L 05 Resistors 1

advertisement

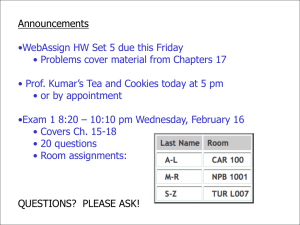

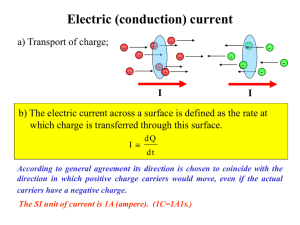

Passive Electronic Components Lecture 5 Page 1 of 22 17-Apr-15 Resistors 1 Lecture Plan 1. Physical basics 2. Parameters specified 3. Construction 1. Physical basics 1.1. Electrical resistivity and conductivity. Physical parameter that characterizes ability of material to conduct electric current is called electrical conductivity [-1m-1] or [Sm-1]. It connects between electric field E [V/m] and current density j [A/m2] inside physical body: j E , where is a tensor for anisotropic materials and a scalar for isotropic materials. Only isotropic materials will be considered further. Reciprocal value of electrical conductivity is called electrical resistivity [m]. Electrical conductivity varies by over 27 orders of magnitude depending on type of material. It is the greatest variation of physical property. Compare for example electrical conductivity range to the range of stable solid elements density. The lightest one is Lithium (0.534g/cm3), the heaviest one is Iridium (22.65g/cm3). Their densities ratio is 22.65/0.534 42. It is less than 2 orders of magnitude. Al2O3 Alumina Both electrical and thermal conductivities of metals depend on the number and mobility of conduction electrons. The ratio of thermal conductivity and electrical conductivity of the given metal at a given temperature is a constant that does not depend on a type of a metal (Wiedemann-Franz Law): L K 2k 2 T 3e 2 L = 2.4510-8 W/K2 (Lorenz number), K – thermal conductivity [W/(mK)], - electrical conductivity [-1m-1], T – temperature [K], k = 1.380710-23 J/K (Boltzmann’s constant), e = 1.602210-19 C (electron charge). Theoretically evaluated value of Lorenz number is in a good agreement with experimentally found values for many pure metals and deluted alloys. Passive Electronic Components Lecture 6 Page 2 of 22 Thermal and electrical conductivity of selected metals Thermal conductivity @ 273-373K , W/mK Electrical conductivity @ 293K, 107 (m)-1 Lorenz number calculated at T=293K, 10-8 W/K2 Silver 429 6.13 2.39 Copper 401 5.92 2.31 Gold 318 4.52 2.40 Aluminum 237 3.75 2.16 60W-Cu 188 2.39 2.68 Nichrome 80/20 A 13.4 0.093 4.92 Material Electrical conductivity is sometimes expressed in terms of %IACS (International Annealed Copper Standard). Conversion from resistivity in µcm to conductivity in %IACS may be performed as the following: [Conductivity in %IACS] = 172.41/ [Resistivity in µcm] Material Silver Copper Gold Aluminum Nickel Zinc Brass Iron Tin Phosphor Bronze Nickel Alum. Bronze Lead Steel Electrical conductivity, IACS, % 105 100 70 61 22 27 28 17 15 15 7 7 3…15 Silver is the best electrical and thermal conductor among the metals. Copper takes the second place, gold - the third. Electrical resistance may be introduced in the same manner as thermal resistance. Suppose that a physical body is connected to some external electrical circuit by its two connection terminals (surfaces) A and B (see picture below), and conducts electrical current I [A]. Each of two terminals Passive Electronic Components Lecture 6 Page 3 of 22 is equipotential: A 1 const ; B 2 const. Both potentials are measured in Volts [V]. The resistance R [] of the body is defined as R 2 1 I b a S B A A 1 B 2 C n 0 C Resistance R may be expressed in the terms of electric field E or in the terms of potential function : E dl 2 1 b R I E ds a S R 2 1 I 2 1 . d s S Here S is cross-section of the body, a and b are the arbitrary points on the terminals A and B respectively. Resistance determination. A. Determination of harmonic function that can be found as solution of Laplace equation (1) 2 2 2 2 0 x 2 y 2 z 2 with the following boundary conditions: A 1 ; B 2 n 0. C (1) Passive Electronic Components Lecture 6 Page 4 of 22 B. Determination of : ix iy iz . x y z (2) C. Determination of resistance: R 2 1 I 2 1 j ds S 2 1 2 1 . E ds ds S (3) S Example 1. Resistance of a prism. (A) The potential distribution is given: kx, where k is arbitrary scalar constant. l z S O x y V (B) Check that: (a) is harmonic function, (b) it complies to all boundary conditions (potentials in each of the terminals are constant, electrical current flows through terminal surfaces only). 