Heating and Air Conditioning

advertisement

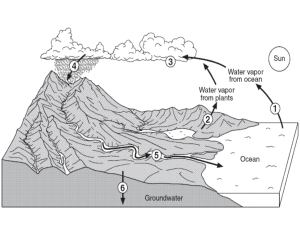

Energy Efficient Buildings Heat Gain/Loss through Infiltration Infiltration is air leakage into and out of a building. Buildings may also have forced ventilation. Neglecting air storage and changes in air density (which are almost always quite small), the total volume flow rates of air moving into and out of a building are almost always nearly identical. Heating or cooling this air requires significant amounts of energy. Thus, energy-efficient buildings are designed and built using construction practices the reduce air leakage to the minimum level acceptable for adequate ventilation. To reduce energy usage further, energy-efficient buildings may also employ forced ventilation with a heat exchanger between the incoming and exhaust air streams to capture heat that would otherwise be lost. This chapter discusses the drivers of infiltration, how to calculate average and hourly rates of infiltration, the heating and cooling energy required to heat and cool infiltration air, and the heat recovery ventilators. Infiltration Drivers The primary drivers of infiltration in buildings are stack effect, wind effect, combustion effect, exterior ducts, unbalanced supply and return air. These effects are discussed below. Stack Effect Stack effect occurs when warm air rises and pressurizes the upper part of a room or building. As this pressurized air leaks out the top, cool air is drawn into the lower part of the room or building. The pressure difference depends on vertical height and indoor/outdoor air temperature difference. Hence, stack-driven infiltration is higher in multi-story buildings and during winter. Z ΔP zgP 1 1 2R Toa Tia Wind Effect Wind effect occurs as wind impinges on the windward side of a building then moves over the top and around the sides of the building. The moving air increases the pressure on the windward side of the building. As the air passes over and around the building it entrains air on the leeward side into the air stream, creating a negative pressure on the leeward side of the building. This pressure difference between the windward and leeward sides of the building drives infiltration. The pressure difference is proportional 1 to the square of wind velocity V; hence wind-driven infiltration increases significantly during windy weather. Wind shading by terrain, vegetation and other buildings significantly reduces wind-driven infiltration. V PH PL V ρv ΔP 2 2 Combustion Effect Combustion effect occurs when combustion devices such as furnaces use indoor air for combustion, and then expel exhaust gasses through stacks to the outdoors. Air must leak into the building to make up the air lost through the exhaust stack. Combustion effect is greatest during winter when combustion furnaces, boilers, and hot water heaters burn more fuel. mex m a minf mag Exterior Ducts In warm climates it is common to run air supply ducts through unconditioned spaces such as attics. Air supply ducts are rarely tightly sealed and typically leak air. Air leaked from supply ducts into unconditioned spaces is replaced through infiltration. Air lost from leaky ducts can be a major driver of infiltration; the average infiltration rate in 50 houses in Florida with exterior ducts increased from 0.46 when the air conditioner was off to 2.10 when the air conditioner was on. ma 50 houses in Florida: N ac, off 2.10 N ac, on .46 minf AC 2 Unbalanced Supply & Return Air Furnaces and air conditioners supply conditioned air to rooms and draw return air back to the furnace or air conditioner. When supply and return ducts are not located in the same room, rooms with supply ducts are over-pressurized and rooms with return ducts are under-pressurized. These pressure differences increase air infiltration. Thus, recommended practice is for each room to have equally sized supply and return ducts. minf Return return in each room 0 N central return 1.5N otherwise N Calculating Energy Loss/Gain Due to Infiltration Furnaces and boilers increase air temperature, but do not add or remove moisture from the air. Hence, infiltration heat loss