Water Safety Plan Guide: Groundwater Abstraction * Springs

advertisement

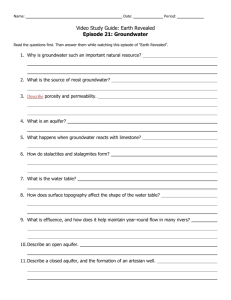

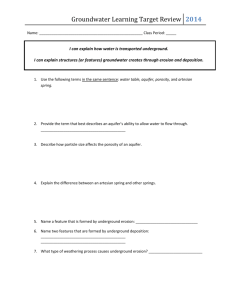

Water Safety Plan Guide Groundwater Abstraction – Springs Version 1, Ref P1.4 January 2014 Citation: Ministry of Health. 2014. Water Safety Plan Guide: Groundwater Abstraction – Springs, Version 1, ref p1.4. Wellington: Ministry of Health. Published in January 2014 by the Ministry of Health PO Box 5013, Wellington, New Zealand ISBN: 978-0-478-42710-3 (print) ISBN: 978-0-478-42711-0 (online) Previously published in 2001 as Public Health Risk Management Plan Guide: Groundwater Abstraction – Springs, Version 1, ref p1.4. This publication’s title and any reference within the text to ‘public health risk management plan’ was changed in January 2014 to reflect the December 2013 legislation change of the term ‘public health risk management plan’ to ‘water safety plan’. No other changes have been made to this document. This document is available at: www.health.govt.nz This work is licensed under the Creative Commons Attribution 4.0 International licence. In essence, you are free to: share ie, copy and redistribute the material in any medium or format; adapt ie, remix, transform and build upon the material. You must give appropriate credit, provide a link to the licence and indicate if changes were made. Contents Introduction 1 Risk Summary 3 Risk Information Table 4 Contingency Plans 8 Water Safety Plan Performance Assessment Ref P1.4 Version 1, January 2014 Water Safety Plan Guide: Groundwater Abstraction – Springs 10 iii Introduction Source water abstraction is the process of taking water from the source for transmission to the treatment plant or pre-treatment storage. This Guide is concerned with the abstraction of water from springs. If an event related to abstraction occurs (ie, the quantity or quality of water is affected by the abstraction process), the following could happen: If there is not enough source water available to meet demand, sickness can be caused by poor hygiene and by low pressure letting germs and chemicals get into the distribution system If contamination gets into the spring box,‡ germs and chemicals can cause sickness If contamination gets into the aquifer, germs and chemicals can cause sickness If a problem with the bore/wellhead does not allow enough water to be drawn from the aquifer, sickness can be caused by poor hygiene and by low pressure letting germs and chemicals get into the distribution system. Activities during the operation and construction of a spring source may present risks to the health of staff. These are acknowledged but are not discussed further, as such risks are the subject of health and safety in employment legislation. When constructing a bore/well you need to be aware of the requirements of: the Resource Management Act specific requirements of local authorities and regional councils. Drawing water from the source, and the risks associated with it, cannot be viewed in isolation; the process influences, and is influenced by, other water supply elements: Land use and activities carried out in the area where water enters the aquifer may affect the quality of the water being abstracted (see Guide S1.1) The quality of the groundwater will influence the treatment it requires (see P5, P6, P7, and P8 series of Guides). Several factors influence the likelihood of contamination of the spring water: how close local pollution sources are: – – – – – ‡ septic tanks or other waste disposal systems chemical or fertiliser stores intensive agriculture refuse dumps underground fuel tanks Construction to collect the water at the spring. Ref P1.4 Version 1, January 2014 Water Safety Plan Guide: Groundwater Abstraction – Springs 1 how easily the groundwater can be contaminated (influenced by, for example): – – – – – – water table confining layers hydraulic conductivity soil characteristics rainfall use of irrigation contamination of the aquifer due to: – – – back-siphoning poor construction of the spring box poor design of the spring box, and surroundings that allow surface run-off into it. The risk to groundwater quality therefore depends on the quality of the water in the aquifer and the design, construction and operation of the spring. 2 Water Safety Plan Guide: Groundwater Abstraction – Springs Ref P1.4 Version 1, January 2014 Risk Summary The events creating the two greatest risks involved in abstracting water from the source are not being able to draw enough water (see P1.4.1, P1.4.4), and contaminated water getting into the spring box (see P1.4.2). The most important preventive measures are: regularly inspect the intake (see P1.4.4.1) take steps to conserve water when a water shortage looks likely (see P1.4.1.1) place covers over the spring box, and put drains to stop run-off getting into it (see P1.4.2.1) put a fence around the spring to stop contamination by stock (see P1.4.2.2). (References in parentheses are to the Risk Information Table.) Ref P1.4 Version 1, January 2014 Water Safety Plan Guide: Groundwater Abstraction – Springs 3 Risk Information Table Reliable information about water quality is essential for the proper management of a water supply. Knowledgeable and skilled staff are also essential for minimising the public health risks associated with water supplies. Please read the staff training (Guide G1) and the monitoring guides (Guide G2). While we haven’t pointed out every detail of how these documents are linked with the present document, the links are many and are important. Abbreviations: DWSNZ – Drinking-Water Standards for New Zealand. Causes Preventive measures Checking preventive measures What to check Corrective action Signs that action is needed Event: NOT ENOUGH SOURCE WATER AVAILABLE FOR ABSTRACTION Hazards: Germs and chemicals that get into the water because of low system pressure; hazards associated with poor hygiene. Level of risk: High P1.4.1.1 Drought. P1.4.1.2 Resource consent limitations. 