Lesson 1

advertisement

Lesson 1. Atomic Scale Structure of Materials

This teaching and learning package provides an introduction to crystalline,

polycrystalline and amorphous solids, and how the atomic-level structure has radical

consequences for some of the properties of the material. It introduces the use of polarised

light to examine the optical properties of materials, and shows how a variety of simple

models can be used to visualise important features of the microstructure of materials.

Aims

Introduction

Single crystals: Shape and anisotropy

Single crystals: Mechanical properties

Single crystals: Optical properties

Polycrystals

Defects

Summary

Aims: On completion of this tutorial you should:

know the differences between single crystal, polycrystalline and amorphous solids

be able to identify the characteristic features of single crystals and polycrystals

understand the nature of crystal defects

appreciate the use of polarised light to examine optical properties

Introduction.

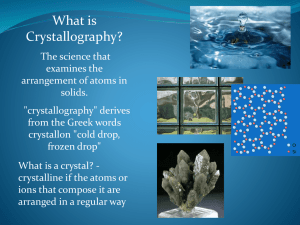

The fundamental difference between single crystal, polycrystalline and amorphous solids is

the length scale over which the atoms are related to one another by translational symmetry

('periodicity' or 'long-range order'). Single crystals have infinite periodicity, polycrystals

have local periodicity, and amorphous solids (and liquids) have no long-range order.

An ideal single crystal has an atomic structure that repeats periodically across its

whole volume. Even at infinite length scales, each atom is related to every other

equivalent atom in the structure by translational symmetry.

A polycrystalline solid or polycrystal is comprised of many individual grains or

crystallites. Each grain can be thought of as a single crystal, within which the atomic

structure has long-range order. In an isotropic polycrystalline solid, there is no

relationship between neighbouring grains. Therefore, on a large enough length scale,

there is no periodicity across a polycrystalline sample.

Amorphous materials, like window glass, have no long-range order at all, so they have

no translational symmetry. The structure of an amorphous solid (and indeed a liquid)

is not truly random - the distances between atoms in the structure are well defined and

similar to those in the crystal. This is why liquids and crystals have similar densities both have short-range order that fixes the distances between atoms, but only crystals

have long-range order.

The range of crystalline order distinguishes single crystals, polycrystals and

amorphous solids. The figure shows how the periodicity of the atomic structure of each type

of material compares.

Many characteristic properties of materials, such as mechanical, optical, magnetic and

electronic behaviour, can be attributed to the difference in structure between these three

classes of solid.

Single crystals: Shape and anisotropy

A single crystal often has distinctive plane faces and some symmetry. The actual shape

of the crystal will be determined by the availability of crystallising material, and by

interference with other crystals, but the angles between the faces will be characteristic of the

material and will define an ideal shape. Single crystals showing these characteristic shapes

can be grown from salt solutions such as alum and copper sulphate.

Gemstones are often single crystals. They tend to be cut artificially to obtain

aesthetically pleasing refractive and reflective properties. This generally requires cutting

along crystallographic planes. This is known as cleaving the crystal. A familiar example is

diamond, from which decorative stones can be cleaved in different ways to produce a wide

range of effects.

Consider the following three-dimensional

Octahedron: 8

shapes:

identical

equilateral

triangles

Cube: 6

identical

Rhombohedron:

squares

6 identical

parallelograms

with sides of

Tetrahedron: 4

equal length

identical

equilateral

triangles

These three shapes are the most important in materials science, and you should be very

familiar with them! The symmetry exhibited by real single crystals is determined by the

crystal structure of the material. Many have shapes composed of less regular polyhedra, such

as prisms and pyramids.

Hexagonal prism: 2 hexagons and 6 rectangles

Square-based pyramid: 4 triangles and a square

Not all single crystal specimens exhibit distinctive polyhedral shapes. Metals, for

example, often have crystals of no particular shape at all.

