supplementary

Supporting Information

Direct and Quantitative Photothermal Absorption Spectroscopy of Individual Nanostructures

Jonathan K. Tong 1 , Wei-Chun Hsu 1 , Sang Eon Han 1,† , Brian R. Burg 1,‡ , Ruiting Zheng 2 ,

Sheng Shen 3 , and Gang Chen 1,*

1 Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, MA, 02139

2 Key Laboratory of Radiation Beam Technology and Materials Modification of Ministry of Education,

College of Nuclear Science and Technology, Beijing Normal University, Beijing 100875, P.R. China

3 Department of Mechanical Engineering, Carnegie Mellon University, Pittsburgh, PA 15213

† Present Address: Department of Chemical and Nuclear Engineering, University of New Mexico,

Albuquerque, NM 87131

‡ Present Address: IBM Research Division, Zürich Research Laboratory, 8803 Rüschlikon, Switzerland

* Correspondence and requests for materials should be addressed to G.C. (email: gchen2@mit.edu

)

1. Sample Synthesis/Attachment

The silicon nanowire arrays were prepared by the metal assisted chemical etching of n-type silicon (100) wafers with a resistivity of 2-2.7 Ωxcm. Silicon chips with an area of 2×2 cm 2 were ultrasonically cleaned in deionized water, acetone and ethanol in sequence, and then boiled in the

H

2

SO

4

/H

2

O

2

(4:1 volume ratio) for 15 min. The cleaned silicon chips were dipped into the dilute HF solution for 2 min. to remove the silicon oxide layer and then immersed into an aqueous mixture of 8 M

HF and 0.02 M AgNO

3

(1:1 volume ratio) for 1 min. to deposit Ag nanoparticles (AgNPs). After that, the

AgNP-coated silicon chips were soaked into the aqueous mixture of 8 M HF and 0.4M H

2

O

2

(1:1 volume ratio) for 10 min. at room temperature (20 °C), to obtain the silicon nanowire arrays. Finally, the samples were cleaned in the boiled 50 vol.% HNO

3

for 1 h to remove the residual AgNPs, followed by a wash in deionized water and dried for use.

The silicon nanowire was attached to the bilayer cantilever using a dual-focused ion beam system (JEOL, JIB-4500) (see Fig. S1). The electron beam was used exclusively during this process to avoid gallium implantation in the sample. For attachment, an ultra-high vacuum adhesive (Kleindiek,

SemGlu) was used to minimize sample contamination from more conventional deposition processes.

Piezoelectric nanomanipulators (Kleindiek) were used for manipulation of the silicon nanowires. Long silicon nanowires (L ≈ 100 μm) were chosen to minimize end effects and to maximize the absorbed power to ensure a sufficiently high signal-to-noise ratio.

To extract a nanowire from the array, the probe tip was coated in adhesive and placed in contact with the free end of the nanowire. The glue was cured for 5 min. by exposure to a high intensity electron beam which was achieved with a higher magnification and a larger beam spot. Once the glue was cured, the nanowire was pulled from the array. Next, glue was applied using a second manipulator to the cantilever. The nanowire was then carefully positioned until the free end, which was originally at the base of the array, comes into contact with the cantilever. The glue was cured for 10 min. under

similar conditions as before. A third manipulator was then used to shear the nanowire from the first manipulator. To ensure the nanowire was sufficiently attached to the cantilever, a second coating of glue was applied using the second manipulator and cured for 10 min.

Figure S1. Nanowire attachment process. (a) A silicon nanowire at the edge of a wafer. (b) A probe tip is then coated in SemGlu. (c) The probe tip is brought into contact with the nanowire immersing it in glue.

The glue is then cured by enlarging the electron beam spot size and increasing magnification. (d) The nanowire is broken free from the wafer. (e) The cantilever is then coated with glue. (f) The nanowire is then carefully lowered until contact is made with the cantilever. The glue is once again cured. (g) A second probe tip is used to shear the nanowire from the first probe tip. (h) An additional layer of glue is applied on top of the nanowire to ensure the nanowire is fully anchored to the cantilever.

2. Calibrations

The spectral bending response, X(λ), was measured by illuminating the silicon nanowire with monochromatic light in the wavelength range of 420 to 600 nm in increments of 10 nm (see Fig. S2a).

The light source was allowed to thermalize for 1 hour prior to measurement. A lock-in amplifier was used to provide the necessary sensitivity to detect the bending response. To achieve a sufficient the signal-to-noise ratio, a bandwidth of 2.6 mHz was chosen. Furthermore, the measurement was conducted under vacuum at a pressure of 10 -5 Torr to eliminate convection losses which both improves sensitivity and reduces uncertainty.

