Initial Project Proposal

advertisement

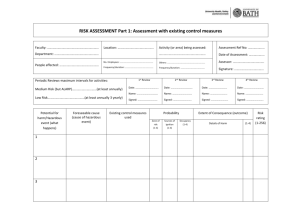

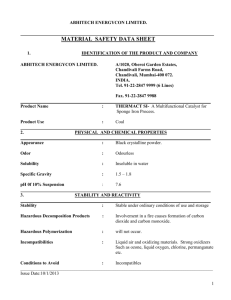

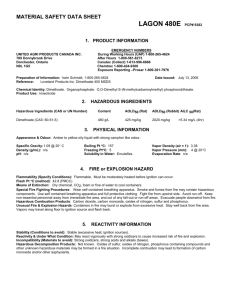

Class II Division 2 Occupancy Sensors James Fisher, Michael Gazda, Russell Gee, JoAnne Hitchcock, Gledi Progonati, Chris Zannoni Department of Electrical and Computer Engineering, University of Connecticut, Storrs, Connecticut 06269 Sensor Switch, 900 Northrop Road, Wallingford, CT 06492 Occupancy sensors detect human occupancy in an area using passive infrared technology. To use this system in class II division 2 hazardous environments, it must meet specific safety regulations including heat output, power, inductance, and capacitance for example. The focus for this device will be one that meets dust ignition proof, intrinsically safe requirements in order to be compliant with the safety regulations. Background Occupancy sensors are devices that allow for automatic lighting of a room or area. Rather than using the traditional system of turning on the lights via a light switch, the sensor system will do it based on occupancy. This takes out the human factor which could allow for extended use of the lights even when no one is present in the area. The current technology being utilized to detect human occupancy is passive infrared (PIR) and microphonics. PIR detects occupancy by absorbing the infrared energy only in the range of which the human body produces This energy is focused onto the sensor with a lens such as a Fresnel lens (a flat lens that is cheap to manufacture) [1]. This lens allows the sensor to absorb the energy from many different locations and when the temperature reading indicates a difference between consecutive areas, occupancy is detected. A signal is then sent from the device to a relay to automatically turn on the lights. Microphonics is the use of a microphone to use audible clues to indicate continued occupancy in the area [2]. For example, if a person enters the area, but remains still for an extended period of time, the sensor may come to the conclusion that the room is unoccupied. However, if the person is talking or typing on a computer, for example, the microphone in the device will pick up the sound and keep the lights on. The devices are set to turn off the lights after a predetermined length of time during which the PIR is not detecting a presence and the microphone is not detecting sound. Since the microphone only keeps the lights on after a human presence has been detected through PIR, there is no possibility of a false positive to keep the lights on without human occupancy. In most circumstances, occupancy sensor systems help to reduce the cost of lighting by limiting power consumption only to times of human occupancy. This could also extend the life expectancy of the light bulbs thus reducing the cost of both the electricity and frequent replacement of bulbs. There are so many benefits to the occupancy sensor system that it would be a great investment for any area where occupancy is infrequent or limited in duration. Thus, an ideal location for these systems would be a Class II Division 2 hazardous environment. This environment is one in which combustible dusts are present under abnormal circumstances. For example, warehouses that store packaged flour or bags of charcoal would be considered Class II Division 2 environments [3]. Although the presence of hazardous dusts is infrequent, the area must be treated as if it were constantly dangerous to reduce the risk of igniting any dusts. In order to implement the occupancy sensor system, it must first be guaranteed compliant with all safety regulations for this environment. These regulations include limits to the amount of inductance, capacitance, power, and especially heat output of the device among other regulations [4]. A device that is dust ignition proof covers all of these limitations. By definition, dust ignition proof means: “A dust ignition proof component prevents dust entering from outside. Arcs, sparks and heat generated inside of the enclosure will not be able to ignite the exterior surroundings near the component.” [6] Hazardous Dusts Hazardous dusts fall into many different categories depending on each one’s electrical resistivity. Within class II division 2, there are three groups: E, F, and G with group E being most hazardous and group G being the least hazardous. Group E hazardous dusts are typically metal dusts that are both conductive and explosive. The resistivity of these dusts is less than 100 kΩ/cm. Some examples of group E dusts are aluminum, calcium silicide, and titanium. Group F dusts have a resistivity between 100 kΩ/cm and 100 MΩ/cm; only some are conductive, but all are explosive. Carbon black, activated Charcoal, and asphalt dusts are all examples of group F. Finally, Group G dusts are not conductive, but all are explosive with a resistivity greater than 100 kΩ/cm. Flour, starch, grain, combustible plastics and explosive, chemical dusts would fall under this category. abnormal circumstances. Figures 1, 2, and 3 below show the ignition curves for inductive, resistive, and capacitive circuits respectively. In order for the device to be considered intrinsically safe, the parameters must fall below the curves. Another possibility would be separating the intrinsically safe portion of the device from the parts that aren’t using an energy limiting barrier such as a zener diode barrier. Design Restrictions: Intrinsic Safety If a device were intrinsically safe, it would meet all the safety regulations for class II division 2 environments. Intrinsic safety by definition is: "Equipment and wiring which is incapable of releasing sufficient electrical