Influence of Key Process Parameters on Injection Blow Molding

advertisement

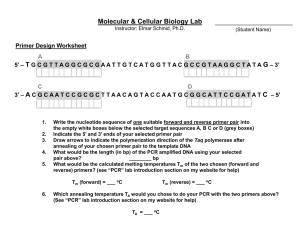

American University of Armenia Influence of Key Process Parameters on Injection Blow Molding Quality Design and Analysis of Experiments College of Science and Engineering Instructor: Alexan Simonyan Students: Asdghig Ashekian, Avedis Keoshkerian Fall 2015 Contents Introduction .................................................................................................................................................. 3 The Response Variable .................................................................................................................................. 4 The Factors Which the Response Variable May Depend On and Their Levels ............................................. 5 Operations : .................................................................................................................................................. 5 Tests & Results .............................................................................................................................................. 6 Checking for normality (Kolmogorov-Smirov test): .................................................................................. 6 Performing Mann-Witney U test to compare mean value of percentage of defectives in the two types of performs: .............................................................................................................................................. 7 Performing Mann-Witney U test to compare mean value of percentage of defectives in the two machines: .................................................................................................................................................. 7 Chi Square test for independence (Machines and perform types): ......................................................... 8 Kruskal-Wallis test for 4 independent samples: ....................................................................................... 8 2 Independent sample test within the 4 groups:...................................................................................... 9 Machine A, virgin VS PCR ...................................................................................................................... 9 Virgin Machine A VS Machine B ............................................................................................................ 9 Machine A , virgin VS Machine B, PCR: ............................................................................................... 10 Machine A,PCR VS Machine B, virgin: ................................................................................................. 10 PCR Machine A VS Machine B: ............................................................................................................ 11 Machine B virgin VS PCR: .................................................................................................................... 12 Kruskal-Wallis test for color effect on percentage of defectives: .......................................................... 12 Regression Analysis: ................................................................................................................................ 13 Test for correlation between numerical variables:............................................................................. 13 Linear Regression: ............................................................................................................................... 14 Curve Estimation ................................................................................................................................. 15 OLAP Cubes ............................................................................................................................................. 16 Conclusions ................................................................................................................................................. 17 2 Introduction Blow molding: is a manufacturing process by which hollow plastic parts are formed. