2014 Specification Only

advertisement

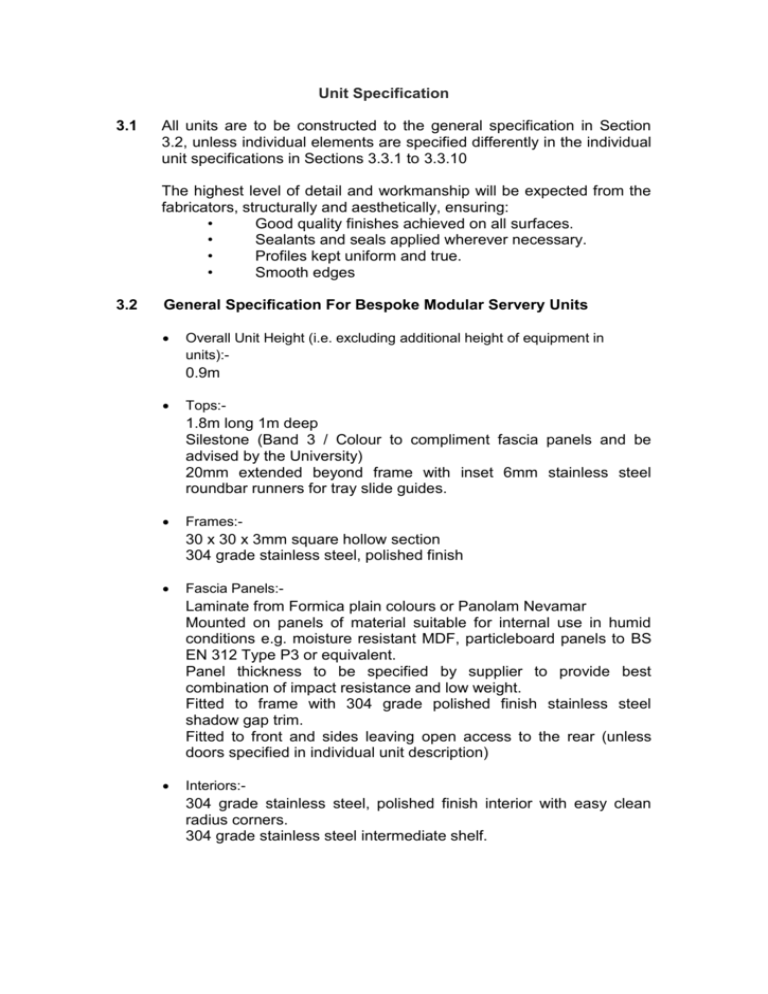

Unit Specification 3.1 All units are to be constructed to the general specification in Section 3.2, unless individual elements are specified differently in the individual unit specifications in Sections 3.3.1 to 3.3.10 The highest level of detail and workmanship will be expected from the fabricators, structurally and aesthetically, ensuring: • Good quality finishes achieved on all surfaces. • Sealants and seals applied wherever necessary. • Profiles kept uniform and true. • Smooth edges 3.2 General Specification For Bespoke Modular Servery Units Overall Unit Height (i.e. excluding additional height of equipment in units):- 0.9m Tops:- 1.8m long 1m deep Silestone (Band 3 / Colour to compliment fascia panels and be advised by the University) 20mm extended beyond frame with inset 6mm stainless steel roundbar runners for tray slide guides. Frames:- 30 x 30 x 3mm square hollow section 304 grade stainless steel, polished finish Fascia Panels:- Laminate from Formica plain colours or Panolam Nevamar Mounted on panels of material suitable for internal use in humid conditions e.g. moisture resistant MDF, particleboard panels to BS EN 312 Type P3 or equivalent. Panel thickness to be specified by supplier to provide best combination of impact resistance and low weight. Fitted to frame with 304 grade polished finish stainless steel shadow gap trim. Fitted to front and sides leaving open access to the rear (unless doors specified in individual unit description) Interiors:- 304 grade stainless steel, polished finish interior with easy clean radius corners. 304 grade stainless steel intermediate shelf. Toe Kicks / Plinths:- 304 grade stainless steel, polished finish to unit side and ends. Castors:- Base units mounted on adjustable and lockable heavy duty castors Gantries / Superstructures:- Ø50mm 304 grade stainless steel, polished finish round tube with high level curved glass sneeze screens With either 300 watt quartz heater lamps or fluorescent light fittings Electrical Connections:- Each unit will require an individual incoming electrical connection, min 10mm cable and plug (commando style if required on loads above 3.1kw), complete with main distribution board and all MCB’s and breakers built into the counter, as required. 2 x 13A 2-gang switched plug sockets on one outer side of unit (to supply any counter top equipment, plate dispenser, and till equipment) Cables fixed to frame to limit risk of “snagging” beneath castors and trip hazards when units are moved. Refrigeration Requirements:- Equipment in units incorporating refrigeration must be designed to meet the EN ISO 23953 standard, providing M1 cabinet class conditions and exceeding climate class 3 environment of 25°C at 60% relative humidity. In use the unit will maintain the core temperature of pre chilled food below 5°C in ambient temperatures up to 27°C - 50% relative humidity and adequate ventilation allowed to unit. 3.3 Individual Specifications For Bespoke Modular Servery Units 3.3.1 Bespoke Unit Housing Wet Heat Bain Marie 304 grade stainless steel, polished finish top hung sliding doors to the rear with removable door bar. Each unit housing: 1 x Victor Synergy Model DHBW4 Wet Heat Bain Marie Capable of accepting 4 x GN1/1 gastronorm containers (supply not required) Gastronorm compatible fan assisted hot cupboard sections below fitted with removable base and two mid shelves to accept 65mm deep gastronorm containers. Fan units to be removable from the base of the unit for ease of servicing. Electrical Load (bain marie & hot cupboard combined) 5kw single phase 1 3.3.2 Bespoke Unit Housing Single Stack Heated Plate Dispenser No individual incoming electrical connection or switched plug sockets on outer side of unit required. All access holes in unit/panels to be large enough to allow plugs to be passed though and edges finished with a