Bioethanol_Final_Draft_

advertisement

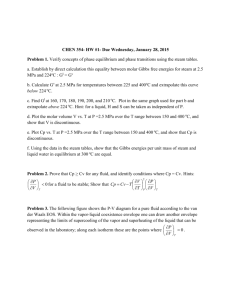

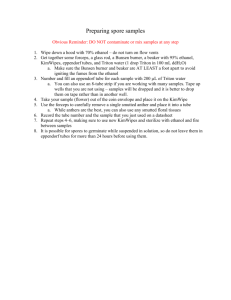

Executive Summary (Dana Olson) As the movement to “go green” progresses around the world there has been much desired to move away from the use of fossil fuels and towards a biobased fuel to reduce greenhouse gas emissions. As yet many of the methods used while technologically possible have been economically infeasible. Recently the US Department of Energy has partnered with the National Renewable Energy Laboratory to develop a process for producing ethanol from lignocellulosic biomass and a similar process is presented in this research paper. (Too introductory??) A feedstock of 2000 metric tons of corn stover is to be consumed every day. This corn stover is sent through a pretreatment process to liberate the fermentable sugars from the ligin structure. The fermentable sugars then go through a saccharification process where they are hydrolyzed by three cellulase enzymes endo-p-glucanase, exo-p-glucanase and ßglucosidase to five and six carbon sugars. Then these sugars are sent to the fermentation process where a genetically modified strain of Saccharomyces cerevisiae is used to ferment the sugars to ethanol. Finally, the ethanol is recovered by a distillation process, first being passed through a beer column and second a rectifying column. An azeotropic mixture of ethanol and water is removed as the distillate from the rectifying column and is sent to a molecular sieve adsorption column to purify the ethanol to 99.5% at a production rate of 170,000 gallons of ethanol per day. Fermentation Optimization (Dana Olson) Several different microorganisms were considered for the fermentation process. They needed to be robust and have high productivity while being able to ferment a wide variety of sugars to ethanol. A high tolerance to ethanol is also a very favorable trait. Saccharomyces cerevisiae, Zymomnas mobilius and Escherichia coli were all considered as possibilities but S. cerevisiae was found to have the most favorable characteristics for this process. Include discussion of E. coli and Z. mobilius?? S. cerevisiae has a high ethanol tolerance and can ferment sugars to ethanol anaerobically at low pH conditions. These low pH conditions minimize the likelihood of contamination of the fermentation tanks by other microorganisms. Wild types of S. cerevisiae do not naturally ferment pentoses and as such recombinant DNA technologies must be used to incorporate sugars such as xylose into the pentose phosphate pathway of the metabolic flux [Lu]. This can be done by incorporating genes from Pichia stipitis by utilizing inverse metabolic engineering. The necessary genes were found to be D-xylolukinase, or XYL3, and an open reading frame segment labeled PsTAL1 which is highly homologous to the native gene ScTAL1. These genes were found to improve xylose uptake and ethanol production in S. cerevisiae without hindering its ability to grow on glucose [Jin]. Furthermore, S. cerevisiae has natural glucose transporters that are also capable of transporting xylose across the cell membrane, however there is a delay as glucose is selectively transported first [Lu]. To isolate the modified strains of S. cerevisiae that are capable of growing on and therefore fermenting xylose the genes were first transfected into wild type strains of the yeast. They were then grown up on minimal xylose media for several cycles and then replated onto either glucose or xylose rich agar plates. The colonies on the glucose rich plates were found to be of equal size indicating they had the same growth rate, while those on the xylose rich agar plates ranged in sizes. The larger colonies had a higher growth rate 1 - From Watanabe. Fermentationofof and therefore increase xylose assimilation [Jin]. Under Figure Figure ##. From ???. Fermentation sugars in modified strain of S. The sugars in modified strain of cerevisiae. S. cerevisiae, aerobic conditions, the specific ethanol productivity of strains squares and circles are glucose and xylose squares and circles are glucose and with PsTAL1 over expressed was increased by 70% from the consumption respectively, the diamonds are xylose consumption respectively, the ethanol production and the triangles are diamonds are ethanol production and the xylitol accumulation. triangles are xylitol accumulation base strain and a 100% increase in the specific growth rate of the cells on xylose media [Jin]. In a similar experiment by Watanabe et. al, the best strain isolated was found to have a yield of 