Brian Blanchette IDEAL INDUSTRIES, INC Contact: brian.blanchette

advertisement

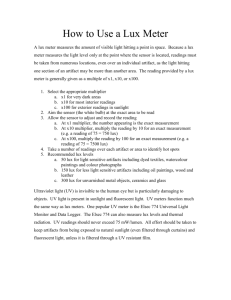

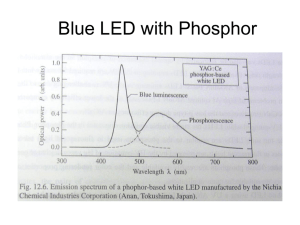

Brian Blanchette Everything You Always Wanted to Know About Measuring LIGHT, but Were Afraid to Ask IDEAL INDUSTRIES, INC Contact: brian.blanchette @idealindustries .com LED, Incandescent, Fluorescent, Induction Lighting! So many different options. When a customer or an inspector requires you to measure the amount of light in an area or on a surface what do you have to know? Light can be a very complex measurement if you want to comprehensively analyze all the aspects of measurement. But the good news is, if you are selling lamps and lighting, or if you are required to determine minimum light levels, you can do it easily and economically. First of all, let’s limit the discussion to the most common light measurement. Think about what you need to know about light. The two most important things are: 1. How bright is the light source, called Radiance, and 2. How much light is falling on a particular area, called Illuminance. The amount of light from any single source is really dictated by two factors, the brightness of the source, and the distance from the source. So, when we want to measure how much light is falling on a surface, the measurement you will be making as a salesperson or inspector is Illuminance. When switching out lamps for conservation or remodeling, you also have to consider the ‘brightness’ or radiance of the source you are installing, as compared to the radiance of the source you are replacing. If the distance from the lamps remains the same, and the new lamp is not as bright, the amount of light striking a surface will be less. How bright is the lamp? In many cases, the unit for comparison of brightness is Lumens. So, when measuring Illuminance, we need to start somewhere. That starting point is based on a very basic measurement. The amount of light produced by a single candle at a distance of one foot is called a Foot-Candle. The light produced by two candles at that distance would be two foot-candles. In the USA, all sources of light are compared to that amount of light. A more modern term is used in the lighting industry, and that is the Lumen. A Lumen is the equivalent of one foot-candle of light falling on a one square foot surface. So, for Illuminance measurement, if you have a lumen, you have a footcandle, and vice-versa. Most light meters with a foot-candle scale also have a conversion scale for Lux. A Lux is a metric equivalent of the Lumen. The Lux is one lumen falling on one square meter. So, doing the math, the Lux is equal to 0.09 foot candles, and is also a measurement of illuminance. You can think of one Lux as being one meter-candle, compared with our unit of measurement, one foot-candle. As the amount of light that falls on any surface comes from a combination of sources, and those sources all have light content that varies in wavelength, the light color content and many other factors have to be considered. Once again, the problem is already solved for you if you choose the correct light meter. Here is why. The human eye responds to light in a very specific way. This chart demonstrates how our eye sees light. The Human eye peaks for some reason on the color green. Perhaps, this is because that is color of money! Nobody knows for certain why, but it is an interesting fact. This curve established by the International Commission on Illumination represents the way a human eye sees light. A proper light meter includes filtering on the sensor that changes the sensor’s own sensitivity so that it matches that of the human eye. In this way, using a CIE corrected sensor, you automatically take into account a lot of the differences between daylight and artificial light sources. Not every light source produces the same wavelengths of light in the same amount. Here is an example of the light output of a typical white LED. Today, a common method of producing white LEDs is to use a blue LED treated with phosphor. This method involves coating LEDs of one color (mostly blue LEDs made of InGaN) with phosphor of different colors to form white light; the resultant LEDs are called phosphor-based white LEDs.[70] A fraction of the blue light undergoes a shift from shorter wavelengths to longer. Depending on the color of the original LED, phosphors of different colors can be employed. If several phosphor layers of distinct colors are applied, the emitted spectrum is broadened, effectively raising the color rendering index (CRI) value of a given LED.[71] Here is a light output curve of just such an LED This white LED is made from a blue LED treated with phosphor Spectrum of a “white” LED clearly showing blue light directly emitted by the GaN-based LED (peak at about 465 nm) and the more broadband Stokes light emitted by the Ce3+:YAG phosphor, which emits at roughly 500–700 nm. If we were to plot the light from one of these LEDs against the light from a standard Tungsten incandescent lamp, you would see a very different output based on the wavelength of light. There would be a visible color difference between the two, but the amount of light perceived by the human eye is going to be predicated on the light from the sources that falls in the area of that seen by the eye, and the response of the human eye to certain colors, like green. The ability of any light source to produce the proper color rendering is not part of the light meter’s job, but that characteristic is described by the Color Rendering Index (CRI