Institute of Industrial Engineering Arena Student

advertisement

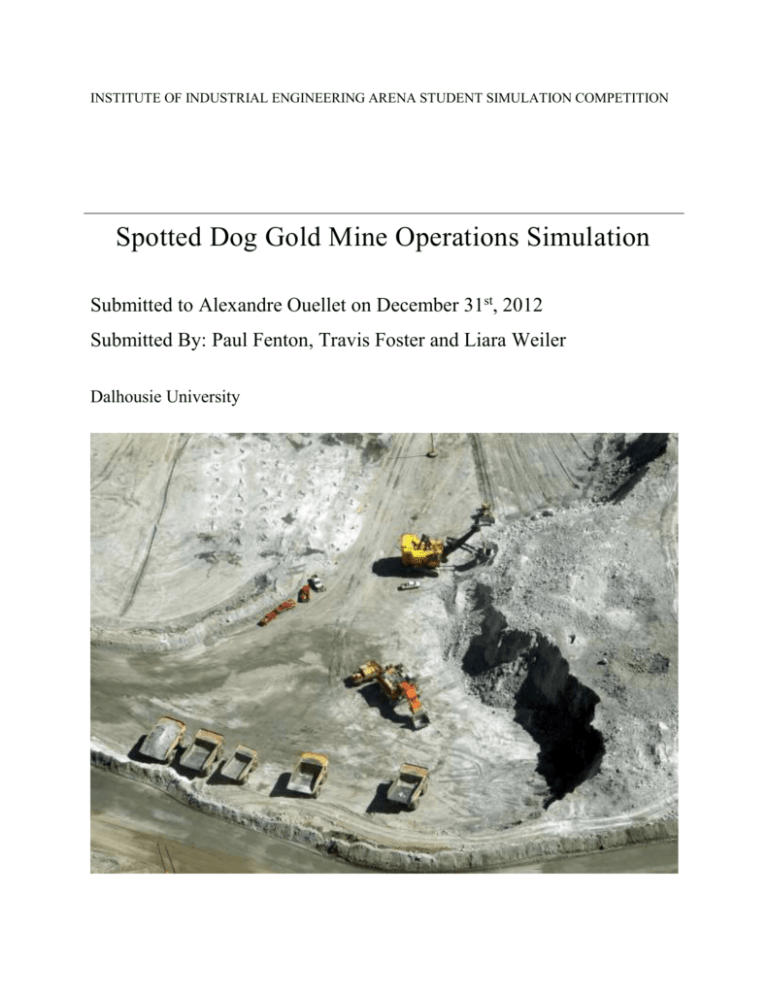

INSTITUTE OF INDUSTRIAL ENGINEERING ARENA STUDENT SIMULATION COMPETITION

Spotted Dog Gold Mine Operations Simulation

Submitted to Alexandre Ouellet on December 31st, 2012

Submitted By: Paul Fenton, Travis Foster and Liara Weiler

Dalhousie University

Executive Summary

The Spotted Dog Mine is an open pit gold mine located in western United States. Operations at the mine

include drilling, blasting, loading/hauling material, Recovering gold from ore, and dumping waste.

American Mining Services (AMS) is responsible for providing reliable dump truck transportation

between the loading shovels and the various material destinations at the mine.

Operations at the Spotted Dog Mine are scheduled to advance through four phases in the coming years.

Hauling distances for the trucks will grow with each phase. AMS must determine the optimal number of

trucks required for each of the four stages in order to maximize profits by exceeding production targets

and maintaining a high level of truck utilization.

This report documents the problem solving approach that was used to arrive at a set of recommendations

for expanding trucking capacity as time goes forward. The following steps were taken to arrive at a

reliable set of solutions:

An Arena model was constructed to capture relevant system characteristics.

The model was validated based on analytical solutions and field data.

The model was run under a variety of potential scenarios to determine the optimal number of

trucks at each phase of operations.

The results were analyzed according to key performance indicators for the system.

A set of recommendations were put together based on the analysis of the simulation model.

Upon running the simulation with the provided haul profiles for each stage, the optimal number of trucks

was determined to be 30 trucks in Phases 1 and 2, 31 trucks in Phase 3, and 33 trucks in Phase 4. It is

recommended that AMS provide this amount of trucks for phases of operation in order to achieve the

highest expected profit.

i

Table of Contents

Executive Summary ....................................................................................................................................... i

List of Tables ............................................................................................................................................... iii

List of Figures .............................................................................................................................................. iii

1.0)

Problem Statement ............................................................................................................................ 1

1.1)

Key Performance Indicators.......................................................................................................... 2

1.2)

Problem Scope .............................................................................................................................. 3

2.0)

Methodology and Assumptions ........................................................................................................ 3

2.1)

Input Data...................................................................................................................................... 3

2.2)

Model Specifications .................................................................................................................... 4

3.0)

Experimental Design ......................................................................................................................... 5

4.0)

Results ............................................................................................................................................... 6

4.1)

Phase 1 .......................................................................................................................................... 7

4.2)

Phase 2 .......................................................................................................................................... 8

4.3)

Phase 3 .......................................................................................................................................... 9

4.4)

Phase 4 ........................................................................................................................................ 10

5.0)

Analysis........................................................................................................................................... 11

5.1)

Warm-Up Period ......................................................................................................................... 11

5.2)

Number of Replications .............................................................................................................. 11

6.0)

Verification and Validation ............................................................................................................. 12

6.1)

Shovel constraint productivity approximation: ........................................................................... 13

6.2)

Shovel constraint productivity with shovel failures .................................................................... 13

6.3)

Numerical Calculation ................................................................................................................ 13

6.4)

Truck constraint productivity approximation.............................................................................. 13

6.5)

Queuing theory validation ........................................................................................................... 14

7.0)

Implementation Plan ....................................................................................................................... 15

8.0)

Conclusions and Recommendations ............................................................................................... 15

Bibliography ............................................................................................................................................... 16

Appendix A - Representative Data Distributions........................................................................................ 17

Appendix B - Gradient Speed Reduction Calculation ................................................................................ 18

Appendix C - Monthly Truck Operating Cost Estimation .......................................................................... 21

Appendix D – Expected Profit Tables ........................................................................................................ 22

Appendix E – Utilization Tables................................................................................................................. 24