To measure the frequency response correction factor, β, the TTL modulated laser (Lasermate

Group, LTC6702A5-T) was used to provide a steady or periodic heat input at the tip of the cantilever. By taking a ratio of the bending response from a periodic heat input and a steady heat input, the degree of attenuation was measured. This is formulated as follows,

β =

(S1) where X(f = 140 Hz) is the bending response under periodic heating and X(f = 0 Hz) is the bending response under steady heating. The bending response was measured as before using the detector laser and the PSD. Care was taken to ensure the driving voltage and current provided equal output power for both measurements.

The measurement of the power sensitivity, S p

, follows a modified approach taken from Shen et

1, 2 The power sensitivity is formulated as follows,

X

S = =

X

Sum

P abs

Sum P abs

(S2) where S p

is the power sensitivity, X is the bending response and P abs

the absorbed power by the cantilever. For this calibration, the power of the CW detector laser was varied by changing the input

voltage from 2.15 to 2.56 mW. The bending response was then recorded using a PSD. This calibration was conducted under identical experimental conditions with the spectral bending response, X(λ).

To measure the absorbed power by the cantilever, a photodiode (Newport, 1918C/818-UV) was used to measure the incoming laser power and bypass laser power (see Fig. S2b). The bypass laser power represents the portion of the laser beam that does not hit the cantilever. By subtracting the bypass power from the incoming power, the laser power incident on the cantilever was obtained. The absorbed power was calculated by multiplying the incident power with the absorptivity. The gold film on the cantilever was optically thick with an absorptivity of 0.066. This measurement was conducted in ambient conditions. Variations in the laser alignment on the cantilever between vacuum and ambient conditions were accounted for by correlating the bending response X and the absorbed power P abs

to a sum signal as shown in equation (S2). The sum signal is proportional to the total power incident on the

PSD.

The total output power from the optical fiber, P tot

(λ), was measured using a photodiode

(Newport, 818-UV/1918-C) under ambient conditions (see Fig. S2c). The photodiode was placed 1 cm from the end of the optical fiber to provide optimal coverage of the detector. The total power was measured in the wavelength range from 420 to 600 nm in increments of 10 nm.

The fraction of light incident on the sample, f inc

, is dependent on the position of the sample in the beam spot and the Gaussian distribution of the intensity profile. The silicon nanowire was positioned

50 µm from the optical fiber. The divergence of the beam spot was therefore negligible and its size was assumed equal to the optical fiber core diameter of 200 µm. Only 50% of the sample was illuminated in an effort to minimize illumination on and stray light scattering to the cantilever.

To determine the Gaussian distribution, a series of beam profile measurements were conducted to obtain the standard deviation of the Gaussian profile as a function of distance from the optical fiber.

The data was fitted to a spectral intensity function which accounts for the divergence of the beam spot.

From this fitting, a separation distance of 50 µm yielded a standard deviation of σ ≈ 50 µm.

Assuming the Gaussian distribution is radially symmetric, f inc

was calculated by integrating over the illuminated cross section of the nanowire as follows,

1

2π

2π

0

2

2σ

2

1

dθ

2σ

2

(S3) where r

1

(θ) and r

2

(θ) are polar functions that define the shape of the nanowire in a cylindrical coordinate system (see Fig. S2d). Note equation (S3) includes normalization to the total beam spot cross section.

Figure S2. Calibration results and definitions. (a) The spectral bending response, X(λ) as a function of the data points taken. The wavelength is denoted in the figure. (b) A schematic defining the distribution of laser power for the power calibration. The absorbed power is obtained from these parameters resulting in the power sensitivity, S p

. (c) The total input power from the optical fiber, P tot

(λ). (d) The

shape functions r

1

(θ) and r

2

(θ) used to obtain the fraction of light, f inc

, incident on the silicon nanowire.

The inset is a magnified view of the shape functions.

3. Uncertainty Analysis

To estimate the uncertainty of the data taken in this study, each parameter in the spectral absorption efficiency must be analyzed. Recall, the spectral absorption efficiency, in terms of the experimental parameters is defined as follows,

Q abs

P

P abs inc

=

p

P tot

inc

(S4)

From error propagation, the uncertainty in the spectral absorption efficiency, Q abs

(λ), is, dQ abs

Q abs

=

dX

X

2

+

dβ

2

β

+

dS

S

p p

2

+

dP

tot

P

tot

2

+

df

inc

f

inc

2

(S5)

In this study, three sets of data were taken for each parameter except for the fraction of incident light, f inc

. To obtain a 95% confidence interval, two standard deviations were taken for each parameter.

