Proposal - Draft 8 - aos-hci-2012-research

advertisement

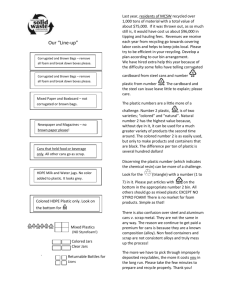

Microbial Degradation Activities Project Proposal Poh Yong Rui Ong Kim Yao Hwa Chong Institution (High School) Mentor: Mrs Har Hui Peng 1 Introduction In the 20th century, the demands of society have caused a great rise in the usage of plastic. Plastics are defined as polymers which are mouldable upon heating, to take on a desired shape and then retain that shape (Shah, 2007). The use of plastics has become a significant part of today’s economy. Various kinds of plastic have been used extensively for manufacturing a wide range of products. Polyethylene has been used to make plastic bags, food packaging films and toys; polystyrene for making disposable cups, packaging material and laboratory ware; and polypropylene for making bottle caps, straws, and car seats. Plastics are non-polar and inert in nature, hence they remain almost unaffected once disposed . As plastics do not biodegrade they pose detrimental consequences on the environment, and thus the extensive usage of plastics has drawn much attention. Plastic sheets and bags are impermeable to water and air and, if buried in the ground will cause infertility in soil, disrupt degradation of other substances, deplete underground water resource and pose danger to the ecosystem. In the sea, plastic rubbish from ropes and nets chokes and entangles marine life. Plastic waste cannot be incinerated as they release air pollutants which cause various health problems. The burning of polyethylene and polystyrene produces toxic irritant products, leading to human disorders and their classification as human carcinogens (Shah, 2007). There is thus an increasing need to dispose plastic waste in an environmentally friendly manner. Despite the inert nature of polymer plastics, past research has shown that biodegradation of plastic is not impossible or improbable. Degradation is termed as the physical or chemical change in polymer as a result of environmental factors, such as light, heat, moisture, chemical 2 conditions or biological activity. Past research has shown that some bacterial and fungus are able to degrade plastic, the process is catalysed by exposure to light, UV radiation, and heat. This project aims to investigate the optimal conditions for photodegradation (physical degradation of polymer into shorter chains) and thermal degradation (chemical degradation of polymer by rupture of bonds into radical sites). Their efficiency under different aerobic activity will also be investigated, so that the most efficient breakdown of plastic may occur. This is coupled with the biodegradation of HDPE plastics by Pseudomonas putida and Sphingomonas macrogoltabidus. Such information would not only allow for efficient biodegradation of polymer plastic, but also, plastic can now be produced from monomers vulnerable to the degredation of microorganisms, allowing them to be biodegradable. 3 Literature Review High-density polyethylene (HDPE) is a synthetic polymer which consists of chains of ethylene (Nanda et al., 2010). The light weight and durability of HDPE plastics has resulted in its widespread use. However, its rapid use has resulted in landfills to be filled with HDPE. Coupled with the low biodegradability of HDPE, rapid growth of landfills has posed a threat to the ecosystem. Delgi-Innocenti et al. (2001) showed that polymer which may appear safe for degradation may instead produce toxic chemicals on degrading (as cited in Nanda et al., 2010, p. 57). This has caused a pressing need to find alternatives to accelerate the biodegradation process of HDPE. Much research has shown that microbes can help to degrade plastics. Microbes can attach to the hydrophilic surfaces of HDPE, and grow with the plastic polymer as the carbon source (Arutchelvi et al., 2008). They will then secrete extracellular enzymes, resulting in the cleavage of carbon-carbon bonds of the HDPE (Premraj & Doble, 2005), thereby releasing oligomers and monomers which are utilised by the microorganisms as energy (Nanda et al., 2010). Cornware, also known as starch-polyethylene plastics, are polyethylene mixed with other biodegradable substances such as corn, yam and starch (Olive Green Marketing, n.d.). These plastics are more environmentally friendly than HDPE due to its use of starch, which is biodegradable. Furthermore, the use of starch in making plastic has decreased the time taken for biodegradation to occur (Borghei et al., 2010). Bastioli (2001) showed that such