Appendix F – Productivity Slope Calculation ............................................................................................ 26

ii

List of Tables

Table 1 - Experiment Summary Table .......................................................................................................... 6

Table 2 - Expected Profit (Phase 1), Selection ............................................................................................. 7

Table 3 - Expected Profit (Phase 2), Selection ............................................................................................. 8

Table 4 - Expected Profit (Phase 3) .............................................................................................................. 9

Table 5 - Expected Profit (Phase 4) ............................................................................................................ 10

Table 6 - Trial Run Results ......................................................................................................................... 11

Table 7 - Implementation Plan .................................................................................................................... 15

Table 8 - Representative Data Distributions ............................................................................................... 17

Table 9 - Uphill Speed Factor ..................................................................................................................... 18

Table 10 - Pit Ramp Downhill Speed Factor .............................................................................................. 20

Table 11 - Dump Ramp Downhill Speed Factor......................................................................................... 20

Table 12 - Expected Profit (Phase 1) .......................................................................................................... 22

Table 13 - Expected Profit (Phase 2) .......................................................................................................... 22

Table 14 - Expected Profit (Phase 4) .......................................................................................................... 23

Table 15 - Expected Profit (Phase 3) .......................................................................................................... 23

Table 16 - Asset Utilization (Phase 2) ........................................................................................................ 24

Table 17 - Asset Utilization (Phase 1) ........................................................................................................ 24

Table 18 - Asset Utilization (Phase 4) ........................................................................................................ 25

Table 19 - Asset Utilization (Phase 3) ........................................................................................................ 25

List of Figures

Figure 1 - Arena Animation of Spotted Dog Gold Mine Pit ......................................................................... 1

Figure 2 - Expected Monthly Profit (Phase 1) .............................................................................................. 7

Figure 3 - Asset Utilization (Phase 1) ........................................................................................................... 7

Figure 4- Expected Monthly Profit (Phase 2) ............................................................................................... 8

Figure 5 - Asset Utilization (Phase 2) ........................................................................................................... 8

Figure 6 - Expected Monthly Profit (Phase 3) .............................................................................................. 9

Figure 7 - Asset Utilization (Phase 3) ........................................................................................................... 9

Figure 8 - Expected Monthly Profit (Phase 4) ............................................................................................ 10

Figure 9 - Asset Utilization (Phase 4) ......................................................................................................... 10

Figure 10 - Model Comparison ................................................................................................................... 12

Figure 11 - Birth-Death Process.................................................................................................................. 14

Figure 12 - Gradeability/Speed/Rimpull ..................................................................................................... 18

Figure 13 - Standard Retarding, Continuous .............................................................................................. 19

Figure 14 - Standard Retarding, 1500 m ..................................................................................................... 20

iii

1.0) Problem Statement

The Spotted Dog Mine is an open pit gold mine located in the western United States. The mine operates

using a truck-shovel system. Rock is extracted from the mine using three large mining excavators,

commonly referred to as shovels. Two shovels excavate ore material, while the third excavates waste

material. The rock is classified after extraction, according to the estimated gold concentrations in the

mined rock. Forty percent of the ore material is classified as ‘ore’, leaving sixty percent classified as

‘leach’. All of the waste material is classified as ‘waste’. Trucks haul the material to one of three locations

according to the material classification. Ore material is hauled to the crusher where there are two

unloading spots, while leach and waste material is hauled to their respective dumps. Trucks arrive at the

shovels, are loaded with material, haul the material to its destination and then return to the next available

shovel to repeat the process.

These operations of drilling,

blasting, loading and hauling

are contracted out to

American Mining Services,

Inc. (AMS).

AMS is paid according to

the amount of material

hauled each month; the more

Figure 1 - Arena Animation of Spotted Dog Gold Mine Pit

material hauled, the more AMS

is paid. If too many trucks are onsite, lines will form at the various stations, resulting in a decrease of

truck utilization. AMS must provide a number of trucks that will balance both these considerations. In

addition, the nature of an open pit mine is to expand over time. The Spotted Dog Mine breaks its

expansion into four phases. The distance trucks will be required to haul material out of the mine will

increase with each phase. As such, the number of trucks provided in each phase is expected to increase as

well.

Variability is also an important part of Spotted Dog Mine operations. This includes the speeds that trucks

travel, the rate that trucks are loaded/unloaded, as well as shovel breakdown rates and repair times. In

order to incorporate this variation and determine the number of trucks required to haul material at each

stage, an Arena model was built. This model was validated and ran under a variety of experiments to

determine the optimal amount of trucks for each phase of operations.

1.1)

Key Performance Indicators

When solving any problem, criteria are required in order to evaluate and compare solutions. Three key

performance indicators (KPI) were identified to analyze results from the Spotted Dog Mine simulation.

All model variations will be evaluated using these KPI:

Profit:

Profit refers to AMS revenue multiplied by the provided pay factor of PF = 0.8p75 + p100 + 1.2p130. In this

equation, p75, p100, and p130 are the ratio of production days in the month where production was <75%,

between 75 and 100%, and between 100 and 130% of production targets, respectively. Thus:

̂ 𝒐 (𝒏)𝑑̂𝑜 + 0.65𝑷

̂ 𝒘 (𝒏)𝑑𝑤 )

𝐸[𝑅(𝑛)] = 226.8 ∙ 30 ∙ 𝑷𝑭 ∙ (0.9𝑷

𝑤ℎ𝑒𝑟𝑒 𝐸[𝑅(𝑛)] 𝑖𝑠 𝑡ℎ𝑒 𝑒𝑥𝑝𝑒𝑐𝑡𝑒𝑑 𝑚𝑜𝑛𝑡ℎ𝑙𝑦 𝑟𝑒𝑣𝑒𝑛𝑢𝑒 𝑓𝑟𝑜𝑚 𝑎 𝑠𝑦𝑠𝑡𝑒𝑚 𝑤𝑖𝑡ℎ 𝑛 𝑡𝑟𝑢𝑐𝑘𝑠.