For the bending response, X, the average uncertainty for all wavelengths was 1.46% with a maximum of 4.36% at 430 nm. The uncertainty for the frequency correction factor, β, was 0.0069% indicating a highly repeatable measurement. The power sensitivity, S p

, required two separate measurements since the absorbed power could not be simultaneously measured with the bending response. To do so, the sum signal, which is proportional to the intensity on the PSD, is used to connect the two measurements, 2

X

Sum

Sum P abs

(S6)

Based on equation (S6), the uncertainty of each term is needed to determine the overall uncertainty in the power sensitivity. For the first term, X/Sum, the uncertainty was found to be 4.12%. For the second term, Sum/P abs

, error propagation can be used to expand this term even further, d

Sum/P

abs

Sum/P

abs

=

dSum

2

Sum

+

dP

abs

P

abs

2

dSum

2

+

Sum

inc

P

abs

2 byp

2

(S7)

From equation (S7), the uncertainty in the sum signal was 0.68%. The uncertainty in the absorbed power was 7.06%. Therefore, the uncertainty to the overall power sensitivity was 8.22%. For the total output power, P tot

, the average uncertainty for all wavelengths was 0.52% with a maximum of 1.62% at a wavelength of 500 nm. To assess the uncertainty in the fraction of light incident on the nanowire, f inc

, the precision in the position of the nanowire was estimated to be +/- 2.5 µm. A standard deviation was computed for f inc

using the known position of the nanowire and the relative limits. This resulted in an uncertainty of 9.24%. The overall uncertainty to the spectral absorption efficiency was therefore 12.53% on average with a maximum of 13.12% at a wavelength of 430 nm.

4. Size Average

A size average was performed to account for non-uniformity in the nanowire. In Fig. 4a, variations in the diameter of the nanowire can be observed. The standard deviation of this nonuniformity was 28 nm for the section of the nanowire illuminated. As a simple approximation, a weighted average is performed as follows,

Q s abs

=

1

N

N n=1

Q

abs

(S8) where N is the total number of points averaged along the length of the nanowire, d n

is the diameter of the nanowire at each point and Q s abs is the size-averaged spectral absorption efficiency. The diameter was digitally measured from SEM images.

Figure S3: An SEM image detailing the size averaging scheme used to correct for non-uniformities in the nanowire. The illuminated region represents the section of nanowire illuminated by the light input. The diameter of the nanowire is measured at a series of points represented by white tick marks. In the illuminated region, the index n = 1 and n = N represent the first and last points used for size averaging, respectively. The scale bar is 5 µm.

5. Wavelength Average

A wavelength average was performed to account for the finite bandwidth of the incoming light.

The full-width half-maximum was measured to be 7-8 nm for all wavelengths. A typical measurement is shown in Fig. 4b. As a simple approximation, a linear fit is applied and used as a weighting function. The wavelength average was thus performed as follows,

Q

λ abs

=

N n=1 w n

Q abs

N n=1 w n

(S9) where w n

is the linear weighting function, λ n

is the wavelength and Q

λ abs is the wavelength averaged spectral absorption efficiency.

Figure S4: Spectroscopic characterization of the incident light from the optical fiber show a full width half maximum of 7-8 nm across the measured wavelength range. A linear fit is imposed as a weighting function to be used for wavelength averaging.

6. Angle of Incidence Analysis

The Mie theory results presented in this work assumes light is normally incident on the nanowire. Normal incidence is taken perpendicular to the nanowire axis. However in the experiment, not all the light rays will be transmitted at normal incidence since the optical fiber supports multiple modes. Therefore angular components in the incoming light may alter the results. To assess this effect, beam profile measurements are fitted to a radiant intensity function. This analysis can be found in

Mandel et al.

3

In this analysis, a Gaussian-Schell model is used to model the light from the optical fiber. In this model, the intensity and coherency of the light source are assumed Gaussian. Figure S5 shows the coordinate system used in this analysis where L is the distance from the end of the optical fiber, ρ is the radial distance from the centerline axis of the optical fiber and θ is the angle of incidence.