plastic reduced the greenhouse effect (Borghei et al., 2010) In addition to this eco-friendly advantages, the use of starch allows the use polyethylene to be maximised as well as provide an alternative to our limited resources due to the “consistent growth of plants” (Kaur & Gautam, 2010). A research done by Borghei et al. (2010) showed that low-density polyethylene (LDPE) with potato starch can biodegrade to a greater extent than LDPE, and to 4 an even greater extent by Pseudomonas aeruginosa. This was because starch became the only source of carbon for the bacteria, and the breakdown of starch caused a fracture in the polyethylene structure, thereby resulting in biodegradation. Providing pre-treatment to the plastic such as UV and thermal radiation before inoculating them in bacteria culture have been observed to accelerate chemical degradation through the absorption of energy. This is because the plastic polymer absorbs the radiant energy which will cause a cleavage (breaking of bonds) within the bonds of the polymer plastic, resulting in the formation of free radicals from the plastic (Gijsman et al., 1999). These radicals cannot recombine easily (Albano et al., 2005), thereby speeding up the biodegradation process. A research done by Albano et al. (2005) showed a decrease in tenacity of HDPE plastic with increasing gamma irradiation, further suggesting that pre-treatment will enhance the breakdown of plastic. Thermal exposure has also been shown to catalyse the breakdown of plastics. Thermal exposure allows the plastic to reach a higher temperature than its surroundings (Andrady, 1999) and this rise in temperature results in an acceleration of light-induced degradation. It is thus suggested that pre exposure to heat will cause accelerated breakdown of polymer plastic due to the synergistic effect with UV pre- treatment. Also, thermal exposure is interconnected to humidity which also affects breakdown. High humidity is known to accelerate the rates of biodegradation of polymer plastic as absorbed water leads to increased accessibility of atmospheric oxygen. As such, exposure to heat as pre- treatment is likely to show synergistic biodegradation under aerobic conditions. 5 Plastic biodegradation can occur under 2 conditions: aerobic and anaerobic. Under aerobic conditions, enzymes secreted by the bacteria catalyses the breakdown of polymer plastic into oligomers, which diffuse into the bacteria (Arutchelvi et al., 2008). These oligomers are then converted into energy or assimilated. The final products are heat, carbon dioxide, water and biomass. A research done by Huang et al. (2004) suggested that the breakdown of PEGs (polyethylene glycols) under aerobic conditions was more efficient due to “the employment of efficient microbes”. This research suggests that HDPE, which is polyethylene as well, undergoes biodegradation more efficiently with oxygen. Under anaerobic conditions, polymer plastics are first broken down into monomers, catalysed by bacterial enzymes. The monomers are then converted into carbon dioxide and organic acids containing C and H. Methane is then produced, largely a result of the reduction of carbon dioxide with hydrogen, together with the breakdown of organic acid bonds to form carbon dioxide and methane (Verma, 2002). The final products are thus carbon dioxide, water and methane (Arutchelvi et al., 2008). While Huang et al. (2004) suggested that PEGs break down more efficiently under aerobic conditions, Rees (1980) showed that aerobic biodegradation might cause the temperature to rise above 70°C (as cited in Lanini et al., 2001, p. 68). This might in turn hinder the development of the bacteria, as well as contribute to global warming. While much research has been done on biodegradation of plastic in liquid medium, Sierra et al. (2003) suggested that biodegradation of polychlorinated biphenyls (PCBs) would occur faster under soil conditions. The presence of natural compounds such as flavonoids and lignin would help to replace conditions that enhance PCB degradation such as biphenyl addition, which poses adverse health effect. Though PCBs are not plastic, this gives a general idea of how soil conditions can accelerate the biodegradation of plastic, by providing organic compounds. Furthermore, research has suggested that loamy soil would result in higher 6 biodegradation rate than sandy soil, due to different growth conditions for microbes, and environmental differences between different soil, such as temperature and moisture (Mostafa et al., 2010). 