during winter includes only sensible heat loss. Air conditioners cool warm and humid air below the dew point temperature and condense moisture out of the air. Hence, the air conditioners remove both energy sensible and latent energy from the air. Thus, infiltration heat gain during summer must include both sensible and latent cooling. Winter Heating 2h2 m 1h 1 Q net,out Q inf m (h2 h1 ) m V ρ (h2 h1 ) Toa V N ρ (h2 h1 ) m1 Tia m2 In winter, furnaces & heat pumps add sensible heat only. Thus Δh = cpΔT inf V N ρc p (T2 T1 ) Q ρc p (Tia Toa ) Q inf V N where 3 V volume of house ft 3 N air changes per hour 1hr Btu ρc p 0.018 3 ft F Example Calculate Q inf for a 1,500 ft2 house with 8 ft ceilings if N 1.0, Tia 72F, Toa 30F . Q inf VN ρc p (Tia Toa ) 1 Btu Btu (1500 8) ft 3 1.0 .018 3 (72 30)F 9,072 hr ft F hr Summer Air Conditioning 1h1 m 2 h2 Q net,in Q inf m (h1 h2 ) m ρ (h2 h1 ) but h includes both Q sensible VN & Q latent ) In summer, A/C removes sensible & latent heat (dries air), Thus Q inf Q inf,sensible Q inf,latent Q inf,sensible V N ρc p (T1 T2 ) V N ρc p (Toa Tia ) Q inf,latent energy required to condense water from cooling coil w h fg m a ω 1 ω 2 h fg m V N ρ ω 1 ω 2 h fg where V volume of house ft 3 hr N air changes per hour 1 ρ density of air .075 lba ft 3 ω 1 specific humidity of outside air from psychromet ric chart lbw ω 2 specific humidity of inside air from psychromet ric chart lbw h fg enthalpy of evaporatio n 1,076 Btu lbw lba lba 4 Example Calculate the sensible & latent infiltration loads on a 1,500 ft2 house with 8 ft ceilings if hr , 1.0 1 N Tia 70F, RHin 50%, To a 90F, RHoa 80% From the psychrometric chart: lba T 90F, RH 80% .0248 lbw lba ω ia T 70F, RH 50% .0078 lbw ω oa Q inf,sensible V N ρc p Toa Tia 1 Btu Btu 1500 8 ft 3 1.0 .018 3 90 70F 4,320 hr ft F hr 5 Q inf,latent V N ρ ω oa ω ia h fg 1 lba lbw Btu Q inf,latent 1500 8 ft 3 1.0 .075 3 .0248 .0078 1,076 hr ft lba lbw Btu Q inf,latent 16,463 hr Btu Q inf Q inf,sensib le Q inf,latent 4,320 16,463 20,783 hr Calculating Average Air Infiltration Air infiltration is typically measured in terms of the number of times the entire volume of air in a building is replaced each hour. This unit is called “air changes per hour” N . The actual number of air changes per hour in a building varies continuously over time with drivers of infiltration such as wind velocity. Instantaneous measurements of infiltration can be made by releasing a tracer gas in a house and recording the rate of decay in the concentration of the gas. However, this method is somewhat impractical for wide spread use. Two methods for estimating the average number of air changes per hour are described below. ASHRAE Method The ASHRAE method provides a simple way to estimate air infiltration based on the tightness of construction, seasonal variations in wind speed, and the indoor/outdoor air temperature difference that drives the stack effect. a b Tia Toa N Time of year Construction Tight Winter Medium Loose Tight Summer Medium Loose a 0.280 0.408 0.483 0.210 0.310 0.310 b 0.00630 0.00873 0.01224 0.00720 0.00840 0.01400 Blower Door Method The blower door method estimates the average air infiltration by depressurizing a house with a blower and measuring the quantity of air that must be removed from the house to maintain a constant pressure difference between indoor and outdoor air. Leaky houses will require more air to maintain a constant pressure difference than tight houses. To use the blower door method, install a blower door in a door way and seal the door against the door jam to minimize leakage. Next, depressurize house until 6 ΔP = Pia – Poa = 50 Pascals The air flow required to maintain a 50 Pa pressure difference is called V 50 or “CFM50.” Use the following relation to convert from V 50 (CFM50) to N 50 (ÄCH50) 3 1 min N50 V 50 ft 60 3 hr min Vhouse ft CFM50 60 or ACH50 V ft 3 The “Princeton” Method to estimate the average N from N 50 is: N50 N 20 ACH50 or ACH 20 The “Sherman” Method to estimate the average N from N 50 is: N N 50 C H S L ACH50 or ACH C H S L where the following coefficients can be estimated from the graph and tables that follow. C = leakage