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. Injection blow molding is used for the Production of hollow objects in large quantities. The main applications are bottles, jars and other containers. The injection blow molding machine is based on an extruder barrel and screw assembly which melts the polymer. The molten polymer is fed into a manifold where it is injected through nozzles into a hollow, heated pre form mold. The pre form mould forms the external shape and is clamped around a mandrel (the core rod) which forms the internal shape of the pre form. The pre form consists of a fully formed bottle/jar neck with a thick tube of polymer attached, which will form the body. PET Preform A hot pre form is clamped in a blow mold. A stretch rod is usually used to stretch the pre form to the base of the mold, while low pressure compressed air is used to “pre-blow” the pre form into a bubble. Then high pressure air is applied to push the PET bubble into all the details of the blow mold, and to cool the newly-made bottle. Time is allotted in the cycle to depressurize the mold before opening it and removing the bottle. Blowing Process 1 Our study is focused on the blowing part of the process. Lebanese bottling company provided us with their data that includes the following: Number of used pre forms 3 Adequate produced bottles Pre form color: Pre form type Pre form temperature Blowing machine Blowing pressure (pressure difference) Preform type: The company purchases two types of performs;PCR (post consumer recycled), and virgin (non recycled) .We think that the type of the preform affects the quality of the production. Preform color: The Company produces 3 different colored bottles (clear, green, and blue).The color may also has the its impact on the quality of the products. Preform temperature: It is the temperature recorded by the sensor in the blow molding machine just before blowing the perform. Blowing machine: The Company has two machines from different manufacturers, both machines are set to work on the same rate, pressure, and perform temperature. Blowing pressure: he pressure of blowing can differ from the specification. This also can affect the quality. The Response Variable We want to introduce the response variable as the percentage of defective produced bottles. Defective% = No. of used preform − No. of adequate botlles ∗ 100% No. of used preform 4 The Factors Which the Response Variable May Depend On and Their Levels 1. Preform type a. PCR =1 b. Virgin =0 2. Preform color a. Clear = 1 b. Green = 2 c. Blue =3 3. Preform temperature 4. Blowing machine a. Machine A =0 b. Machine B=1 5. Blowing pressure Difference Operations : PCR vs Virgin: Determine whether there is significant difference between percentages of defectives from the mentioned two types. Machine 1 vs Machine 2: Determine whether there is significant difference between percentages of defectives from the mentioned two machines. Clear vs Blue vs Green: Determine whether there is significant difference between the percentage of deffectives of the 3 colors. Regression:We will search for the independent variables that our response variable mostly depend on, and fit a regression model. (add dummy variables if needed). Perform Olap cubes using preform types, colors, and blowing machines. 5 Tests & Results Checking for normality (Kolmogorov-Smirov test): Tests of Normality Kolmogorov-Smirnova Machine percentage of defectives Statistic Df Shapiro-Wilk Sig. Statistic df Sig. machine A .252 52 .000 .736 52 .000 machine B .115 52 .083 .939 52 .010 a. Lilliefors Significance Correction Tests of Normality Kolmogorov-Smirnova type percentage of defectives Statistic df Shapiro-Wilk Sig. Statistic df Sig. virgin .124 52 .045 .903 52 .000 PCR .247 52 .000 .809 52 .000 a. Lilliefors Significance Correction As it is shown in the tables above, according to Kolmogorov-Smirnov test 3 out of the 4 groups have non normal distributions, therefore it’s more accurate to continue our tests with the assumption of non normality. Instead of doing ANOVAs we will perform non parametric 2 and K independent samples tests. Also because the numbers of cases are equal in each group the mean ranks will hint us to determine which of the groups have higher percentage of defectives in average. 6 Performing Mann-Witney U test to compare mean value of percentage of defectives in the two types of performs: Ranks type percentage of defectives N Mean Rank Sum of Ranks virgin 52 60.02 3121.00 PCR 52 44.98 2339.00 Total 104 Test Statisticsa percentage of defectives Mann-Whitney U 961.000 Wilcoxon W 2339.000 Z -2.542 Asymp. Sig. (2-tailed) .011 a. Grouping Variable: type Asymp. Sig. is less that 0.05 which means we reject the null hypothesis of the mean ranks equality, in other words we can conclude that PCR performs has less defectives than virgin performs. Performing Mann-Witney U test to compare mean value of percentage of defectives in the two machines: Ranks Machine percentage of defectives N Mean Rank Sum of Ranks machine A 52 41.07 2135.50 machine B 52 63.93 3324.50 Total 104 Test Statisticsa percentage of defectives Mann-Whitney U Wilcoxon W Z Asymp. Sig. (2-tailed) 757.500 2135.500 -3.865 .000 a. Grouping Variable: Machine 7 Asymp. Sig. value is 0, this means the mean ranks for the two groups are significantly different. Mean ranks shows that in