Main Research Areas

advertisement

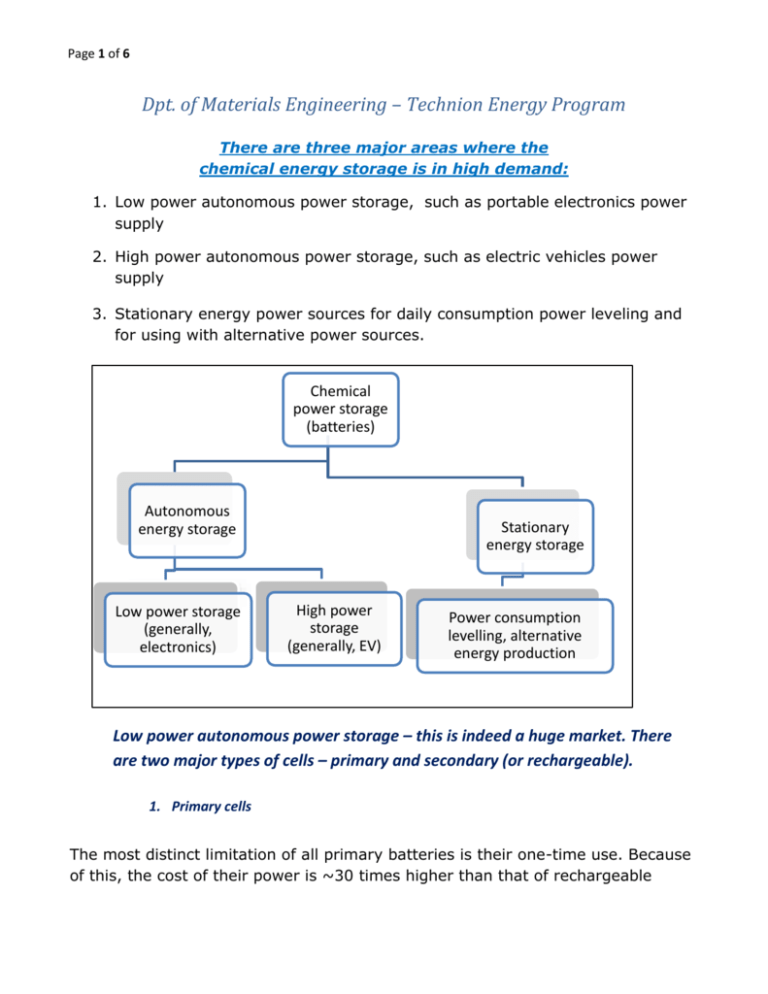

Page 1 of 6 Dpt. of Materials Engineering – Technion Energy Program There are three major areas where the chemical energy storage is in high demand: 1. Low power autonomous power storage, such as portable electronics power supply 2. High power autonomous power storage, such as electric vehicles power supply 3. Stationary energy power sources for daily consumption power leveling and for using with alternative power sources. Chemical power storage (batteries) Autonomous energy storage Low power storage (generally, electronics) Stationary energy storage High power storage (generally, EV) Power consumption levelling, alternative energy production Low power autonomous power storage – this is indeed a huge market. There are two major types of cells – primary and secondary (or rechargeable). 1. Primary cells The most distinct limitation of all primary batteries is their one-time use. Because of this, the cost of their power is ~30 times higher than that of rechargeable Page 2 of 6 Dpt. of Materials Engineering – Technion Energy Program batteries. The cost becomes even more excessive if the packs are replaced after each usage (fully discharged or partially used)... It would be much simpler to issue fresh packs before each activity. Keeping track of these packs in the military and public sector is time-consuming and awkward. Does it mean that rechargeable batteries are obsolete relicts of the past? Consider this: Cheap alkaline cells (these cells are a kind of outgrowth of Leclanché cell, patented in 1866) are still on demand. To be sure, households with kids, particularly younger ones, still use primary batteries, because more-popular gaming devices chew up disposable batteries. All around the world, people are still buying nearly equal amount of primary alkaline cells and rechargeable Li-ion cells. No wonder that currently a lot of attention of scientists and industrialists is focused on the reduction of Zn corrosion, which enhances Zn utilization and increases battery’s shelf life. Our group is on the cutting edge of this development. Currently we are developing a new approach to the problem of inhibition of Zn-corrosion; first results on the matter are – undeniably! – encouraging. 2. Secondary cells As it is explained above, overall secondary cells are cheaper and more convenient than primary cells. Apparently, secondary cells are more “consumer friendly” since they may be “redeemed” using a common wall power socket. Whereas a piece of a secondary cell commonly cost more than a piece of an alkaline cell, finally secondary cells provide cheaper electricity because such cells may be used repeatedly. Currently, the most advanced and promising cells are Li-ion cells. Since secondary cells are used in more demanding applications than common alkaline cells, they are required to be good performers; particularly, a high energy performance is desirable. The increasing of Li-ion cell voltage is the clear ways to improve its energy density. Our group is answering this need and the research in the field of 5-volt Li-ion cell is currently standing high on our waiting list. Page 3 of 6 Dpt. of Materials Engineering – Technion Energy Program The other issue is the battery safety; particularly, safety is the first priority if a product is supposed to be on sale for common public. It could be also easily comprehended that the higher the energy density of the battery, the bigger hazard it may potentially pose. Our group is not standing outside of this research; we are now involved in the project, which is aimed at the of Li-ion technology safety enhancement. High power autonomous power storage – this is the market of the future! The major potential segment – electric vehicles (EV) Nowadays, vehicle manufacturers are experiencing challenges of the environmental regulations and also of skyrocketing gas prises. In response, serious efforts have been made to develop commercially-viable EV (vehicles with the battery/[electric motor] propulsion system instead of the common [fossil fuel]/[internal combustion engine – ICE] propulsion system. It may be argued that despite of the fact that EV operation is environmentally safe the production of the needed extra energy would pose a pressure on environment. In depth consideration reveals, though, that: (i) Whereas currently power plants are substantial contributors to environmental pollution, [fossil fuel]/[power-station]/EV combination is significantly more energy efficient than [oil well]/refinery/[ICE vehicle] combination. This fact promises a substantial gas (and money!) saving and a sizable overall decrease of pollution. (ii) If renewable (i.e. wind, solar, etc.) or nuclear energy is used to generate electricity, the environment impact caused by the energy sector may be greatly reduced, and the benefits of the electric vehicle are not outweighed. At this time, the major hurdles, which are preventing the widespread implementation of electric vehicles, are all related to the fact that battery technology is not adequately advanced yet. Namely, the major issues are: too low battery energy performance (i.e. to high battery weight), too high battery price and insufficient battery safety. Page 4 of 6 Dpt. of Materials Engineering – Technion Energy Program With the most currently advanced Li-ion technology, typical EV battery weights about 240 kg for 160 km of one-charge-travel; highly performing EV (Tesla Roadster) has 350 km one-charge-travel but its battery weights about 500 kg, comprising one third of the car’s curb weight. This vehicle is now