infiltration ratio: 26 (hot climate) < C < 14 (cold climate) H = height correction factor S = wind shielding correction factor L = leakiness correction factor 7 Coefficients for Sherman Method Example Use the Sherman method to calculate the average infiltration rate for a 1,500 ft2 house in Dayton, OH with 8 ft ceilings, a single story, average shielding, and average cracks, if the measured CFM50 = 1,800 cfm. CFM50 ft 3 min 1800 60 1 N 50 ACH50 9.00 60 3 V ft min hr 1500 8 hr N ACH ACH50 9.00 1 .45 C H S L 20 1.0 1.0 1.0 hr LBNL Effective Air Leakage Area The LBNL method calculates an effective air leakage area, ELA at 0.016 inwc from a blower door test. The air flow due to infiltration, Q, is then calculated as: Q = ELA (Cs (Tia-Toa) + Cw U2)0.5 Where Cs is stack coefficient, Cw is wind coefficient and U is wind speed. Values of these coefficients are listed in the tables below. 8 Source: ASHRAE Fundamentals, 2005 p. 27.21 Estimating Hourly Air Infiltration Researchers at Lawrence Berkeley National Laboratory have developed methods to estimate hourly infiltration based on “effective leakage area”, building characteristics, and weather drivers. The effective leakage area at a typical pressure difference of 4 Pa (ELAat4Pa) can be estimated from air density (p) and the volume of air displaced from a building at 50 Pa (CFM50) during a blower door test; p = density (kg/m3) = 1.2 Q50 (m3/s) = CFM50 (ft3/m) / (35.314 ft3/m3 x 60 s/m) ELAat4Pa (m2) = (p/8)^.5 Q50 (4/50)^.65 0.106188433 The effective velocity of air (s) through the effective leakage area (ELAat4Pa) can be calculated from a stack effect coefficient (fs) and the indoor outdoor air temperature (dT), and from a wind effect coefficient (fw) and wind speed (ws). Values for fs and fw for typical residential buildings are shown below. dT = [Tindoor – Toudoor]+ fs (m/s-K^0.5) = 0.120 9 fw = 0.132 s = (fs^2 dT + fw^2 ws^2)^0.5 The volume flow rate of infiltration (V) is the product of the effective velocity (s) and the effective leakage area (ELAat4Pa). The number of air changes per hour (ACH) is the ratio of volume flow rate and the volume of the conditioned space (Vol). V = s ELAat4Pa N = ACH = V / Vol Example Calculate the number of air changes per hour for a residential building in which the volume of air displaced at 50 Pa (CFM50) during a blower door test is 3,000 cfm. The floor area is 1,500 ft2, the ceiling height is 8 ft. The temperature difference between the indoor and outdoor air is 10 C and the wind speed is 4 m/s. Input Data CFM50 (cfm) A = floor area (ft2) H = height (ft) dT = Indoor outdoor temperature difference (deg C) ws = wind speed (m/s) 3000 1500 8 10 4 Constants p = density (kg/m3) n fs (m/s-K^0.5) fw 1.2 0.65 0.12 0.132 Calculations A = floor area (m) (1 m2 = 10.76 ft2) H = height (m) (1 m = 3.28 ft) Q50 (m3/s) = CFM50 / (35.314 x 60) ELA(at 4 Pa) (m2) = (p/8)^.5 Q50 (4/50)^.65 s (m/s) = (fs^2 dT + fw^2 ws^2)^0.5 Q (m3/s) = ELA s = air flow Vol = A H (m3) ACH (1/hr) = Q/ Vol x 3600 s/hr 139.4052 2.439024 1.415869 0.106188 0.650218 0.069046 340.0127 0.731045 10 The chart below shows hourly air change per hour rates for a residential building calculated using this procedure and TMY3 temperature and wind speed data from Dayton, Ohio. Hourly infiltration rates are higher during winter when the indooroutdoor air temperature is larger. Hourly variations in wind speed cause significant variations in Infiltration rates throughout the year. Hourly and average air changes per hour for a residential building in Dayton, Ohio. Typical Air Infiltration Rates An independent study of air infiltration rates in new Minnesota houses found average rates of ACH50 = 4.2 and ACH = 0.27. ASHRAE research shows that 75% of newly constructed homes have infiltration rates between 0.25 and 0.75 air changes per hour. Older homes have higher infiltration rates. Source: ASHRAE Fundamentals, 2005 p. 27.15 11 Recommended Air Ventilation/Infiltration Rates U.S. E.P.A. Energy Star The U.S. Environmental Protection Agency awards “Energy Star” designation to highly energy efficient houses. One of the criteria for the Energy Star award is based on a