spill control and countermeasure plan

advertisement

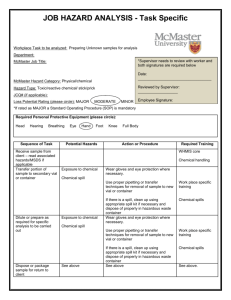

SPILL CONTROL AND COUNTERMEASURE PLAN In response to the OSHA standard CFR 1910,120 Hazardous Material Containment, COMPANY NAME has developed a Spill Control Plan. SCOPE This procedure describes the containment and cleanup methods to be implemented in the event of a spill of hazardous materials, petroleum products and materials of unknown origin. This procedure applies to both virgin stock and process wastes. RESPONSIBILITIES RESPONSBILE PERSONS NAME shall be responsible for training Spill Coordinators and employees assigned to spill cleanup, in proper safety, first aid and spill control techniques. RESPONSBILE PERSONS NAME shall revise the procedure as necessary based on new regulatory requirements, materials and/or processes. RESPONSBILE PERSONS NAME shall monitor and ensure compliance with all safety requirements, maintain respiratory protective equipment and emergency response kit, and coordinate employee training program. RESPONSBILE PERSONS NAME shall assign specific supervisors on each shift and for weekends, holidays and plant shutdowns to act as Spill Coordinators, and who shall be responsible for implementation of all aspects of this procedure in the event of a spill. During a spill incident, all regular duties of the Spill Coordinator shall be suspended for period required to control cleanup and document activities. Spill Coordinators shall exercise their judgment in applying procedures described herein based on their evaluation of the extent and degree of hazard in spill situations. Spill Coordinator shall select employees under his charge who will be required to implement the control and cleanup measures described herein. In all areas that Hazard chemicals are stored there shall be a listing of local police and fire departments, and hospital addresses and telephone numbers which can be called to provide necessary emergency or support services. SAFETY REQUIREMENTS During control and cleanup of a spill other than nonflammable petroleum products, employees shall, at the discretion of the Spill Coordinator, wear as a minimum, chemical goggles or chemical face shield in conjunction with safety glasses, neoprene rubber gloves and boot covers. In addition to the items specified in the previous paragraph, the following protective clothing/equipment shall be worn as determined by the Spill Coordinator: rubberized pants, rubberized raincoat and a fullface, self-contained breathing apparatus (SCBA) during control cleanup of acid spills, flammable solvents, fuel spills and materials of unknown identity. Other appropriate forms of respiratory protection may be used as determined by COMPANY NAME based on analytical tests or as deemed necessary by sound judgment. A buddy system shall be employed during spill containment and cleanup and consist of at least two (2) employees to provide immediate aid or procure help should an accident occur to employees performing cleanup work. Employees shall have been medically cleared, tested and trained in respirator usage per COMPANY NAME "Respirators; Purchase, Use, Maintenance, Storage and Employee Training". Fire fighting/control equipment shall be made immediately available for use at the site of a flammable solvent, fuel or spill of unknown origin. COMPANY NAME Emergency Response Team shall be reported to Management when the spill is first reported. GENERAL REQUIREMENTS Procedure 1. All spills which involve container ruptures, leakage, or overflows shall be reported to the __________. 2. COMPANY NAME shall investigate and mobilize necessary trained personnel and equipment. 3. All spills shall be contained with Zorb-All or equivalent, and procedure followed as outlined below for specific spill classes. 4. Spill area shall be secured with physical barricades or employees stationed at access points. 5. For portable containers (drums, pails pressure tanks), position container, where possible, to reduce or eliminate additional material leakage. 6. Where possible, transfer drum contents to new container compatible with material in question. 7. The following emergency service facilities have been supplied with a copy of this contingency plan and may be called upon to provide emergency assistance. When calling, Spill Coordinator shall provide as much information as possible and include the nature of the material, volume, time of occurrence, caller's name, Company name, phone number at which caller may be reached and control and cleanup measures being implemented. 