Attachment-D.-

advertisement

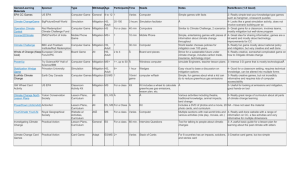

Attachment D. Environmental Mitigation and Monitoring Plan (EMMP) for DOWA Demonstration Farm Subproject/Grant Activity 1. Finalizing facilities layout 2. Staking perimeter of each component 1. Level land (approximately 30000 square meter) 2. Install drip irrigation system – laying buried pipes, installing heads Potential Environmental Impact Planning and Design None NA None Mitigation Measure NA Construction and Handover Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful grading of the construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Worker safety Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots and hard hats). Soil erosion Soil erosion Monitoring Indicator Frequency of Monitoring Responsible Party Cost NA NA NA NA NA NA NA NA 1. Visual inspection of site and adjacent areas for signs of soil erosion off site Weekly RADP-S I. Visual Inspection of workers/work site Weekly RADP-S Weekly RADP-S Mitigation Measure 2: Develop & implement a worker site safety plan; PPE; enforce and monitor the site safety plan. 2. Review of safety plan Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of the Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas for signs of soil erosion off site Subproject/Grant Activity Potential Environmental Impact Worker safety Mitigation Measure implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan, train workers in the use of PPE; enforce and monitor the site safety plan. 3. Installation of two PVC water tank with concrete floor and foundation Soil erosion Construction solid waste disposal Noise Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: Monitoring Indicator I. Visual Inspection of workers/work site Frequency of Monitoring Responsible Party Weekly RADP-S Weekly RADP-S Weekly RADP-S 2. Review of safety plan 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas for signs of soil erosion off site 1. Visual inspection of work site 2. Review of waste removal/ transport logs 1. Complaints from residents Cost Subproject/Grant Activity Potential Environmental Impact Worker safety Mitigation Measure In populated areas, avoid work early in the morning, in the evening and overnight Engineering noise control – reduce noise from machines and equipment; relocate noisy equipment by isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, such as generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of personal protection equipment; enforce and monitor the site safety plan. 4. Erect greenhouses (4) – land leveling, erecting Steel structure, installing plastic sheeting outer shell Construction solid waste disposal Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Monitoring Indicator and management Frequency of Monitoring Responsible Party 2. Visual (aural) inspection of equipment at work site I. Visual Inspection of workers/work site Weekly RADP-S Weekly RADP-S 2. Review of safety plan 3. Visual inspection of worker safety training 1. Visual inspection of work site 2. Review of waste removal/ transport logs Cost Subproject/Grant Activity Potential Environmental Impact Noise Worker safety 5. Construction of approximately 782 m gravel paths inside the farm Soil erosion Mitigation Measure Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Monitoring Indicator 1. Complaints from facility residents and management Frequency of Monitoring Weekly Responsible Party RADP-S Weekly RADP-S Weekly RADP-S 2. Visual (aural) inspection of equipment at work site I. Visual Inspection of workers/work site Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. 2. Review of safety plan Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas Cost Subproject/Grant Activity Potential Environmental Impact Construction solid waste disposal Noise Worker safety Mitigation Measure inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Monitoring Indicator for signs of soil erosion off site 1. Visual inspection of work site Frequency of Monitoring Responsible Party Weekly RADP-S Weekly RADP-S Weekly RADP-S 2. Review of waste removal/ transport logs 1. Complaints from residents area and management 2. Visual (aural) inspection of equipment at work site I. Visual Inspection of Cost Subproject/Grant Activity Potential Environmental Impact Mitigation Measure Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. 6. Installation of approximately 1160 m ,90 cm underground irrigation pipe for pumping canal water to purposed farm with a pump house and pump Soil erosion Construction solid waste disposal Noise Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, Monitoring Indicator workers/work site Frequency of Monitoring Responsible Party 2. Review of safety plan 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas for signs of soil erosion off site 1. Visual inspection of work site Weekly RADP-S Weekly RADP-S Weekly RADP-S 2. Review of waste removal/ transport logs 1. Complaints from residents area and management 2. Visual (aural) inspection of equipment at work site Cost Subproject/Grant Activity Potential Environmental Impact Worker safety Mitigation Measure reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. 7. Development of two 80 m borehole water wells, diameter of well shall be 12 inches and 6 inches casing pipe shell be installed. Soil erosion Construction solid waste disposal Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, Monitoring Indicator I. Visual Inspection of workers/work site Frequency of Monitoring Responsible Party Weekly RADP-S Weekly RADP-S Weekly RADP-S 2. Review of safety plan 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas for signs of soil erosion off site 1. Visual inspection of work site Cost Subproject/Grant Activity Potential Environmental Impact Noise Worker safety Mitigation Measure organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. Monitoring Indicator 2. Review of waste removal/ transport logs 1. Complaints from residents area and management Frequency of Monitoring Responsible Party Weekly RADP-S Weekly RADP-S 2. Visual (aural) inspection of equipment at work site I. Visual Inspection of workers/work site 2. Review of safety plan 3. Visual inspection of worker safety training Cost Subproject/Grant Activity 8. Installation of Training, Office, bathrooms and storage facilities at the farm from 40 feet containers. All facilities will be install on 10cm poured concrete. Potential Environmental Impact Soil erosion Construction solid waste disposal Noise Mitigation Measure Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to Monitoring Indicator 1. Visual inspection of site and adjacent areas for signs of soil erosion off site Frequency of Monitoring Weekly Responsible Party RADP-S 1. Visual inspection of work site Weekly RADP-S Weekly RADP-S 2. Review of waste removal/ transport logs 1. Complaints from residents area and management 2. Visual (aural) inspection of equipment at work site Cost Subproject/Grant Activity Potential Environmental Impact Worker safety Mitigation Measure remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. 