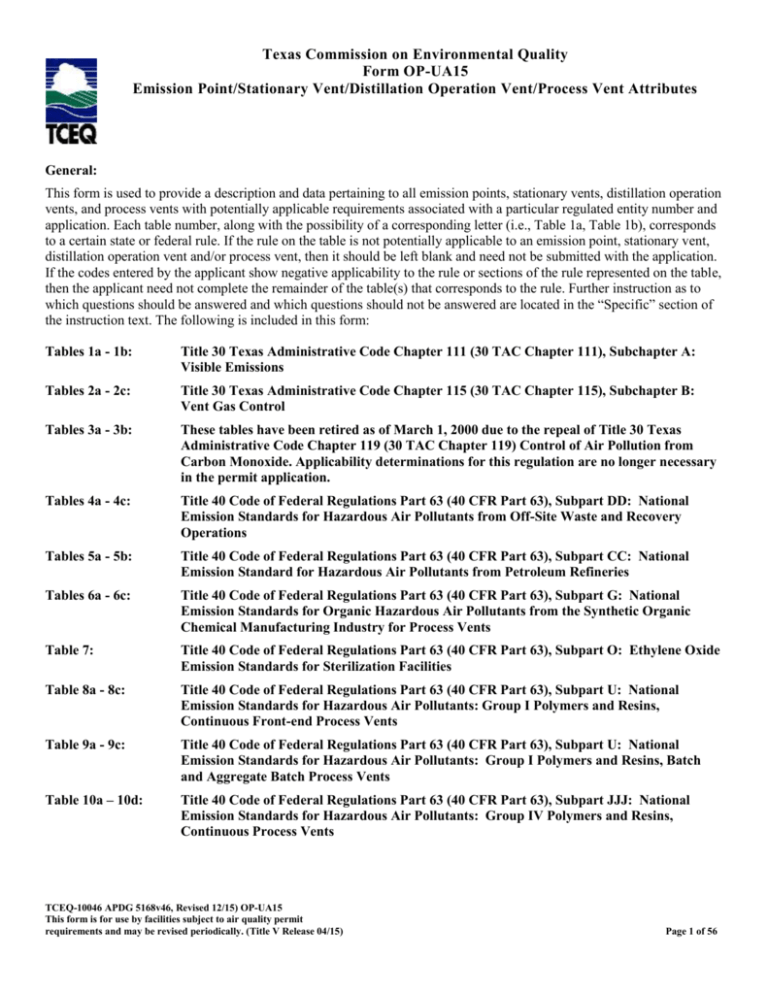

TCEQ-Form OP-UA15 Emission Point/Stationary Vent/Distrillation

advertisement