These quartz specimens show a range of shapes typically exhibited by crystals. Most

single crystals show anisotropy in certain properties, such as optical and mechanical

properties. An amorphous substance, such as window glass, tends to be isotropic . This

difference may make it possible to distinguish between a glass and a crystal. The

characteristic shape of some single crystals is a clue that the properties of the material might

be directionally dependent. The properties of polycrystalline samples can be completely

isotropic or strongly anisotropic depending on the nature of the material and the way in

which it was formed.

Single crystals: Mechanical properties

Gypsum can be cleaved along particular crystallographic planes using a razor blade.

The bonding perpendicular to these cleavage planes is weaker than that in other directions,

and hence the crystal breaks preferentially along these planes. Quartz and diamond do not

have such distinct cleavage planes, and so cleaving these crystals requires much more effort

and care.

There are distinct planes in the gypsum structure, with no bonding between them.

These are the cleavage planes. It is much more difficult to cleave gypsum along planes other

than these. In contrast, all of the planes in the quartz structure are interconnected and the

material is much more difficult to cleave in any direction. This is a demonstration of a way in

which the crystal structure of a material can influence its mechanical properties.

Certain crystals, such as gypsum, can be cleaved with a razor blade along particular

crystallographically-determined planes.

Glass is impossible to cleave. As an amorphous substance, glass has no

crystallographic planes and therefore can have no easy-cleavage directions. Glassy materials

are often found to be mechanically harder than their crystalline equivalents. This is an

example of how mechanical properties of crystals and amorphous substances differ.

Single crystals: Optical properties

Quartz crystals are birefringent, so they exhibit optical anisotropy. Consider plane

polarised light passing through a birefringent crystal. Inside the crystal, the light is split into

two rays travelling along permitted vibration directions (p.v.d.s). The two rays are subject to

different refractive indices, so the light travelling along each p.v.d. reaches the opposite side

of the crystal at a different time. When the two rays recombine, there is a phase difference

between the two rays that causes the polarisation state of the transmitted light to be different

from that of the incident light.

Optical anisotropy in thin samples can be observed by placing the sample between

crossed polarising filters in a light box. The bottom filter, between the light source and the

sample, is called the polarizer. The top filter, between the sample and the observer, is called

the analyzer. The polariser and analyser have polarising directions perpendicular to one

another.

The apparatus used for examining optical

anisotropy consists of a white-light source, two

polarising filters and a frame to hold them apart so

creating a working space.

When no sample is in place the light that reaches

the analyser is polarised at 90° to the analyser's

polarisation direction, so no light is transmitted to the

observer. When a quartz sample (with favourable

orientation, see later) is placed between the filters, the

crystal changes the polarisation state of the light that is

transmitted through it. When this light reaches the

analyser, some component of it lies parallel to the

polarisation direction of the analyser, and therefore

some light is transmitted to the observer.

If a quartz slice shows optical anisotropy, the

intensity of light transmitted through the analyser

varies as a function of the angle of rotation of the

quartz sample in the plane of the filters. At certain orientations, no light is transmitted. These

'extinction positions' are found at 90° intervals. When the same experiment is done using a

piece of glass, it is found that light is nottransmitted for any orientation. This is because the

glass is optically isotropic, and does not change the polarisation state of the light passing

though it.

In quartz, there is one direction of propagation for which no birefringence is observed.

If a sample is cut so that the incident light is parallel to this direction, the sample behaves as

if it is optically isotropic and no light is transmitted. The crystallographic direction that

exhibits this property is known as the optic axis.

When the quartz sample is cut so that the incident light is parallel to the optic axis, no

light is transmitted in any orientation.

This experiment demonstrates that some single crystals, such as quartz, show

anisotropic optical properties. The phenomenon depends on the crystallographic orientation

of the crystal with respect to the incident light. Amorphous materials like glass have no

'distinct' crystal directions, so anisotropic properties are generally not observed.