7 Rationale While past researches have identified the use of bacteria to enhance the biodegradation of HDPE, little have been done to find out the effect of soil contents on biodegradation of plastics. Studies by Sierra et al. (2003) suggested that the presence of compounds such as lignin would help to enhance biodegradation as well. Therefore, this project investigates the effect of soil bacteria on the biodegradation of plastic under various conditions. UV radiation during the pre-treatment process contributes to the biodegradation process since it releases free radicals from plastic, thereby increasing the surface area for bacterial enzymes to act on. Therefore, this project seeks to study the optimum exposure time for UV irradiation on HDPE that accelerates the biodegradation process. Objectives The objectives of this project are: 1. To study the effects of different environmental conditions on the biodegradation of HDPE by the selected microbes. 2. To study the effects of varying exposure time of HDPE to UV radiation on its biodegrability by the selected microbes. 3. To determine the optimum conditions to achieve maximum biodegradation of HDPE by the selected microbes. Hypothesis The following factors affect the rate of biodegradation of HDPE plastic: Types of microbe culture Environmental conditions for biodegradation 8 Exposure time to UV radiation Types of plastic Variables Independent Variables Types of bacterial culture Exposure time to UV radiation Dependent Variables Constant Variables Change in dry mass Amount of of HDPE samples bacterial culture Amount of dissolved used Environmental conditions O2 gas present in for soil degradation tube Amount of culture medium for bacteria/fungus Types of plastic Amount of HDPE plastic used Other possible independent variables (can be experimented on if time allows) Wavelength of UV radiation Temperature and time of thermal radiation Apparatus Sterile test containers Inoculating loop Alcohol burner Incubator Tweezer Oven (capable of 150°C) 9 UV lamp (for 365 nm UV radiation) Measuring scale Autoclave Vernier dissolved O2 probe Datalogger Spatula Thermometer (to measure small changes in temperature of at least 0.25°C) Spectrophotometer Rotary shaker Materials Bacteria (as suggested from AOS side) o P. putida bacterial strain Obtained from ATCC (Catalog Number: 4359) o S. macrogoltabidus bacterial strain Obtained from ATCC (Catalog Number: 51380) Nutrient broth Loamy soil (obtained from Far East Flora Singapore) Wire mesh Ethanol Aluminium foil Paper towels HDPE plastic (from grocery bags, with the symbol “2”) Deionised water Bleach 10 M63 minimal media Cornware Petri dishes LB agar powder 11 Outline of method The flow chart below summarises our method: Preparing bacterial culture Preparing soil conditions Pre-treatment of plastic Treatment of plastic by microbes Change in dry mass of HDPE samples Amount of carbon dioxide gas present in flask Temperature of contents of flask Cell density of bacterial culture A. Preparing bacterial culture 1. 17 test containers will be prepared. They will be labelled as shown below: Liquid medium +115°C, 48h +115°C, 48h Ctrl + UV, H Ctrl + UV, H Sphingomonas macrogoltabidus Ctrl + UV, H Ctrl – H UV – 120h UV – 96h UV – 72h Ctrl + H – UV UV – 120h UV – 96h UV – 72h Pseudomonas putida UV – 72h 96h 120h Control Legend: H: heat treatment, UV: UV treatment Soil conditions Ctrl Sphingomonas macrogoltabidus Best Ctrl Best Ctrl Best Pseudomonas putida Control For soil conditions, the best conditions concluded from plastic biodegradation in liquid medium will be used, as shown in the above diagram. 12 Each set-up above will be done in triplicates. This can be simplified by the diagram below: Liquid medium Add microbes individually Control (x3) Treatment Control UV radiation (72h, 96h and 120h) This set-up will contain bacterial culture and heattreated HDPE plastic which is not UVirradiated. 3 set-ups will be prepared. All 3 will not contain bacterial culture. The 3 setups will contain heattreated HDPE plastics which are UV-irradiated for 72h, 96h and 120h respectively. Soil conditions By using the best conditions concluded from plastic degradation in liquid medium, degradation under soil conditions will be carried out. The controls will be Thermal radiation with microbes Thermal radiation without microbes UV radiation without microbes 2. Bacterial culture (Pseudomonas putida and Sphingomonas macrogoltabidus) will be prepared by inoculating each bacteria in 10ml of NB broth. P. putida culture will be inoculated overnight, while S. macrogoltabidus culture will be inoculated for 48h. 13 The cell density of the bacteria culture will be adjusted to approximately 4 × 108 cells/ml, as suggested by Farrell & Quilty (2002). The corresponding cell densities are 0.44 AU for P. putida and 0.46 AU for S. macrogoltabidus (according to Section H). 