160715123024paietalsubmitted

advertisement

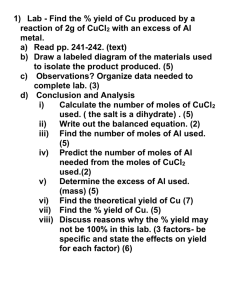

SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai Photocatalytic H2 generation over Cu-Ti-O photocatalysts in up-scaled reactors under sunlight Mrinal R. Pai*,Sushma A. Rawool, A. M. Banerjee and S. R. Bharadwaj Chemistry Division, Bhabha Atomic Research Centre, Mumbai-400085, INDIA *mrinalpai9@gmail.com; mrinalr@barc.gov.in, Ph. 022- 25592288 1. Introduction: Photocatalytic water splitting is one of the important solar energy conversion methods and success of the process primarily depends on the availability of suitable photocatalyst [1].Several titania based (In2TiO5, Cu doped TiO2, nanocomposites of NiO-TiO2,CuO-TiO2, CuO,) and carbon based photocatalysts (g-C3N4, Pt/g-C3N4, carbon nanodots/gC3N4andcarbon-TiO2 heterostructures) were developed and their properties were investigated by us [1-3]. In the present communication, in addition to lab scale results, photocatalytic H2 generation has been demonstrated in upscaled photoreactors (0.5L, 1L and ~2 L capacity) under sunlight over Cu0.02Ti0.98O2 photocatalyst to validate the extrapolation of activity results obtained at lab scale. The dependence of H2 yield on factors such as illumination area, form of catalyst (powder/films), catalyst concentration and different sacrificial agents (Glycerol/methanol) were investigated. Apparent quantum efficiency (AQE) and solar to fuel efficiency (SFE) of the photocatalysts under different conditions were calculated. 2. Material and Methods: Cu-Ti Photocatalysts were synthesized by sol gel method, characterized by X-ray diffraction, X-ray photoelectron spectroscopy, N2-BET, Raman spectroscopy, inductively coupled plasma-optical emission spectroscopy, high resolution transmission electron microscopy/selected area electron spectroscopy and diffuse reflectance UV-visible spectroscopy. Photocatalytic properties of samples were investigated under sunlight, visible and UV-visible irradiation. The emission spectra of both light sources along with reaction assemblies are shown in our earlier publications [2]. Experiments under sunlight were carried out on terrace of our institute. At lab scale, 50 mg to 100 mg of photocatalyst was suspended in a mixture of water + methanol (15 ml), evacuated and irradiated in ~100 ml capacity square quartz photoreactor equipped with gas collection and evacuation ports. Photocatalyst was also tested in upscaled photoreactors of capacity 0.5L, 1L and 2 L under different conditions in which upto 1g of sample was suspended in 250 ml water + methanol or Glycerol mixtures and irradiated under sunlight. Photocatlytic H 2 yield was monitored using Gas chromatograph with molecular sieve as column and thermal conductivity detector. Flux of both sunlight and medium pressure mercury lamp was measured using a silicon photodiode based light meter LX 1108, Lutron Electronic. 3. Significant Results and Discussion Photocatalytic properties of TiO2 modified by incorporation of Cu ions as dopant as well as forming composite with CuO in varying ratios were investigated. Among these the most active photocatalyst, Cu0.02Ti0.98O2, was tested in upscaled photoreactors. XRD and EXAFS of Cu0.02Ti0.98O2 revealed tetragonal anatase phase, with distorted lattice. Cu existed in +2 and +1, Ti in +4 and O as O2- and OH- ions was confirmed by XPS of Cu0.02Ti0.98O2 oxide. Various experimental parameters such as amount of sacrificial agent, geometry of photoreactor with respect to the irradiator, effect of stirring in both horizontal and vertical geometry, illumination area and catalyst loadings were