Polycrystals

Single crystals form only in special conditions. The normal solid form of an element

or compound is polycrystalline. As the name suggests, a polycrystalline solid or polycrystal

is made up of many crystals. The properties of a polycrystal are notably different from those

of a single crystal. The individual component crystallites are often referred to as grains and

the junctions between these grains are known as grain boundaries .

The size of a grain varies according to the conditions under which it formed.

Galvanised steel has a zinc coating with visibly large grains. Other materials have much finer

grains, and require the use of optical microscopy.

In galvanised steel, the grains are big enough to be seen unaided. The plate measures

5 cm across. In many other metals, such as this hypoeutectoid iron-carbon alloy, the grains

may only be seen under a microscope.

This polycrystal contains randomly oriented grains that allow transmission at different

angles. Consequently different regions of the polycrystal are seen in these two photographs.

The three-dimensional shape of grains in a polycrystal is similar to the shape of

individual soap bubbles made by blowing air into a soap solution contained in a transparent

box.

The surface between bubbles is a high-energy feature. If the area of the surface is

decreased, the overall energy of the system decreases, so reduction of surface area is a

spontaneous process. If all the bubbles were the same size, the resulting structure would be a

regular close-packed array, with 120° angles between the surfaces of neighbouring bubbles.

In practise, bubble growth can occur because the surface area of a few large bubbles is

lower than that of many small bubbles. Large bubbles tend to grow, and small bubbles tend

to shrink. The bubbles are therefore different sizes so there are large deviations from the

close-packed structure. On average, however, three bubbles meet at a junction, and the angle

between the bubble surfaces is usually within a few tens of degrees of 120°.

The curvature of the surfaces is also important. Surfaces with a smaller radius of

curvature have a higher energy than those with a larger radius of curvature. As a result, some

small bubbles cannot shrink and disappear, even though the surface area would decrease if

they did so. This is because the curvature of the boundaries, and the associated energy,

would be too high.

In a real polycrystal, the grain boundaries are high-energy features, similar to the

surfaces between bubbles. The soap froth is a very good model for the grain structure of a

simple polycrystalline material, and many similar features can be observed in the two

systems. The soap bubbles are analogous to the grains, and the surfaces of the bubbles are

analogous to the grain boundaries. Compare the photographs of the soap bubbles with the

micrograph of a polycrystalline material that has been etched to reveal the grain boundaries.

The packing of soap bubbles is somewhat similar to the packing of crystals - both

systems seek to minimise their surface area. Note the angles at the junctions of grain

boundaries.

The grains of this hypereutectoid iron-carbon alloy are packed in a similar way to the

bubbles in the previous photographs.

Grain boundaries in a polycrystalline solid can relax (move in such a way to decrease

the total energy of the system) when atomic rearrangement by diffusion is possible. In real

materials, many other effects can influence the observed grain structure

.

Defects

Within a single crystal or grain, the crystal structure is not perfect. The structure

contains defects such as vacancies , where an atom is missing altogether, and dislocations ,

where the perfection of the structure is disrupted along a line. Grain boundaries in

polycrystals can be considered as two-dimensional defects in the perfect crystal lattice.

Crystal defects are important in determining many material properties, such as the rate of

atomic diffusion and mechanical strength.

The balls within a grain arrange themselves into close-packed planes. In metals, closepacking of atoms is a very common structure. This pattern is typical of hexagonal closepacked and cubic close-packed lattices. Note that in this 2-D model, each ball touches six

others. In a 3-D crystal, such as a real one, each ball would also touch three on the plane

above, and three on the plane below.

A close-packed plane.

In the shot model, the balls are normally arranged in to a polycrystalline form, shown

schematically below:

A polycrystal will typically have crystalline regions (grains) bounded by disordered

grain boundaries. These boundaries are marked in the picture on the right.

Note that the packing of atoms at the grain boundaries is disordered compared to the

grains. At a grain boundary, the normal crystal structure is obviously disturbed, so the

boundaries are regions of high energy. The ideal low energy state would be a single crystal.

