Dimethyl-2,2`

advertisement

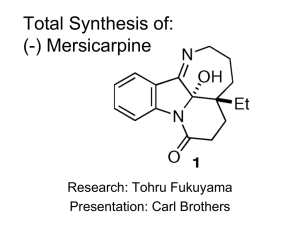

Jennifer Davis Gaston Bonenfant Scott Zellmer Organic Chemistry Lab: 102 Special Library Project Synthesis Paper March 23, 2012 Proton Abstraction from 4-Picoline through a Palladium Catalyst to Yield 4,4’-Dimethyl-2,2’-Bipyridine Introduction/Purpose: The function of 4,4’-Dimethyl-2,2’-Bipyridine is to act as a carrying agent able to complex with a separate molecule in order to form functional groups through the process of photoreactivation. 2,2’-Bipyridines are often used as ligands and as such are versatile in organometallic and inorganic chemistry.7 Liglands are a substance that can complex with an additional bimolecule for some biological and mechanistic purpose. Essentially, it is a signal triggering molecule that binds to a site on a target protein. The binding of a receptor alters its chemical conformation in turn determining the ligland functional state. 13 When a bipyridine ligand is attached to a ruthenium complex in the presence of blue light, the ruthenium ion looses an electron to the surrounding functional groups, making the compound unstable. This new unstable complex is an outstanding oxidizing agent and is able to produce a desired purpose.10 For example, 4,4’-Dicarboxy-2,2’Bipyridine, an easy transition from 4,4’-Dimethyl-2,2’-Bypridine, is employed as an essential ligand for the dye-sensitized solar system of ruthenium.8 Organic dyes can generate electricity at oxide electrodes in electrochemical cells.9 4,4’-Dimethyl-2,2’-Bipyridine is being synthesized for the purpose of Dr. Contakes research. It is his desire that in the future the synthesized compound is to be complexed with a ligand and tested for a specific purpose, similar to the example above. Chosen Procedure: The overall chosen scheme/reaction and mechanism for the synthesis of 4,4’Dimethyl-2,2’-Bipyridine is shown bellow. *Overall reaction *Reaction Mechanism 10g of 4,4’-Dimethyl-2,2’-Bipyridine will be synthesized in accordance to a previous journal entry by Sprintschnik published in 1977.1 To begin, 175mL of freshly distilled 4-picoline ($0.71/g) and 7g of palladium on 10% charcoal is refluxed for 72 hours. The reflux is set using a boiling flask and water jacket. The mixture is under constant boiling in conjunction with a magnetic stir bar. Using this refluxation method, the palladium catalyst pulls electrons away from the pyridine nitrogen in effect weakening the nearby C-H bonds. This bond weakening facilitates H abstraction.3 After having refluxed for approximately three days, 62.5mL of hot toluene is added and the reflux is continued for an additional half hour. The mixture is then filtered from the palladium catalyst while the solution is still hot. The filtrate is evaporated and concentrated in vacuo to approximately 75mL. Recrystallization form ethyl acetate finally yields 10g of colorless crystals, which is the desired 4,4’-Dimethyl-2,2’Bipyridine product.1 It is important to note that the above method borrowed form Sprintschnik was originally designed for synthesizing 40g of 4,4’-Dimethyl-2,2’-Bipyridine. In the above procedure the reactants are modified and scaled to yield approximately 10g of product. Because of this, all the reactant quantities in the article were divided by a quarter. An additional note is this is a crude experiment involving cheap reactants and a simple mechanism. With this is mind it makes since that the synthesized percent yield is very low. The expected value is a mere 6.06%. Theoretical yield is calculated to be 165g with 4-picoline acting as the limiting reagent. Sprintschnik’s journal article provided physical data for the synthesis of 4,4’Dimethyl-2,2’-Bipyridine. They are as follows: MP 175-179°C. NMR spectrum (in CDCl3): d at 8.54, t at 8.24, dq at 7.14, and s at 2.42.1 A second article by V. Alexander provided further spectral data for comparison. MP 174 °C. 1H NMR (400 MHz, CDCl3, 298 K): δ2.42 (s, CH3, 6H), 7.45 (d, H5,5’, 2H), 7.66 (t, H6,6’, 2H), 8.52 (d, H3,3’, 2H). 13C NMR (100 MHz, CDCl3, 298 K): δ21.0, 121.9, 124.5, 132.9, 148.8, 155.9. Mass Spec: m/z 183 (M+). 2 No information on IR was provided through the obtained articles. However, using the organic laboratory technique textbook, predicted IR absorptions include 1500-1700 cm-1, 680-860, ~3300, 3300-3500, and 2850-2950. 