2 0; 0, y, z const ; l , y, z const ; 0. y z (C) determination: kix . (D) Resistance determination: R k x 2 x1 k ds S l l . S S (4) Passive Electronic Components Lecture 6 Page 5 of 22 The well-known formula (4) is used in engineering practice. Resistance is calculated using the following parameters of the physical body: material resistivity [m], cross section area S [m2], and length l [m]. Example 2. Ring sector. The resistance between terminals A and B will be found in cylindrical coordinates r, , z. The angle between the terminals is /2. (A) The potential distribution is given: k , where k is arbitrary constant. C A I a B b I Check that is harmonic function, i.e. complies to Laplace equation 1 1 2 2 0 r r r r r 2 2 z 2 and complies to all boundary conditions. A k 1 ; B k 2 n 0. C (B) determination: 1 ir i iz ; r r z k i . r (C) Resistance determination: 1 k 2 R . b b b khdr hk ln 2h ln r a a a k 2 1 Passive Electronic Components Lecture 6 Page 6 of 22 1.2. Sheet resistivity. Resistive films are widely used in the modern resistors. Their thickness is significantly less than their outline dimensions. Resistance of a film pattern is calculated basing on the concept of sheet resistivity. Suppose that very thin rectangular resistive element is characterized by the following parameters: material resistivity , cross section area S [m2], width b, thickness , and length l [m]. b l S R l l l . S b b Parameter of the film is called sheet resistivity. It has dimensions of Ohms but it is always referred to as [/□] or [/sq] - Ohms per square. Conclusion: resistance of rectangular film pattern depends on its form factor l / b and does not depend on its absolute outline dimensions. Example 1. Calculate resistance of the film resistor (see below) having sheet resistivity . The resistive film is crosshatched. The terminals are orange. Solution. Form factor of the resistor is 5. Therefore R 5 . Example 2. Calculate resistance of the film resistor (see below) having sheet resistivity . There are corner squares in this example. Resistance of the corner element is approximately 0.56 . Therefore R 37 0.56 16 46 . Passive Electronic Components Lecture 6 Page 7 of 22 1.3. Ohm unit: [] = [V/A] = [kg·m2·s−3·A−2] Ohm is not SI base unit (unlike m, kg, s, A, K, mol, cd). It is derived from Volt and Ampere. Since 1990 Quantum Hall Effect is used in national laboratories to represent resistance standard with accuracy 1×10-8. (The higher accuracy is reached only in standard of time: 2×10-16). QUANTUM HALL EFFECT Dr. Edwin Hall discovered in 1879 that a magnetic field B applied perpendicular to the direction of a current I flowing through a metal plate (see picture below) develops voltage V H in the third perpendicular direction. It may be explained as the result of deflection of charge carriers towards the edge of the sample by the magnetic field (Lorentz force). It may be shown that VH I B , ned where n – density of mobile charges in the metal, e – electron charge, d – plate thickness. The ratio VH I may be regarded as some imaginary resistance Rxy VH 1 B I ned (By the way the actual resistance of the plate R xx U I ). Sheet resistivities of the plate xx , xy may be calculated as R xx , R xy divided by aspect ratio of outline dimensions of the plate. Plots of xx , xy as functions of magnetic field B are presented in the right picture below. U z 0 x y Passive Electronic Components Lecture 6 Page 8 of 22 In 1985 Klaus von Klitzing won the Nobel Prize for discovery of the Quantum Hall Effect (QHE). If the plate considered above is cooled down to millikelvin temperatures a series of steps appear in the Hall resistance as