8. Absorbed or neutralized materials shall be placed in DOT open top drums. 9. All cleanup wastes shall be clearly labeled and held pending disposition by the Hazardous Waste Coordinator. Following completion of cleanup tasks, Spill Coordinator shall issue a detailed written report of all actions taken during control and cleanup measures, including employee names and ID's and suspected cause of spill incident. Report is mandatory for any spill which has escaped from or occurred. 10. COMPANY NAME and Maintenance personnel shall review cause of spill and control and cleanup measures taken, to determine necessary preventive measures to preclude future occurrences and evaluate the effectiveness of the spill procedure. First Aid Following first aid procedures apply to all material covered under this procedure: Eye exposure: Wash eyes immediately with large amounts of water, lifting the lower and upper lids occasionally. Obtain medical attention immediately. Skin exposure: Immediately flush contaminated skin with large amount of water. If clothing has been contaminated, remove clothing and flush underlying area with large quantities of water. For petroleum products, wash with soap and water. Obtain medical attention immediately. Breathing: If a person has inhaled large amounts of gas mist or vapor, move to fresh air at once. Administer artificial respiration (if qualified) if breathing has stopped. Keep person warm. Obtain medical attention immediately. Swallowing: Give large quantities of water. DO NOT INDUCE VOMITING. Obtain Medical attention immediately. TYPES OF SPILLS Oil Spills and Non-Flammable Solvents Cleanup should be followed in procedures 1 though 10. Absorb remaining liquid and dry area with Zorb-All or equivalent. Using shovels and broom, collect contaminated sorbent and containerize. Contact Hazard Communications Coordinator and dispose of properly. Flammable Solvents Cleanup should be followed in procedures 1 though 10. Keep all ignition sources away and keep people from smoking at, or near, the spill site. If liquid is transferred from a ruptured container to new one, insure both containers are grounded to avoid static electricity and possibility of explosion. Absorb liquid and dry area with Zorb-All or equivalent. Should spill occur in outdoor yard areas, the same steps should be taken in procedures 1 though 10. Use shovels and broom and collect contaminated sorbent and containerize. Caution should be exercised with clay absorbed flammable solvents as the potential for fire or explosion still remains. Acids (Liquid) Cleanup should be followed in procedures 1 though 10. If possible, dilute acid with water and then neutralize with soda ash. Try to contain spill to a limited area. CAUTION: Mixing of soda ash with concentrated acid can result in release of concentrated acid fumes which can be very harmful. Dilution will reduce acid gas evolution. When material has completely neutralized, as evidenced by no foaming upon application of additional soda ash, clean up with brooms and shovels and dispose of properly. Alkalis (Liquid) and Hydrogen Peroxide Cleanup should be followed as in Procedures 1 though 10. Procedure includes lime slurry, sodium hydroxide and ammonia. Approved negative pressure dust/mist respirator may be employed however, use of Self Contained Breathing Apparatus equipment is recommended. Absorb with oil dry (Zorb-All). Use brooms and shovels and clean up and containerize. Flush residue to sewer with large quantity of water. Dry Acids and Alkalis Cleanup should be followed as in Procedures 1 though 10. Approved negative pressure dust/mist respirator may be employed however, use of SCBA is recommended. Use broom and shovel and clean up and containerize. Flush residue to sewer with large quantity of water. Unidentified Materials Follow all safety procedures as specified in procedures 1 though 10. Application of soda ash to a "corrosive" labeled liquid will indicate if material is acidic or alkaline. Acidic materials will foam or bubble due to release of carbon dioxide gas. If material does not foam, material MIGHT be alkaline, however, further confirmation with pH paper must be used to verify its alkaline nature. Equipment Needed for Spill Containment Following emergency equipment/materials are maintained in the facility: 1. 500# bags of soda ash for neutralization. 2. 500# bags of Zorb-All clay-base sorbent for containment and absorption. 3. Shovels 4. Squeegee 5. Brooms 6. Respirator(s) 7. Ansul Class BC fire extinguisher or equivalent. 8. Eye wash fountain 9. Emergency shower station 10. Barricades to stop traffic flow