average machine A has lower percentage of defectives than machine B. Chi Square test for independence (Machines and perform types): Chi-Square Tests Value Asymp. Sig. (2- Exact Sig. (2- Exact Sig. (1- sided) sided) sided) df .000a 1 1.000 Continuity Correctionb .000 1 1.000 Likelihood Ratio .000 1 1.000 Pearson Chi-Square Fisher's Exact Test 1.000 Linear-by-Linear Association .000 N of Valid Casesb 104 1 .578 1.000 a. 0 cells (.0%) have expected count less than 5. The minimum expected count is 26.00. b. Computed only for a 2x2 table Since the Asymp. Sig. for Pearsons chi-square test is 1 this means that the two variables are fully independent. Next we will compute a new categorical variable with 4 levels to test the four machines and perform types combinations. Kruskal-Wallis test for 4 independent samples: Ranks M_T percentage of defectives N Mean Rank machine A,virgin 26 50.02 machine A,PCR 26 32.12 machine B,virgin 26 70.02 machine B,PCR 26 57.85 Total 104 Test Statisticsa,b percentage of defectives Chi-Square Df Asymp. Sig. 21.636 3 a. Kruskal Wallis Test .000 b. Grouping Variable: M_T Asymp. Sig. value is 0, which means that the mean ranks of at least 2 of the groups are not equal. 8 2 Independent sample test within the 4 groups: Machine A, virgin VS PCR Ranks M_T percentage of defectives N Mean Rank Sum of Ranks machine A,virgin 26 31.10 808.50 machine A,PCR 26 21.90 569.50 Total 52 Test Statisticsa percentage of defectives Mann-Whitney U 218.500 Wilcoxon W 569.500 Z -2.188 Asymp. Sig. (2-tailed) .029 a. Grouping Variable: M_T Asymp. Sig. is less than 0.05, H0 is rejected, which means the mean ranks are not equal, and the ranks shows that PCR type has lower percentage of defectives than virgin in machine A. Virgin Machine A VS Machine B Ranks M_T percentage of defectives N Mean Rank machine A,virgin 26 21.38 556.00 machine B,virgin 26 31.62 822.00 Total 52 Test Statisticsa percentage of defectives Mann-Whitney U 205.000 Wilcoxon W 556.000 Z Asymp. Sig. (2-tailed) Sum of Ranks -2.434 .015 a. Grouping Variable: M_T 9 Asymp. Sig. is less than 0.05, H0 is rejected, which means the mean ranks are not equal, and the ranks shows that machine A has less percentage of defectives than machine B when it comes to virgin performs. Machine A , virgin VS Machine B, PCR: Ranks M_T percentage of defectives N Mean Rank Sum of Ranks machine A,virgin 26 24.54 638.00 machine B,PCR 26 28.46 740.00 Total 52 Test Statisticsa percentage of defectives Mann-Whitney U 287.000 Wilcoxon W 638.000 Z -.933 Asymp. Sig. (2-tailed) .351 a. Grouping Variable: M_T The test shows that the null hypothesis cannot be rejected which means that there s no significant difference between the percentage of defectives of the 1st and 4th groups. Machine A,PCR VS Machine B, virgin: Ranks M_T percentage of defectives N Mean Rank Sum of Ranks machine A,PCR 26 17.83 463.50 machine B,virgin 26 35.17 914.50 Total 52 10 Test Statisticsa percentage of defectives Mann-Whitney U 112.500 Wilcoxon W 463.500 Z -4.128 Asymp. Sig. (2-tailed) .000 a. Grouping Variable: M_T Asymp. Sig. is less than 0.05, H0 is rejected, which means the mean ranks are not equal, and the ranks shows that the percentage of defectives are greater in machine B, virgin group than in machine A, PCR group. PCR Machine A VS Machine B: Ranks M_T percentage of defectives N Mean Rank Sum of Ranks machine A,PCR 26 19.38 504.00 machine B,PCR 26 33.62 874.00 Total 52 Test Statisticsa percentage of defectives Mann-Whitney U 153.000 Wilcoxon W 504.000 Z Asymp. Sig. (2-tailed) -3.387 .001 a. Grouping Variable: M_T Asymp. Sig. is less than 0.05, H0 is rejected, which means the mean ranks are not equal, and the ranks shows that machine A has less percentage of defectives than machine B when it comes to PCR performs. 11 Machine B virgin VS PCR: Ranks M_T percentage of defectives N Mean Rank Sum of Ranks machine B,virgin 26 30.23 786.00 machine B,PCR 26 22.77 592.00 Total 52 Test Statisticsa percentage of defectives Mann-Whitney U 241.000 Wilcoxon W 592.000 Z -1.775 Asymp. Sig. (2-tailed) .076 a. Grouping Variable: M_T The test shows that the null hypothesis cannot be rejected which means that there s no significant difference between the percentages of defectives of the machine B either for virgin or PCR performs. Kruskal-Wallis test for color effect on percentage of defectives: Ranks Color percentage of defectives N Mean Rank Clear 36 57.31 Green 35 47.81 Blue 33 52.23 Total 104 12 Test Statisticsa,b percentage of defectives Chi-Square 1.761 df 2 Asymp. Sig. .415 a. Kruskal Wallis Test b. Grouping Variable: Color Because Asymp. Sig. is greater than 0.05, h0 cannot be rejected , in other words color don’t effect on the percentage of defectives. Regression Analysis: Test for