priced at approximately €66,000 whereas ICE vehicle of similar quality (BMW Z4) costs 40% less and runs for 500 km after fuelling. At approximately €13-15,000 per piece, the battery is an expensive component, but an EV is expensive not only because of the costly battery but also due to the high battery weight, so designers have to implement expensive weight-saving aerospace-grade construction materials to compensate the battery weight. The above deliberation hints that, first and foremost, the EV-related R&D is to be focused on the cell chemistries with high energy performance. In this relation, metal-air batteries appear to have a considerable promise since these cells demonstrate the highest specific energy compared to all other batteries. The reason is that the cells are utilising the ambient air, and so there is no need to store the cathode reactant inside the battery. This feature provides a substantial weight reduction. Just to give an idea how large the weight reduction might be, it may be noted that in case of a common Li-MnO2 battery, the cathode reactant’s weight is 30 times higher than the weight of the metal anode. Up to now, the development of metal/air batteries is mostly focused on Zn/air aqueous system, whereas Al-Si-Mg-Li/O2–redox couples have a substantially higher specific energy than Zn/O2-redox couple. The reason of this is that Al, Si, Mg and Li being highly reactive suffer a substantial corrosion in aqueous electrolytes, and so the practically viable design of such Al-Si-Mg-Li/O2 cells should be based on implementation of non-aqueous electrolytes. The other important matter lies in the metal-air battery rechargeability. Aqueous metal/air cells are primary systems par excellence, and up to now attempts to develop a rechargeable Zn/air cell were unsuccessful; being a one-time use cells, such systems don’t fit EV application. Contrastingly, non-aqueous metal-air systems are in essence rechargeable. Our group is the world leader of non-aqueous metal-air chemistry R&D. We are currently participating in several projects, which are related to the research related to Si-Al-Mg-Li/air cells. Page 5 of 6 Dpt. of Materials Engineering – Technion Energy Program • Stationary energy storage Daily and yearly power consumption is very uneven, so power generation capacity commonly exceeds the average yearly electric sales twice. The output of main workhorses of world power production (the thermal coal-firing powerhouses and nuclear powerhouses) is not malleable, and so certain “pickload power stations” have to be used. The hydraulic power stations are ideal for this purpose but in most cases these are gas turbine power stations, whose energy is expensive and which are highly polluting. The other issue is the need of energy infrastructure, which is adequate for high power pick consumption. The best solution is to use the “smart distribution greed” (SG); such SG comprises of combination of energy-transporting means and energy-storing means. The energy-transporting means are to convey the energy from the power station to consumers, and energy storage facilities are to be allocated near consumers being capable storing the energy during low demand hours and supply the energy to the consumer during pick hours (load leveling facilities). The introduction of SG would make the existing power production and energy transporting capabilities to be adequate for several upcoming decades, and also would avoid the need of pick-load power stations. The other issue is that the calls on the development of alternative power production also suggest the introduction of SG. Indeed, the available clean power sources (wind, solar energy) have the variable nature and thus cannot be practical without SG introduction. Currently, the most promising candidate for such energy storage is chemical power storage, i.e. a battery. The battery-based energy storage facility has many attractive features. Specifically, it may work without human intervention, in automatic mode, and needs only minor yearly maintenance, while the stored energy is available on instant demand; the facility may be easily fortified and may store energy for many hours in the case of emergency (wars, earthquakes, hurricanes, etc.). It is possible to start with building a moderately-sized battery-based electricity facility near particular consumer and extend it on demand; this eliminates the necessity of investing a vast amount of money at once and also makes it unnecessary to build new transmitting lines and distribution facilities with expanding consumer power demands. All these Page 6 of 6 Dpt. of Materials Engineering – Technion Energy Program features make chemical power storage an attractive option for a net-centric energy infrastructure - SG. The power rating of such storage could be up to several tens of megawatts; the energy storage rating may get up to hundreds of megawatts. The storage is to be reasonably compact but the energy and power density are not crucial parameters. Really important features are: low installment cost low operational cost long operational life high efficiency Currently redox flow battery technology are considering as holding promise to suite these requirements; up to now, pilot facilities with flow batteries have been build having several megawatt-hours energy rating and several megawatt power rating. At the same time, this technology is not sufficiently developed yet; the current state-of-art offers too high installment cost, too low operational life and inadequate efficiency. Our group is keeping track of this technology, and is preparing to step up to the plate