a function of magnetic field (see plot below) instead of the monotonic increase (compare with the above plot). And what is more, these steps occur at incredibly precise values of resistance which are the same no matter what sample is investigated. The resistance is quantized in units of Klitzing (1 Klitzing = h/e2) divided by an integer number. (e – electron’s electric charge, h – Plank's constant). h J s A V s 2 V 25813 25813 25813 25813; 2 2 2 A e C C 19 e 1.602177 10 C ; RK h 6.6260755 10 34 J s. The Von Klitzing constant, RK , is named in honor of Klitzing's discovery of the Quantum Hall Effect. The above figure shows the integer quantum Hall effect in a GaAs-GaAlAs heterojunction, recorded at 30mK. It is interesting that sheet resistivity xx turns to zero in the regions corresponding to plateau in xy plot. Important points to note are: The value of xy sheet resistivity at given magnetic field may be expressed through fundamental physical constants: e (electron’s electric charge) and h (Plank's constant). The expression is accurate to 1 part in 100,000,000. (For comparison precision of the most precise foil resistor is 1 part in 100,000 or 0.001%). The QHE can be used in primary standards of electrical resistance. Passive Electronic Components Lecture 6 Page 9 of 22 1.4. Noise in resistors Resistor noise "White" noise Thermal noise (Johnson noise) "Pink" noise (Flicker noise) Fluctuation noise (Shot noise) Thermal noise. (Called Johnson or Johnson-Nyquist noise). Thermal noise is due to the random thermal motion of electrons in a resistor and is unaffected by the presence or absence of electrical current. The voltage power spectral density (PSD) Sth [V2/Hz] of thermal noise is proportional to absolute temperature and electrical resistance of resistive element. It does not depend on material of resistive element. S th 4kRT . k = 1.38.10-23 J/K (Boltzmann constant); T - temperature (K); R - resistance (). This noise is "white", i.e. its voltage power spectral density is constant (for frequencies less than around 1013 Hz). RMS value of noise voltage in f bandwidth [Hz} may be calculated as the following: U RMS f2 S th df f 1 1 2 4kRT f . Conclusion. The ways of thermal noise reduction are: a) reduction of resistance, b) reduction of temperature, c) reduction of amplifier bandwidth. Example. For T = 296K, R = 1M, f = 20kHz calculation gives: U RMS = 18V. Passive Electronic Components Lecture 6 Page 10 of 22 Shot noise. Fluctuation noise. It results from random fluctuations of the electric current that is forced through conductive medium. The noise is caused by discrete nature of electrical current and by fluctuation of the charge carriers (electrons) number in the unit of material volume. This noise is "white" (its power spectral density SFl [A2/Hz] is constant for frequencies less than about 1012 Hz): S Fl 2eI ; I RMS f2 S Fl df f 1 1 2 2eI f , where e – electron’s charge (e = 1.6 .10-19 C); I - DC current, A; f - bandwidth, Hz; IRMS - RMS value of noise current, A. This noise does not depend on material of resistive element. RMS values IRMS and URMS of the noise in f bandwidth [Hz] may be calculated as the following. Suppose that U is the signal voltage drop on resistor with resistance R (no bias voltage is applied). Then noise/signal ratio may be calculated as the following: U RMS I RMS R I RMS 2e f , U I R I I Conclusion. The ways of noise/signal ratio reduction in the case of fluctuation noise are: a) reduction of amplifier bandwidth, b) increase of signal current value (at that, bias current should be reduced). Example. For signal current I = 1mA running through resistor f I RMS U RMS I U 20kHz 2.53 10 6 20GHz 2.53 10 3 Excess noise. Current noise, Contact noise, Flicker noise (in vacuum tubes). This is a fundamental noise found in various physical and biological phenomena. Voltage power spectral density of excess noise in resistors SE [V2/Hz] is found experimentally to be proportional to