rubber/plastic gromit. Each unit housing: 1 x Victor Synergy Model 72-0325 Single Stack Heated Plate Dispenser. Electrical Load .4kw each 3.3.3 Bespoke Unit Housing Wet Heat Bain Marie and Single Phase Soup Station 304 grade stainless steel, polished finish top hung sliding doors to the rear with removable door bar. Each unit housing: 1 x Victor Synergy Model DHBW4 Wet Heat Bain Marie Capable of accepting 4 x GN1/1 gastronorm containers (supply not required) 1 x Victor Synergy Model SOUP 2 Single Phase Soup Station fitted with an inset 10 ltr dry heat soup kettle with notched lid Gastronorm compatible fan assisted hot cupboard sections below fitted with removable base and two mid shelves to accept 65mm deep gastronorm containers. Fan units to be removable from the base of the unit for ease of servicing. Electrical Load (bain marie & hot cupboard combined) 5kw single phase Electrical Load (soup station)1.35kw 3.3.4 Bespoke Unit Housing Blown Air Dolewell 304 grade stainless steel round tube full length gantry illuminated by slimline fluorescent fitting with food enhancing light. Independently switched with clear curved glass sneeze screens to both sides. Each unit housing: 1 x 304 grade stainless steel blown air dolewell with double sided gantry Capable of accepting 4 x GN1/1 100mm deep gastronorm containers (supply not required) Electronic temperature control pre-set at 2ºC. Automatic de-frost cycle. Digital temperature display as standard. Compressor mounted below complete with ventilation grill. Electrical Load 2.5kw – 240v 2 3.3.5 Bespoke Unit Housing Multi Tier Refrigerated Display Each unit housing: 1 x Victor Synergy Model DRMT4 Multi Tier Refrigerated Display Capable of accepting 4 x GN1/1 gastronorm containers (supply not required) Electrical Load 3kw single phase. 3.3.6 Bespoke Unit To Accept Counter Top Equipment By Others 304 grade stainless steel base and intermediate shelf. Internally fitted with 2 x 13A 2-gang switched plug sockets and 2 x Cat 5E RJ45 coupler data points. All access holes in unit/panels to be large enough to allow plugs to be passed though and edges finished with a rubber/plastic gromit. 3.3.7 Bespoke Satellite Cash Unit 1.5m long x 1m deep No individual incoming electrical connection or switched plug sockets on outer side of unit required. All access holes in unit/panels to be large enough to allow plugs to be passed though and edges finished with a rubber/plastic gromit. Electrical Load 1kw – 240v 3.3.8 Bespoke Satellite Cutlery & Condiments Counter 1.5m long x 1m deep No individual incoming electrical connection or switched plug sockets on outer side of unit required. With 12 inset stainless steel perforated cutlery cylinders 3.3.9 Bespoke Dirties Clearing Stations for Trays, Cutlery, Crockery, Food Waste & Recycling 2.2m long x 1m deep (for the purposes of assessment. Final unit may be designed by Supplier and University to best utilise space available) No individual incoming electrical connection or switched plug sockets on outer side of unit required. 16swg 304 grade stainless steel top. To accommodate individually:Trays (each approx. 45cm x 35cm) Cups (each approx. 8cm diameter, 6.5 cm deep) Cutlery Dinner Plates (each approx. 26.5cm diameter, 2.5cm deep) Side Plates (each approx. 16.5cm diameter, 2cm deep) Bowl (each approx.16cm diameter, 5cm deep) Glasses Food waste bin Recycle bins – one each for paper, plastic, and cans 3 3.3.10 Bespoke Beverage Stations to Support a Chilled Juice Dispenser and Bulk Brewing Unit (Supplied By Others). 16swg 304 grade stainless steel top. 2 hinged doors with 304 grade stainless steel frame and back, and door front to match facia panels No intermediate shelf to accommodation cup trolleys underneath/within Electrical load TBC subject to juice / brewer specifications 3.4 Other Modular Servery Units 3.4.1 2 door Foster EcoPro G2 Model EP12H 1/2 Refrigerated Food Prep Counter 304 grade stainless steel interior 4