or thermal energy under normal or abnormal conditions to cause ignition of a specific hazardous atmospheric mixture in its most easily ignited concentration." (ISA-RP12.6) By limiting the electrical and thermal energy of the device, the possibility of ignition is removed making this the safest standard available. An intrinsically safe device is cheap, universally accepted, and easy to install. The limitation on the energy of the device means that the device would be very simple in design using as few components as possible. This would make it cheaper to manufacture and easier to install meaning less installation costs for the consumer and an overall less expensive product. Also, since the device is incapable of igniting any hazardous dusts within the class II division 2 dust groups (E, F, and G), it would be universally accepted as a safe product. Thus, there would be a larger consumer market available to sell the product in. An intrinsically safe device could be composed of simple apparatuses [4]. A simple apparatus would be one that comprised of components that store little or no energy. There are energy curves related to each type of system indicating the amount of energy allowed before ignition would be caused. Similarly, there are temperature restrictions depending on the dusts that may be present in the environment. For intrinsic safety, the device must not be capable of getting near the temperature of lowest ignition under either normal or Fig. 1: “Inductive Circuit Ignition Curves” Fig. 2: “Resistive Circuit Ignition Curves” enclosed within the box could ignite, or char, dust layers or clouds near the device. Also, all raceways and conduits made to the enclosure must be sealed and made of either PVC or metal that meets the requirements previously stated. Any wires going to the device need to be supported to reduce the tension on connections that could eventually expose the internal components to the hazardous environment. The enclosure should have a long life time to limit replacement costs and ensure the longevity of the device, thus, it should be corrosion resistant. Another significant consideration is the transmissibility of the material used to make the enclosure. For wireless communications to be possible, the material must be chosen carefully. Fig. 3: “Capacitive Circuit Ignition Curves” Enclosure Considerations In order to protect the device from the environment as well as keep any internal sparks, arcs, or explosions from normal or abnormal operating conditions away from the environment, the enclosure must be well designed. For this design, at minimum, a dust ignition proof enclosure is required. OSHA (Occupational Safety and Health Administration) has many requirements for an enclosure to be considered dust ignition proof. For example, the apparatus must completely enclose arcs and sparks so that they do not come in contact with the hazardous dusts in the atmosphere [5]. Furthermore, it will not allow the surface of the enclosure to become hot enough to ignite, or char, the lowest combustion temperature dusts even under surface dust accumulation conditions. Table 1, shown to the right, demonstrates the different temperature codes and the maximum allowable temperature the device may reach to be coded as such. It’s critical that the heat transfer of the enclosure remain as low as possible with low thermal conductivity to eliminate the risk of combustion. If the heat transfer isn’t low enough, device temperature of components North American Temperature Code T1 T2 T2A T2B T2C T2D T3 T3A T3B T3C T4 T4A T5 T6 IEC/CENELEC/NEC 505 Temperature Classes T1 T2 T3 T4 T5 T6 Maximum Temp. °C °F 450 842 300 572 280 536 260 500 230 446 215 419 200 392 180 356 165 329 160 320 135 275 120 248 100 212 85 185 Table 1: “Temperature Codes with Max. Temperatures” Cost Considerations In order for the device to be useful to the consumer, it must not cost more than the savings they would expect from using it. Based on calculations, this means the device should cost less than $430-$1200 this range depends on the size and typical occupancy of the area to use the sensor system. To meet this goal, the material chosen for the enclosure should have a low cost which meets all the previously stated requirements. It should also have a low production cost. Injection mold plastics, for example, would be ideal for this. The enclosure design should also limit installation time. This would reduce both the cost to install the system, which in turn would reduce the overall cost of the product. Another way to ensure a low-cost system would be to use inexpensive components that meet the requirements. References: [1] "Avoiding and Overcoming Installation Problems with Occupancy-Sensing Lighting Control Systems." Rensselaer Polytechnic Institute, 2 Dec. 2002. Web. 10 Oct. 2012. <http://www.lrc.rpi.edu/researchAreas/reducin gBarriers/pdf/occupancySensorElecGuide.pdf> [2] "Energy Efficiency | Outside the Box Construcion." Outside the Box Construction, 2010. Web. 13 Oct. 2012. <http://www.outsidetheboxconstruction.com/e nergyefficiency.html>. [3] "Hazardous (Classified) Locations." Hazardous (Classified) Locations. OSHA, May 1996. Web. 10 Oct. 2012. <http://www.osha.gov/doc/outreachtraining/ht mlfiles/hazloc.html>. [4] "Intrinsic Safety "i" Type of Protection." Siemens, 2012. Web. 12 Oct. 2012. <https://moodle.dce.fel.cvut.cz/file.php/17/Ma nualy/expb1_e.pdf>. [5] Stahl, R. "Innovative Global Explosion Protection." Automation Catalog 8000. R Stahl, 2012. Web. 26 Sept. 2012. [6] "North American Hazardous Area Protectio" Engineering Tool Box, 2012. Web. 27 Oct. 2012. <http://www.engineeringtoolbox.com/hazardou s-area-protection-d_487.html>.