the square of DC voltage U applied across the resistor and reversely proportional to the frequency f [1, p.164]: SE C U2 . f C is a constant that depends on material of resistive element. Excess noise level essentially depends on material of resistive element and extreme values of frequency band. Passive Electronic Components Lecture 6 Page 11 of 22 This noise appears in resistor as an AC component of voltage when DC voltage is applied across it. Excess noise is usually expressed in RMS V/V. It may be also expressed in Noise Index [NI]dB in decibels: NI dB 20 log U RMS , U where U is applied to resistor DC voltage measured in V, URMS is root mean square noise voltage over a 1-decade bandwidth measured in V. RMS value of noise current in (f2 , f1) band [Hz] may be calculated as the following: f2 2 U RMS C f1 U2 df . f Relationship between excess noise expressed in RMS V/V and Noise Index [NI]dB is the following: [NI]dB 15 10 5 0 -5 V/V 5.60 3.20 1.80 1.00 0.56 [NI]dB -10 -15 -20 -25 -30 V/V 0.32 0.18 0.10 0.056 0.032 An interesting fact is the correlation between the noise power and the current that flows through the resistor. One of the theories states that the noise stems from the defects in conductive medium (unstable contacts between domains of resistive material, between resistive element and terminals, etc.). Operation of devices with little or no bias reduces this noise and may allow a system to be operated in a shot or thermal noise dominated mode. Excess noise commonly exceeds thermal noise at frequencies below 100 Hz. Excess noise predominates Thermal noise predominates Excess noise measurements are often used for diagnostic purposes. When excess noise in particular resistor exceeds the average noise level in the lot of the similar resistors it may indicate a defect in the resistor with increased noise. Passive Electronic Components Lecture 6 Page 12 of 22 Excess noise is typical for composite resistive materials that are used in carbon composition and thickfilm resistors. It was shown [2] that excess noise in carbon composition resistor (see the next lecture) is inversely proportional to its volume. Therefore using of bigger composition resistors (having higher power rating than it is needed for proper power dissipation) results in reduction of excess noise. The same phenomenon is observed in thick-film and thin-film chip resistors (see graph below). The bigger is chip resistors the lower is its noise index. (The designation of chip size in the below diagram is metric: 1005 means 1.0 mm x 0.5 mm and so on). Conclusion. The ways of excess noise reduction are a) to refrain from using low frequency band, b) to reduce the voltage applied to resistor, c) to increase the volume of resistive material, d) to use resistor based on “less noisy” resistive material. The most noisy resistive materials are composite materials used in carbon composition and thick-film resistors. The least noisy are resistive elements made of bulk metal material (foil, wire). 1.5. High frequency characteristics of the resistors. Fixed film resistors show a capacitive and inductive reactance at high frequencies in addition to their pure ohmic resistance. Equivalent circuit of leaded resistor Simplified equivalent circuits of chip resistor Passive Electronic Components Lecture 6 Page 13 of 22 For example in 0603 (inch) chip resistor with outline dimensions 1.6 mm 0.8 mm approximate values of parasitic inductance and capacitance in above equivalent circuit are: Lterm 0.4 nH, Cterm 0.3 pF. Further simplification of the above equivalent circuit may be performed as it is shown below. The impedance Z of this equivalent circuit is given by the following equation: Z R j L . 1 2 LC jRC The above expression for impedance Z may be illustrated by the following plot of Z R ratio supposing that C = 0.1 pF, L = 1 nH: Passive Electronic Components Lecture 6 Page 14 of 22 It may be shown that: For R L C the impedance Z is capacitive. The more is resistance R the less is the maximum working frequency. For R L C the impedance Z is inductive. The less is resistance R the less is the maximum working frequency. For R L C resistor have the widest range of working frequencies. 