𝑤ℎ𝑒𝑟𝑒 𝑷𝑭(𝑛) = (0.8𝑝75 + 𝑝100 + 1.2𝑝130 )

𝑤ℎ𝑒𝑟𝑒 𝑑̂𝑜 = 2 ∙ (0.4𝑑𝑐𝑟𝑢𝑠ℎ + 0.6𝑑𝑙𝑒𝑎𝑐ℎ )

̂ 𝒐 (𝒏) & 𝑷

̂ 𝒘 (𝒏) 𝑎𝑟𝑒 𝑡ℎ𝑒 𝑒𝑥𝑝𝑒𝑐𝑡𝑒𝑑 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑙𝑜𝑎𝑑𝑠 𝑜𝑓 𝑝𝑟𝑜𝑑𝑢𝑐𝑡𝑖𝑜𝑛 𝑝𝑒𝑟 𝑑𝑎𝑦 𝑓𝑜𝑟 𝑛 𝑡𝑟𝑢𝑐𝑘.

𝑤ℎ𝑒𝑟𝑒 𝑷

Expected profit per month is the main indicator used to evaluate the different experiments ran. This

evaluation is ultimately used to build the set of recommendations made.

Truck Utilization:

Truck utilization refers to the percentage of time a truck is actively participating by being loaded or

delivering material for the mine. Trucks are not utilized if there is consistently an empty queue of trucks

waiting to be loaded by a shovel.

Shovel Utilization:

Shovel Utilization is defined as the percentage of time a shovel is being used to load a truck. The

utilization of shovels and trucks are inherently related; as the number of trucks increases, truck utilization

decreases while shovel utilization approaches 100%. Ultimately, revenue increases with more trucks, but

the benefit of each additional truck is not as great as the previous truck.

2

1.2)

Problem Scope

As with any system, the mining operations at the Spotted Dog Mine have an inherent variability.

Specifically to this system, variability includes extracted material classification, overall production, truck

travel speeds and loading/unloading times. If variability is not accounted for in a model, decision makers

have a limited ability to understand and account for the system’s true behaviour. This limits their ability

to make a well informed decision. Arena is designed to account for the stochastic nature of these

processes, so it was used to build a model to analyze the problem described in Section 1.0.

Several aspects of mining operations at the Spotted Dog Mine were deemed to be out of scope for this

project. The market demand for gold is not included in the model, nor is staffing requirements. In

addition, the required operations to process material before excavation and after unloading are out of

scope. As such, only the material handling aspect of the mine is modelled. Section 2.0 describes all the

assumptions made throughout the construction of the model in further detail.

2.0) Methodology and Assumptions

Throughout the construction of the Arena model, numerous assumptions were made. These assumptions

can be classified into two categories – input data and model specifications. Input data refers to the

distributions provided to Arena in order to control various activities, while model specifications refer to

assumptions that influenced the make-up of the model.

2.1)

Input Data

Data regarding loaded truck speeds, empty truck speeds, shovel failure rates, shovel repair times, shovel

loading times and truck dumping times were provided to describe operating conditions at the Spotted Dog

Mine. As distributions representing data sets is more representative than exact past data, the Arena Input

Analyzer was used to determine the most accurate distributions that should be used in the model. Results

from this analysis are presented in Appendix A.

The 793F Mining Truck specifications indicate the maximum unloaded speed of the truck is 60 km/h, or

1000 m/min. Some of the data provided included values above this speed; these data points were

considered outliers and removed from the dataset. It was assumed that all of the trucks speeds were

collected while trucks were travelling on flat ground and calculated by dividing total time by total

distance travelled. The specifications also indicated that truck speeds must decrease when traversing

downhill to prevent the brakes from overheating. Using the Standard Retarding graphs in Appendix B, a

factor of 8/15 was applied to the calculated empty truck speed distribution in order to appropriately slow

the trucks down.

3

The truck specifications also indicated that when loaded trucks are travelling uphill, their speed should

also be reduced. Using the provided gradeability graph, a factor for speed reduction was calculated to be

2. As such, the speed of loaded trucks travelling uphill is half that of loaded trucks travelling on flat

ground.

2.2)

Model Specifications

A simulation model was needed to model the complex and dynamic behavior of the stochastic processes

at the Spotted Dog Gold Mine. The processes and their interactions were mapped, and an Arena model

was created to approximate them. The replication lengths and resource schedules are based on two nine

hour shifts per day, and a monthly payment schedule. In order to compare the benefits of purchasing

additional trucks, a VBA controller uses a MS Excel spreadsheet to drive a set of experiments and recover

continuous responses from the system based on the controls defined by the experiment. These

experiments are described in Section 3.0. Several methodologies and assumptions were used in order to

create a simplified, yet representative model. These are summarized below:

Shovel Process Model

With sufficiently high number of trucks, the shovels will be the constraint to production at the mine. The

shovelling process seizes two resources, (a truck and a shovel), delays for a random loading time, releases

the shovel, and the truck proceeds to deliver the loaded material to its destination. The shovel model

makes use of the following assumptions about the system:

An infinite supply of crushed rock is available for the shovels to excavate

Shovel loading times account for all changes in position that a shovel makes within a phase

External demand for gold and the proportion of waste to ore is assumed to be constant. This

results in a permanent allocation of one shovel mining gold ore, and two shovels mining waste

Shovel operators are scheduled for two 9 hour shifts a day

Each shovel has a dedicated repair crew. When two failures occur simultaneously they are still

repaired according to the same distribution

Trucking/Hauling Process Model

The number of trucks in the system is the variable that is optimized. At the start of a replication, the

number of trucks for the current policy of the experiment is loaded into the system. Trucks are resources

that only become available when they are “returned” to the empty truck queue beside the shovels in the

mine pit. A truck is seized by a shovel, sent to a destination, and then returns empty to the queue. The

following assumptions were made when modelling the trucking process:

4

Truck drivers are considered always available

Shovels stop operations at 9 hours while the rest of the system continues to work until it is empty

Trucks haul material at the full capacity of 250 tonnes

There are no capacity constraints associated with roads, ramps, or intersections in the model

Trucks do not experience failures

Route times are calculated by dividing effective distance by a stochastic velocity; effective

distances are defined in Appendix B

Destination Process Model

Processing at the destination uses the following set of assumptions to simplify this aspect of the model:

One distribution is fit to a set of data and used to model dumping at all destinations

There are no capacity restrictions on leach & waste dumps

Ore production targets consist of the amount of both leach and ore material hauled each month

The pay factor is calculated according to the total amount of ore material and waste material

hauled by trucks each month

The effective grade of each ramp is estimated to never be greater than 15%

The monthly aggregate truck cost is $250,000; see Appendix C

3.0) Experimental Design

The run controller for the model can feed a set of control parameters into the model at the start of each

replication, and output data out of the model at the end of the replication. The different scenarios to be

considered are represented as sets of values for the control parameters, which can be defined in a

spreadsheet that is linked to the model through the run controller.

