thermodynamic and microstructural investigations of the al-mg

advertisement

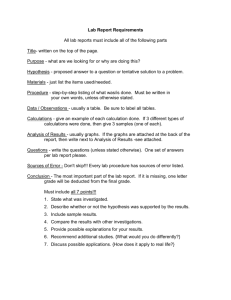

THERMODYNAMIC AND MICROSTRUCTURAL INVESTIGATIONS OF THE AL-MG-SI EXTRUSION ALLOYS: CRITERIA FOR PHASE SELECTION AND FORMABILITY K. Korgiopoulos1, *A.R. Farkoosh1, O. Rodop1, L.A. Villegas Armenta1, B. Cook1, H. Blanchette2 and M. Pekguleryuz1 1 McGill University 3610 University Street Montreal, Canada H3A 0C5 (*Corresponding author: amir.rezaeifarkoosh@mcgill.ca) 2 Raufoss Canada 4050 Rue Lavoisier Boisbriand, Canada J7H 1R4 ABSTRACT The excellent corrosion resistance and good formability of the Al-Mg-Si alloys make them a suitable candidate material for automotive industry. The alloying additions, Si and Mg impart strength through agehardening, whereas Mn produces thermally stable dispersoids which prevent recrystallization and grain growth during hot deformation. In this study the effects of varying levels of Si (0.5-1.5wt%), Mg (0.51.5wt%) and Mn (0.1-2.5wt%) on the phase selection have been studied through thermodynamic calculations to understand the effects of the constituent particles, specifically, age-hardening precipitates, dispersoids, and primary intermetallic phases on the grain structure, strength and formability. Thermodynamic calculations, equilibrium and non-equilibrium, were conducted via FactSage™ software using the FTlite database. Selected compositions have been cast, heat treated, extruded and characterized through scanning electron microscopy (SEM) with energy dispersive spectroscopy (EDS) and electron backscatter diffraction (EBSD) techniques. Calculations showed that at the hot deformation temperature (~540 oC) Mg and Si higher that a specific amount lead to the presence the retained β-Mg2Si intermetallics and Si particles at the grain boundaries in addition to α-Al-(Mn,Cr,Fe)-Si. It was suggested that, in order to avoid the undesirable consequences of the retained β-Mg2Si particles, Si+2Mg should be less than 2.3wt% (Figure 1). According to the calculations, Mn increase from 0.5wt% to 1wt% leads to a higher amount of dispersoids (increase from 1wt% to 2wt%). This increase will potentially slow down the recrystallization and grain growth during hot deformation and lead to a better formability. Calculations at room temperature also shows that for an alloy with 0.7wt% Mg, excess Si beyond 0.7 wt% promotes the precipitation of Si clusters in the Al matrix which leads to an accelerated natural age-hardening. Results are confirmed by experimental investigations. Si + 2Mg < 2.3 Figure 1- The amount of the retained Mg2Si at 540oC KEYWORDS FactSageTM, 6082 aluminum alloy, Age hardening, Primary intermetallics, Dispersoids, Automotive