Industry Know-how

advertisement

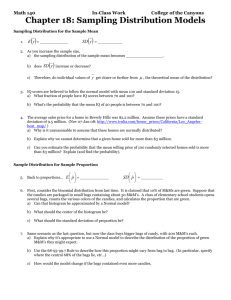

Industry Know-how Raw material packaging formats explained There is some confusion as to which materials are supplied in what packaging formats, why this is done and if required how it can be changed. As shown in the table below with the exception of PVC Resin and PET Resin (APET) the default packaging format is 25kg bags. This is an historic legacy that is unlikely to change, despite pressure in the UK to reduce the weight to 20kgs in order to make compliance with Health & Safety Manual Handling Guidelines easier. Material PVC Resin PET Resin Polyolefins Styrenics Masterbatch Engineering Polymers Compounds Y = Available N = Not Available S = Sometimes Available 20kg bags N N N N Y N S 25kg bags N N Y Y Y Y Y Min Max Pallet Size kgs N/A N/A 1,250 1,000 1,000 1,000 1,000 Pallet Size kgs N/A N/A 1,500 1,375 1,000 1,250 1,375 Big Gaylords Octabins Bags N N Y N N Y N S N N S N N S N S S N Y Y Y Bulk Y Y S S S S S Pallet Size. Originally pallets were 1,000kgs although in order to achieve better pallet utilization and transport efficiency pallets now typically are 1,375 kgs (55 x 25kg bags). Depending upon vehicle type this has enabled delivery size to increase from 20 tonnes to 27.5 tonnes on the same 20 pallets. Pallet Dimensions. These are typically determined to enable a 5 bag per layer configuration that provides maximum stability. Pallet Wrapping. In order to keep the bags on the pallet during transport typically one of the following forms of wrapping is used: 1. Stretch Hoods. A large plastic bag is physically stretched and then placed over the bags on the pallet. 2. Shrink hoods. A large plastic bag is placed over the bags on the pallet, heat is then applied and the large plastic bag shrinks & cools adopting the shape of the bags on the pallet 3. Machine Stretch Wrap. A tacky pre-tensioned plastic film is wound around the bags on the pallet. 4. Hand Stretch Wrap. A tacky plastic film is wound around the bags on the pallet. Stretch Hoods Shrink Hoods Power Stretch Wrap Hand Stretch Wrap Stability Excellent Good Good Poor Weather Resistance Good Good Poor Poor Risk of Adhesion to bags* None High None None * The process of heating results in the Shrink Hood becoming welded to the material bag Not applicable to paper bages. In the case of low bulk density materials the bags are often embossed to improve stability of the bags on the pallet and in some cases adhesive is applied for the same reason. Types of 20 & 25kg Bags Various types of bags are used depending upon type & origin of the polymer. The variants can be summarized as follows: Type PE Paper PP Rafia Laminated Strength Good Reasonable Excellent Good Material Types All Mainly Engineering Plastics & ABS All Hydroscopic Bulk Density. In addition to variations in actual density of different thermoplastics and formulations, pellet/granule geometry will also affect the mass of material that can be contained within a specific volume – the bulk density. Bulk density is particularly important when calculating the volume of tanks & silos so as to ensure that their capacity is suitable for the intended weight of polymer granules. Quantities Less than one pallet. Often customers require quantities of less than one pallet and denominations of 25 kg (20kg) are available. A premium is charged to cover the additional costs and this may include: < 100kgs – Courier Service, Boxes, Picking Charges >100kgs < 500kgs – Cost of pallet, pallet wrapping, picking charges, delivery premium (delivery charges from logistics companies are based upon number of pallets rather than weight, with a minimum charge of one pallet. >500kgs < 1,000, 1,250, 1,375 (depending upon original packaging) Cost of pallet and picking charges. Ocatbins Otaboxes & Gaylords. This packaging allows quantities greater than 25kg bags to be shipped in one container on a pallet. Weights range from 900 to 1,250 kgs depending on material type and supplier. ‘Gaylords’ are designed for use in shipping containers where they offer better stability and more efficient use of space. Big Bags FIBCs (Flexible Intermediate Bulk Containers). These are woven PP raffia sacks which can be either lifted by means of loops at the top of the bags or are supplied on pallets. The weight of polymer supplied in each bag is typically 1,000 kgs. In addition to extensive use for PET and PVC resin this format is often used in the compounding and recycling sectors. Bulk Supply Optons. Bulk is a term used to refer to materials that will be stored in silos. Historically road tankers were used to collect material from a polymer producer’s silo and deliver it directly to a customer’s silo. The need for dedicated vehicles with low utilization (due to return journeys being empty) has restricted the ability of high usage customers to take advantage of this option. Options to overcome these restrictions and enable access to overseas sources include: 1. ‘Rip & Tip’. In this operation 20, 25 kg bags, big bags or octabins are emptied into a road tanker for onward delivery to a customer. In effect the raw material supplier takes on responsibility for materials handling, and so overcomes the issues of geographical restrictions. 2. Sea Bulk. This type of packaging involves the use of shipping containers which are often modified to facilitate filling & emptying. The containers are lined with a plastic bag to remove any risk of contamination. The containers are suitable for ‘multi-modal transport’ (sea, rail and road), and can be also used as storage vessels. A specialist trailer is only required for the final journey to enable the material to be transferred into silo. If you have a question about packaging formats please contact us for further assistance.