Hazardous waste disposal

advertisement

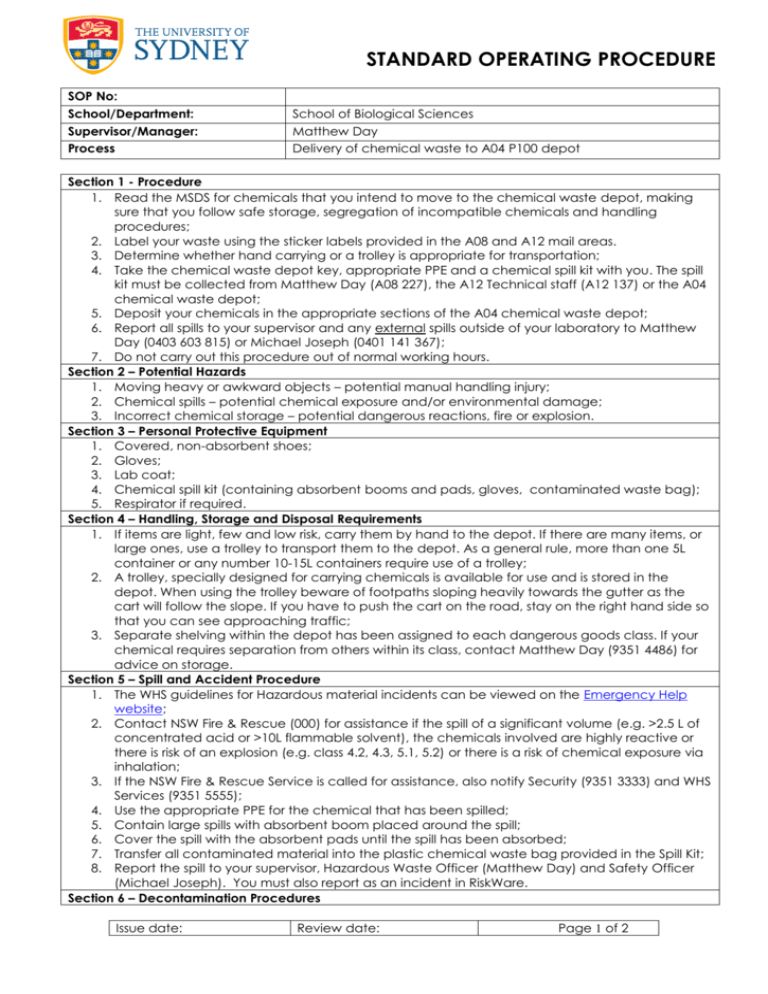

STANDARD OPERATING PROCEDURE SOP No: School/Department: Supervisor/Manager: Process School of Biological Sciences Matthew Day Delivery of chemical waste to A04 P100 depot Section 1 - Procedure 1. Read the MSDS for chemicals that you intend to move to the chemical waste depot, making sure that you follow safe storage, segregation of incompatible chemicals and handling procedures; 2. Label your waste using the sticker labels provided in the A08 and A12 mail areas. 3. Determine whether hand carrying or a trolley is appropriate for transportation; 4. Take the chemical waste depot key, appropriate PPE and a chemical spill kit with you. The spill kit must be collected from Matthew Day (A08 227), the A12 Technical staff (A12 137) or the A04 chemical waste depot; 5. Deposit your chemicals in the appropriate sections of the A04 chemical waste depot; 6. Report all spills to your supervisor and any external spills outside of your laboratory to Matthew Day (0403 603 815) or Michael Joseph (0401 141 367); 7. Do not carry out this procedure out of normal working hours. Section 2 – Potential Hazards 1. Moving heavy or awkward objects – potential manual handling injury; 2. Chemical spills – potential chemical exposure and/or environmental damage; 3. Incorrect chemical storage – potential dangerous reactions, fire or explosion. Section 3 – Personal Protective Equipment 1. Covered, non-absorbent shoes; 2. Gloves; 3. Lab coat; 4. Chemical spill kit (containing absorbent booms and pads, gloves, contaminated waste bag); 5. Respirator if required. Section 4 – Handling, Storage and Disposal Requirements 1. If items are light, few and low risk, carry them by hand to the depot. If there are many items, or large ones, use a trolley to transport them to the depot. As a general rule, more than one 5L container or any number 10-15L containers require use of a trolley; 2. A trolley, specially designed for carrying chemicals is available for use and is stored in the depot. When using the trolley beware of footpaths sloping heavily towards the gutter as the cart will follow the slope. If you have to push the cart on the road, stay on the right hand side so that you can see approaching traffic; 3. Separate shelving within the depot has been assigned to each dangerous goods class. If your chemical requires separation from others within its class, contact Matthew Day (9351 4486) for advice on storage. Section 5 – Spill and Accident Procedure 1. The WHS guidelines for Hazardous material incidents can be viewed on the Emergency Help website; 2. Contact NSW Fire & Rescue (000) for assistance if the spill of a significant volume (e.g. >2.5 L of concentrated acid or >10L flammable solvent), the chemicals involved are highly reactive or there is risk of an explosion (e.g. class 4.2, 4.3, 5.1, 5.2) or there is a risk of chemical exposure via inhalation; 3. If the NSW Fire & Rescue Service is called for assistance, also notify Security (9351 3333) and WHS Services (9351 5555); 4. Use the appropriate PPE for the chemical that has been spilled; 5. Contain large spills with absorbent boom placed around the spill; 6. Cover the spill with the absorbent pads until the spill has been absorbed; 7. Transfer all contaminated material into the plastic chemical waste bag provided in the Spill Kit; 8. Report the spill to your supervisor, Hazardous Waste Officer (Matthew Day) and Safety Officer (Michael Joseph). You must also report as an incident in RiskWare. Section 6 – Decontamination Procedures Issue date: Review date: Page 1 of 2 1. The generated waste from any spills should be treated as chemical waste and added to the A04 chemical waste depot; 2. Remove PPE and wash hands thoroughly. Section 7 - Material safety data sheets (to be available and accessible) 1. Section 8 - References 1. WHS (http://www.usyd.edu.au/whs) website; 2. WHS Emergency Help website http://sydney.edu.au/whs/emergency/index.shtml#hazardous 3. AS/NZS 2243.1:2005 – Safety in Laboratories: Planning and Operational Aspects; 4. AS/NZS 2243.10:2004 – Safety in Laboratories: Storage of Chemicals; WHS Consultation and Approval (Ensure this section is completed and copied onto rear of SOP) (Completion Instructions) Print names and enter signatures and dates to certify that the persons named in this section have been consulted/trained in relation to the development and implementation of this Standard Operating Procedure. Note that the WHS Representative (WHS Committee) certifies that consultation has taken place, and may not be involved in the original consultation. Position Manager/ Supervisor Name Signature Date Michael Joseph Safety Officer Manager Teaching & Research Support. First employee using SOP Second employee using SOP (if applicable) Third employee using SOP (if applicable) WHS Representative (WHS Committee) SOP Approval Name Authorising (Printed): ..................................................................................................... Signature: ..........................................................................Date: ................................................ Issue date: Review date: Page 2 of 2