value) and other indexes used by the lighting industry. The graphic below shows the response of a CIE corrected light meter sensor, compared to the light from a white LED (blue phosphor) and a standard Tungsten lamp. These phosphor treated LEDs are much less expensive to make than 3 color RGB LEDs, but it is certain that technology will change. No matter what the source of light, as long as the filter is constructed properly the professional light meter will provide a measurement of illuminance that is as close as possible to the visual response of the human eye. There is another issue and that is when light comes from reflected surfaces and multiple light sources. If a sensor does not have a line of sight to the source, it may not include this part of the light in the measurement. In order to compensate for that incidental light, a white domed filter is usually installed over the sensor. This is called a cosine correction diffusion filter, and it captures light from all angles so that off-axis light will be measured. Now you are beginning to see that if you choose the right light meter, much of the hard work of measuring illuminance is done for you. To begin making measurements of illuminance, you begin by selecting the right light meter. As you can see now, the light meter should be equipped with a Cosine Correction filter, and it should incorporate a CIE response filter. Because of the newly arrived LED lighting, you should check the specifications to make certain that LED lamp filters are included in the specification sheet. You should see a confirmation of the accuracy of the meter to Incandescent, Fluorescent, and LED lamps. If all three types are not specifically mentioned, check with the manufacturer to be certain. In general it is very hard to obtain greater than 10% accuracy when making illuminance measurements in the field. Technique is important. There are some things you can do to help increase the accuracy of your measurements. First, remove the protective cap from the light sensor, and allow it to be exposed to the light to be measured for a few minutes. The output of the sensor will change as it acclimates to its new surroundings. Second, when you make your measurements, get as far away as you can from the sensor. Your body will be blocking a great deal of light, and reflecting light from other sources. Be aware of your position in relation to the light hitting the light sensor. A sensor that is on a long lead is helpful in this case, because you can get more distance from the measurement point and still be able to read the meter. Once you have obtained your first reading, you may have to take other readings. You might want to measure the light at a desktop workstation, the light one foot from the floor at an exit, or the average light in a room. You may need to measure distances, make multiple measurements, and average readings. Whatever method you choose you can be sure that by taking a little extra care with your measurement technique, you will get better and more consistent results with more accurate measurements. If you would like to know what some average and recommended illuminance measurements are like, here is a list for your study and comparison. Because of the nature of measuring illuminance in the field, generally we use the equivalent that 1 foot candle is equal to 10 Lux. This value is within the measurement uncertainty of most commercial light meters. Light Measurement Equivalents and Common Illumination Levels: - 1 square meter (M2) = 10.7638 ft2 - 1 Lux is defined as 1 lumen/ m2 of a surface; thus 1 Lux= 0.0929 FC, - 1 foot candle (FC) is 1 Lumen/ ft2 of a surface; thus 1 FC=10.7638 Lux - There are 12.57 square meters on the surface of a 1 meter radius sphere. In real life, objects are illuminated and measured in Lux and Foot-Candles: - Full Daylight is about 1,000 Foot-candles or about 10,000 Lux (remember 10:1 ratio conversion) (Imagine 1,000 foot-candles each and every square foot!) - Cloudy day is about 100 FC or 1,000 Lux - A lighted parking lot at night is about 1 FC or 10 Lux - A full moon is about 0.02 FC or 0.2 Lux. OSHA Lighting Level Recommendations for Work Spaces (pre 1985): - Public spaces with dark surroundings 3 FC (30 Lux) - Simple orientation for short temporary visits 5 FC (50 Lux) - Working spaces where visual tasks are only performed occasionally 10 FC (100 Lux) - Performance of visual tasks of high contrast or large scale 30 FC (300 Lux) - Performance of visual tasks of medium contrast or small size 50 FC (500 Lux) - Performance of visual tasks of low contrast or very small size 100 FC (1,000 Lux) Office spaces are often over-lit as a result of the lighting being designed and installed prior to 1985, or perhaps because rules of thumb based on out of date lighting technologies were used. These older lighting systems are designed to accommodate paper-based reading tasks at light levels of 750-1,000 Lux (75 to 100 FC) . Current office operations primarily involve computer based and higher quality printed tasks such that overhead lighting can be reduced to between 300 and 500 Lux (30 to 50 fc). In a second paper, we will discuss the ways to measure Radiance, and those units of measure which are Candlepower or the more modern Candela. There are important things to know about Radiance, especially when you have to compare sources that radiate light in all directions, as compared to only a limited direction, as with LEDs. However, that is out of the scope of everyday illuminance measurement that most salespeople and inspectors must perform.