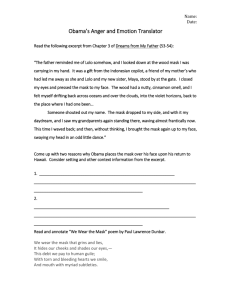

The engineering and environmental

advertisement