Polycrystals form from a melt because crystallisation starts from a number of centres

or nuclei . These developing crystals grow until they meet. Since they are not usually aligned

before meeting, the grains need not necessarily be able to fit together as a single crystal,

hence the polycrystalline structure.

After crystallisation the solid tends to reduce the boundary area, and hence the internal

energy, by grain growth. This can only happen by a process of atomic diffusion within the

solid. Such diffusion is more rapid at a higher temperature since it is thermally activated .

Summary

The focus of this package is the difference between single crystals, polycrystals and

amorphous solids. This is explained in terms of the atomic scale periodicity: single crystals

are periodic across their entire volume; polycrystals are periodic across individual grains;

amorphous solids have little to no periodicity at all.

The different atomic structures can have effects on the macroscopic properties. A

single crystal may exhibit anisotropy - we have seen mechanical anisotropy of gypsum, and

optical anisotrpy of quartz. Polycrystals may also be anisotropic within each grain, as seen

when the polycrystalline quartz-feldspar mix was placed between the crossed polarisers.

Amorphous solids do not have anisotropic mechanical or optical properties, since they are

isotropic on the atomic scale.

Defects may exist in all structures, even single crystals. They include vacancies and

grain boundaries, where the regular repeating structure is disrupted.

Glossary

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Alloy. A metal-like substance produced by mixing two or more metals or non-metals.

Ceramics can also be mixed to form alloys. A binary alloy contains two components.

A ternary alloy contains three

Crystal. A crystal consists of identical structural units, consisting of one or more

atoms, which are regularly arranged with respect to each other in space.

Crystallite. A small crystalline region, usually in the context of polycrystalline

materials or in semi-crystalline polymers, where crystallites are embedded in an

amorphous matrix.

Single crystal. A sample with a single crystallographic orientation across the whole

volume. Single crystals have no grain boundaries.

Polycrystalline A structure that consists of many crystals joining one another on their

boundaries is described as polycrystalline. The crystals are ordered in planes, called

lattices.

Translational symmetry. A structure is said to have translational symmetry if it can

be mapped exactly onto itself by translation of the whole structure through a specified

translation vector. In crystal structures, the translation vectors are known as lattice

vectors.

Anisotropic.

Not isotropic; i.e. having different properties in different

directions.Some materials, such as wood and fibre-reinforced composites are very

anisotropic, baing much stronger along the grain/fibre than across it. Although metals

and alloys tend to be relatively more isotropic, they too can exhibit significantly

anisotropic behaviour. This is especially important in processes such as deep-drawing.

Isotropic. Having uniform physical properties, such as elastic constants, in all

directions.

Crystal plane. A distinct plane in a crystal lattice, specified by Miller indices.

Miller index. Miller indices are a notation for describing directions and labelling

planes in lattices and crystals. The basis for determining the index is the unit cell. It is

important to be clear about the unit cell being used. A direction is expressed in terms

of its ratio of unit vectors in the form [uvw] where u, v and w are integers. A family of

crystallographically equivalent directions is expressed as <uvw>. A Miller index for

a plane is expressed as (hkl), where h, k and l are integers. A family of

crystallographically equivalent planes is expressed as {hkl}.

Miller-Bravais index. If crystal planes and directions in hexagonal systems are

indexed using Miller Indices, then crystallographically equivalent planes have indices

which appear dissimilar. To overcome this the Miller-Bravais indexing system is used,

where a fourth index is introduced to the three of the Miller system. A plane is then

specified using four indices (hkil), where h, k, i and l are integers. The third index is

always the negative of the sum of the first two and can be determined from the Miller

system. A direction is specified as [uvtw] where u, v, t and w are integers. The values

of u, v and t are adjusted so that their sum is zero. The direction index cannot be

written down from the equivalent Miller index.

Cleavage plane. A plane through a material along which it splits most easily. Usually

requires some form of lattice, with relatively few bonds across that particular plane.

13. Cleavage. Fracture of a crystal along certain crystallographically determined planes,

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

resulting in a smooth and shiny fracture surface, although the cleavage plane may

change over the fracture surface.