Due to the small computational size of the model, and the need to only optimize one control variable, a

brute force approach is used to run the model under a range of different truck quantities. The experiments

in Table 1 were run to produce results for analysis.

5

Table 1 - Experiment Summary Table

Experiment

Range of Trucks

Experiment

Number of

parameters

replications (days)/

Filename

truck quantity

Phase 1 Truck

{1,5,10,15,20,23,25,27,29,30

Phase 1 Route

Optimization

31,32,33,34,35,36,37,38,39,40}

Times

Phase 2 Truck

{1,5,10,15,20,23,25,27,29,30

Phase 2 Route

Optimization

31,32,33,34,35,36,37,38,39,40}

Times

Phase 3 Truck

{1,5,10,15,20,23,25,27,29,30

Phase 3 Route

Optimization

31,32,33,34,35,36,37,38,39,40}

Times

Phase 4 Truck

{1,5,10,15,20,23,25,27,29,30

Phase 3 Route

Optimization

31,32,33,34,35,36,37,38,39,40}

Times

1800

Scenarios\ScenariosP1004.xlsx

1800

Scenarios\ScenariosP2004.xlsx

1800

Scenarios\ScenariosP3004.xlsx

1800

Scenarios\ScenariosP4008.xlsx

4.0) Results

The Spotted Dog Mine simulation was run using the current and future average haul profiles in order to

determine the optimal number of trucks in each phase. These results are presented in the following

subsections, each with an Expected Monthly Profit table, graph and an Asset Utilization graph. The

figures of Expected Monthly Profit and Asset Utilization show the relationship between the number of

trucks provided by AMS, and the service level that would be achieved, as the higher the service level, the

more AMS will be paid.

The Expected Monthly Profit graph displays the relationship between the number of trucks and the profit

AMS should expect to receive. The method used to calculate costs in these graphs is reviewed in

Appendix C. The Expected Monthly Profit table shows a selection of the number of truck values as well

as correlating expected profit. The highest expected profit value for each phase is highlighted in dark

green, while the second highest value is highlighted in light green. The complete tables are displayed in

Appendix D. The Asset Utilization graph shows the trade-off between truck utilization and shovel

utilization. The number of trucks and the truck utilization level at the shovel and truck utilization

intersection is highlighted. The tables used to create these graphs can be found in Appendix E. In each

phase, the highest expected profit was achieved when shovel utilization reached its maximum and truck

utilization was at approximately 80%.

6

4.1)

Phase 1

The following graphs and table show the results of the simulation for Phase 1 of the mine.

Monthly Values

Millions

Expected Monthly Profit (Phase 1)

$60

$50

30, $48.82

$40

Profit

$30

Revenue

$20

Costs

$10

$0

0

5

10

15

20

25

30

Number of Trucks

35

40

45

Figure 2 - Expected Monthly Profit (Phase 1)

Table 2 - Expected Profit (Phase 1), Selection

# Trucks

25

27

29

30

31

32

E[Profit]

$43,884,200.59

$48,188,519.40

$48,595,555.38

$48,824,497.98

$47,926,955.35

$47,833,640.87

Asset Utilization (Phase 1)

1.20

Utilization

1.00

0.80

0.60

Shovel Utilization

0.40

Truck Utilization

0.20

0.00

0

10

20

30

Number of Trucks

Figure 3 - Asset Utilization (Phase 1)

7

40

50

4.2)

Phase 2

The following graphs and table show the results of the simulation for Phase 2 of the mine.

Millions

Monthly Values

Expected Monthly Profit (Phase 2)

$70

$60

$50

30, $52.70

$40

Profit

$30

Revenue

$20

Costs

$10

$0

0

5

10

15

20

25

Number of Trucks

30

35

40

Figure 4- Expected Monthly Profit (Phase 2)

Table 3 - Expected Profit (Phase 2), Selection

# Trucks

25

27

29

30

31

32

E[Profit]

$45,563,883.49

$47,866,630.94

$52,664,305.29

$52,700,645.84

$52,363,084.08

$52,231,892.43

Asset Utilization (Phase 2)

1.20

Utilization

1.00

0.80

0.60

Shovel Utilization

0.40

Truck Utilization

0.20

0.00

0

10

20

30

Number of Trucks

Figure 5 - Asset Utilization (Phase 2)

8

40

50

4.3)

Phase 3

The following graphs and table show the results of the simulation for Phase 3 of the mine.

Millions

Monthly Values

Expected Monthly Profit (Phase 3)

$70

$60

$50

31, $56.43

$40

Profit

$30

Revenue

$20

Costs

$10

$0

0

5

10

15

20

25

30

Number of Trucks

35

40

45

Figure 6 - Expected Monthly Profit (Phase 3)

Table 4 - Expected Profit (Phase 3)

# Trucks E[Profit]

29 $52,762,373.86

30 $55,506,655.85

31 $56,434,501.75

32 $56,422,539.31

33 $56,395,519.02

34 $56,276,585.62

Asset Utilization (Phase 3)

1.2000

Utilization

1.0000

0.8000

0.6000

Shovel

Utilization

0.4000

0.2000

0.0000

0

10

20

30

Number of Trucks

Figure 7 - Asset Utilization (Phase 3)

9

40

50

4.4)

Phase 4

The following graphs and table show the results of the simulation for Phase 3 of the mine.