9. Installation of solar powered electrical system for the well and farm facilities such as pumps, fans, exhaust, lights, switches, coolers, wiring and all other necessary electrical works Worker safety 10. Construction of Livestock facility for two cows with an outside concrete floor, shed, graveling, fencing, and electrical, plumbing and other necessary work. Soil erosion Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Monitoring Indicator I. Visual Inspection of workers/work site Frequency of Monitoring Responsible Party Weekly RADP-S Weekly RADP-S Weekly RADP-S 2. Review of safety plan 3. Visual inspection of worker safety training I. Visual Inspection of workers/work site 2. Review of safety plan 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas for signs of soil erosion off site Cost Subproject/Grant Activity Potential Environmental Impact Construction solid waste disposal Noise Worker safety Mitigation Measure Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. Monitoring Indicator 1. Visual inspection of work site Frequency of Monitoring Weekly Responsible Party RADP-S Weekly RADP-S Weekly RADP-S 2. Review of waste removal/ transport logs 1. Complaints from residents area and management 2. Visual (aural) inspection of equipment at work site I. Visual Inspection of workers/work site 2. Review of safety plan Cost Subproject/Grant Activity 11.Installation of model pack house and storage area – land, pouring concrete pad and installation of electricity and plumbing Potential Environmental Impact Soil erosion Construction solid waste disposal Noise Mitigation Measure Mitigation Measure 1: Impacts due to soil erosion will be mitigated by careful Grading of Construction site such that water is not allowed to run off the site into adjacent drainages, agricultural fields or inhabited areas. Where excavated soils are stored onsite, adequate measures will be implemented to control runoff, including covering exposed soils, construction of settling basins, or erection of erosion control barriers surrounding stored soil. Mitigation Measure 1: Solid waste shall be stored in a secure and sanitary on site facility, and shall be transported off site and disposed of in an approval solid waste disposal facility. To the extent possible, organic waste shall be composted or otherwise used in a productive manner (e.g. livestock fodder) and all inorganic waste with a market value shall be recycled. Mitigation Measure 1: Ensure that all processes, machines and equipment used will implement one or more of the following measures: In populated areas, we will avoid work early in the morning, in the evening and overnight Engineering noise control, e.g., modifying noisy processes, machines and equipment, relocating noisy processes or isolating them within enclosures, erecting sound barriers, reducing kinetic or potential energy and regularly maintaining machines and equipment; Use quiet running machinery and equipment when available in the market, including generators and compressors. Provide hearing protectors for Monitoring Indicator 3. Visual inspection of worker safety training 1. Visual inspection of site and adjacent areas for signs of soil erosion off site 1. Visual inspection of work site Frequency of Monitoring Responsible Party Weekly RADP-S Weekly RADP-S Weekly RADP-S 2. Review of waste removal/ transport logs 1. Complaints from residents area and management 2. Visual (aural) inspection of equipment at work site Cost Subproject/Grant Activity Potential Environmental Impact Worker safety Mitigation Measure workers who are exposed to excessive noise and ensure that they are worn at all times. Install warning signs in areas with excessive noise to remind workers that hearing protectors must be worn. Mitigation Measure 1: Insure that all workers are provided with appropriate PPE (e.g. gloves, goggles, boots, and hard hats). Mitigation Measure 2: Develop and implement a worker site safety plan; train workers in the use of PPE; enforce and monitor the site safety plan. Monitoring Indicator I. Visual Inspection of workers/work site Frequency of Monitoring Responsible Party Weekly RADP-S Quarterly RADP-S Quarterly RADP-S 2. Review of safety plan 3. Visual inspection of worker safety training 1. Irrigating crops Groundwater withdrawal 2. Applying fertilizer and pesticides to crops Groundwater contamination Operation Mitigation Measure 1: To the extent possible obtain data regarding pre-intervention (e.g. baseline) groundwater quantities and withdrawal rates to determine a sustainable withdrawal rate for irrigation system operation. Mitigation Measure 1: Apply fertilizers in the amounts specified for the particular crops. Do not overuse fertilizers. Mitigation Measure 2: Apply pesticides to specific crops (timing and quality) as specified in the USAID/Afghanistan PERSUAP 1. Liters of water withdrawn from groundwater well 1. Quantity of fertilizer used (for each different fertilizer type) 2. Quantity of pesticide used (for each different pesticide type) Cost Subproject/Grant Activity Potential Environmental Impact Worker safety Mitigation Measure Mitigation Measure 1: Assure that workers applying pesticides are trained in the proper/safe application of those specific pesticides and use the appropriate personal safety equipment as specified in the USAID/Afghanistan PERSUAP. Monitoring Indicator 3. Visual inspection of pesticide application logs to determine timing of application I. Visual Inspection of workers/work site Frequency of Monitoring Responsible Party Quarterly RADP-S Monthly RADP-S 2. Review of safety plan 3.animal Manure Management Groundwater Contamination Mitigation Measure 1: Store animal Manure in Manure area on time, Apply manure in the amounts specified for the particular crops and soil. Do not overuse manure. 3. Visual inspection of worker safety training 1.Quantity of Manure used for crops and soil 2. Visual inspection of Manure storage and application Worker safety Mitigation Measure 1: Assure that workers store and applying manure are trained in the proper, store/safe application of manure use the appropriate personal safety equipment. . Visual Inspection of workers/work site Cost Subproject/Grant Activity 4. Weeding fields None anticipated Potential Environmental Impact None NA Decommissioning Mitigation Measure Monitoring Indicator 2. Review of safety plan 3. Visual inspection of worker safety training NA Frequency of Monitoring NA Responsible Party NA Cost NA