4 Start water conservation measures as soon as water shortage becomes likely. Water demand. Source usage rate. Drop in system pressure. System pressure. Customer complaints about low pressure. Plan the development and use of the water source, and the need to identify and develop new sources, based on flow records of the spring. Negotiate new resource consents. Prepare new resource consent application. Find new sources. Increase storage capacity. Partially close valves through the network to equalise pressures. Water demand. Source usage rate. Drop in system pressure. Find new sources. System pressure. Customer complaints about low pressure. Increase storage capacity. Water Safety Plan Guide: Groundwater Abstraction – Springs Ref P1.4 Version 1, January 2014 Causes Preventive measures Checking preventive measures What to check Corrective action Signs that action is needed Event: CONTAMINATION GETS INTO THE SPRING BOX Possible hazards: Germs and chemicals. Level of risk: High P1.4.2.1 Heavy rain leading to high levels of turbidity and organic matter. P1.4.2.2 Install upstream cutoff drains to minimise contamination from run-off. Ensure spring box is covered, and constructed so that water cannot enter through manholes. Observed or known contamination in area of spring. Raw water: turbidity, suspended solids, microbiological quality. Non-compliance with DWSNZ: 2000 particularly turbidity, and E. coli counts. Increased filter backwash frequency (if filtering). Difficulty in achieving free available chlorine residual in treated water (if chlorinating). Spring box not covered. Fence off abstraction area, and undertake regular inspection and repair. Review pretreatment options. Review alternative source options. Increase chlorine residual in treated water. Event: CONTAMINATION OF THE AQUIFER (the source) Possible hazards: Germs and chemical determinands appropriate to contamination sources. Level of risk: High P1.4.3.1 Contamination sources (eg, stock, septic tanks, chemical sources) in aquifer recharge zone. Identify potential sources of contamination when source is being selected (see Guide S1.1). Monitor changes in land use (including urban developments) and the potential for contamination they create, once the source is in use. Restrict activities in the aquifer recharge zone that may contaminate the water (see S1 Guide series). Gather information about the vulnerability of the aquifer before undertaking development. Ref P1.4 Version 1, January 2014 Microbiological quality. Chemicals that the potential contamination source is likely to produce. No survey of potential sources of contamination undertaken. No aquifer tests carried out. No system in place for obtaining information about changing land use. Add treatment processes to remove identified contaminants. Instigate system for gathering information about land use changes. Water Safety Plan Guide: Groundwater Abstraction – Springs 5 Causes Preventive measures Checking preventive measures What to check Corrective action Signs that action is needed Event: TOO LITTLE WATER CAN BE DRAWN FROM THE SPRING TO MEET DEMAND Possible hazards: Germs and chemicals that get into the water because of low system pressure; hazards associated with poor hygiene. Level of risk: High1 P1.4.4.1 Screens damaged or clogged with organic matter. P1.4.4.2 Screens clogged with iron or calcium deposits. P1.4.4.3 Intake and screen clogged with debris – common problem with coffer dam type intakes. P1.4.4.4 6 Regular programme of inspection of screens. This should be intensified during times of low flow conditions. Regular programme of inspection and cleaning of dam with increased frequency during autumn. Ensure there is no vegetation overhanging the dam. Regular maintenance and inspections of the intake. Early warning system installed to indicate change in flow. Intake inspections, regularly and directly after floods etc, with follow-up action if required for existing protection (eg, fences, vegetation and soil instability). Telemetric alarm at treatment plant for low flows. Catastrophic failure (eg, flood, slips or earthquakerelated damage). 1 Failure of the intake structure. P1.4.4.5 Regular inspection and cleaning of screens which should be intensified during times of flood (sediment) and under low flow conditions (algae, weed slimes). Flow (from intake). Reduced flow. Biological growths on screens. Flow (from intake). Reduced flow. Scale build-up on leaking couplings, pipe joints etc. Flow (from intake). Reduced flow. Vegetation floating in the water. Flow (from intake). Low or no flows. Weather conditions. Reduced or no flow. Modify intake. Change screen pore or slot size. Investigate covering the seepage area. Re develop spring area. Review maintenance and inspection procedures. Repair damage and revise inspection schedule. The level of risk will probably increase the lower the flow of the water is. Water Safety Plan Guide: Groundwater Abstraction – Springs Ref P1.4 Version 1, January 2014 Causes Preventive measures Checking preventive measures What to check Corrective action Signs that action is needed Event: TOO LITTLE WATER CAN BE DRAWN FROM THE SPRING TO MEET DEMAND cont’d P1.4.4.6 Pump failure (see Guide 10). Maintenance according to manufacturers’ recommendations. Telemetric records. No water. New pumps. Alarm activated. Maintenance records. No maintenance record. Instigate maintenance