$80

$70

$60

$50

$40

$30

$20

$10

$0

Millions

Monthly Values

Expected Monthly Profit (Phase 4)

33, $60.45

Profit

Revenue

Costs

0

5

10

15

20

25

30

Number of Trucks

35

40

45

Figure 8 - Expected Monthly Profit (Phase 4)

Table 5 - Expected Profit (Phase 4)

# Trucks

31

32

33

34

35

36

E[Profit]

$57,675,666.54

$59,807,701.76

$60,450,155.45

$60,225,660.79

$60,028,961.52

$59,616,718.45

Asset Utilization (Phase 4)

1.2

Utilization

1

0.8

0.6

Shovel Utilization

0.4

Truck Utilization

0.2

0

0

10

20

30

Number of Trucks

Figure 9 - Asset Utilization (Phase 4)

10

40

50

5.0) Analysis

The conclusions from the results presented in Section 3.0 are dependent on AMS’s policy on truck

utilization. If an increased profit with lower truck utilization is acceptable, AMS should employ 30 trucks

in Phases 1 and 2, 31 trucks in Phase 3 and 33 trucks in Phase 4. However, if AMS desires a certain

threshold for truck utilization to be met, Appendix E should be consulted. For instance, if AMS wishes

their trucks to maintain 80% utilization, then a policy of 29 trucks in Phase 1, 30 trucks in Phase 2, 32

trucks in Phase 3 and 33 trucks in Phase 4 would be desirable. Alternately, if they wish to meet certain

shovel utilization standards (and keep a constant flow of production), Appendix E should again be

consulted.

5.1)

Warm-Up Period

The Spotted Dog Mine operates two 10 hour shifts each day. As these are discrete time blocks, a warm-up

period is not required for the simulation. The mine only has 18 hours of effective operations, so it is

assumed that any waste and ore in a truck will leave the system, and the trucks will immediately be

available to the shovels once operations start anew.

5.2)

Number of Replications

The number of replications is important to determine for statistical accuracy in the model. The larger the

number of replications, the smaller the confidence interval, and the more accurate the model is. However,

the more replications required, the longer the model takes to run.

To determine the appropriate number of replications, a trial run of 30 months was conducted for 30 trucks

during Phase 4. The pay for each month was calculated, and the 95% confidence interval was calculated.

It was decided that this confidence interval should be no larger than 1% then the average value of monthly

pay. This value was chosen because the optimal number of trucks can be changed with slight variations in

the model. The results from this trial run are displayed in Table 6.

Table 6 - Trial Run Results

Variable

Alpha

Average

Standard Deviation

95% Confidence Interval

Confidence Interval/Average

Value

1.96

$ 32,655,016.72

$ 288,595.89

$ 103,272.71

0.32%

The calculated confidence interval from the trial run was 0.32% of the average monthly pay, therefore

thirty replications for each phase was deemed adequate

11

6.0) Verification and Validation

A discrete event simulation is the best tool for modeling the interplay between the series of stochastic

processes that represent operations at the Spotted Dog Mine. Due to the complexity of the system

response, it can be difficult to identify problems in the modeling logic. Analytic models can be used to

provide a reference point for the behavior of the simulation model. Once a simulation has been validated

with analytic models, features of simulated system behavior can be trusted as applicable in real life.

A mining operation has some characteristics that allow for accurate analytic models in certain

circumstances. The validation phase of model creation compared a variety of analytic and simplified

numerical models to the output of the simulation model. This comparison is summarized by Figure 10

below:

Model Comparison: Expected Daily Loads Delivered

(Phase 4)

Simulated Amount

Avg. Loads Delivered / Day

1200

1000

Truck Constraint

Approximation

800

Shovel Constraint

Approximation

600

400

Queueing Theory

Approximation

200

Shovel Constraint

Approximation w/

Failures

0

0

10

20

30

Number of Trucks

40

50

Figure 10 - Model Comparison

Each of these models was created based on the system structure, and validated to the output

characteristics presented in Appendix A. The reasoning and calculations supporting the key

approximations are described below.

12

6.1)

Shovel constraint productivity approximation:

When the number of trucks is increased beyond the optimum level, the shoveling process becomes a

bottleneck in the material handling process. In this situation, a large queue of empty trucks forms at the

shovel stations and the productivity of the mine (as a function of number of trucks) approaches a constant

value. This value can be given by the following equation:

𝑃𝑠 (𝑛) ≅

1080 ∙ 3

𝑡𝑙𝑜𝑎𝑑

The loading times are represented by a shifted lognormal distribution. The average loading time is:

𝑡𝑙𝑜𝑎𝑑 = 𝐸[2 + 𝐿𝑂𝐺𝑁(1.52,0.716)] = 2 + 1.52 = 3.52

Solving for the shovel productivity constraint gives:

𝑙𝑜𝑎𝑑𝑠

𝑃𝑠 (𝑛) ≅ 920.45 (

)

𝑑𝑎𝑦

6.2)

Shovel constraint productivity with shovel failures

When shovel failures are added to the model, the new steady state productivity can be given by

multiplying the equation in Section 5.1 by the steady state availability of the shovel:

𝑃′ 𝑠 (𝑛) ≅

𝑀𝑇𝐵𝐹

1080 ∙ 3

∙

𝑀𝑇𝐵𝐹 + 𝑀𝑇𝑇𝑅 𝑡𝑙𝑜𝑎𝑑

Where shovel failure times follow the Weibull distribution, and repair times follow a lognormal

distribution, this equation becomes:

1

𝜆Γ (1 + )

1080 ∙ 3

𝑘

𝑃 𝑠 (𝑛) ≅

∙

1

𝜆Γ (1 + ) + 1.4 𝑡𝑙𝑜𝑎𝑑

𝑘

𝑙𝑜𝑎𝑑𝑠

𝑃′ 𝑠 (𝑛) ≅ 879.422 (

)

𝑑𝑎𝑦

′

6.3)

Numerical Calculation

Using a simple set of processes to model shovels in Arena, steady state productivity was estimated (see

file ShovelValidation.doe for further information):

𝑃′(𝑛)≅880.33

6.4)

Truck constraint productivity approximation

When the number of trucks is reduced below the optimum level, the trucking process becomes a

bottleneck in the material handling process. In this situation, the shovels must wait for trucks to arrive,

and the average loads/day can be approximated by the linear function:

13

𝑃𝑡 (𝑛)𝑖 ≅ (

1080 ∙ 𝑣̂

) 𝑛𝑖

𝑑̂𝑖 + 𝑣̂(𝑡𝑙𝑜𝑎𝑑 + 𝑡𝑑𝑢𝑚𝑝 )