0.43 g ethanol per g of total consumed sugars which was 84% of the theoretical yield [Watanabe]. These best growing strains could then be isolated and grown up in Figure 2 - From Dombek. Fermentation rate as a a seed train of continuously increasing bioreactors before function of ethanol concentration. being inoculated into the process. Under optimal conditions S. cerevisiae can produce ethanol at a rate of 50 mmol ethanol per hour per gram of cell protein. During batch fermentation this optimal rate is only maintained for a brief period followed by a rapid decline as ethanol accumulates in the broth. Accumulation of ethanol is known to reduce membrane permeability and can increase hydrogen ion flux into the yeast cells. This increased proton flux has been proposed as the cause in the ethanolinduced reduction of fermentation rates. However, replacement of the fermentation broth containing ethanol does not immediately restore the fermentative activity. It was found that ethanol concentrations below 12% (vol/vol) do not denature the glycolytic enzymes or cause significant irreversible inhibition of the fermentative activity [Dombek]. Ethanol Recovery and Purification (Dana Olson) Ethanol vaporizes at 78°C and water vaporizes at 100°C. If distilled an azeotropic mixture of ethanol and water will form the distillate (95.6% ethanol to 4.4% water). Since the ethanol-water mixture is not ideal a multi-stage process must be implemented [Lu]. Typically the fermentation mixture will be fed to a beer column. Carbon dioxide leaves out the top with water coming out the bottom and ethanol is removed from a side-draw. The carbon dioxide vented from the top of the column is sent to a scrubber to remove any ethanol which is recycled to the rectifying column. The water contains solids which are removed by pressurized filtration. The purified water is recycled to the process while the filters are combusted for energy. The beer column is 32 trays with the feed entering at tray four. The tray spacing is two feet and the column has a diameter of 14.3 feet. The side draw of ethanol removed at tray eight is 39.4% pure by weight [Aden]. This ethanol is fed to a rectifying column, the product of which is the azeotropic mixture. This mixture cannot be further purified using distillation. The rectifying column contains 60 trays and is fed at tray 44 with the side draw from the beer column. The column diameter is 4 feet below tray 44 and 11.5 feet above tray 44 to accommodate the increased flow [Aden]. The distillate of the rectifying column is fed to a dehydration unit. Typically a molecular sieve adsorption unit can be used. The zeolites in the molecular sieve unit selectively adsorb 95% of the water from vapor mixtures, further purifying the ethanol. Two adsorption columns are required so that while one is dehydrating the azeotropic mixture, the other can be regenerated. This results in a 99.5% ethanol pure product produced at a rate of 170,000 gallons per hour [Aden]. Resources 1. Aden, A., M. Ruth, K. Ibsen, J. Jechura, K. Neeves, J. Sheehan, B. Wallace, L. Montague, A. Slayton, and J. Lukas. Lignocellulosic Biomass to Ethanol Process Design and Economics Utilizing Co-Current Dilute Acid Prehydrolysis and Enzymatic Hydrolysis for Corn Stover. National Renewable Energy Laboratory, 2002. Print. 2. Dombek, K. M., and L. O. Ingram. "Ethanol Production during Batch Fermentation with Saccharomyces cerevisiae: Changes in Glycolytic Enzymes and Internal pH." Applied and Environmental Microbiology 53.6 (1987): 1286-291. Department of Microbiology and Cell Science, University of Florida, Gainesville. Web. 6 Dec. 2009. 3. Jin, Yong-Su, Hal Alper, Yea-Tyng Yang, and Gregory Stephanopoulos. "Improvement of Xylose Uptake and Ethanol Production in Recombinant Saccharomyces cerevisiae through an Inverse Metabolic Engineering Approach." Applied and Environmental Microbiology 71.21 (2005): 8249-256. Department of Chemical Engineering, Massachusetts Institute of Technology. Web. 4 Dec. 2009. 4. Lu, Yulin, and Nathan S. Mosier. "Current Technologies for Fuel Ethanol Production from Lignocellulosic Plant Biomass." Genetic Improvement of Bioenergy Crops. Ed. Wilfred Vermerris. Gainesville, FL: Springer, 2008. 161-77. Print. 5. Watanabe, Seiya, Ahmed Abu Saleh, Seung Pil Pack, Narayana Annaluru, Tsutomu Kodaki, and Keisuke Makino. "Ethanol Production from xylose by recombinant Saccharomyces cerevisiae expressing protein-engineered NADH-preferring xylose reductase from Pichia stipitis." Microbiology 153 (2007): 3044-054. Kyoto University. Web. 6 Dec. 2009.