Brittle. A brittle material has a tendency to fracture by brittle fracture, in which there

is no significant plastic deformation and where fracture occurs by crack propagation.

A brittle material has a low fracture toughness.

Ductile. A ductile material is capable of undergoing large plastic (permanent) strains

before fracture.

Birefringence. A material is birefringent if a ray of light passing through it

experiences two refractive indices. The effect of this is to change the polarisation state

of the transmitted light. The extent of the change depends on the material and the

thickness of the specimen. Birefringence can be induced in some materials by the

presence of an applied or residual stress.

Vibration direction. A vector specifying the orientation of the electric field of an

electromagnetic wave. For a plane-polarised wave, the 'plane' is specified by the

vibration direction and the propagation direction.

Polarising filter. A material that plane-polarises light passing through it by means of

some highly anisotropic microstructure. When electromagnetic radiation is incident on

a material, it induces an electric field, which subsequently becomes the source for the

reflected / transmitted wave. A polarising filter generally has a microstructure that

allows electric fields in one direction far more easily than in others. Thus the reflected

/ transmitted waves are all aligned with that direction. The most common

microstructure of a polarising filter contains long molecules that should be all aligned,

thus giving the preferred direction of induced field (electrons will mostly move along

the molecules, rather than normal to them).

Polariser. In apparatus used to examine samples between crossed polarising filters,

the filter that is between the light source and the sample is called the polariser.

Analyser. In the apparatus used to examine samples between crossed polarisers, the

polariser that is between the sample and the observer is called the analyser.

Grain. In metallurgy this refers to any of the small randomly distributed crystals of

varying sizes that compose a solid metal. The grains contact each other at surfaces

called grain boundaries. The structure and size of the grains determine important

physical properties of the solid metal. Forming modifies the grains of a metal ingot to

improve the mechanical properties in the direction of grain length. Internal stresses at

grain boundaries may be relieved by annealing to restore ductility in certain alloys or

to harden other alloys.

Annealing. A heat treatment designed to soften a metal or alloy. Microstructurally,

annealing is associated with recovery, recrystallisation and/or grain growth.

Grain growth. The increase in the average grain size of a polycrystalline material that

occurs at elevated temperatures.

Forming. Forming processes include forging, pressing, piercing, drawing, extruding,

and most importantly, rolling. The forming processes convert solidified steel into

products useful for the fabricating and construction industries. They produce a desired

shape, improve cast steel's physical properties, and produce a surface suitable for a

specific use. Most forming takes place at about 1,200 °C

25. Grain boundary. Zone formed at the junction of individual crystals in a

polycrystalline material. Impurities tend to accumulate here by being excluded from

normal growth of each crystal.

26. Vacancy. A site in a crystal unoccupied by an atom. Vacancies are important in a

number of processes, not least diffusion, in which they provide a means for atoms to

move relative to the lattice. The concentration of vacancies increases exponentially

with temperature.

27. Dislocation. A lattice imperfection in a crystal structure which exerts a profound

effect on a structure sensitive properties such as strength, hardness, ductility and

toughness. Has a configuration of an extra half plane of atoms inserted in the crystal

stacking and the associated structural displacements near the end of the half plane

result in the atomic movement at much lower applied stresses than would occur in a

perfect crystal. There are two types, edge and screw, both of which are characterized

by a Burgers vector which represents the amount and direction of slip when the

dislocation moves.

28. Burgers vector. A crystal vector which denotes the amount and direction of atomic

displacement which will occur within a crystal when dislocation moves.

29. Diffusion. Diffusion is accomplished by the generation and movement of vacancies.

Diffusion may involve only one atom species (self diffusion) or in an alloy, may

involve more than one type of atom (solute diffusion). In the latter case, diffusion will

often result in atoms from a region of high solute concentration moving to regions of

lower solute concentration thus evening out any concentration gradients in the

material. Diffusion is the controlling mechanism for the climb of dislocations in

crystalline materials.