𝑙𝑜𝑎𝑑𝑠

𝑤ℎ𝑒𝑟𝑒 𝑃𝑡 (𝑛) 𝑖𝑠 𝑚𝑖𝑛𝑒 𝑝𝑟𝑜𝑑𝑢𝑐𝑡𝑖𝑣𝑖𝑡𝑦 𝑤ℎ𝑒𝑛 𝑡𝑟𝑢𝑐𝑘𝑠 𝑎𝑟𝑒 𝑡ℎ𝑒 𝑐𝑜𝑛𝑠𝑡𝑟𝑎𝑖𝑛𝑡. (

)

𝑑𝑎𝑦

𝑚

𝑣̂ 𝑖𝑠 𝑡ℎ𝑒 𝑎𝑣𝑒𝑟𝑎𝑔𝑒 𝑡𝑟𝑢𝑐𝑘 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦. (

)

𝑚𝑖𝑛

𝑑̂𝑖 𝑖𝑠 𝑡ℎ𝑒 𝑎𝑣𝑒𝑟𝑎𝑔𝑒 𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒 𝑡𝑜 𝑑𝑒𝑙𝑖𝑣𝑒𝑟 𝑎 𝑙𝑜𝑎𝑑 𝑖𝑛 𝑝ℎ𝑎𝑠𝑒 𝑖. (𝑚)

𝑡𝑙𝑜𝑎𝑑 𝑖𝑠 𝑡ℎ𝑒 𝑎𝑣𝑒𝑟𝑎𝑔𝑒 𝑙𝑜𝑎𝑑𝑖𝑛𝑔 𝑡𝑖𝑚𝑒. (𝑚𝑖𝑛)

𝑡𝑑𝑢𝑚𝑝 𝑖𝑠 𝑡ℎ𝑒 𝑎𝑣𝑒𝑟𝑎𝑔𝑒 𝑑𝑢𝑚𝑝𝑖𝑛𝑔 𝑡𝑖𝑚𝑒. (𝑚𝑖𝑛)

𝑛 𝑖𝑠 𝑡ℎ𝑒 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑟𝑢𝑐𝑘𝑠 𝑖𝑛 𝑡ℎ𝑒 𝑠𝑦𝑠𝑡𝑒𝑚.

The calculations for the productivity slope for each phase can be found in Appendix F.

6.5)

Queuing theory validation

Due to the capacity constraints in the crushing or dumping processes, the shovels will never have to wait

for trucks. As such, the utilization level of the shovels provided by the trucking system can be estimated

analytically using a birth-death process to model the queue of empty trucks waiting to be filled at the

shovels. An example is shown in Figure 11 below.

Figure 11 - Birth-Death Process

In this model, the arrival rate is defined as the rate that empty trucks are added to the queue. The service

rate is defined as the rate that the shovels can fill trucks and cause them to exit this simplified system.

This model is analogous to an M/M/s queuing system with finite calling population.

To apply this model to the Spotted Dog gold mine, the arrival and service rates were estimated from the

model parameters for Phase 4 of operations. The arrival rate was found by calculating the average amount

of time a truck spends delivering a load. The total arrival rate to the queue is the number of trucks in the

system that are currently delivering loads, divided by the average time to deliver a load, as shown in the

following equation:

14

𝜆≈(

1080 ∙ 𝑣̂

1080 ∙ 472.82

) = 36.711

)=(

13482.23 + 472.82 ∙ 0.90423

𝑑̂ + 𝑣̂𝑡𝑑𝑢𝑚𝑝

The service rate is equal to the production rate of a single shovel:

𝜇≈

1080 1080

=

= 306.818

𝑡𝑙𝑜𝑎𝑑

3.52

7.0) Implementation Plan

In order to implement the simulation results, AMS should follow the schedule described in Table 7.

Table 7 - Implementation Plan

Phase Number

Number of Trucks

Phase 1

30

Phase 2

30

Phase 3

31

Phase 4

33

8.0) Conclusions and Recommendations

In order to determine the number of trucks required by AMS in order to serve the Spotted Dog Mine, a

simulation model was built in Arena. Numerous assumptions were made throughout the construction of

the model. These assumptions were presented in three categories – shoveling, hauling and dumping. An

array of experiments was run to try different quantities of trucks for the different phases of operation. The

key performance indicators presented in this report were used to compare the results from each

experiment. To maximize expected profit, Phases 1 and 2 require 30 trucks, Phase 3 requires 31 trucks

and Phase 4 requires 33 trucks. Several validation and verification techniques were used to confirm the

reliability of this result. These results taken from the current perspective will result in a plan to purchase

one truck for phase 3, and then two more additional trucks for the final phase of mine operations.

15

Bibliography

Catepillar Inc. (2010). 793F Mining Truck Operating Specifications. AEHQ6038-03 (03-2010).

Hillier, F. S., & Lieberman, G. J. (2010). Introduction to Operations Research, 9th Edition.

Rossetti, M. D. (January 2009). Simulation Modeling and Arena.

Walpole, R. E., Myers, R. H., Myers, S. L., & Ye, K. (2007). Probability & Statistics for Engineers &

Scientists, 8th Edition.

16

Appendix A - Representative Data Distributions

Table 8 - Representative Data Distributions

Data Set

Distribution

Arena Code

Mean

Comments

Loaded Truck

Beta

311 + (211*BETA(2.99,3.9))

= 311

Best fit from the input

analyzer

𝛼

+ 211 (

)

𝛼+𝛽

Speed

= 402.566

Empty Truck

Erlang

308 + GAMM(57.9, 4.06)

= 308 + 𝑘𝜃

Speed

= 543.074

Shovel Time

Weibull

WEIB(30.7,1.06)

Between

1

= 𝜆Γ (1 + )

𝑘

Failure

= 30.0054

Shovel Time

= 1.4

Lognormal

LOGN(1.4,1.79)

Lognormal

2+ LOGN(1.52, 0.716)

to Repair

Shovel

= 3.52

Loading Time

Truck

= 2 + 1.52

Gamma

GAMM(0.459,1.97)

= 𝑘𝜃

= 0.904

Dumping

Time

17

Removed truck speeds

that were over safe

driving limit. Best fit

from input analyzer

(gamma fit had lower

kurtosis)

Among the best fits from

input analyzer. Linearly

increasing hazard

function is a good model

for failures.