optimized. Effect of illumination area on photocatalytic activity was investigated by performing the activity tests in large sized reactors. H2 yield enhanced from 110 to 183 and further to 251 moles/h when exposed to illumination area of 20, 32 and 45 cm2 respectively (Table-1). However, there was no increase in efficiencies (table-1) as the ratio of H2 yield obtained at a given illumination area remains constant (column-6, Table-1) in AQE and SFE calculations. AQE is directly proportional to H2 yield and inversely with illumination area. This implies AQE will increase only if H 2 yield increases at a constant illumination area. Therefore, in another set of experiments, illumination area was kept constant by fixing the reactor volume and solution volume (water + methanol) to 990 and 250 ml respectively, and concentrations of Cu0.02Ti0.98O2 photocatalyst were varied (g/l, Table-1). AQE obtained for different catalyst loadings are mentioned in Table-1. Although 1g loading of catalyst has shown maximum H2 yield of 735 moles/h with AQE of 7.5 %, it is emphasized that the rise in H2 yield is non -linear with catalyst loading. Higher concentrations are unfavourable for H2 yield. Probably at higher concentrations, the upper layer of photocatalyst shadows the lower layer and also blocks the penetration of light hence under limited light illumination the contribution of lower layer towards H 2 yield was restricted. A catalyst loading of ~1 g/L is an optimized concentration under the above conditions. 1 SusChemE 2015 International Conference on Sustainable Chemistry & Engineering October 8-9, 2015, Hotel Lalit, Mumbai Table-8 Effect of illumination area, catalyst loadings on photocatalytic H2 yield over Cu0.02Ti0.98O2 (CuTi) in an upscaled photoreactor of 990ml capacity. Comparison of H2 yield over CuTi powder and CuTi/ ITO/PET films and effect of glycerol as sacrificial agent is also given here. Illumination (mol/h) Reactor Volume (ml) Area (cm ) (L/h/m ) Lab scale 6.33 1.33 110 183 251 81 569 569 20 32 45 0.1 198 990 84 (4 films * 21cm2) 0.1 0.2 0.5 1.0 2.0 4.0 136 477 541 612 675 735 4.0 460 990 990 990 990 990 990 990 Catalyst amount+ solution volume Concentration (g/L) 100mg + 15 ml 100mg + 15 ml 100mg + 75 ml CuTi/ITO/PET films + 250 ml 25mg + 250 ml 50 mg+ 250 ml 125 mg+ 250 ml 250mg + 250 ml 500mg + 250 ml 1000mg+ 250 ml 1000mg+ 250ml (15% v/v glycerol) H2 yield H2 yield AQE (%) SFE (%) 1.23 1.28 1.24 3.13 3.23 3.19 1.06 141 141 141 141 141 141 0.529 0.217 0.758 0.716 0.972 1.072 1.167 3.06 1.41 4.14 5.27 5.64 6.6 7.5 1.56 0.72 2.11 2.7 2.9 3.4 3.9 141 0.730 5.0 2.6 2 2 4. Conclusions: We have demonstrated photocatalytic H2 generation in upscaled photoreactors under sunlight. Maximum rate of H2 generation achieved was 1.167 L/h/m2 over Cu0.02Ti0.98O2-photocatalyst with AQE of 7.5% and SFE of 3.9%. Our results suggests that with this efficiency H2 @ 1L/h can be achieved if Cu-Ti is exposed to illumination area of 0.9 m2 under sunlight. TiO2 modified by Cu2+ ions is an efficient low cost visible light photocatalyst that can be targeted for large scale H2 production under sunlight. References: 1. M. R. Pai, A. M. Banerjee, A. K. Tripathi, S. R. Bharadwaj, in: S. Banerjee and A. K. Tyagi (Eds.) “Functional Materials: preparations, Processing and Applications”, Elsevier, USA, 2012, pp. 579-606;A. A. Ismail, D. W. Bahnemann, Solar Energy Materials & Solar Cells 128 (2014) 85–101. 2. M. R. Pai, J. Majeed, A. M. Banerjee, A. Arya, S. Bhattacharya, R. Rao, S. R. Bharadwaj, J Phys.Chem.C, 116, 2012, 1458. 3. A. M. Banerjee, Mrinal R. Pai, A. Arya, S. R.Bharadwaj, RSC Advances, 5, 2015, 61218. 2