The Synthesis, Separation, and Analysis of Organic Fruit Volatiles

advertisement

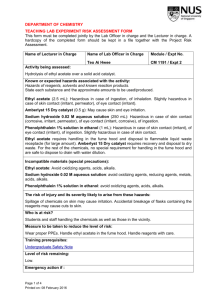

The Synthesis, Separation, and Analysis of Organic Fruit Volatiles Nicole Bernstein Department of Chemistry, The Pennsylvania State University, University Park, PA 16802 nwb5129@psu.edu Abstract Hexyl Acetate (1)—an organic volatile contained in apples—was synthesized from 1hexanol (2) and acetic acid (3) by running a Fischer Esterification reaction in a Dean-Stark apparatus. The efficiency of the reaction was measured by running 1H NMR and IR analyses of the product, and determining any impurities in the spectra. The technique of fractional distillation was then explored by separating an unknown mixture of two fruit volatiles, which were determined to be ethyl acetate (4) and 1-butanol (5). This type of distillation was found to be an efficient separation technique of two compounds with similar boiling points. Introduction This module surrounds the study of organic volatiles—compounds which are partially responsible for the smell and taste of fruit. Each different fruit has as many as a hundred compounds working to produce its aroma. Yet, some single ester compounds can be used to approximate the natural odor of the fruit, and are often used in food production as artificial fragrances and flavor.1 An objective of this module is to synthesize one such compound—hexyl acetate, which is responsible for the aroma of apples. Hexyl acetate (1) is an ester which can be synthesized via a Fischer Esterification reaction of 1-hexanol (2) and glacial acetic acid (3) (Scheme 1). An ion-exchange resin is used as an acid catalyst for the reaction, as it is easily filtered out of the solution once the product has been obtained. The resin protonates the carbonyl carbon of acetic acid, which then encourages attack by the nucleophilic 1-hexanol.While the equilibrium constant of this reaction is not extremely favorable, using a Dean-Stark Apparatus to remove water (the bi-product) from the reaction mixture will push the synthesis to completion. This module also examines the technique of fractional distillation, which is used to separate compounds with relatively close boiling points. As a simple distillation will not achieve accurate results unless the compounds have boiling points separated by at least 75oC, a fractioning column must be used to induce multiple theoretical plates, which allows the components of a mixture to be separated more efficiently. This technique is useful, because it not only allows for efficient distillation of components with boiling points which may be close together, but it also aids with the identification of unknowns by providing an accurate boiling 1 point. In this experiment, fractional distillation was used to separate a mixture of two unknown fruit volatiles. Scheme 1. Fischer Esterification Reaction of 1-Hexanol and Glacial Acetic Acid OH + 2 O H+ OH min. O + O 3 H2O 1 Results and Discussion The Synthesis of Hexyl Acetate The Fischer Esterification of 1-hexanol (2) and glacial acetic acid (3) was carried out on a microscale to produce hexyl acetate (1) and water. The acid catalyst—Dowex 50 x 2-100 ion exchange resin—was filtered from the solution and the resulting product has a distinct smell of sour apples, a sign that the reaction was successful. The identity of the product was confirmed by both 1H NMR and IR spectral analyses. The splitting pattern and the number of signals were consistent with what one would expect of hexyl acetate. The key observations included a triplet at 4.06 ppm with an integration of 2, which is indicative of hydrogen next to an electron withdrawing group such as oxygen, and a single with integration 3 at 2.05 ppm, both distinct to hexyl acetate. A peak at 3.64 ppm indicates contamination from unreacted 1-hexanol, which has a characteristic peak at this value. Additional contamination from 1-hexanol affected the integration values of the peaks at 1.60 ppm, 1.32 ppm, and 0.89 ppm. An analysis of the contamination showed that the ratio of product hexyl acetate to 1-hexanol was 2:1. Contamination from acetic acid also appeared as a singlet peak at 2.07 ppm, in a ratio of hexyl acetate to acetic acid of 2:1. In the future, to assure that no reactants impurified the product, the reaction would be allowed to run longer, as that would ensure that it had run to completion. Additionally, a stirrer bar would be used instead of boiling chips, as the boiling chips were not effective in preventing bumping, which therefore may have caused errors in the reaction. The IR spectrum contained a C=O stretch at 1736.2 cm-1 and a C— O stretch at 1236.2cm-1, which are consistent with