In terms of both accuracy and stability, the results are very encouraging relative to the traditional Roe scheme. Hence, the scheme is applied to large eddy simulation (LES) of a subsonic hot jet. The jets Reynolds number is 4 x 105 and the temperature ratio between the jet and ambient air is 2.7. The explicit nozzle geometry is modelled in the simulation with 34 million cell meshes. The near flow field is resolved using LES with a RANS (Reynolds Averaged Navier-Stokes) layer on the nozzle wall. The latter prevents nonphysical boundary layer separations. The mean flow field simulated by the KEP scheme shows better agreement with the measurements (Bridge, 2010) than that from Roe scheme, in Fig. 1. The Ffowcs Williams-Hawkings (FW-H) equation is used to get the far field sound. Four cylindrical FW-H surfaces, shown in Fig. 2, are used at various radial distances from the centreline. The FW-H surfaces are closed at the downstream end with multiple endplates. Eleven endplates are placed at x=25.0D-30.0D with Δ=0.5D apart. Three strategies are employed in this study to work out the best practice guidelines on how to use the multiple FWH surfaces for the reliable far field noise prediction: 1) four FWH surfaces without endplates; 2) FWH surface with single endplate; 3) FWH surface with averaging over multiple endplates. Fig. 3 shows that the far-field noise predictions are highly dependent on the choice of FW-H surfaces. For the four FWH surfaces without endplates, the overall sound pressure level (OASPL) for the two surfaces farther from the jet can collapse to the physically measured value, while the surfaces close to the jet flow are over predicting the sound due to large turbulent structures passing through. Then the endplate effects are investigated using the furthest cylindrical FWH surface. The study shows that the endplate location has great impact on the noise prediction. Improved results can be obtained by putting a single endplate that is far downstream enough. An averaging procedure over endplates can then be used to alleviate the endplate location choice with the similar accuracy. Finally, the fourth order time-space correlation is calculated to give an insight to the sound generation mechanism in the hot jet. (a) Axial velocity (b) Turbulent intensity Fig. 1 Velocity and turbulent intensity along the nozzle centerline (a) p / t (b) Temperature Fig. 2 Instantaneous flow field and FWH surfaces (a) Four FWH surfaces without endplates (b) the furthest FWH surface with endplates Fig. 3 Overall Sound Pressure Level in the far field (Colours indicate the FWH surface locations)