blower door test: Energy Star House: CFM50 [cfm] 0.35 A ft 2 Example The measured infiltration rate at 50 Pa indoor/outdoor pressure difference in a 1,500 ft 2 house is 1,800 cfm. Determine whether the house meets the U.S. Energy Star criteria for air leakage. CFM50 1,800 cfm 1.2 0.35 A ft 2 1,500 ft 2 The house does not meet the U.S. Energy Star criteria for air leakage. ASHRAE Standard 62-1989 ASHRAE Standard 62-1989 recommends that all houses have ventilation rates exceeding 0.35 ACH to remove air contaminants. Thus, in very tight houses in which the natural infiltration rate is less than 0.35 ACH, recommended practice is to install an air-to-air heat exchanger, which continually brings in and exhausts outdoor air but recovers energy between the two air streams. 12 Blower Door Instructions Blower doors measure infiltration rate for a house. Infiltration is the amount of air that is moved from within a house to outside. Because this air carries with it heat/cooling put into it by the boiler/air conditioner, that energy must then be replaced. Reducing infiltration is an important part of conserving energy for a house. Infiltration rate is typically measured in Air Changes per Hour (ACH), or the amount of house volumes drafted out in a one-hour period. A good ACH for a tightly sealed house is about 0.5. Blower doors measure approximate ACH by depressurizing the house. Blower Door Operation 1. Make sure house is tightly sealed. 2. Select Time Mode of 5 seconds. (Turn dial to Time Mode, and push down on Select). 3. Fan Select 3-0 (Turn dial to Fan Mode. Type 3 (select up), Configuration 0 (select down)). 4. Range – Low. 5. Channel-Set to channel A. 6. Gauge Setup (refer to diagram next page) Connect Channel A reference knob with a tube to outside of the house. Leave Channel A input knob open Connect Channel B input knob with a tube to the blower door fan. Leave Channel B reference knob open 7. Remove all 3 rings from fan. 8. Keep gauge level. 9. Raise fan speed until pressure reads about 50. Then switch to cfm, and record CFM. 13 ACH calculation 1. Calculate the volume of the house. You can find area of the floor on housing.udayton.edu. Multiply the area by about 8 to get the volume of the house in cubic feet. CFM(measured) 60 2. ACH at 50 Pascals, or ACH50 . Volume 3. Find N C H S L . 4. Let C = 19, S = 1, L = 1 (normal house), 0.7 (drafty house), H = 1 (one story), 0.8 (2 stories). House Pressure CRF ACH50 45 1.1 5. ACH . 40 1.2 N 35 1.3 If you can’t reach 50 Pa, then your house is either big or very 30 1.4 leaky. Use the Can’t Reach Fifty (CRF) Factor on the speed dial 25 1.6 of the fan. Then multiply your ACH50 by this CRF. 20 1.8 15 2.2 Example EEB Infiltration Measurements 229 Lowes Built ~1930 Vol. = 14,120 ft3 CFM50 = 5704 dP = 45 Pa (therefore factor of 1.1) Fan dP = 143 Pa; CFM50 60 ACH50 24.21 Volume ACH50 N 1.21 (Princeton Method) 20 435 Kiefaber (Built 1999) Vol. = 15,683 ft3 CFM50 = 3255 Total dP = 50 Pa Fan dP = 46 Pa; CFM50 60 ACH50 12.45 Volume ACH50 N .62 (Princeton Method) 20 14 Reducing Infiltration Losses in Energy Efficient Buildings Create Wind Shields Build an earthen berm, locate the garage, or plant trees and shrubs on the windward side of a building to shield it from the wind. Supply Outside Air to Combustion Devices Use PVC piping to directly supply outside air for combustion to natural gas furnaces, boilers and water heaters. This will reduce drafts of cold air directly into the conditioned space. Seal Air Leaks Probably the single most cost effective measure to improve energy efficiency is sealing leaks. In new construction, the goal is to create a continuous air barrier. This entails sealing joints between the foundation, sill plate, floor joist header, sub-floor, wall framing plates and upper rim joist with caulk and/or other materials. In addition, seal all penetrations in the wall and ceiling drywall including electrical boxes and plumbing. Finally, tape and seal all joints in the house wrap and moisture barriers. One study found that at 50 P pressure difference, air leakage in a sealed house averaged 1.24 air changes per hour compared with 2.41 air changes