1.6. Skin-effect. High frequency current does not penetrate uniformly into the depth of conductive material. Therefore, the resistance associated with a conductive element at a high frequency is higher than its DC resistance. This effect is known as “skin effect” since the high frequency current flows mostly in a thin layer (skin) close to the surface of the conductor. The lower boundary of the skin is supposed to be at the distance from conductor’s surface at which the current density decays to 1/e (about 0.37) of the current density on the surface of the conductor. The skin thickness can be calculated as shown below: 1 f . - skin thickness (m), f - frequency (Hz), - permeability of material (H/m). For most conductive materials o = 1.256610-6 H/m (permeability of free space), - electrical conductivity of material (S/m). The values in the below table were calculated using the above formula for silver and nichrome that are used respectively for manufacturing of resistor terminals and resistive element. Passive Electronic Components Lecture 6 Page 15 of 22 Skin Depth, m Frequency, Hz Silver Nichrome 63 20 6.3 2.0 0.63 1.3102 41 13 4.1 1.3 =0.63108 S/m =0.010108 S/m 0 1 0 15 1M 10M 100M 1G 10G It may be concluded from the above table that thin-film nichrome resistive element having film thickness less than 1 m are not prone to skin-effect at high frequencies up to 10 GHz. But conductivity of about 10 m silver terminal in thick-film resistor deteriorates at frequencies above 10 MHz. 2. Parameters of resistor that are specified in its datasheet Resistor specifications Electrial Mechanical Environmental performance Resistance range, Ohm Dimensions Thermal shock Resistance tolerance, % Terminal strength Short time overload TCR, ppm/C Solderability High/low temperature exposure Voltage rating, V Marking Moisture resistance Power rating, W Packing Resistance to soldering heat Voltage coefficient, ppm/V Load life Noise, V/V We consider electrical specifications only. Mechanical and environmental specification will be considered later. 2.1. Nominal resistance value is desired resistance value of the resistor expressed in Ohms with respective multiplier (m, , k, M). Examples of marking by digits and letters: 10R (10 Ohm), 1K2 (1.2 kOhm), 10M (10 MOhm). Color code marking is sometimes used (see appended). Standard series of nominal values or so called “Preferred number series” are defined in the standards (see for example IEC 60063 international specification). They are formed as explained in Lecture 2, paragraph 8. 2.2. Resistor tolerance is characteristic of resistor in as-delivered condition. It designates permissible deviation of actual resistance from its nominal value. It is expressed in percents and has to be Passive Electronic Components Lecture 6 Page 16 of 22 defined at 25C with no appreciable load applied. For example, a 100 resistor with a tolerance of 1% can range in value from 99 to 101 . Tight tolerance makes sense if it is associated with high stability of resistor. 2.3. Temperature Coefficient of Resistance. Electrical resistance of conductive materials is a function of the temperature: R f (T ) . In many cases it is non-linear function. In engineering practice it is characterized in the given temperature range T1 ...T2 by parameter that is called Temperature Coefficient of Resistance (TCR) and is calculated according to the following relationship: R2 R1 [1/K]. R1 T2 T1 where R1 is resistance at temperature T1, R2 is resistance at temperature T2. Temperature Coefficient of Resistance is commonly expressed in parts per million per Celsius or Kelvin degree: ppm/°C, ppm/K. (1ppm =10-6= 0.0001%): R2 R1 10 6 [ppm/K]. R1 T2 T1 TCR is commonly related to