12 Alternative Methods: Method #1: Transformation of 2-Amino-4-Methylpyridine to Yield 2-Bromo-4Methylpyridine, a Precursor of 4,4’-Dimethyl-2,2’-Bipyridine One equivalent method to that above included two different procedures in order to produce the intermediate product, 2-Bromo-4-methylpyridine. This intermediate can be used to create the final product, 4,4’-Dimethyl-2,2’-Bipyridine. Because the intermediate, 2-Bromo-4-methylpyridine, is fairly expensive ($34.30/g), it is more cost effective to generate the compound from cheaper materials. The synthesis involves 17mL of bromine ($0.04/mL) added to a solution containing 12g of 2-amino-4-methypyridine ($0.30/g) in 70mL of 47% HBr. 21g of sodium nitrite ($0.07/g) in 115mL of water is added to the previous reaction mixture at a temperature below 25°C. The oil that results is extracted with ether and distilled in vacuo. 15g of liquid product is obtained resulting in a 77% yield.4 The 15g of synthesized product costs approximately $5.75 instead of purchasing a pre-prepared version at over $450.00. To create the final product, 4,4’-Dimethyl-2,2’-Bipyridine, zinc dust ($0.38/g) is added to a solution of dry THF, Et4NI, & Ni(PPh3)2Cl2 ($3.86/g) under argon. The mixture is heated to 50°C and 2-Bromo-4-methylpyridine in THF is added. The reaction is allowed to sit for 12 hours at 50°C upon which the mixture is poured over 2M aqueous ammonia. It is then filtered and washed with equal amounts of ether and benzene. The organic layer can then be separated, washed with water and aqueous sodium chloride, dried over anhydrous magnesium sulfate, and evaporated. Purification involves silica-gel column chromatography (neutral, 100-200 mesh) using petroleum ether-ethyl acetate (98:2, v/v) as the eluent.5 One problem with the above method is time. Compared to the selected method by Sprintschnik, this reaction would most likely take an additional two days. In addition, there is limited spectral data given in the article in regards to 2-Bromo-4-methylpyridine, which is necessary to confirm the identity of the product. Method 2: Formation of 2,2’-Bipyridyl by Ligand Coupling on the Phosphorous Atom This method produced a high percent yield of 84% for the desired product 4,4’Dimethyl-2,2’-Bipyridine. However, it also accounted for a 17% yield of the by-product 4-methylpyridine. This clearly presents a problem because over a 100% yield is obtained. With this in mind, the article may not be taken as seriously as others on the same subject. The procedure presented was very simple and clear, however. 4,4’-Dimethyl-2,2’Bipyridine was produced through the coupling of 4-methyl-2-pyridiyl within the phosphonium salt, benzyltri[2-(4-methylpyridyl)]phosphonium bromide. When this ion undergoes nucleophilic attack with water on the phosphorous atom, a pentacoordinated intermediate is formed that allows for ligand coupling. The procedure includes the reaction of benzyltri[2-(4-methylpyridyl)] – phosphonium bromide with dilute HCl at room temperature for 30 minutes. The addition of NaOH makes the mixture slightly alkaline, and is then extracted with CH2Cl2.. The organic layer is dried with Na2SO4 to obtain the product. No re-crystallization or purification methods were proposed in this procedure. The product was subjected to GC analysis to confirm its structure. An additional problem with this simple process is the difficulty in finding the reactant benzyltri[2-(4-methylpyridyl)]phosphonium bromide.6 Method 3: Dehydrogenative Coupling of 4-Substituted Pyridines Catalyzed by Diruthenium Complexes The final proposed synthesis involves a ruthenium catalyst opposed to the primarily suggested palladium catalyst. The synthesis of 4,4’-Dimethyl-2,2’-Bipyridine, through a transition-metal-catalyzed cross-coupling reaction method. works by dehydrogenative coupling of functionalized pyridines by way of direct C-H bond activation in an alternative, economical, and environmental point of view. The reaction of 4-methylpyridine ($0.71/g) is catalyzed by diruthenium complexes, Cp*Ru(μ-H)4RuCp and (Cp*Ru)2(μ-H)( μ-PMe2)( μ-C6H6). Prices for the exact diruthenium complex used were not listed, however similar compounds were found, and can be regarded as too expensive to purchase for this synthesis. This necessary reactant was found to be greater than $194.80/g. In addition to the difficulty of finding one of the necessary reactants, the synthesis accounted only for a 50% yield within 20 hours. Very slight instructions were given in regards to the way the experiment was carried out, and no additional properties for product conformation were provided. Discussion: Although all of the procedures outlined above would synthesized the desired 4,4’Dimethyl-2,2’-Bipyridine, several problems, here addressed, lead to the selection of the chosen method using 4-picoline refluxed with palladium on charcoal. The first alternative procedure involves a large number of steps to yield the 4,4’-Dimethyl-2,2’-Bipyridine. One in particular involves the synthesis of 2-bromo-4-methylpyridine that acts as a primary