Excluded zeroes from

data. Best fit from input

analyzer.

Best fit from the input

analyzer

Best fit from the input

analyzer

Appendix B - Gradient Speed Reduction Calculation

Figure 12 - Gradeability/Speed/Rimpull

Figure 12 was used to calculate the proper gear (and, subsequently, the maximum speed) of the 793F

Mining Truck while travelling uphill. Table 9 displays the factor used to decrease the truck speed while

travelling uphill.

Table 9 - Uphill Speed Factor

Full Uphill Pit Ramp

Phase 1

Phase 2

Phase 3

Phase 4

Gear

4th

4th

4th

4th

Truck Max Speed (km/h)

60

60

60

60

Max Speed (km/h)

30

30

30

30

Factor

1/2

1/2

1/2

1/2

If the effective grade is anywhere between 10% and 15%, the truck must be in 4th gear.

18

Figure 13 - Standard Retarding, Continuous

Figure 13 was used to calculate the proper gear (and, subsequently, the maximum speed) of the 793F

Mining Truck while travelling downhill, for roads that are longer than 1500 metres.

19

Figure 14 - Standard Retarding, 1500 m

Figure 14 was used to calculate the proper gear (and, subsequently, the maximum speed) of the 793F

truck while travelling downhill, for roads that are roughly 1500 metres. Tables 10 and 11 show the factor

used to decrease the truck speed while travelling downhill.

Table 10 - Pit Ramp Downhill Speed Factor

Empty Downhill Pit

Ramp

Phase 1 (1500 m)

Phase 2 (Continuous)

Phase 3 (Continuous)

Phase 4 (Continuous)

Speed (km/h)

32

32

32

32

Factor

8/15

8/15

8/15

8/15

Table 11 - Dump Ramp Downhill Speed Factor

Empty Downhill Dump Ramp

Phase 1 (1500 m)

Phase 2 (1500 m)

Phase 3 (1500 m)

Phase 4 (1500 m)

Speed (km/h)

32

32

32

32

Factor

8/15

8/15

8/15

8/15

If the effective grade is anywhere between 10% and 15%, the truck must be in 4th gear.

20

Appendix C - Monthly Truck Operating Cost Estimation

Since the Spotted Dog Mine pays AMS on a monthly basis, it is useful to express all of the fixed and

operating costs of a single truck as a recurring monthly cost. A methodology for calculating a monthly

truck cost is summarized below.

Relevant Cost Model:

A simple yet powerful model for asset purchase costing breaks the costs into three classifications: A fixed

unit purchase cost, a series of equally spaced variable costs that are incurred throughout the assets’

operations, and finally a salvage value that is recovered at the end of its operational life. These costs are

represented by Figure 15.

Figure 15 - Cash Flow Diagram

Conversion to monthly cost:

Due to the time value of money, these costs cannot be compared unless they are converted to a common

reference point. This can be accomplished using the following equation:

𝑪𝒕𝒐𝒕𝒂𝒍 = (𝐴⁄𝑃 , 𝑀𝐴𝑅𝑅, 𝑁) ∙ 𝑪𝒇𝒊𝒙𝒆𝒅 + 𝑪𝒗𝒂𝒓 − (𝐴⁄𝐹 , 𝑀𝐴𝑅𝑅, 𝑁) ∙ 𝑪𝒔𝒂𝒍𝒗𝒂𝒈𝒆

𝑤ℎ𝑒𝑟𝑒𝑪𝒇𝒊𝒙𝒆𝒅 , 𝑪𝒗𝒂𝒓 , 𝑪𝒔𝒂𝒍𝒗𝒂𝒈𝒆 𝑎𝑟𝑒 𝑡ℎ𝑒 𝑟𝑒𝑙𝑒𝑣𝑎𝑛𝑡 𝑐𝑜𝑠𝑡𝑠.

𝑤ℎ𝑒𝑟𝑒 𝑪𝒕𝒐𝒕𝒂𝒍 𝑖𝑠 𝑒𝑥𝑝𝑟𝑒𝑠𝑠𝑒𝑑 𝑖𝑛 𝐷𝑜𝑙𝑙𝑎𝑟𝑠⁄𝑀𝑜𝑛𝑡ℎ

𝑤ℎ𝑒𝑟𝑒 𝑀𝐴𝑅𝑅 𝑖𝑠 𝑡ℎ𝑒 𝑐𝑜𝑚𝑝𝑎𝑛𝑖𝑒𝑠′ 𝑀𝑖𝑛𝑖𝑚𝑢𝑚 𝐴𝑐𝑐𝑒𝑝𝑡𝑎𝑏𝑙𝑒 𝑅𝑎𝑡𝑒 𝑜𝑓 𝑅𝑒𝑡𝑢𝑟𝑛

𝑤ℎ𝑒𝑟𝑒 𝑁 𝑖𝑠 𝑡ℎ𝑒 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑚𝑜𝑛𝑡ℎ𝑠 𝑎 𝑡𝑟𝑢𝑐𝑘 𝑤𝑖𝑙𝑙 𝑜𝑝𝑒𝑟𝑎𝑡𝑒 𝑓𝑜𝑟.

−𝑛 −1

1 − (1 + 𝑖)

𝑤ℎ𝑒𝑟𝑒 (𝐴⁄𝑃 , 𝑖, 𝑛) = 𝑃 [

𝑖

]

Assumption of monthly cost:

Using this method would require the estimation of several unknown parameters, so a total monthly cost of

$250,000 is assumed for the cost analysis. This value was used to calculate expected monthly profits

based on the number of trucks used.

