assingment - WordPress.com

advertisement

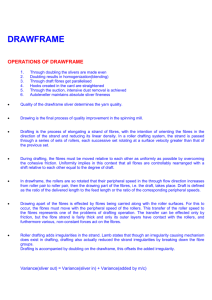

Faults/defects of draw frame Faults of draw frame are as follow as 1. End missing. 2. Irregular drafting. 3. Roller lapping. 4. Excessive sliver breaks. 5. Fuzzing at the tube wheel bore. 6. Fuzzing at the front roller . 7. Impurities in the sliver. End missing: Any sliver may break when doubling is 5-6; this is known as fine sliver or end missing. Cause: 1. 1.If stop motion does not work. 2. Carelessness if the operator. Remedies: 1. Stop motion must be in working condition. 2. Operator should be careful. Irregular sliver: These types of sliver may contain thick-thin places, variation in count along the sliver etc. Cause: 1. 1.Incorrect roller setting 2. Incorrect distribution of draft. 3. Improper roller pressure. 4. Nip movement due to eccentric rollers. Remedies: 1. Correct roller setting 2. Correct distribution of drafts. 3. Proper roller pressure should be maintained. 4. Roller slip should be prevented. 5. Top roller should be varnished for regular diameter. Roller lapping When sliver passes through the drafting roller sometimes the fiber are snarl with the roller specially bottom roller. This is roller lapping. Cause 1. Improper cleaning of the roller. 2. Improper temperature. 3. Improper relative humidity. 4. Oil on the roller covering. 5. Cracked roller surface. Remedies: 1. 2. 3. 4. 5. 6. 7. The roller covering should be free from oil and wax. The covering should be well varnished. Correct setting of ermen clearer. Damaged roller should be replaced and any impurities in the roller fluting to be cleaned. Rough calendar roller surface require varnishing and any wax as them to be removed. Correct relative humidity percentage. Adjust correct roller speed for long staple. Excessive sliver breaks During the process of drafting by various aspect the sliver are breakage. Cause 1. Feed zone: Feed tension. 2. Draft zone: Roller lapping, Entanglement of sliver in can. 3. Delivery zone 4. Improper stock filling. 5. Thick and thin place. 6. Uneven web. 7. Bad coiling Remedies: 1. Proper feed tension required. 2. Proper stock filling required. 3. Remove thick and thin place. 4. Even web is need 5. Good coiling is needed. Fuzzing at the tube wheel bore. Cause: 1.Impurities or roughness in the tube wheel bore. Remedies: 1.Polish the bore Fuzzing at the front roller: Cause: 1. Higher front roller speed for combed sliver where greater parallelism & straightening are achieved. Remedies: 1.Reduce front roller speed to 120 ft/min on tradition draw frame. Impurities in the sliver Cause: 1. Insufficient cleaning occasioned by incorrect setting of the various clearers. 2. Worn clearer clothes Remedies: 1. The clearer setting and condition of the cloth should be checked. Conclusion: From the upper discussion we know about the different types of draw frame faults and we can know how can we reduce from this problem. Reference: 1. http://textile4bd.blogspot.com/2011/03/yarn-manufacturing-technology-part-1.html 2. http://www.autexrj.com/cms/zalaczone_pliki/1-07-2.pdf 3. Principle of short staple spinning= Professor dr. Eng.Ayub Nabi Khan