3. For liquid medium, the test containers will be prepared according to Huang et al. (2004), with some modifications. 2ml of bacterial culture (prepared in Section A Step 2) will be inoculated in a centrifuge tube with 13.5ml of M63 minimal media and 4.5ml of NB. The NB will allow the bacteria to grow and adapt to its environment before plastic degradation starts. The control tube will contain 15ml of M63 minimal media and 5ml of NB. B. Preparing soil conditions 1. The soil samples will be prepared according to Mostafa et al. (2010) and Orhan et al. (2004), with some modifications. Loamy soil will be purchased from Far East Flora Singapore, and sieved with a mesh to remove gravel. 2. The soil will be autoclaved to remove any microbes present in the soil. 3. The test containers will be filled with 20cm3 of loamy soil, and the soil will be adjusted to 50% of its maximum water holding capacity. The maximum water holding capacity of the soil will be determined by adding deionised water to a centrifuge tube filled with 50cm3 of autoclaved soil, until the tube is filled to the brim. The volume of water added is the maximum water holding capacity of the soil. 4. 2ml of bacterial culture (prepared in Section A Step 2) will be added to the soil each. The control set-up will contain the soil only. 5. The containers are kept at room temperature and 70% humidity. C. Pre-treatment of HDPE 1. HDPE plastics will be cut from a grocery bag for UV radiation. UV radiation will be carried out according to Johnson et al. (1993) and Morancho et al. (2006), with some 14 modifications. Each HDPE sample will be exposed to UV radiation with a wavelength of 365 nm using a UV lamp. The exposure time will be varied as 72h, 96h and 120h (since Morancho et al. (2006) suggested an exposure time of 98.7h). The control plastic samples will not be exposed to any UV radiation. 2. The samples will then be exposed to heat treatment at 115°C for 48 hours in an oven. 3. The plastics will be cut into small pieces of plastics, with masses between 0.015g and 0.025g. The mass of each plastic sample will be recorded. The plastics will be placed in test containers, and the containers will be labelled with the type of bacteria and UV irradiation time, as shown in Section A Step 1. D. Treatment of HDPE with bacteria 1. The treatment process will be carried out according to Nanda et al. (2010), with some modifications. HDPE samples will be disinfected with ethanol before they are placed into the liquid medium in the respective test containers prepared in Section A Step 3 (1 HDPE sample each). The containers are then loosely capped and kept at 37°C. 2. Separate HDPE samples will be placed in the soil in the respective containers prepared in Section B Step 4 at 2.5cm depth, and kept at room temperature (1 HDPE sample each). 3. The set-ups containing liquid medium will be placed on a slow rotary shaker to ensure that the HDPE samples are evenly exposed to the bacterial culture. 4. The M63 media will be changed every week as suggested by Pometto et al. (1992). The HDPE sample will be removed, and the culture will be allowed to stand for 1h. 5ml of liquid medium will then be removed using a pipette. New M63 media will then be added to replace the amount of culture removed. (refer to Section F). This process will remove waste materials and dead cells from the medium. 15 5. The HDPE samples will be exposed to the bacterial culture until a significant change in the mass of plastic is recorded. Readings will be taken every 7 days. E. Dry mass of plastic samples after treatment 1. At every reading (every 7 days), the HDPE samples will be removed from the tube using a tweezer. 2. The HDPE samples will be rinsed with deionised water. This will help to remove any bacterial biofilm and cell mass attached to the samples. 3. Bleach will be added to the waste materials before disposal. 4. The samples will then be dried and weighed. To find the percentage change in mass, the difference between the final mass and initial mass (after pre-treatment) of the samples will be divided by the initial mass. This can be summarised by the below formula: Percentage change in mass Initial mass (measured after pre-treatment) Final mass 100% Initial mass 5. A graph will then be plotted to show the percentage change in mass of HDPE samples over time. A faster rate of decrease in HDPE mass would indicate a faster rate of biodegradation. 