starting material. (4, 5) The article provides no data analysis for 2-bromo-4methylpyridine making the possibility of error too great. Also, a large number of reagents complicate the procedure indicating that this synthesis is not the best option. In the second alternative procedure, the inability to obtain the phosphonium salt, benzyltri[2-(4-methylpyridyl)]phosphonium, that acts as the starting material renders this procedure unrealistic. Regardless of the fact that the synthesis of 4,4’-Dimethyl-2,2’Bipyridine is an extremely simple procedure requiring little time and common reagents with a high percent yield of 84%. (11) The third alternative method follows a similar mechanism found in our selected synthesis, yet the cost of the diruthenium complexes, Cp*Ru(μ-H)4RuCp & (Cp*Ru)2(μH)( μ-PMe2)( μ-C6H6) that catalyze the reaction are far too expensive as it ranges around $190/g. (7) In addition, the experiment also gives a relatively low yield of 50% while using costly reagents with a limited procedure description. The lack of any product analysis data, in addition to these other difficulties, places this procedure in an unfavorable light. The exorbitant costs, inconveniently long reaction times, incomplete instructions, or lack of product confirming data for the alternative procedures makes our selected synthesis procedure the preferred option. The refluxing of 4-picoline with 10% palladium on charcoal provides a cost effective and simple procedure. Our selected procedure produces a relatively low yield of 6.06%, however the benefits far outweigh this negative aspect. 4-picoline costs $33.90/50-mL from Aldrich Chemicals and only 175mL is required in the chosen procedure. The price of palladium over charcoal is not included because the Westmont laboratory already owns some of this reusable catalyst. Therefore, the overall cost of the selected synthesis totals $135.60. Toluene and ethyl acetate are also relatively inexpensive and are available at the laboratory site. Sprintschnik’s article also provided a wealth of spectral data confirming the product including melting point, H1-NMR, C13NMR, and mass spectroscopy. The synthesis of the final product, 4,4’-Dimethyl-2,2’Bipyridine, is simple in comparison to the other methods. It is a “brute-force” method where the molecules are heated and forced to combine. (10) Works Cited: 1 Sprintschnik, G.; Sprintschnik, H.W.; Kirsch, P.P.; Whitten, D.G.; Journal of the American Chemical Society, 1977, 99 (15), 4947-4954, “Photochemical reactions in organized monolayer assemblies. 6. Preparation and photochemical reactivity of surfactant ruthenium(II) complexes in monolayer assemblies and at water-solid interfaces” 2 Alexander, V.; Rajalakshmanan, E.; Synthetic Communications. 2005, 35, 891-895. “Synthesis of Dimethylbipyridines by the Reductive Coupling of 2-Halomethylpyridines with Nickel Catalyst” 3 Neal L.M., Everett M.L., Hoflund G.B., Hagelin-Weaver H.E., Journal of Molecular Catalysis A: Chemical, 2010, 335, 210-221, “Characterization of palladium oxide catalysts supported on nanoparticle metal oxides for the oxidative coupling of 4-methylpyridine.” Case, F.; Temple University, 1946, 68, 2574-2577, “The Synthesis of Certain Substituted 2,2’-Bipyridyls” 5 Rajalkshmanan, E.; Alexander, V.; Synth. Comm. 2005, 35, 891-895. “Synthesis of Dimethylbipyridines by the Reductive coupling of 2-Halomehtylpyridines with Nickel Catalyst” 4 de França, K.W.R.; Oliveira, J.L.; Florêncio, T.; Silva, A.P.; Navarro, M.’ Léonel, E.; Nédélec, J.Y.; J. Org. Chem. 2005, 70, 10778-10781. “Mixed Effect of the Supporting Electrolyte and the Zinc Anode in the Electrochemical Homocoupling of 2-Bromopyridines Catalyzed by Nickel Complexes in an Undivided Cell.” 6 7 Kawashima, T.; Tako, T.; Suzuki, H.; J. AM. Chem. Soc. 2007, 129, 11006-11007. “Dehyrogenative Coupling of 4-Substitited Pyridines Catalyzed by Diruthenium Complexes” O’Regan. B.; Grätzel. M. Nature 1991. 353. 737-740, “A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films” 8 9 Gerischer, H.; Michel-Beyerle, M.; Rebentrost, E.; Tributsch, H. Electrochemica Acta, 1968, 13, 1509-1515, “Sensitization of Charge-Injection into Semiconductor with Large Band Gap” 10 Contakes, Stephen. Personal Interview. 22-03-2012. 11 Kozawa, H; Uchida, Y.; Pergamon Press. 1989, 30, 46, 6365-8. “Formation of 2,2’bipyridyl by Ligand Coupling on the Phosphorous Atom” 12 Pavia, Donald, Gary Lampman, George Kriz, and Randall Engel. Introduction to Organic Laboratory Techniques: A Microscale Approach . 4. Belmont: Brooks Cole, 2006. 851. Print. 13 Wikipedia contributors. "Ligand (biochemistry)." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 21 Mar. 2012. Web. 23 Mar. 2012.