particular operating temperature range (commonly it is 55°C… +125°C). For example a resistor characterized by TCR=100 ppm/°C will change 0.1% over a 10°C temperature change and 1% over a 100°C change. TCR of modern commodity resistors in the most cases does not exceed 200 ppm/K. 2.4. Power Rating is maximal permissible power dissipation in mounted resistor. Power rating is normally specified at +25°C and must be reduced when resistor’s temperature exceeds specified maximal temperature (commonly +70C). A so called derating chart (see graph below) is often used. Power ratings are based on many factors: physical size, construction, permissible resistance change over life, thermal conductivity and stability of materials (insulating, resistive, terminal), ambient operating conditions. Commonly: (a) the more is a power rating the more are outline dimensions of resistor; (b) the more is a safety factor in power dissipation the safer is design. Power derating chart 2.5. Maximal element voltage limits the voltage that may be safely applied to the resistor. Passive Electronic Components Lecture 6 Page 17 of 22 2.6. Rated voltage is defined as PR where P is rated power, R – nominal resistance. 2.7. Critical resistance value is characterized by possibility for resistor to experience maximal element voltage and dissipate rated power simultaneously: Vmax PRcr ; 2 Rcr Vmax P. Chip case (inch) 0402 0603 0805 1206 Parameters of standard thick-film resistors Chip dimensions, Maximal Rated Critical mm element power, value, k voltage, V W 50 0.063 39 1.00 0.50 0.35 75 0.100 56 1.60 0.85 0.45 150 0.125 180 2.00 1.25 0.45 200 0.250 160 3.20 1.60 0.55 Insulation voltage, Vpeak >75 >100 >200 >300 2.8. Voltage coefficient of resistance (ppm/V). Specific resistance change caused by nonlinearity of resistor when a voltage is applied. Non-linearity of resistor may also be characterized by the amplitude ratio (V/V) of measured 3rd harmonic and applied sinusoidal alternating voltage (1st harmonic). 2.9. Insulation voltage that isolation coating of resistor can tolerate for 1 min (see example in table above). 2.10.Insulation resistance (). It is resistance of isolation coating of resistor. Its order of magnitude is commonly 109. 2.11.Pulse power dissipation. Commonly it is represented by graph that shows dependence of pulse power from pulse duration. Steady-state power dissipation of resistor may be increased by reduction of thermal resistance of PCB. But pulse power dissipation is inherent to particular type of resistor and cannot be increased by external means. (See Lecture 9 for details). Passive Electronic Components Lecture 6 Page 18 of 22 3. Construction 3.1 Classification according to mounting method. Resistors Leaded Clamp mountable Surfacemountable Radial MELF *) Axial Rectangular chip *) MELF is the acronym for Metal Electrode Leadless Face. Passive Electronic Components Lecture 6 Page 19 of 22 3.2 Laser trimming. Film and metal-strip resistors pass special process of resistance adjustment - laser-trimming. It forms resistive element and defines its resistance, load capability, and stability. There are two possibilities of laser trimming process applications: a. Trimming in resistor manufacturing process. Resistive elements (both thick-film and thin-film) may be printed or deposited on substrate with approximately 15…20% tolerance. Modern industry requirements for resistor tolerance are 0.1…5%. They may be met if some kind of resistance adjustment follows film printing or deposition process. (Coarse tolerances 5% and 10% may be reached by sorting of the resistors). b. Resistance trimming after circuit assembly. For this purpose special trimmable resistors (flat chip resistors) are manufactured. They are laser trimmed after assembly (in-circuit). The alternative approach is the use of trimmers (mechanically adjustable resistors). Expensive laser trimming system is not needed for trimmers. This is their advantage. But