Port of Bin Qasim Terminal Information

Port of Bin Qasim Terminal Information

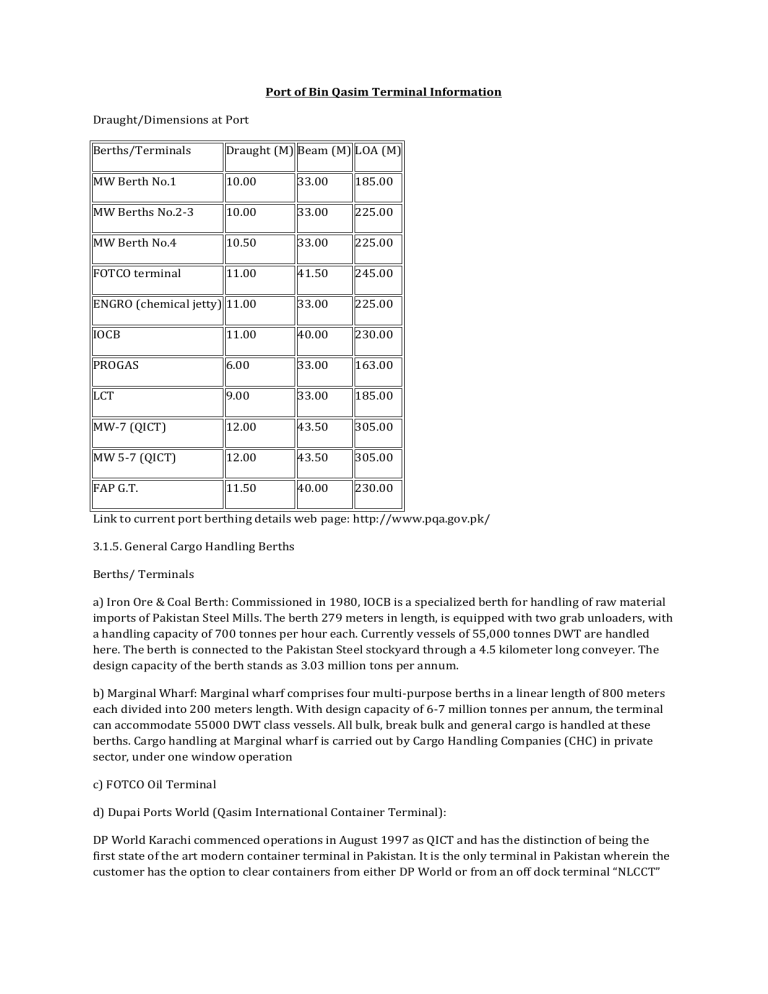

Draught/Dimensions at Port

Berths/Terminals Draught (M) Beam (M) LOA (M)

MW Berth No.1

MW Berths No.2-3

10.00

10.00

33.00

33.00

185.00

225.00

MW Berth No.4

FOTCO terminal

10.50

11.00

ENGRO (chemical jetty) 11.00

IOCB 11.00

33.00

41.50

33.00

40.00

225.00

245.00

225.00

230.00

PROGAS

LCT

MW-7 (QICT)

MW 5-7 (QICT)

6.00

9.00

12.00

12.00

33.00

33.00

43.50

43.50

163.00

185.00

305.00

305.00

FAP G.T. 11.50 40.00 230.00

Link to current port berthing details web page: http://www.pqa.gov.pk/

3.1.5. General Cargo Handling Berths

Berths/ Terminals a) Iron Ore & Coal Berth: Commissioned in 1980, IOCB is a specialized berth for handling of raw material imports of Pakistan Steel Mills. The berth 279 meters in length, is equipped with two grab unloaders, with a handling capacity of 700 tonnes per hour each. Currently vessels of 55,000 tonnes DWT are handled here. The berth is connected to the Pakistan Steel stockyard through a 4.5 kilometer long conveyer. The design capacity of the berth stands as 3.03 million tons per annum. b) Marginal Wharf: Marginal wharf comprises four multi-purpose berths in a linear length of 800 meters each divided into 200 meters length. With design capacity of 6-7 million tonnes per annum, the terminal can accommodate 55000 DWT class vessels. All bulk, break bulk and general cargo is handled at these berths. Cargo handling at Marginal wharf is carried out by Cargo Handling Companies (CHC) in private sector, under one window operation c) FOTCO Oil Terminal d) Dupai Ports World (Qasim International Container Terminal):

DP World Karachi commenced operations in August 1997 as QICT and has the distinction of being the first state of the art modern container terminal in Pakistan. It is the only terminal in Pakistan wherein the customer has the option to clear containers from either DP World or from an off dock terminal “NLCCT”

located in the heart of the city. It is the No. 1 terminal in Pakistan in terms of yearly throughput amongst 4 terminals presently in operation in Pakistan. It holds a 36% market share.

