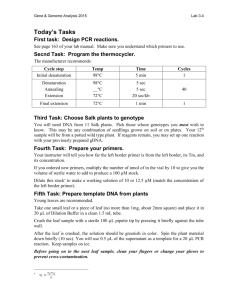

PCR Primer optimization

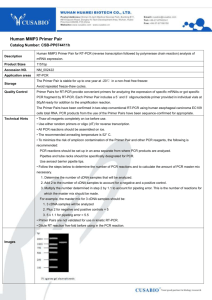

advertisement

PCR Primer optimization Written by Steve Doyle (s.doyle@latrobe.edu.au) - March 2014 - - PCR is a simple molecular technique in theory, however, it can be difficult in practice, sometimes without any logical reason as to why. It is important therefore to optimize and control the parameters that you can to ensure you can have the best chance of it working correctly. To do this, the main steps that we take every time we get a new primer set are to: o Correctly determine the primer concentrations (PCR/HRM/qPCR) You should not believe the values that the primer synthesis company gives you – in most cases, it is more that what is stated, and having too much primer can lead to non-specific amplification and primer dimers o Perform a gradient PCR to determine the actual optimal annealing temperature (PCR/HRM/qPCR) Again, you should not trust the providers’ estimate of Tm. There are many algorithms out there to predict the Tm, however, in your hands, it will ultimately depend on the polymerase and buffer that you use. The old general rule of annealing temp = Tm-5C is fine, however, if you have access to a gradient PCR machine, it is best to test it out for yourself. o Determine the primer amplification efficiency (HRM/qPCR) Primer efficiency tests the doubling rate of the PCR. A perfect PCR will have an efficiency of 100%, which means that the concentration of PCR product will double with each cycle (ie. 2n , where n= # PCR cycles). However this is not always the case, and primer efficiencies will deviate from 100% due to factors such as non-specific amplification or PCR inhibitors. Knowing the efficiency of the reaction is especially important for qPCR, as it is often used in the analysis calculations o Perform a melt curve analysis at the end of the PCR (HRM/qPCR) This is only relevant if you are using the qPCR machine. You can add a melt curve to the end of the PCR cycle program, which allows to determine if the PCR product you have generated is a single product, or if there has been non-specific amplification such as primer dimers. Both HRM and qPCR require a single specific product, which will translate into a single melt peak. The above recommendations are probably the most critical for success, however, other relevant parameters that could be optimized are: o Primer concentration - o DNA template concentration (we will address this in the qPCR section) o Magnesium concentration o Cycling times Relevant reading/links associated with the section o IDTDNA website (www.idtdna.com) and oligo analyser tools (https://sg.idtdna.com/analyzer/Applications/OligoAnalyzer/) My preferred website for predicting primer properties. o MIQE guidelines (see Bustin 2009 paper; Biorad tech note - a practical approach to RT-qPCR) These are quite specific for qPCR, but have very relevant info for standard PCR and HRM o Biorad notes qPCR assay design and optimization (http://www.bio-rad.com/enau/applications-technologies/qpcr-assay-design-optimization) SsoAdvanced Universal SYBR Green Supermix (http://www.biorad.com/en-au/product/ssoadvanced-universalsupermixes/ssoadvanced-universal-sybr-green-supermix) STEP 1: Determine Primer concentrations - primers are typically delivered to you as a lyophilised pellet, which need to be resuspended in either TE buffer or H2O. - we typically resuspend in H2O to make a stock concentration of 100 μM - once the concentration is confirmed, we make aliquots at 10 μM working concentrations - to determine the concentration of the dissolved primer stock, we need to measure the absorbance of the primers using a spectrophotometer Equipment and consumables needed - vortex centrifuge spectrophotometer Protocol 1. before you start, calculate the volume of liquid required to achieve a concentration of 100 μM 2. centrifuge the primer tube at max speed for 30 seconds a. some primer may be stuck to the sides/top of the tube, and you don’t want it to escape when you open the tube 3. add the required volume of liquid to the primer tube 4. vortex the tube for 5 seconds 5. centrifuge the tube for 10 seconds 6. repeat steps 4 and 5 for a total of 2X vortex/spins 7. per primer stock, make three 1/100 dilutions, ie. triplicates a. add 2 μl of primer to 198 μl of H20 in a new microcentrifuge tube 8. determine the absorbance at 260 nm (A260) for each of the triplicates for each primer stock using the spectrophotometer 9. calculate the mean absorbance (μA260) value of your triplicate tubes 10. calculate the concentration using the following formula (Beer-Lambert Law) a. Concentration (M) = (μA260 x Dilution Factor) / extinction coefficient i. Dilution Factor = 100 ; you made 1/100 dilutions above ii. Extinction coefficient = specific for each primer – the primer synthesis provider should give you this, but if not, you can use the Oligo Analyser tools at www.idtdna.com 11. Adjust the concentration of the stock tube to 100 μM using C1V1=C2V2 12. Make 1/10 dilutions of the primer stocks to achieve the final 10 μM working stock 13. Primer stocks can now be stored in the freezer