the functionalities of hexyl acetate. The Fractional Distillation of Two Unknown Fruit Volatiles The fractional distillation of unknown mixture number 73 was an effective method for separating the two unknown fruit volatiles. The first compound to separate was found to have a boiling point range of 77oC to 79oC (Figure 1). The NMR spectrum consisted of a quartet at 4.12 ppm, a singlet at 2.03 ppm, and a triplet at 1.25 ppm, with integrations of 2, 3, and 3 respectively. This data is consistent with what one would expect of the compound ethyl acetate (4). Ethyl Acetate had a boiling point of 77o, which agrees with the experimental value.1 The IR 2 spectrum displayed a C=O stretch at 1736.0cm-1 and a C—O stretch at 1233.7cm-1, also consistent with ethyl acetate. The second distillate was found to have a boiling point range of 107oC to 109oC (Figure 1). The 1H NMR spectrum consisted of a distinct triplet that integrated to three hydrogens at 0.93 ppm, indicative of a compound containing a terminal methyl group next to a secondary carbon. It also contained two multuplets at 1.54 ppm and 1.38 ppm, a singlet at 3.23 ppm, and another triplet at 3.60 ppm, all indicative of the compound 1-butanol. Contamination from ethyl acetate (4) was seen as a quartet at 4.12 ppm, a singlet at 2.05 ppm, and a triplet at 1.26 ppm. Relative integration values showed that the ratio of 1-butanol to ethyl acetate was 6:1. The IR spectrum indicated an O—H stretch at 3327.8cm-1. These spectroscopic results override the boiling point data, which was close enough to be consistent with 1-butanol’s true boiling point of 118 oC, and are consistent with what one would expect of the compound 1-butanol (5). As can be seen in Figure One, Fractional distillation allowed for an effective method of separation for the two unknowns. Plateaus at 77oC and 109oC indicate the separate boiling points of ethyl acetate (4) and 1-butanol (5). A sharp spike in temperature after 53 drops of liquid denotes the change in distillate from the first unknown to the second unknown. The clarity of this curve denotes the effectiveness of fractional distillation. O O OH 5 4 Figure One. Distillation Curve for Fractional Distillation 120 Temperature oC 110 100 90 80 70 60 0 10 20 30 40 50 60 70 80 Number of Drops 3 Conclusion The synthesis of hexyl acetate was successful, as spectroscopic data indicated successful formation of the product with little contamination from the reactants. The Dean-Stark apparatus which was used to push the chemical equilibrium to the products was instrumental in obtaining a good percent yield of hexyl acetate. The fractional distillation of the two component solution of fruit esters was successful, as a combination of boiling point data and spectroscopic analyses allowed for identification of the unknown compounds. The two components were identified as ethyl acetate and 1-butanol. Experimental General Methods All compounds were purchased by the course instructor for CHEM 213H, and were used by the student without further purification. 1H NMR spectra were run on a 60 MHz spectrometer, and then on a 400 MHz Bruker AVANCE spectrometer if further clarity was needed. IR spectra were collected on a Thermo Nicolet 380 FT-IR. Melting point ranges were found using a thermometer during the fractional distillation. Hexyl Acetate (1) Dowex 50 x 2-100 ion exchange resin (0.200g) was washed with distilled water and filtered in a vacuum filtration apparatus. Glacial acetic acid (0.6mL, 10.48 mmol) and 1-hexanol (1.3mL, 10.35 mmol) were added to the resin, and the reaction mixture was inserted into a sand bath and hooked up to a Dean-Stark apparatus. The Varistat was set to 50, and the reaction was allowed to heat to reflux for 40 minutes. The resulting mixture was clear in color, with the solid orange resin. The product was filtered to remove the resin, producing a clear liquid that smelled strongly of sour apples. FT-IR 2928.9, 1736.2, and 1236.2 cm-1; 1H NMR (CDCl3, 400 MHz) 4.07 (t, J =6.8 Hz, 1H), 3.62 (t, J = 6.7 Hz, 1H), 2.03 (s, 3H), 1.60 (m, 2H), 1.38 (m, 6H), 1.1 (t, J = 6.5 Hz, 3H). Acknowledgements The author wishes to thank Katherine Masters, the course administrator for CHEM 213H, as well as Zachary Reitz who assisted with the editing of the lab guide. David Juang is also owed credit for the development of this agricultural sciences module. The author also wishes to thank Jerry Feng, the teaching assistant for her laboratory section. References 1. Masters, K. M. Chem 213H Lab Guide, Spring 2013 Edition Supporting Information 4 5 6 7 8 9 Annotated Spectral Data for Hexyl Acetate 10 Annotated Spectral Data of Ethyl Acetate 11 Annotated Spectral Data for 1-butanol 12