6. The HDPE samples will then be disinfected using ethanol, to reduce the chances of contamination by other microbes, before being returned to the tube. F. Amount of dissolved oxygen present in the tube 1. The amount of dissolved oxygen will be monitored every 7 days. 2. Dissolved oxygen concentration will be measured from the liquid medium using a carbon dioxide probe and a datalogger. 16 3. Oxygen is taken in during the biodegradation process and through respiration. Thus, a decrease in oxygen concentration will suggest microbe activity in the containers. 4. Similarly, a graph will be plotted to show the change in amount of oxygen over time. G. Cornware 1. The entire experiment will be repeated with cornware in place of HDPE plastics. H. Plotting the standard curve 1. A standard curve will be plotted before the experiment for each bacteria to determine the turbidity of bacteria culture at different cell densities. It will be carried out according to Reynolds & Farinha (2005), with some modifications. 2. Bacterial culture samples will be prepared by inoculating 1 loopful of bacteria into 10ml of NB. 3. 10-fold serial dilutions will be carried out until 10-8. 4. 0.1ml and 1ml of bacterial culture for each dilution factor will be added to a petri dish respectively. The petri dishes will be labelled with the dilution factor and volume of culture added. 5. NB agar will be prepared by adding deionised water to NB agar powder. The agar will be autoclaved, poured into the petri dishes and allowed to solidify. Directions for preparing agar plates will be followed. 6. The agar plates will then be inverted and incubated at 37°C for 24h. 7. At the end of the incubation, the number of colonies on each plate will be counted. Plates with too many colonies and cannot be counted, and plates with less than 30 colonies will not be counted. 8. The cell density of the bacterial culture of each dilution factor will be calculated using the following formula (assuming each colony represents 1 bacteria cell): 17 Cell density (no. of bacteria cells/ml ) Number of colonies Dilution factor Amount of bacterial culture plated (ml ) 9. Following that, 1ml of bacterial culture for each dilution factor (prepared in Section J Step 3) will be pipetted into a cuvette and its optical density will be read at an absorbance of 550nm. 1ml of NB will be used as the blank. 10. A graph will be plot showing the optical density of each sample against the cell density of the sample. 11. The cell density of the bacterial culture will be adjusted to 4 × 107 cells/ml according to the graph plotted (refer to Section A Step 2). Safety precautions During the experimentation, latex gloves will be worn when handling microorganisms. All microbial cultures and vessels used to contain them will be decontaminated by autoclaving before disposal. Perpex goggles will be worn when working with UV irradiation, and plastic pieces will be irradiated in an opaque box. Timeline Period Activity Write proposal October – November 2011 Confirm methods and proposal November 2011 Experimentation March – July 2012 Analyse results May – July 2012 18 Write research paper July 2012 References Aamer Ali Shah (2007). Role of Microorganism in Biodegradation of Plastics. Retrieved October 30, 2011 from http://eprints.hec.gov.pk/2361/1/2216.htm Albano, C., Karam, A., Gonzalez, G., Dominguez, N., Sanchez, Y., Manzo, F. & GuzmanGarcia, C. (2005). Effect of gamma irradiation on HDPE/HA (80:20) composites. Polymers for Advanced Technologies, 16, 283–285. Retrieved October 25, 2011 from http://onlinelibrary.wiley.com/doi/10.1002/pat.580/pdf Anthony L. Andrady (1999). Environmental Degradation of Plastics under Land and Marine Exposure Conditions. Retrived October 30, 2011 from http://www.5gyres.org/media/Environmental_Degradation%20of%20Plastics_by_Andrady.p df Arutchelvi, J., Sudhakar, M., Arkatkar, Ambika, Doble, Mukesh, Bhaduri, Sumit & Uppara, Parasu Veera (2008). Biodegradation of polyethylene and polypropylene. Indian Journal of Biotechnology, 7, 9–22. Retrieved October 25, 2011 from http://nopr.niscair.res.in/bitstream/123456789/7326/4/IJBT%207%281%29%209-22.pdf Borghei, Mehdi, Karbassi, Abdolreza, Khoramnejadian, Shahrzad, Oromiehie, Abdolrasoul & Javid, Amir hossein (2010). Microbial biodegradable potato starch based low density