21

Appendix D – Expected Profit Tables

Table 12 - Expected Profit (Phase 1)

Table 13 - Expected Profit (Phase 2)

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

E[Profit]

$1,553,642.61

$7,723,433.41

$15,319,636.12

$22,595,391.83

$37,313,804.07

$41,716,646.82

$43,884,200.59

$48,188,519.40

$48,595,555.38

$48,824,497.98

$47,926,955.35

$47,833,640.87

$47,743,951.15

$47,467,660.40

$47,146,301.85

$46,993,081.76

$46,889,898.79

$46,673,331.14

$46,393,974.62

22

E[Profit]

$1,570,720.59

$7,835,940.23

$15,541,409.76

$22,945,474.01

$37,041,522.96

$42,951,935.56

$45,563,883.49

$47,866,630.94

$52,664,305.29

$52,700,645.84

$52,363,084.08

$52,231,892.43

$51,650,254.05

$51,674,900.23

$51,400,145.60

$51,507,074.61

$50,947,364.44

$50,691,272.29

$50,443,769.11

Table 15 - Expected Profit (Phase 3)

Table 14 - Expected Profit (Phase 4)

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

40

# Trucks

E[Profit]

$1,592,735.82

$7,928,563.88

$15,748,115.31

$23,310,727.64

$30,425,661.02

$44,081,801.28

$46,917,027.16

$49,500,386.77

$52,762,373.86

$55,506,655.85

$56,434,501.75

$56,422,539.31

$56,395,519.02

$56,276,585.62

$55,749,645.45

$55,609,048.07

$55,476,091.01

$54,727,985.95

$54,913,216.20

$54,470,698.24

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

40

23

E[Profit]

$1,608,044.23

$8,018,633.19

$15,946,018.73

$23,644,373.72

$30,896,561.24

$44,099,016.40

$47,871,327.21

$50,925,169.68

$53,229,384.20

$54,493,700.57

$57,675,666.54

$59,807,701.76

$60,450,155.45

$60,225,660.79

$60,028,961.52

$59,616,718.45

$59,707,959.29

$59,101,739.63

$59,104,619.37

$58,564,448.33

Appendix E – Utilization Tables

Table 17 - Asset Utilization (Phase 1)

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

40

Shovel

Utilization

0.04

0.22

0.43

0.63

0.82

0.91

0.96

0.99

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

Table 16 - Asset Utilization (Phase 2)

Truck

Utilization

0.98

0.97

0.96

0.95

0.92

0.89

0.87

0.83

0.77

0.75

0.72

0.70

0.68

0.66

0.64

0.62

0.61

0.59

0.58

0.56

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

40

24

Shovel

Truck

Utilization Utilization

0.04

0.97

0.20

0.97

0.40

0.97

0.60

0.95

0.78

0.93

0.87

0.91

0.93

0.89

0.97

0.86

1.00

0.82

1.00

0.80

1.00

0.77

1.00

0.75

1.00

0.72

1.00

0.70

1.00

0.68

1.00

0.67

1.00

0.65

1.00

0.63

1.00

0.61

1.00

0.60

Table 19 - Asset Utilization (Phase 3)

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

40

Table 18 - Asset Utilization (Phase 4)

Shovel

Truck

Utilization Utilization

0.04

0.98

0.19

0.97

0.38

0.97

0.57

0.96

0.74

0.94

0.83

0.92

0.89

0.90

0.94

0.89

0.98

0.86

0.99

0.84

1.00

0.82

1.00

0.79

1.00

0.77

1.00

0.75

1.00

0.72

1.00

0.71

1.00

0.69

1.00

0.67

1.00

0.65

1.00

0.63

# Trucks

1

5

10

15

20

23

25

27

29

30

31

32

33

34

35

36

37

38

39

40

25

Shovel

Truck

Utilization Utilization

0.04

0.98

0.18

0.98

0.36

0.97

0.54

0.96

0.70

0.94

0.80

0.93

0.85

0.91

0.91

0.90

0.95

0.88

0.97

0.87

0.99

0.85

1.00

0.84

1.00

0.81

1.00

0.79

1.00

0.77

1.00

0.74

1.00

0.73

1.00

0.71

1.00

0.69

1.00

0.67

Appendix F – Productivity Slope Calculation

Each truck that is filled by a shovel must drive to its destination and return empty to the shovel. As such

the average speed is given by:

1

1

𝑣̂ = ( ) 𝐸[𝑣𝑙𝑜𝑎𝑑𝑒𝑑 ] + ( ) 𝐸[𝑣𝑒𝑚𝑝𝑡𝑦 ]

2

2

𝑣𝑙𝑜𝑎𝑑𝑒𝑑 is given by a shifted beta distribution, and 𝑣𝑒𝑚𝑝𝑡𝑦 is given by a shifted gamma distribution:

1

𝛼

1

𝑣̂ = ( ) (𝐴 +

) + ( ) (𝐵 + 𝑘𝜇)

2

𝛼+𝛽

2

1

211 ∙ 2.99

1

= ( ) (311 +

) + ( ) (308 + 57.9 ∗ 4.06) = 472.82

2

2.99 + 3.9

2

1

2

3

2

𝑑̂𝑖 = (( ) (( ) (𝑑𝑐𝑟𝑢𝑠ℎ +𝑑𝑐𝑟𝑢𝑠ℎ ) + ( ) (𝑑𝑙𝑒𝑎𝑐ℎ +𝑑 𝑐𝑟𝑢𝑠ℎ )) + ( ) (𝑑𝑑𝑢𝑚𝑝 + 𝑑𝑐𝑟𝑢𝑠ℎ ))

3

5

5

3

1

2

3

2

𝑑̂1 = (( ) (( ) (4749 + 4553.38) + ( ) (4483 + 4287.38)) + ( ) (6125 + 5828.63)) = 10963.48

3

5

5

3

1

2

3

2

𝑑̂2 = (( ) (( ) (5049 + 4834.625) + ( ) (4783 + 4568.625)) + ( ) (6625 + 6297.375)) = 11803.058

3

5

5

3

1

2

3

2

𝑑̂3 = (( ) (( ) (5349 + 5115.875) + ( ) (5083 + 4849.875)) + ( ) (7125 + 6766.125)) = 12642.642

3

5

5

3

1

2

3

2

𝑑̂4 = (( ) (( ) (5649 + 5397.13) + ( ) (5383 + 5131.13)) + ( ) (7625 + 7234.88)) = 13482.23

3

5

5

3

The loading times are represented by a shifted lognormal distribution. The average loading time is:

𝑡𝑙𝑜𝑎𝑑 = 𝐸[2 + 𝐿𝑂𝐺𝑁(1.52,0.716)] = 2 + 1.52 = 3.52

The dumping times at each of the truck destinations are represented by a gamma distribution:

𝑡𝑑𝑢𝑚𝑝 = 𝐸[𝐺𝐴𝑀𝑀(0.459,1.97)] = 𝑘𝜃 = 0.90423

26