Supplmentary materials

advertisement

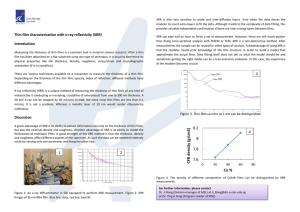

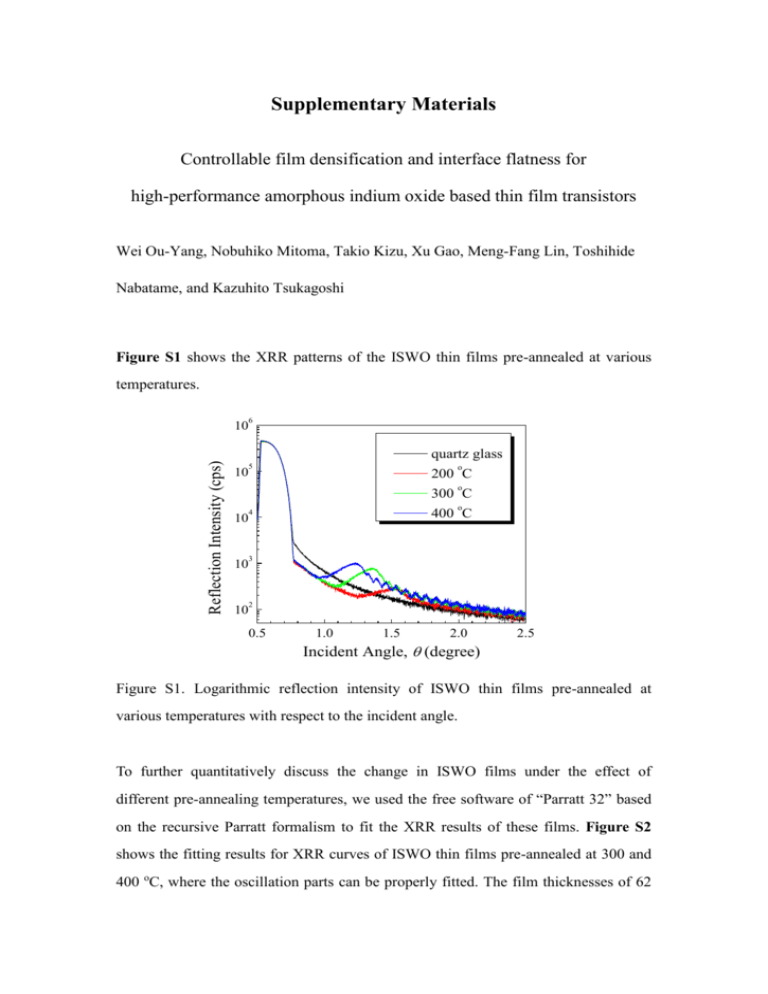

Supplementary Materials Controllable film densification and interface flatness for high-performance amorphous indium oxide based thin film transistors Wei Ou-Yang, Nobuhiko Mitoma, Takio Kizu, Xu Gao, Meng-Fang Lin, Toshihide Nabatame, and Kazuhito Tsukagoshi Figure S1 shows the XRR patterns of the ISWO thin films pre-annealed at various temperatures. 10 6 Reflection Intensity (cps) quartz glass 10 5 o 200 C o 300 C 10 10 10 o 400 C 4 3 2 0.5 1.0 1.5 2.0 2.5 Incident Angle, (degree) Figure S1. Logarithmic reflection intensity of ISWO thin films pre-annealed at various temperatures with respect to the incident angle. To further quantitatively discuss the change in ISWO films under the effect of different pre-annealing temperatures, we used the free software of “Parratt 32” based on the recursive Parratt formalism to fit the XRR results of these films. Figure S2 shows the fitting results for XRR curves of ISWO thin films pre-annealed at 300 and 400 oC, where the oscillation parts can be properly fitted. The film thicknesses of 62 and 60 nm are obtained for the films pre-annealed at 300 and 400 oC, respectively, as shown in Table S2, which are very close to the calculated values using the Kiessig fringe periods. Corresponding with the decreased film thickness as the pre-annealing temperature increase, the film density becomes larger represented the increased scattering length density (SLD) given in the table. In addition, we see the greatly decreased interface roughness at higher temperature reflected from the larger oscillation amplitude. All these fitted data corresponds well with the discussion in the main text. fitting results: 400oC: film: d=600Å, rho=2.1e-5, Im(rho)=4.5 bulk(quartz): 1.89e-5; 2.44 Reflection Intensity (arb. unit) 3.0 2.5 300oC: film: d=620Å, rho=2.0e-5, Im(rho)=4.2 bulk(quartz): 1.89e-5; 2.44 2.0 o 400 C 1.5 1.0 o 300 C 0.5 0.0 1.5 2.0 Incident Angle, (degree) Figure S2. XRR results with oscillation parts of ISWO films pre-annealed at 300 and 400 o C fitted with the free software of Parratt 32 (available on the website of “http://parratt32.software.informer.com/1.6/”). The red and black curves are fitted results. Table S2. Fitted parameters for the ISWO films pre-annealed at 300 and 400 oC in Figure S2. The real part and imaginary part of scattering length density (Re(SLD) and Im(SLD)) are proportional to the film physical density. Temperature (oC) Layer thickness (Å) Re(SLD) (×106 Å-2) Im(SLD) (×106 Å-2) Interface RMS (Å) 300 620 20 0.42 6.0 400 600 21 0.45 3.0