programme. Alarm to indicate faults. No flow. Review with power authority. Standby pump with auto-switch to alternate pumps. Operate duty and standby pumps using an alternate ‘number of days‘ cycle. Telemetric alarm for low flows. Regular inspection of cabling, power lines and connectors. Stand-by generator. Battery backed-up alarms. P1.4.4.8 Construct a fence around the intake site. Vandalism/ sabotage. Damage to the intake. Install intruder alarm. Evidence of attempts to gain access to the intake. P1.4.4.7 Power failure. Ref P1.4 Version 1, January 2014 Water Safety Plan Guide: Groundwater Abstraction – Springs 7 Contingency Plans If an event happens despite preventive and corrective actions you have taken, you may need to consult with the Medical Officer of Health to assess how serious a problem is. Event – Not enough water reaching the treatment plant Indicators: Required actions: Responsibility: 8 Reduced, or no, flow reaching the treatment plant. Unexpectedly high usage. Structural failure of bore/wellhead, or pump failure. Implement the water supplier’s emergency demand management strategy. Consider whether to switch to an alternative source of water until adequate water of acceptable quality can again be supplied, or to use storage. (Make sure that the history of any tanker used to cart water has been investigated before it is used and that the tanker will not contaminate the water). If inadequately-filtered water has entered the reticulation, inform MOH of the transgression. Put conservation measures in place. Close valves at reservoirs to restrict supply if necessary. Increase chlorine residual as an interim measure. If appropriate, identify intake problem and rectify. When restarting the treatment plant, consider doing this at a slower rate. Record cause of failure and corrective steps taken. If shortages occur frequently because of too little water available at the source, plan for finding and developing a new source. Modify water safety plan (formerly known as a public health risk management plan, PHRMP) if necessary. Manager designated responsible for water supplies. Water Safety Plan Guide: Groundwater Abstraction – Springs Ref P1.4 Version 1, January 2014 Event – Contamination gets into the aquifer or spring Indicators: Required actions: Complaints of discoloured, tasting or smelling water coming from taps. Continued contamination of water supply: E coli detected or Priority 2 chemical concentrations more than 50% of MAV. Reports of illness in parts of the community that may be linked to water quality. Close intake. Notify the MOH, and in consultation warn consumers in the affected area not to draw water until further notice. Identify the source of the contamination, and determine whether it is likely to be a transient problem and whether temporary treatment is available. If problem is transient: – drain and flush the affected part of the distribution system, considering the need to flush with elevated chlorine concentrations if the incident may have involved microbiological contaminants. (Consultation with the regional council will probably be required with regard to disposal of the flushed water.) – Responsibility: monitor an appropriate determinand in the affected area to determine the success of the contingency measures, and notify consumers, when the supply is safe to use, that they will need to flush their taps until good quality water an again be drawn. If problem is likely to be long-lasting or permanent: – investigate and develop an alternative supply and/or treatment – provide another source of potable water until water of acceptable quality can again be supplied. Record cause of system failure and steps taken to correct. Modify water safety plan if necessary. Manager designated responsible for the water supply. Ref P1.4 Version 1, January 2014 Water Safety Plan Guide: Groundwater Abstraction – Springs 9 Water Safety Plan Performance Assessment To make sure that your supply’s water safety plan is working properly, periodic checks are needed. The overview document outlines what needs to be done. The following table provides the detailed information for checking this particular supply element. What to measure or observe: How often: Flow records. Turbidity. State of intake. Regular inspection of intake and records (frequency will be sitedependent and should be based on previous findings). The inspection should include, but not be limited to, the following: – – – What to do with the results: Responsibility: 10 after natural or high-risk events chemical and microbiological analysis results inspection reports. Results need to be recorded to meet legislative requirements or to allow water safety plan performance assessment. The WINZ database is good for this. The collected data need to be periodically reviewed to see whether problems with this supply element are developing. This should be done as frequently as the manager responsible considers necessary to minimise risk to public health arising from this supply element. Should this review show any unusual incidents, indicate that proper procedures are not being carried out, or indicate that poor water quality is reaching customers, then review the procedures managing the abstraction of water. Evaluate the monitoring results, and any actions taken as the result of having to implement a contingency plan, to see if the water safety plan needs modification – eg, preventive measures are up to date; the contingency plan steps are still adequate; and changes to the abstraction system are recognised in the plan. Manager designated responsible for water quality. Water Safety Plan Guide: Groundwater Abstraction – Springs Ref P1.4 Version 1, January 2014