ELTC212_Jan2010 - Heartland Community College

advertisement

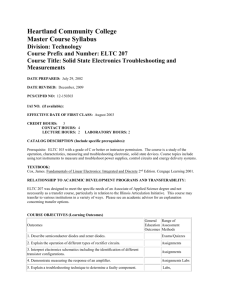

Heartland Community College Master Course Syllabus Division: Technology Course Prefix and Number: ELTC 212 Course Title: Automation and Control Electronics DATE PREPARED: August 17, 2002 DATE REVISED: December, 2009 PCS/CIP/ID NO: 12-150303 IAI NO. (if available): EFFECTIVE DATE OF FIRST CLASS: August 2003 CREDIT HOURS: 3 CONTACT HOURS: 4 LECTURE HOURS: 2 LABORATORY HOURS: 2 CATALOG DESCRIPTION (Include specific prerequisites): Prerequisite: ELTC 206 with a grade of C or better or MAIN 222 with a grade of C or better or instructor permission. Automation and Control Electronics is the study of automating a process. The course covers controlling motors, fluid-power systems and mechanical systems. Application of microprocessor controllers, transducers and sensors to automate a process is studied. Laboratory experiences complement the theories investigated. TEXTBOOK: Humphries, James T., Sheets, Leslie P. Industrial Electronics,4th Ed. Albany, NY: Delmar Cengage Learning, 1993. RELATIONSHIP TO ACADEMIC DEVELOPMENT PROGRAMS AND TRANSFERABILITY: ELTC 212 was designed to meet the specific needs of an Associate of Applied Science degree and not necessarily as a transfer course, particularly in relation to the Illinois Articulation Initiative. This course may transfer to various institutions in a variety of ways. Please see an academic advisor for an explanation concerning transfer options. COURSE OBJECTIVES (Learning Outcomes) Outcomes General Range of Education Assessment Outcomes Methods 1. Discuss different switching devices used in Industry. Exams/Quizzes 2. Explain the function and operation of mechanical and solid state relays. Labs 3. Demonstrate proper use of a transistor in a control device. Exams/Quizzes Labs 4. Install a three-phase motor. Labs 5. Describe at least five types of motor controllers. Assignment, Labs 6. Properly interpret technical schematics and symbols associated with automated systems. Assignment, Labs 7. Correctly apply a microprocessor to an analog measuring device. Labs 8. Demonstrate proper operation and maintenance of a PLC / Microprocessor. Labs 9. Apply automation techniques in self guided labs. Labs 10. Control a motor using a motor controller. Labs 11. Build a complete automated processing system using a PLC, Hydraulic or Pneumatic systems and electrically driven equipment as a final project. PS5 Final Project COURSE OUTLINE: 1. Microcontroller Programming 2. Analog Sensors / Measuring 3. Motor Control Identification 4. Installing a Motor Controller 5. Measuring Temperatures 6. Circuit Building 7. Troubleshooting Automated Systems METHOD OF EVALUATION (Tests/Exams, Grading System): (To be determined by each instructor): Exams / Quizzes 30% Final Project 30% Labs 30% Assignments 10% Grades will be based on the following scale: 90 – 100% A 80 – 89% B 70 – 79% C 60 – 69% D Below 60% F REQUIRED WRITING AND READING: Documentation is an important part of this course. All labs are to include descriptive comments within the write-up/answer section relating to each lab. The final project will require technical support of the constructed project. Students will be expected to read assigned selections from the textbook.