correlation between numerical variables: Nonparametric Correlations Correlations percentage of defectives Spearman's rho percentage of defectives -.423** .101 . .000 .309 104 104 104 -.423** 1.000 .082 Sig. (2-tailed) .000 . .410 N 104 104 104 Correlation Coefficient .101 .082 1.000 Sig. (2-tailed) .309 .410 . N 104 104 104 N P P 1.000 Correlation Coefficient Sig. (2-tailed) Temp temp Correlation Coefficient **. Correlation is significant at the 0.01 level (2-tailed). Since our response variable does not have normal distribution, we will us non parametric(Spearman's) correlation result. The test shows that our response variable is highly correlated with the temperature of performs with negative coefficient, and pressure difference is not correlated with the other variables. 13 Linear Regression: Model Summary Model R Std. Error of the Square Estimate R Square .583a 1 Adjusted R .340 .313 .2476434616 a. Predictors: (Constant), MachineB_PCR, temp, MachineA_Virgin, MachineA_PCR Coefficientsa Standardized Unstandardized Coefficients Model 1 B Std. Error (Constant) 7.747 1.505 temp -.074 .015 MachineA_Virgin -.202 MachineA_PCR MachineB_PCR Coefficients Beta t Sig. 5.146 .000 -.399 -4.820 .000 .069 -.294 -2.939 .004 -.311 .069 -.453 -4.484 .000 -.130 .069 -.189 -1.877 .064 a. Dependent Variable: percentage of defectives In our linear regression model we used the most correlated numerical variable (temperature of preforms) and added 3 dummy variables for the four level categorical variable (Machine*type) Backward method was used , no variables was removed and the Adjusted R Square shows that the model doesn’t fit linear regression , also the P value for MachineB_PCR is greater than 0.05 which means B4=0 % of defectives = 7.747 - 0.074*temp - 020 2*MachineA_Virgin - 0.311* MachineA_PCR 14 Curve Estimation We will split our file into 3 ( MachineA_Virgin , MachineA_PCR, MachineB) Model Summary and Parameter Estimatesa Dependent Variable:percentage of defectives Model Summary Equation R Square F Parameter Estimates df1 df2 Sig. Constant b1 b2 b3 Linear .102 5.690 1 50 .021 5.944 -.057 Logarithmic .103 5.771 1 50 .020 25.918 -5.566 Inverse .105 5.851 1 50 .019 -5.187 547.414 Quadratic .102 5.690 1 50 .021 5.944 -.057 .000 Cubic .164 4.790 2 49 .013 176.989 -2.681 .000 Compound .070 3.760 1 50 .058 5.154E8 .803 Power .071 3.802 1 50 .057 2.013E42 -21.559 9.145E-5 The independent variable is temp. a. splitgroups = 3.00 Model Summary and Parameter Estimatesa Dependent Variable:percentage of defectives Model Summary Equation R Square F Parameter Estimates df1 df2 Sig. Constant b1 b2 b3 Linear .110 2.967 1 24 .098 4.972 -.049 Logarithmic .112 3.018 1 24 .095 22.414 -4.857 Inverse .113 3.069 1 24 .093 -4.741 478.804 Quadratic .110 2.967 1 24 .098 4.972 -.049 .000 Cubic .230 3.442 2 23 .049 238.363 -3.627 .000 Compound .130 3.585 1 24 .070 1.395E12 .731 Power .132 3.658 1 24 .068 2.883E60 -30.969 The independent variable is temp. a. splitgroups = 2.00 15 .000 Model Summary and Parameter Estimatesa Dependent Variable:percentage of defectives Model Summary Equation R Square F Parameter Estimates df1 df2 Sig. Constant b1 b2 b3 Linear .674 49.510 1 24 .000 15.175 -.152 Logarithmic .676 50.075 1 24 .000 68.625 -14.917 Inverse .678 50.630 1 24 .000 -14.658 1.459E3 Quadratic .674 49.510 1 24 .000 15.175 -.152 .000 Cubic .722 29.875 2 23 .000 204.829 -3.066 .000 Compound .489 23.011 1 24 .000 3.440E25 .537 Power .488 22.862 1 24 .000 6.806E119 -60.654 The independent variable is temp. a. splitgroups = 1.00 The test shows that : For Machine B (split group 3) the best fit curve is the cubic with R square = 0.164 For Machine A PCR type perform (split group 2) the best fit curve is the cubic with R square = 0.230 For Machine A virgin type perform (split group 1) the best fit curve is the cubic with R square = 0.722 Only the group one has enough R square value to say that it could fit the mentioned model OLAP Cubes Type machine A percentage of defectives % of Total N Median Machine Machine machine B Total machine A machine B Total Virgin 25.0% 25.0% 50.0% 0.165 0.421 0.318 PCR 25.0% 25.0% 50.0% 0.054 0.247 0.130 Total 50.0% 50.0% 100.0% 0.086 0.368 0.172 16 .000 Conclusions The PCR has lower defectives percentage than the Virgin type performs. The Machine A has lower defectives percentage than the Machine B. The combination of Machine & Type has effect on the percentage of defectives. Regression analysis shows that none of the tested models fit the response variable except of the cubic model in the case of MachineA_Virgin group of samples. To make this research more accurate , we suggest to increase the sample size , which may make the normality assumption valid and that may change some of the observations. 17