per hour in an identical but unsealed house (1). House wrap to reduce infiltration. Close-up of taped joints. In existing buildings, use weatherstripping to seal doors and windows. Felt and open cell foam are inexpensive. However, vinyl and metal weatherstripping tends to last 15 longer and be more effective at reducing air flow. Use caulk to seal joints around plumbing and electrical fixtures and between walls, floors, ceilings, windows and doors. Also, Ducts Locate ducts within the insulated space and use mastic to seal duct joints. The photo below shows a duct located within the insulated space and sealed with mastic. A new technology allows contractors to seal duct leaks by injecting polymer laden air through the ducts. The company reports that the cost for a typical residence is about $800 to $1,500 with about a one year payback. In addition, balance supply and return air in every room to minimize over/under pressurization. The second photo shows a technician measuring the flow rate from a supply duct. Photos: NREL. http://www.nrel.gov/data/pix/ Air-to-Air Energy Recovery Units To minimize heating and cooling energy losses associated with exhausting and replenishing outdoor air, heat can be exchanged between the entering and exiting air streams. All air-to-air energy recovery units transfer sensible heat from the warm air stream to the cool air stream, raising the temperature of the cool air stream and lowering the temperature of the hot air stream. Some air-to-air energy recovery units can also transfer latent heat, in the form of water vapor, between the air steams. In these units, moisture is transferred from the moist air stream to the dry air stream. In an air-conditioned building when the indoor air is dryer than the outdoor air, this decreases the humidity of air entering the building. 16 The schematic below shows an energy recovery unit that uses a heat exchange wheel. As the wheel slowly rotates through the hot side, fins within the wheel absorb heat from air and cool the exit air. When the fins rotate to the cool side, they give up this heat and heat the exit air. The performance of a typical sensible+latent air-to-air heat exchanger is depicted in the schematic. The picture below shows a different type an energy recovery unit with a fixed plate heat exchanger. One air stream is drawn diagonally from upper left to lower right. The other air stream is drawn diagonally from lower left to upper right. Sensible heat is transferred through plates between the two air streams. SUMMER CONDITIONS WINTER CONDITIONS SUPPLY AIR 81°F DB 68°F WB OUTDOOR AIR 95°F DB 78°F WB SUPPLY AIR 53°F DB 40°F WB OUTDOOR AIR 7°F DB 6°F WB RETURN AIR 75°F DB 63°F WB EXHAUST AIR 89°F DB 73°F WB RETURN AIR 72°F DB 54°F WB EXHAUST AIR 27°F DB 73°F WB Source of data: http://www.airxchange.com/ Photo: NREL. http://www.nrel.gov/data/pix/ Energy savings from air-to-air heat exchangers can be modeled using the heat exchanger effectiveness method as: Sensible only: Sensible + Latent: Q = e m cp (Th1 – Tc1) = e V (p cp) (Th1 – Tc1) Q = e m (hh1 – hc1) = e V p (hh1 – hc1) where e is heat exchanger effectiveness, m is mass flow rate, V is volume flow rate, p is density, cp is specific heat, T is temperature, h1 is the entering hot stream and c1 is the entering cold stream. 17 Example Consider a sensible air-to-air heat exchanger moving 100 cfm into and out of a building with effectiveness = 0.70. The inside air temperature is 72 F and the outside air temperature is 30 F. The product of air density and specific heat, (p cp), is 0.018 Btu/ft3F. Determine the energy reclaimed (Btu/hr) and the temperature of the pre-heated as it leaves the heat exchanger and enters the building. The rate of heat reclaimed by the heat exchanger is: Q = e V (p cp) (Th1 – Tc1) = 0.70 100 ft3/min 60 min/hr 0.018 Btu/ft3-F (72 – 30) Q = 3,175 Btu/hr From an energy balance on the incoming cold air stream: Q = V (p cp) (Tc2 – Tc1) Tc2 = Tc1 + Q / [ V (p cp) ] =30 F + 3,175 Btu/hr/[100 ft3/min 60 min/hr 0.018 Btu/ft3-F] Tc2 = 59.4 F References : (1) (http://www.energysavers.gov/your_home/insulation_airsealing/index.cfm/myt opic=11310). 18