Based on these assumptions, a spectral intensity, S(p,z), can be defined as a function of position as follows,

A 2

2

exp

-

ρ 2

2

(S10) where A is a wavelength dependent amplitude, σ s

is the standard deviation of the light source intensity taken at the origin and Δ(z) is a scaling function applied to σ s

that describes how the Gaussian beam spot changes with distance z. Δ(z) can be formulated as follows,

λz

2

;

1 a 2

=

1

s

2

+

1

σ 2 g

(S11) where λ is the wavelength of light and σ g

is the standard deviation of the light source coherency taken at the origin. For a spatially incoherent source, σ s

>> σ g

, the coherency parameter can be approximated as a ≈ σ g

. A radiant intensity, J , can be defined from the spectral intensity in terms of the angle of incidence as follows,

J

= lim

2πz

λ z

2

(S12) where ρ = z×tanθ. Since the angular dependence is of interest, the radiant intensity becomes,

J

λ

2

(S13)

To obtain the radiant intensity, the standard deviation, σ g

, needs to be determined. This was accomplished by conducting a series of beam profile measurements using a knife-edge configuration to measure the standard deviation, σ s

×Δ(z). Then, equation (S11) was used to fit the data to obtain both σ g and σ s

. The results are shown in Fig. S6.

Based on these results the radiant intensity, according to equation (S13) is plotted as shown in

Fig. S7. From Fig. S7, it can be observed that angular components higher than 15 degrees are negligible in this light source. Furthermore, if we compute solutions based on Mie theory for normal incidence (0 degrees) and at an angle of incidence of 15 degrees, it can be shown that results are negligibly different for a silicon nanowire. Based on this analysis, the light from the optical fiber can be assumed normally incident thus matching theory.

Figure S5. Coordinate system used to determine the radiant intensity, J (θ).

Figure S6. The results for

σ g

were determined to be 50 µm and 0.95 µm, respectively. standard deviations

Figure S7. The angular distribution, J (θ). As shown, angular components above 15 degrees are negligible.

7. Polarization Analysis

The Mie theory results presented in this work assumes the incident light is unpolarized.

Experimentally, this may not be the case. To check this, the Stokes parameters were measured. All

Stokes parameters were measured using a retarder and a linear polarizer as shown in Fig. S8 where a lens is used to collimate the light source from the optical fiber. All angles of rotation were taken relative to the polarization axis for the linear polarizer and the fast axis for the waveplate. A retarder can be used so long as the wavelength of the source is different from its rated wavelength such that the retardation will not result in a 180 degree phase shift. For different wavelengths, the phase shift needs to be calibrated. The Stokes parameters were measured at different wavelengths (420 nm, 500 nm, 600 nm). Note that the retarder was a half wave plate rated at 650 nm. Based on the Mueller matrices of each element in Fig. S8, the Stokes parameters were formulated in terms of intensities measured by a photodiode (Newport, 1918C/818-UV) as follows, 4

0

2

2 3 o

2 o

3 o

1 cos

2

o

3 o

0

1 sin

2 o

3 o

0 2

(S14) where

is the phase shift of the retarder. The phase shift is measured by inserting a second linear polarizer before the retarder. It is formulated as follows, cos

2

o

I θ =45 o

-1

The results are summarized in Table SI where the degree of polarization is defined as,

(S15)

P =

1

S

0

2

2

2

3

(S16)

From Table SI, we can clearly see that the light source used in this experiment is for all intents and purposes unpolarized as the Stokes vector at all wavelengths is close to the ideal Stokes vector of

S

o

1 0 0 0

'

for unpolarized light. Although the degree of polarization is relatively high at 600 nm, this is primarily due to the presence of a circular polarization state which does not affect the spectral absorption efficiency in this experiment. Therefore, our original assumption that the incident light in the experiment is unpolarized is validated.

Figure S8. Schematic for measurement of the Stokes parameters.

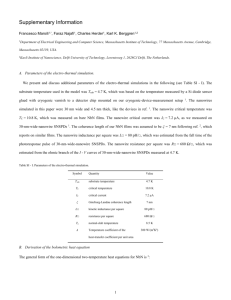

Table SI. The measured Stokes parameters at different wavelengths.

Wavelength

(nm)

Phase Retardation

(degrees)

S

0

(µW) S

1

(µW) S

2

(µW) S

3

(µW)

Degree of Polarization,

P

420

500

600

46.2

114.4

159.6

643.7

952.9

637.5

-22.4

12.2

-7.7

12.6

2.4

17.4

7.5

-4.7

-89.5

0.0416

0.0139

0.1436

Bibliography

1. Burg, B. R.; Tong, J. K.; Hsu, W.-C.; Chen, G. Rev. Sci. Instrum. 2012, 83, (10), 104902-9.

2. Shen, S.; Narayanaswamy, A.; Goh, S.; Chen, G. Appl. Phys. Lett. 2008, 92, (6), 063509-3.

3. Mandel, L.; Wolf, E., Optical Coherence and Quantum Optics. Cambridge University Press: 1995.

4. Collett, E., Polarized light: fundamentals and applications. Marcel Dekker: 1993.