the mechanically adjustable trimmer when compared with the laser trimmable resistor has the following disadvantages: (a) difficulty to automate the adjustment; (b) low reliability; (c) possible drift caused by thermal and mechanical impact; (d) worse compatibility with miniaturization; (e) higher price. Resistance of resistive element depends on its geometry and on resistivity of the resistive material. A laser trim procedure changes resistive element geometry to adjust its resistance. Laser trimming is a material removing by its vaporizing. A laser cut into the resistor area changes form factor of resistive element: lengthens the effective length and shorten the effective width. This is the reason why the resistance can be only increased by this procedure. An effective cut should be made transversely to the current flow direction. A laser works in a pulsed manner. The laser beam has a diameter of about 25 µm for thick film and 4...6 µm for thin film applications. The partial overlapping of the small burnt spots in resistive material results in a continuous cut. The following pictures show examples of laser cuts in flat film resistors. Passive Electronic Components Lecture 6 Page 20 of 22 Scan cut is more expensive because more volume of material has to be evaporated. But resulting current distribution is more uniform in this case and load capability of the resistor is higher. Resistive elements may have some other shapes: Multiplication factor. The ratio of resistance value after laser trimming to resistance value before laser trimming is called multiplication factor. Flat rectangular resistor. Suppose that resistances before and after laser trimming are R1 and R2 respectively. There are n cuts in resistor (see picture below). Multiplication factor M R2 R1 . In the terms of sheet resistivity Terminal L/(n+1) L ; D Dn 1 2 D 2 R2 n 1 ; L n 1 L R1 D 2 L 2 R D D M 2 n2 1 n . R1 L L Cylindrical resistor. Helical laser cut is commonly used in cylindrical resistors. It should be mentioned that it results in significant parasitic induction of resistive element. Suppose that resistances before and after laser trimming are R1 and R2 respectively. Multiplication factor M R2 R1 . N turns of helical cut produce (N-1) turns of film strip and divide cylinder generating line into (N+2) parts: Passive Electronic Components Lecture 6 Page 21 of 22 2 turns of helical cut produce 1 turn of film strip and divide cylinder generating (dotted) line into 4 parts In the terms of sheet resistivity L ; D Dn 1 Dn 2 R2 ; L n 2 L R1 L D R2 D n . R1 L 2 M L/(n+2) Maximal value of M may reach 1000. 3.3 Marking. The digits or color code are used for the marking of resistors. SMD resistors are usually coded with a 3- or 4-digit code. 4-digit code is used for relatively precise (1% or better) resistors. The code represents resistance in Ohms where last digit is the number of zeros to follow the first 2 (or 3) significant digits. Marking of resistances less than 10 Ohms comprises letter R instead of the decimal point. Examples of resistance codes Three Digit Codes Marking code Resistance, 330 33 221 220 683 68K 105 1M 8R2 8.2 Four Digit Codes Marking code Resistance, 1000 100 4992 49.9K 1623 162K 1004 1M 0R56 0.56 Tolerance codes Tolerance, Tolerance % code ±0.1 B ±0.5 D ±1 F ±2 G ±5 J ±10 K ±20 M Passive Electronic Components Lecture 6 Page 22 of 22 Color codes Band 1 Band 2 Band 3 Band 4 st nd Value (1 Value (2 Band Color (Multiplier) (Tolerance) digit) digit) ± 20% None 0.01 ± 10% Silver 0.1 ± 5% Gold 0 1 Black 1 1 10 ± 1% Brown 2 2 100 ± 2% Red 3 3 1k Orange 4 4 10k Yellow 5 5 100k ± 0.5% Green 6 6 1M ± 0.25% Blue 7 7 10M ± 0.1% Violet 8 8 100M ± 0.05% Grey 9 9 1G White Literature 1. Vasilescu Gabriel, Electronic Noise and Interfering Signals: Principles and Applications.Springer-Verlag Berlin Heidelberg, 2005. 709 p. 2. Louis J. DeFelice., 1/f resistor noise. Journal of Applied Physics, Vol. 47(1), pp. 350-352. January 1976