until needed STEP 2: Gradient PCR - gradient PCRs are performed using PCR machines that are capable of generating thermal gradients across the 96-well block - depending on the machine, thermal gradients may run from the bottom (cool) to the top (hot), OR, from left (cool) to right (hot). Make sure you know which gradient direction your machine uses! The Biorad CFX machines have gradients running from the bottom to the top. - Gradient PCRs therefore aim to vary the temperature within each well at a defined step of the PCR, which is typically the annealing step - This allows you to find the optimal annealing temperature of your PCR, which is the highest temperature that shows good amplification, with hopefully no non-specific amplification - DNA: it is best to begin with a sample that you know is good quality and has sufficient concentration to allow you to do a few assays, ie. not a precious sample. As a starting point, I would make an aliquot of DNA at a concentration of 0.1-1 ng/ul. We can work out what the lower detection limits are later, but for now, use a concentration that should work easily. - It is good practice to keep all of your PCR reagents and set up your master-mixes in a dedicated DNA-free area that is separate to where you keep and aliquot your DNA, ie. your workbench. At LTU, we have a DNA-free room dedicated to this. This will help prevent contamination. Equipment and consumables needed - Gradient PCR machine - 8-well PCR strips and caps Protocol In your DNA-free area: 1. For each primer set, prepare a PCR master-mix in a single microcentrifuge tube Reagent Volume (μ) – 1X Master-mix Volume (# samples +1 extra) – 10 rxns SsoAdvanced Universal 5 50 Sense primer (10 μM) 0.5* 5 Antisense primer (10 μM) 0.5* 5 H2O 2 20 SYBR Green master mix * primer concentration is at 500 nM to start with. This can be optimized later if desired In your DNA work area: 2. aliquot 8 μl of master-mix into each well of an 8-well strip, and an extra single PCR tube for a negative (no template) control (NTC) 3. add 2 μl of H2O to the NTC and close the lid – do this before opening any DNA 4. prepare your standardized DNA sample if you have not done so already – you will need at least 16 μl of a 0.1-1 ng/μl solution 5. add 2 μl of the DNA stock to each well in the 8-well strip, and close the strip with strip caps a. each well contains exactly the same reaction – what will differ is the temperature applied to each well 6. ideally – you should centrifuge the 8-well strip for at least 30 secs at max speed to ensure all liquid is at the bottom of the well and that bubbles are minimized a. bubbles can cause two problems: (1) they cause uneven temperature in the well, and therefore you can have problems with amplification, (2) they can cause problems with fluorescence detection, and may not be detected properly 7. load the 8-well strip in the PCR machine, top to bottom, and load the single NTC at the bottom a. the NTC should be at the coolest temperature of the gradient, as this is where you are most likely to see non-specific amplification. If it is clear, you can be pretty confident that at high temps it will also be clear. If it is not clear, but your optimal temperature in your DNA wells is higher, subsequent PCRs at the optimal temperature will also have an NTC, and you can check it again then. Setting up the PCR conditions - to start with, a good place to set the gradient is from 50-70C. This can be refined later if needed, but for the most instances, it will give you all the information you need. - The SsoAdvanced Universal manual will give you basic cycling parameters, which includes using a 2-step PCR (denaturation, followed by annealing and extension in a single step). As we are trying to find the optimal annealing step conditions, we will use a standard 3 step PCR (denaturation, annealing and extension as separate steps). - qPCR and HRM typically runs for 45 cycles. This is obviously longer than a conventional PCR, however, it is important that the amplification curves of each product all reach a plateau so that they can be compared properly. Therefore, we need to cycle for longer. - We will include a melt curve here (best to do it on all PCRs done on the real-time machine), so we can compare the amplification curve and melt curve to find the optimal conditions. 8. setup the following protocol on the PCR machine: 98C 2 min Pre-amp. denature - 98C 5 sec Gradient 15 sec 72C 15 sec PCR amplifica on (45 cycles) 95C 30 sec 60C 2 min Post amplifica on melt and anneal 65C 15 sec 95C 0.5C/read Melt curve the run consists of a conventional PCR that is run for 45 cycles, followed by a fast melt curve analysis o the PCR is run for 45 cycles to ensure that the amplification reaction is finished and the reaction rate has reacted a plateau - o this is important to enable comparison between samples it is important to ensure the sample volume is set correctly to 10 ul on the machine. o The volume affects the rate and time it takes to cycle between temperatures, and if set incorrectly, will result in different temperatures in each well than those programmed NOTE: the gradient step should be set from 50-70C