polyethylene. African Journal of Biotechnology, 9, 4075–4080. Retrieved December 9, 2011 from http://www.academicjournals.org/AJB/PDF/pdf2010/28Jun/Borghei%20et%20al.pdf 19 Farrell, A & Quilty, B (2002). Substrate-dependent autoaggregation of Pseudomonas putida CP1 during the degradation of mono-chlorophenols and phenol. Journal of Industrial Microbiology & Biotechnology, 28, 316–324. Retrieved December 7, 2011 from http://www.springerlink.com/content/15htgedtjefxv22v/fulltext.pdf Gijsman, Pieter, Meijers, Guido & Vitarelli, Giacomo (1999). Cornparison of the UVdegradation chemistry of polypropylene, polyethylene, polyamide 6 and polybutylene terephthalate. Polymer Degradation and Stability, 65, 433–441. Retrieved October 25, 2011 from http://cid.ispa.asso.fr/GEIDEFile/Degrad_0001.PDF?Archive=191929191910&File=Degrad +0001_PDF Huang, Yi-Li, Li, Qing-Biao, Deng, Xu, Lu, Ying-Hua, Liao, Xin-Kai, Hong, Ming-Yuan & Wang, Yan (2004). Aerobic and anaerobic biodegradation of polyethylene glycols using sludge microbes. Process Biochemistry, 40, 207–211. Retrieved October 25, 2011 from http://envismadrasuniv.org/Biodegradation/pdf/Glycols%20using%20sludge%20microbes.pd f Johnson, Kenneth E., Pometto, Anthony L. III & Nikolov, Zivko L. (1993). Degradation of Degradable Starch-Polyethylene Plastics in a Compost Environment. American Society for Microbiology, 59, 1155–1161. Retrieved November 8, 2011 from http://aem.asm.org/content/59/4/1155.full.pdf 20 Kaur, Inderjeet & Gautam, Neena (2010). Starch Grafted Polyethylene Evincing Biodegradation Behaviour. Malaysian Polymer Journal, 5, 26–38. Retrieved December 9, 2011 from http://www.cheme.utm.my/mpj/images/100501_3nee1.pdf Lanini, S., Houi, D., Aguilar, O. & Lefebvre, X. (2001). The role of aerobic activity on refuse temperature rise: II. Experimental and numerical modelling. Waste Management & Research, 19, 58–69. Retrieved October 25, 2011 from http://wmr.sagepub.com/content/19/1/58.full.pdf Morancho, J.M., Ramis, X., Fernández, X., Cadenato, A., Salla, J.M., Vallés, A., Contat, L. & Ribes, A. (2006). Calorimetric and thermogravimetric studies of UV-irradiated polypropylene/starch-based materials aged in soil. Polymer Degradation and Stability, 91, 44–51. Retrieved November 8, 2011 from http://anvalllu.webs.upv.es/papers/2006_DSCTGAUVPPstarchsoil.pdf Mostafa, H. M., Sourell, H. & Bockisch, F. J. (2010). The Mechanical Properties of Some Bioplastics Under Different Soil Types for Use as a Biodegradable Drip Tubes. Agricultural Engineering International: the CIGR Ejournal, 12, 1–16. Retrieved November 7, 2011 from http://www.cigrjournal.org/index.php/Ejounral/article/viewFile/1497/1270 Nanda, Sonil, Sahu, Smiti Snigdha & Abraham, Jayanthi (2010). Studies on the biodegradation of natural and synthetic polyethylene by Pseudomonas spp. Journal of Applied Sciences & Environmental Management, 14, 57–60. Retrieved October 29, 2011 from http://www.bioline.org.br/pdf?ja10027 21 Olive Green Marketing (n.d.). Olive Green. Retrieved December 9, 2011 from http://www.olivegreen.com.sg/ Orhan, Yüksel, Hrenovićb, Jasna & Büyükgüngöra, Hanife (2004). Biodegradation of plastic compost bags under controlled soil conditions. Acta Chimica Slovenica, 51, 579–588. Retrieved November 7, 2011 from http://acta.chem-soc.si/51/51-3-579.pdf Pometto, Anthony L. III, Lee, Byungtae & Johnson, Kenneth E. (1992). Production of an Extracellular Polyethylene-Degrading Enzyme(s) by Streptomyces Species. Applied and Environmental Microbiology, 58, 731–733. Retrieved December 9, 2011 from http://www.ncbi.nlm.nih.gov/pmc/articles/PMC195314/pdf/aem00043-0307.pdf Premraj, R & Doble, Mukesh (2005). Biodegradation of polymers. Indian Journal of Biotechnology, 4, 186–193. Retrieved December 9, 2011 from http://nopr.niscair.res.in/bitstream/123456789/5718/1/IJBT 4(2) 186-193.pdf Reynolds, Jackie & Farinha, Mark (2005). Counting Bacteria. Richland College, 1–10. Retrieved December 7, 2011 from http://www.biotech.ug.edu.pl/odl/doc/numbers.pdf Sierra, Isabel, Valera, José Luis, Marina, M. Luisa & Laborda, Fernando (2003). Study of the biodegradation process of polychlorinated biphenyls in liquid medium and soil by a new isolated aerobic bacterium (Janibacter sp.). Chemosphere, 53, 609–618. Retrieved November 7, 2011 from http://infolib.hua.edu.vn/Fulltext/ChuyenDe2009/CD240/60.pdf 22 Verma, Shefali (2002). Anaerobic Digestion of Biodegradable Organics in Municipal Solid Wastes. Retrieved October 25, 2011 from http://www.seas.columbia.edu/earth/wtert/sofos/Verma_thesis.pdf 23