DP World is the 1 st terminal in Pakistan to achieve a throughput of 751, 000 TEUs in 2009. It has also handled the largest every vessel arriving in Pakistan (304m LOA). It is the first and only terminal in

Pakistan to have achieved ISO 9001: 2000, ISO 14001: 1996 & ISO 18001: 1999, ISO 27001 for information security management. It has also achieved ISO 28000: 2007 certification for Supply Chain

Security Management System.

DP World (QICT) has been developed through conversion of three existing multipurpose berths with a quay length of 600 meters into two berths container terminal at a cost of US$ 100 million on BOT basis.

The terminal is operational since August 1997 and encompasses a total area of 240,000 sq. meters. The

Terminal with design capacity of 0. 85 millions TEUs / annum is capable of handling vessels up to 305 meters length.. The port has no rail-mounted cranes and the cargo is handled only by the ship cranes.

QICT is the ideal location for a purpose built container terminal with the added advantage of having the deeper draft of 11.5 M capable of handling mother vessels. It has always been ports’ policy to invest in terminals outside city limits, thus avoiding traffic congestion. Port Qasim offers advantages compared to

Karachi, which has allowed it to develop as a true international gateway. Among these is the terminal’s location away from the congested city of Karachi. QICT is closer to vital up-country markets, although at the same time just two hours away from the Karachi export-processing zone and the Landhi & Korangi industrial area. Port Qasim industrial zone is located in 5 KM distance. Another key feature of QICT is the deeper draught: 11.5m as opposed to 10.25m at KPT, which allows vessels of up to 60,000 DWT to dock.

QICT is able to hire its own labour and is therefore not controlled or influenced by the dock labour board.

This is an added advantage to the shippers and consignees who complain of their “unreceipted” expenses increase when they use Karachi port, as QICT’s tariffs are published to ensure maximum transparency when dealing with the customer.

The yard offers a total of 3684 x 20’ ground slots for conventional full containers and 216 plugs for reefer boxes. In addition, there are 616 slots available for empty container storage. The maximum holding capacity is currently limited to 8,000 TEUs. A total of five quay cranes, two mobile cranes and nine RTGs running on fixed strips and four reach-stackers, two empty handlers and 16 prime movers available for empty box handling, which mostly undertake front line yard and vessel handling operations. The whole operation is managed by a computer system by navis incorporating a radio-data link between the yard vehicles and the planning center e) Engo VoPak Chemicals Terminals :

An integrated bulk liquid chemical import /export and storage terminal operational was constructed as a joint venture of Engro Chemical of Pakistan Limited and Royal Vopak of the Netherlands on BOT basis in

1998. It has a design capacity of 4 million tonnes per annum. The jetty located in the middle of the Port

Qasim channel is designed to handle ships up to 75000 DWT and is linked to a 2 acre tank farm via a 1.1 km long trestle. Offloading of liquid chemical products is carried out through dedicated marine loading arms or hoses and is transferred via pipelines from the jetty to storage on the mainland. Currently there are 19 storage tanks for storage of various chemicals.

The Terminal and storage farm has been developed to cater for chemical imports, by Engro Pakistan in collaboration with Vopak of Netherlands on BOT basis at a cost of US$ 100 million. Operational since

January 1998, the Terminal can accommodate 75000 dwt class vessels with ultimate design capacity of 4 million tones per annum

f) PROGAS LPG Terminal: The terminal with design capacity of 2 million tonnes per annum has been developed in private sector on BOT basis at a cost of US$ 50 million. The terminal is operational since

2007. g) Liquid Cargo Terminal: LIQUID CARGO TERMINAL

Liquid Cargo Terminal (LCT) has been established at Port Qasim on Build, Operate and Transfer (BOT) basis by Felda Westbury Qasim (Pvt) Limited (FWQ). FWQ is a Joint Venture between FELDA of Malaysia and WESTBURY Group of Pakistan. LCT is the first state-of-the-art dedicated Liquid Cargo Jetty in Private

Sector, capable of berthing vessels (Tankers) up to 35,000 DWT carrying liquid cargoes of Edible Oils,

Molasses and its derivatives, and other permissible products. Soft operations commenced on 30th March

2009 and the Terminal was formally inaugurated by the President of Pakistan on 14th August 2009. LCT has a designed capacity of 4 million tonnes per annum. The jetty can handle ships of up to 185m LOA and

33m Beam. The facility comprises of a jetty, interchanges and pipeline systems. LCT is connected to all

Storage Terminals in Edible Oil / Molasses area through its two interchange systems. LCT maintains international standards of Safety, Security, Health and Environment in its operations. With the construction of LCT at Port Qasim, Pakistan has taken a big jump towards efficient, systematic and hygienic handling of liquid cargo.

The terminal with design capacity of 4 million tonnes per annum has been developed in private sector on

BOT basis at a cost of US$ 15 million to cater for edible oil imports.